1

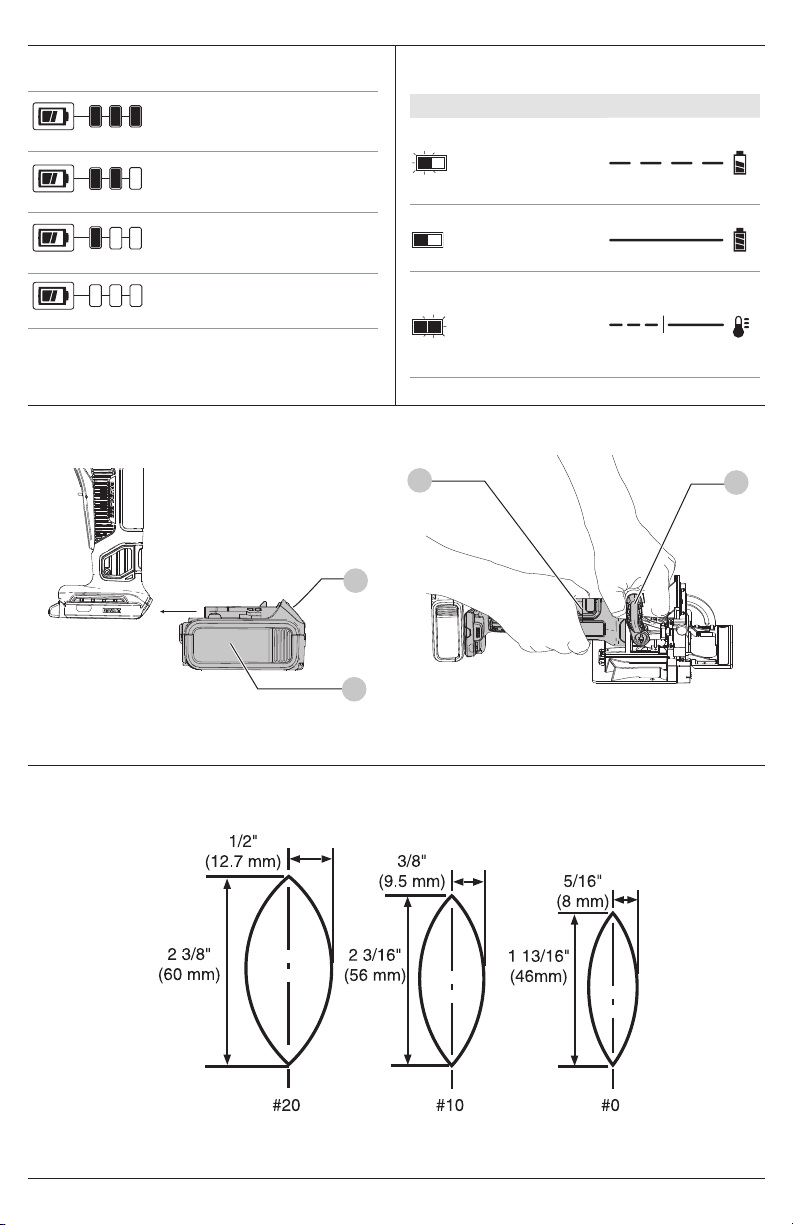

Fig. A

Components

1 Paddle switch

2 Lock‑off switch

3 Auxiliary handle

4 Fence height adjuster

5 Dust extraction outlet

6 Adjustable fence

7 Anti‑slipping pins

8 Plunge depth adjusting knob

9 Locking knob

10 Spindle lock

11 Adjustable fence locking knob

12 Battery

13 Battery release

Composants

1 Interrupteur à palette

2 Levier de verrouillage

3 Poignée supérieure

4 Molette de réglage

5 Dépoussiérage de la poussière

6 Guide réglable

7 Goupilles anti‑glissement

8 Bouton de réglage de la

profondeur

9 Bouton de verrouillage

10 Verrouillage de la tige

11 Bouton de verrouillage du guide

réglable

12 Bloc‑piles

13 Bouton de libération du bloc‑piles

Componentes

1 Interruptor de paleta

2 Bloqueo de apagado

3 Empuñadura superior

4 Perilla de ajuste estriada

5 Puerto de extracción de polvo

6 Uía ajustable

7 Pasadores antideslizantes

8 Perilla de ajuste de profundidad

9 Perilla de bloqueo

10 Bloqueo de husillo

11 Perilla de bloqueo de valla

ajustable

12 Paquete de batería

13 Botón de liberación de batería

3

4

5

8

7

11

1

6

9

12

13

2

10