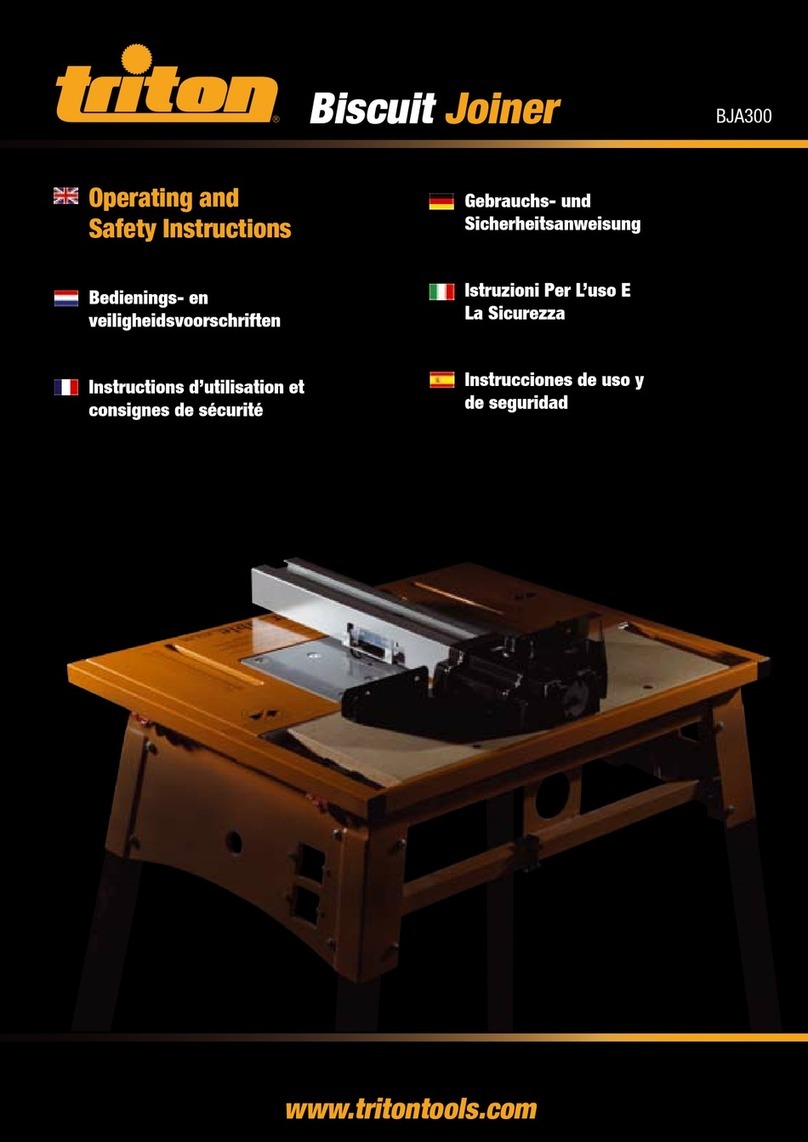

PUA497 2.01

International Offices:

Canada - Toll Free: 1 888 874 8661

Japan - Free Call: 0120 171 079

New Zealand - Ph: (09) 415 2545

South Africa - Free Call: 0800 600 432

United Kingdom - Free Call: 0800 856 7600

USA - Toll Free: 1 888 874 8661

Made in Australia by: Triton Manufacturing & Design Co. Pty. Ltd. ACN 000 195 951 ABN 43 000 195 951

14-18 Mills St, Cheltenham, Vic. 3192 Ph: (03) 9584 6977 Fax: (03) 9584 5510

Page 8

Due to our company policy of continuous product improvement, specifications may change without prior notice.

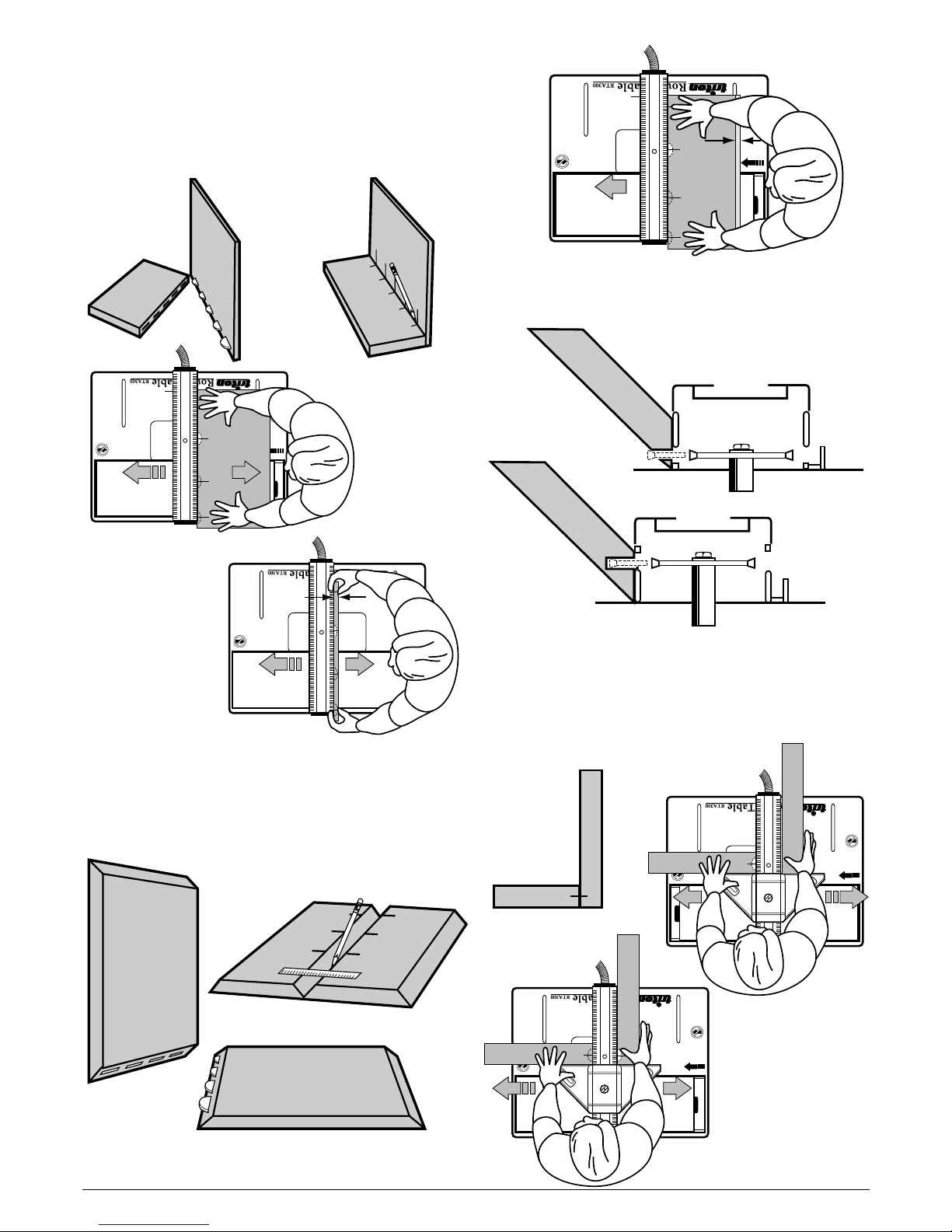

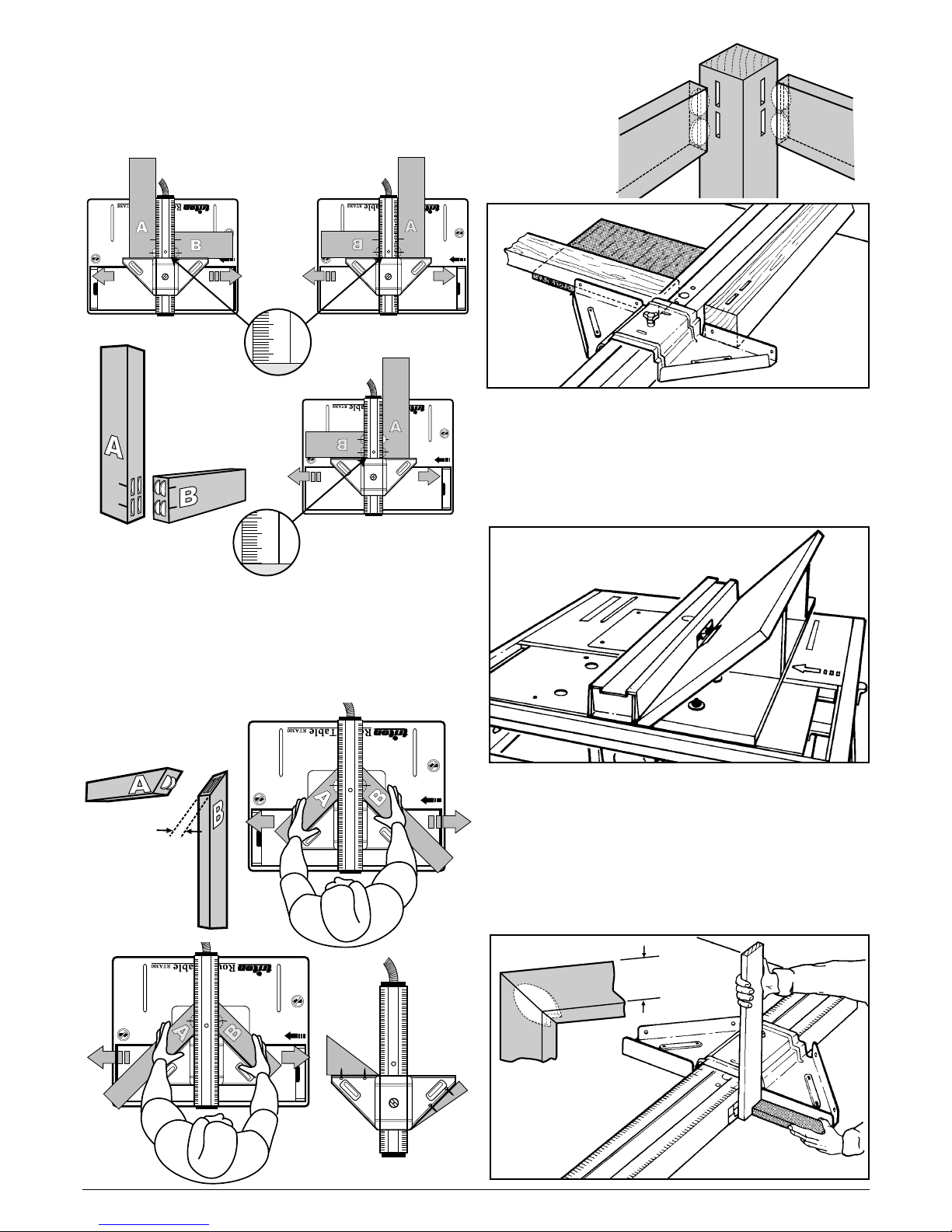

Mid-panel Joinery

The Biscuit Joiner cannot be used for cutting slots more

than 25mm from an end or an edge of a panel. For

certain jobs (eg. sides of a bookcase or cabinet), consider

using another method of fixing shelves or dividers, such

as screws, rebated trenches, cleats or dowels.

If you prefer to use biscuits throughout you can purchase

from Triton a straight carbide cutter with a 4mm cut width

(part no. BJA045).

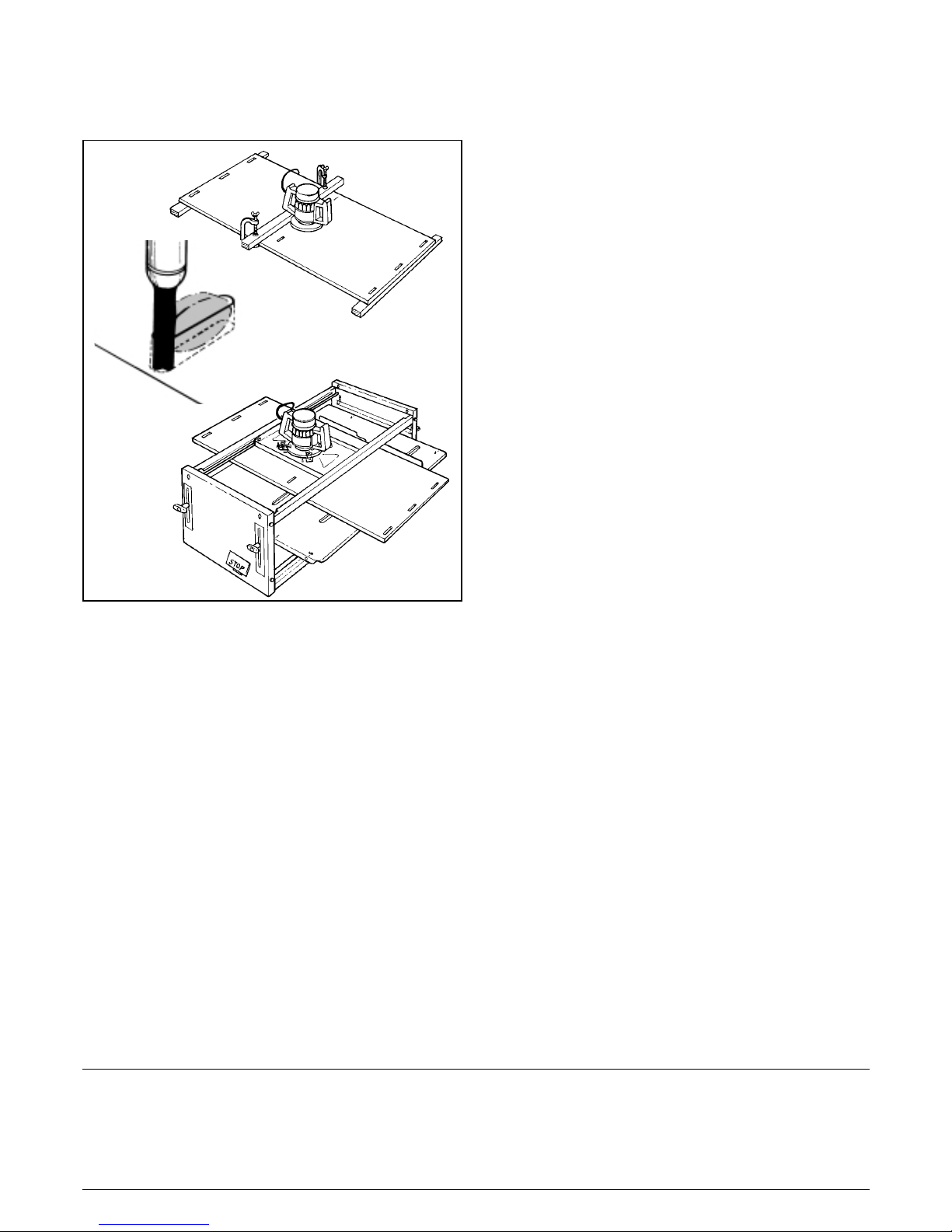

This cutter can be used for cutting mid-panel slots using

the router hand-held against a clamped batten.

Alternatively it can be done in the overhead mode on your

Workcentre using the optional Router Mounting Plate

(AJA150).

With a plunge router, and some practice, you can produce

slots with a curved bottom. However flat-bottomed slots

13mm deep by 40mm long are acceptable, and much

easier.

Biscuit Spacing

The number of biscuits required for particular joints will

depend on the type of material being joined and the loads

which the joint has to carry. As a rule of thumb, use one

biscuit (or row of biscuits) in material up to 20mm thick,

and two biscuits (or rows) in thicker materials, spaced

equally about 1/3rd the way in from either face.

The spacing between the biscuits along edge-to-face

panel joints and bevel joints should be around 150-

200mm. For long edge-to-edge joints, such as for a table-

top in natural timber, around 300mm between biscuits is

generally adequate.

Test Assembly

Test assemble your work before applying the glue to

check alignment and fit. Because the biscuits can move

lengthways in their slots, you can usually true up joints

easily.

The glue faces and the slots should be clean and dry

prior to gluing. Remove any sawdust or shavings by

brushing or blowing.

REPLACEMENT BISCUITS

Triton biscuits are specially shaped to suit the cutter

supplied. Replacement Triton biscuits are available from

your Triton stockist in packs of 50 (BJA050), or 500

(BJA056).

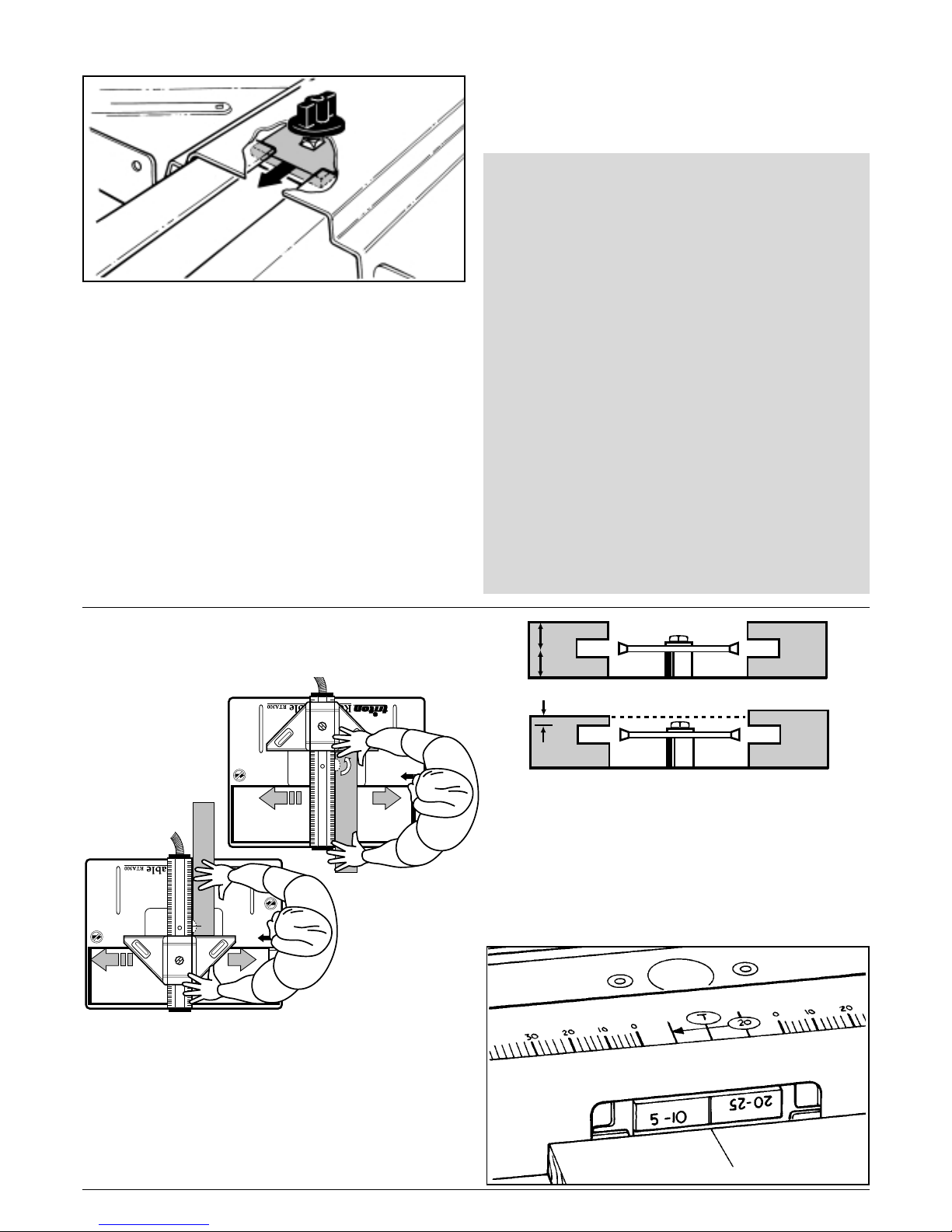

You can use other brands of biscuits, but they are a

different size. These biscuits, commonly called #10 and

#20 biscuits, require elongated slots. Use the reference

lines printed on top of the main body on either side of the

central line. Start at the line marked “20” and move the

wood towards the outside line, in the direction of the

arrow.

The #10 biscuit slots require the depth stops to be

adjusted to reduce the travel of the sliding insert.

GLUES AND GLUE APPLICATION

Good quality water-based adhesives, such as PVA glues,

are the most suitable for biscuit joining because they have

good quality wetting properties, and the moisture makes

the biscuits swell up evenly to tighten the joint. Epoxy and

resorcinol-type adhesives can be used, but we do not

recommend the use of highly viscous glues such as

construction adhesives.

Triton brand Premium Woodworking Adhesive offers

superior bond strength and better sanding and staining

characteristics than most commonly available PVA glues.

Available in 250ml, 500ml and 2.5 litre bottles.

Apply the glue sensibly. It is unnecessary and wasteful to

fill the slots with glue. On the other hand you need

enough glue to fully “wet-out” the sides of the biscuits.

Coat the biscuits with glue and/or paint glue on the walls

of the slots, using a thin spatula, a cotton bud, or a small

paint brush (a #6 artists size is ideal).

The best way to tell if you’re using the right amount of

glue is when you clamp the joint. A fine line of glue should

be squeezed out. Glue liberally dripping out indicates an

excess, and no glue visible means a starved joint.

CARE OF THE CUTTER

Inspect the cutter teeth regularly for chips or bluntness,

and remove accumulated resins from the tips. Have the

cutter professionally sharpened when blunt. When not

fitted to your router the cutter should be stored in its

special housing at the end of the main body to prevent

accidental tooth chipping.

Replacement cutters (BJA038) or cutting discs (BJA039)

can be ordered through your Triton stockist

Fig. 23