FENDT 900 Gal Liquid System User manual

Operator's Manual

Application System

900 Gal Liquid System

AGCx0900xLxxx1001-

1100 Gal Liquid System

AGCx1100xLxxx1001-

1300 Gal Liquid System

AGCx1300xLxxx1001-

North America

4205 River Green Parkway, Duluth GA 30096 USA

FENDT is a worldwide brand of AGCO

© AGCO 2020

Original Operator's Manual

May 2020

609142D1A

English

Congratulations on your selection of an AGCO®Product. We believe you

have exercised excellent judgment in the purchase of your AGCO®

machine. We are most appreciative of your patronage.

Your Dealer has performed the pre-delivery service on your new

machine.

He will discuss with you the operating and maintenance instructions

given in this manual, and instruct you in the correct and varied

applications of this machine. Call on him at any time when you have a

question or need equipment related to the use of your machine.

We recommend that you carefully read this entire manual before

operating the machine. Also, time spent in becoming fully acquainted

with its performance features, adjustments, and maintenance schedules

will be repaid in a long and satisfactory life of the product.

This equipment is covered by a written warranty which will be provided

to you by your AGCO®Dealer at time of purchase.

AGCO®reserves the right to make changes or add improvements to its products at any time

without incurring any obligation to make such changes to products manufactured previously. AGCO

®, or its dealers, accept no responsibility for variations which may be evident in the actual

specifications of its products and the statements and descriptions contained in this publication.

Find manuals at https://best-manuals.com

Application System

1 Safety .................................................................... 9

1.1 A word to the operator .............................................. 1

1

1.1.1 Safety symbol .................................................. 12

1.1.2 Safety messages ................................................ 12

1.1.3 Messages ..................................................... 12

1.1.4 Follow safety instructions .......................................... 13

1.1.5 Prepare for emergencies ...........................................13

1.1.6 Exit the cab in an emergency ....................................... 14

1.2 Operate the machine ................................................ 15

1.2.1 Prevent machine runaway .......................................... 16

1.2.2 Use correct lamps and markers ...................................... 16

1.2.3 Operation on slopes .............................................. 16

1.2.4 Travel on public roads ............................................. 17

1.2.5 Stop and park ................................................... 17

1.2.6 System boom operation ........................................... 17

1.2.7 Avoid Eye Contact with Radar ....................................... 18

1.2.8 Exhaust fumes .................................................. 18

1.2.9 Noise prevention ................................................ 18

1.2.10 Handle fuel correctly ..............................................19

1.2.11 Towing ........................................................19

1.3 Maintenance and service ............................................ 20

1.3.1 Modifications ................................................... 20

1.3.2 Practice correct maintenance ....................................... 20

1.3.3 Chemical safety ................................................. 21

1.3.4 Work in a clean area .............................................. 23

1.3.5 Understand correct service ......................................... 24

1.3.6 Use correct tools ................................................ 24

1.3.7 Support machine correctly ......................................... 25

1.3.8 High pressure fluids .............................................. 25

1.3.9 Service cooling system correctly ..................................... 26

1.3.10 Remove paint before welding or heating ............................... 26

1.3.11 Mobile radio installations .......................................... 26

1.3.12 Fire prevention .................................................. 27

1.4 Safety signs ........................................................ 28

1.4.1 Recirculation valve ............................................... 30

1.4.2 Fresh water reload ............................................... 30

1.4.3 Inhalation ......................................................30

1.4.4 Operator manual ................................................ 30

1.4.5 Pressurized fluid .................................................31

1.4.6 Water tank ..................................................... 31

1.4.7 Crush hazard ................................................... 31

1.4.8 Center boom ................................................... 31

1.4.9 Personal protective equipment ...................................... 32

1.4.10 Liquid system control ............................................. 32

1.4.11 3-Way control panel .............................................. 32

2 Introduction .............................................................. 33

2.1 Introduction ........................................................ 35

2.1.1 Intended use ................................................... 35

2.1.2 How to correctly dispose of the waste ................................ 35

2.1.3 Pre-Delivery Inspection checklist ..................................... 35

Table of contents

Application System

609142D1A

Find manuals at https://best-manuals.com

2.2 Serial numbers ..................................................... 36

2.2.1 System serial number .............................................36

2.2.2 Serial number definition ........................................... 36

3 Operation ................................................................ 39

3.1 System controls .................................................... 41

3.1.1 Drive lever controls .............................................. 41

3.1.2 Armrest controls ................................................ 41

3.1.3 Reload keypad .................................................. 42

3.2 Spray system setup ................................................. 44

3.2.1 Set up the application system ....................................... 44

3.2.2 Boom nozzle spacing table ......................................... 44

3.2.3 Calibrate the nozzles ............................................. 46

3.2.4 Calibrate the flow meter ........................................... 47

3.2.5 Calibrate the speed in monitors and controllers .......................... 49

3.2.6 Determine the main pressure line valve setting .......................... 50

3.2.7 Input - output modules ............................................ 51

3.2.8 End row nozzles .................................................51

3.2.9 Nozzle sizing ................................................... 51

3.3 Plumbing controls .................................................. 52

3.4 Product tank ........................................................ 54

3.4.1 View the tank settings ............................................ 54

3.4.2 Set the product density ........................................... 54

3.4.3 Product tank ................................................... 54

3.4.4 Side reload .................................................... 55

3.4.4.1 Fill the tank from the side using the liquid tender ............... 55

3.4.4.2 Fill the tank from the side using the on-board pump ............. 58

3.4.5 Front reload - if equipped .......................................... 63

3.4.5.1 Fill the tank from the front using the liquid tender ............... 63

3.4.5.2 Fill the tank from the front using the on-board pump ............. 67

3.5 Agitation ........................................................... 73

3.5.1 View the agitation settings ......................................... 73

3.5.2 Set the agitation .................................................73

3.5.3 Agitate the product ...............................................74

3.6 Recirculatory system ................................................ 76

3.6.1 Recirculatory system valve positions .................................. 76

3.6.2 Recirculate the product ........................................... 76

3.7 Chemical eductor ................................................... 79

3.7.1 Operate the eductor with the product tank ............................. 79

3.7.2 Operate the eductor with the liquid tender ............................. 83

3.7.3 Do a check of the chemical eductor performance .........................90

3.8 Fresh water tank .................................................... 91

3.8.1 Fill the fresh water tank ........................................... 91

3.8.2 Fill the hand wash tank ............................................ 92

3.9 Boom procedures ................................................... 93

3.9.1 Fold out the booms .............................................. 93

3.9.2 Fold out the booms using automatic fold ............................... 95

3.9.3 Fold in the booms ............................................... 96

3.9.4 Fold in the booms with the automatic fold .............................. 98

3.9.5 Boom tip break-away ............................................. 99

3.9.6 Automatic full-boom break-away return ............................... 100

3.9.7 Boom control manual override - without Autoboom ...................... 100

3.9.8 Boom control manual override - with Autoboom ......................... 101

3.10 Spray tips ......................................................... 104

3.10.1 Remove a spray tip .............................................. 104

3.10.2 Install a spray tip ................................................104

Table of contents

Application System

609142D1A

Find manuals at https://best-manuals.com

3.10.3 Change a spray nozzle ........................................... 104

3.10.4 Check and clean a spray tip ........................................ 105

3.11 Foam marker ...................................................... 106

3.11.1 View the foam marker settings ..................................... 106

3.11.2 Fill the foam marker tank ..........................................106

3.11.3 Operate the foam marker ......................................... 107

3.12 Chemical injection system .......................................... 109

3.12.1 Fill the chemical injection system ....................................110

3.12.2 Set the rate for the chemical injection ................................ 110

3.12.3 Rinse the chemical injection system ..................................111

3.13 At the end of the job ................................................113

3.13.1 Prepare the machine at the end of the job ............................. 113

3.14 Spray control calculator .............................................115

3.14.1 Spray control calculator ........................................... 115

3.14.2 Determine the application rates and nozzles ............................ 115

3.14.3 Determine the speed range ........................................ 116

3.14.4 Other uses for the spray control calculator ............................. 118

3.15 Electrical power connection ......................................... 120

3.16 Cleaning procedures ................................................121

3.16.1 Valve and product flow indicators ................................... 121

3.16.2 Procedures for product recovery, cleanout, and rinse ..................... 123

3.16.3 Product recovery procedures .......................................123

3.16.4 Rinse the tank ................................................. 125

3.16.5 Clean out the boom without chemical injection ......................... 125

3.17 Diagnostics and calibration ......................................... 127

3.17.1 View the diagnostics screen ....................................... 127

3.17.2 View the calibration menu ........................................ 127

3.17.3 Calibrate the automatic fold ........................................128

3.17.4 Calibrate the tank level sensor ......................................130

3.18 Application system removal and installation ......................... 131

3.18.1 Remove the liquid system ........................................ 131

3.18.2 Install the spinner system ........................................ 140

3.18.3 Set up the Raven Viper 4 for RoGator C series spinner system .............. 146

3.18.3.1 Tire RCI number ...................................... 153

3.18.3.2 Create New Job ...................................... 154

3.18.3.3 Factory default values .................................. 154

3.18.4 Remove the spinner system ....................................... 156

3.18.5 Install the liquid system .......................................... 161

3.18.6 Set up the Raven Viper 4 for RoGator C series liquid system ................ 171

4 TaskDoc™ / AgControl™ Operation ....................................... 177

4.1 TaskDoc™ / TaskDoc Pro™ overview ................................ 179

4.1.1 TaskDoc system overview ......................................... 179

4.1.2 TaskDoc Pro system overview ...................................... 179

4.2 TaskDoc™ menu overview .......................................... 181

4.2.1 TaskDoc menu overview .......................................... 181

4.3 TaskDoc™ / TaskDoc Pro™ commissioning .......................... 182

4.3.1 Install the mini SIM card for Global System for Mobile communication (GSM) ... 182

4.3.2 Condition for the commissioning .................................... 183

4.3.2.1 Switch on ISOBUS .................................... 183

4.3.3 Connection settings ............................................. 184

4.3.3.1 View/adjust the connection settings for the Global Systems for

Mobile Communications (GSM) network .....................184

4.3.4 View the connection settings for the Code Division Multiple Access (CDMA)/

Long Term Evolution (LTE) network .................................. 187

4.4 Connection settings ................................................ 189

Table of contents

Application System

609142D1A

Find manuals at https://best-manuals.com

4.4.1 View/adjust the connection settings for the Global Systems for Mobile

Communications (GSM) network ....................................189

4.4.2 View the connection settings for the Code Division Multiple Access (CDMA)/

Long Term Evolution (LTE) network .................................. 191

4.5 TaskDoc™ operation and settings ................................... 193

4.5.1 TaskDoc information ............................................. 193

4.5.2 View the TaskDoc™ main menu .................................... 194

4.5.3 Make a task ................................................... 194

4.5.4 Copy a task/create a task template .................................. 196

4.5.5 Select a task .................................................. 197

4.5.6 Add categories to a task .......................................... 198

4.5.7 Delete categories from a task ...................................... 199

4.5.8 Filter by categories .............................................. 200

4.5.9 View the TaskDoc™ data settings ................................... 201

4.5.10 View the roaming settings ........................................ 202

4.5.11 View the on-board computer ....................................... 203

4.5.12 Memory space monitoring ........................................ 205

4.5.13 Delete all TaskDoc data ...........................................205

4.6 TaskDoc™ faults and remedy ....................................... 207

4.6.1 System test ................................................... 207

4.6.1.1 Starting the system test ................................ 207

4.6.1.2 System test results .................................... 207

4.7 Auto-Guide™ ...................................................... 210

4.7.1 View the Auto-Guide™ map ....................................... 210

4.7.2 View the worked area settings ......................................211

4.7.3 View the Auto-Guide™ main menu .................................. 212

4.7.4 View the field settings ........................................... 213

4.7.4.1 Add a boundary ....................................... 214

4.7.5 View the implement selection ...................................... 218

4.7.6 View the steering settings ........................................ 219

4.7.7 View the signal settings .......................................... 220

4.7.8 View the correction signal screen ................................... 220

4.7.8.1 Select the signal type .................................. 221

4.7.9 View the system screen .......................................... 223

4.7.10 View the NMEA settings ..........................................224

4.7.11 View the headland settings ........................................ 225

4.7.12 Select the Auto-Guide™ button ..................................... 225

4.8 AgControl™ Section Control operation and configuration ............. 227

4.8.1 SectionControl description ........................................ 227

4.8.2 Section Control overview menu .....................................227

4.8.3 AgControl™ icons .............................................. 228

4.8.4 View the AgControl™ menus ...................................... 229

4.8.5 View the rate control settings ...................................... 230

4.8.6 View the virtual switch box ........................................ 231

4.8.7 View the product flow............................................232

4.8.8 View the nozzle settings .......................................... 232

4.8.9 View the boom settings .......................................... 233

4.8.10 View the life time totals .......................................... 234

4.8.11 Error codes ................................................... 234

4.8.11.1 View the active error codes .............................. 234

4.8.11.2 View the stored error codes .............................. 235

4.8.12 View the Software Information screen ................................ 236

4.9 Section control .................................................... 237

4.9.1 View the section control switches ................................... 237

4.9.2 Select manual or automatic section control ............................ 237

4.9.3 Adjust the switch o time for section control ........................... 237

4.9.4 Adjust the switch on time for section control .......................... 239

Table of contents

Application System

609142D1A

Find manuals at https://best-manuals.com

4.9.5 Automatic Section Control ........................................ 240

4.9.6 View the section control settings ................................... 241

4.9.7 View the section settings ......................................... 242

4.10 AgControl™ Variable Rate Control (VRC) operation and settings .......243

4.10.1 AgControl Variable Rate Control (VRC) System requirements ............... 243

4.10.2 View the TaskDoc™ data settings ................................... 243

4.10.3 AgControl Variable Rate Control (VRC) make an application map with a field

database ..................................................... 244

4.10.4 AgControl Variable Rate Control (VRC) TaskDoc requirements ............... 245

4.10.5 Activate the AgControl Variable Rate Control (VRC) ....................... 246

4.10.6 AgControl Variable Rate Control (VRC) Pause task ....................... 248

4.10.7 AgControl Variable Rate Control (VRC) map view and layer selection .......... 249

4.10.8 AgControl Variable Rate Control (VRC) example map views ................. 250

4.11 TaskDoc™ quick start guides ........................................252

4.11.1 Start a task from scratch .......................................... 252

4.11.1.1 Add a boundary (optional) ................................257

4.11.1.2 Save task to USB ......................................261

4.11.1.3 Save task by wireless transfer ............................ 263

4.11.2 Use a task uploaded from a USB .................................... 263

4.11.2.1 Add a boundary (optional) ................................268

4.11.3 Use a task uploaded Wirelessly .................................... 274

4.11.3.1 Add a boundary ....................................... 278

4.12 Management ...................................................... 284

4.12.1 Machine administration, implement administration and field administration; data

exchange ..................................................... 284

4.12.1.1 Data exchange with a USB stick ........................... 284

5 Maintenance ............................................................ 287

5.1 Maintenance introduction .......................................... 289

5.1.1 Lubricant filling reminders ......................................... 289

5.2 Maintenance schedule ..............................................290

5.3 Boom trees ........................................................ 291

5.3.1 Lubricate the large boom tree ...................................... 291

5.3.2 Lubricate the small boom tree ......................................291

5.3.3 Adjust the boom wear pad clearance ................................. 292

5.4 90 and 100 ft booms ................................................ 295

5.4.1 Lubricate the 90 and 100 ft booms .................................. 295

5.4.2 Adjust the 90 ft - 100 ft boom breakaway .............................. 296

5.4.3 Adjust the boom lead on 90 and 100 ft booms .......................... 297

5.4.4 Placement of the foldback rest and wear angle for 90 ft booms ............. 298

5.4.5 Placement of the foldback rest and wear angle for 100 ft booms ............. 299

5.5 120 ft booms ...................................................... 300

5.5.1 Lubricate the 120 ft booms ........................................ 300

5.5.2 Adjust the boom lead on 120 ft booms ............................... 301

5.5.3 Adjust the 120 ft boom breakaway ...................................301

5.5.4 Adjust the 120 ft boom tip breakaway ................................ 302

5.5.5 Placement of the foldback rest bump stop and wear angle for 120 ft booms .... 304

5.6 132 ft booms ...................................................... 306

5.6.1 Lubricate the 132 ft booms ........................................ 306

5.6.2 Tighten the boom attachment hardware .............................. 307

5.6.3 132 ft boom adjustments ......................................... 308

5.6.4 Align the Y axis ................................................ 308

5.6.5 Adjust the boom fold bump stop .................................... 310

5.6.6 Adjust the secondary shelf rest ..................................... 312

5.6.7 Primary/Secondary fold cylinder adjustment ............................ 313

5.6.7.1 Adjust the cylinder clevis ................................313

Table of contents

Application System

609142D1A

Find manuals at https://best-manuals.com

5.6.7.2 Adjust the double heim joint ..............................314

5.6.8 Align the X axis ................................................ 314

5.7 Plumbing .......................................................... 316

5.7.1 Check and clean a tip ............................................ 316

5.7.2 Clean the high volume system line strainer ............................ 316

5.7.3 Clean the low volume system line strainers ............................ 317

5.7.4 Liquid system hoses .............................................318

5.7.5 Hydraulic lines ................................................. 319

5.8 System storage .................................................... 320

5.8.1 Prepare the application system for storage ............................ 320

5.8.2 Winterize the liquid system ........................................ 320

5.8.3 Winterize the foam marker system .................................. 323

5.8.4 Winterize the chemical injection system .............................. 324

6 Troubleshooting ......................................................... 327

6.1 Fault code reference ................................................ 329

7 Specifications ........................................................... 349

7.1 Liquid system specifications ........................................ 351

7.1.1 Liquid system weight ............................................ 352

8 Index ................................................................... 353

Table of contents

Application System

609142D1A

Find manuals at https://best-manuals.com

1 Safety

1.1 A word to the operator .................................................. 1

1

1.1.1 Safety symbol ...................................................... 12

1.1.2 Safety messages .................................................... 12

1.1.3 Messages ......................................................... 12

1.1.4 Follow safety instructions .............................................. 13

1.1.5 Prepare for emergencies .............................................. 13

1.1.6 Exit the cab in an emergency ........................................... 14

1.2 Operate the machine .................................................... 15

1.2.1 Prevent machine runaway ..............................................16

1.2.2 Use correct lamps and markers ......................................... 16

1.2.3 Operation on slopes .................................................. 16

1.2.4 Travel on public roads ................................................. 17

1.2.5 Stop and park ...................................................... 17

1.2.6 System boom operation ............................................... 17

1.2.7 Avoid Eye Contact with Radar ........................................... 18

1.2.8 Exhaust fumes ..................................................... 18

1.2.9 Noise prevention .................................................... 18

1.2.10 Handle fuel correctly ................................................. 19

1.2.11 Towing ........................................................... 19

1.3 Maintenance and service ................................................ 20

1.3.1 Modifications .......................................................20

1.3.2 Practice correct maintenance ........................................... 20

1.3.3 Chemical safety ..................................................... 21

1.3.4 Work in a clean area ..................................................23

1.3.5 Understand correct service .............................................24

1.3.6 Use correct tools .................................................... 24

1.3.7 Support machine correctly ............................................. 25

1.3.8 High pressure fluids .................................................. 25

1.3.9 Service cooling system correctly .........................................26

1.3.10 Remove paint before welding or heating ................................... 26

1.3.11 Mobile radio installations .............................................. 26

1.3.12 Fire prevention ..................................................... 27

1.4 Safety signs ............................................................ 28

1.4.1 Recirculation valve ................................................... 30

1.4.2 Fresh water reload ................................................... 30

1.4.3 Inhalation ......................................................... 30

1.4.4 Operator manual .................................................... 30

1.4.5 Pressurized fluid .................................................... 31

1.4.6 Water tank ........................................................ 31

1.4.7 Crush hazard ....................................................... 31

1.4.8 Center boom ....................................................... 31

1.4.9 Personal protective equipment .......................................... 32

1.4.10 Liquid system control .................................................32

1.4.11 3-Way control panel .................................................. 32

Table of contents

Application System 9

609142D1A

Find manuals at https://best-manuals.com

1.1 A word to the operator

It is your responsibility to read and understand the

safety section in this manual and the manual for all

implements before you operate this machine. You

are responsible for your safety. Good safety

procedures prevent injury to you and the persons

around you.

Make the information in the safety section of this

manual a part of your safety procedure. This safety

section is written only for this type of machine.

Safety is your responsibility. You can prevent injury

and death.

This safety section gives basic safety examples

that can occur during the operation and

maintenance of your machine. This safety section

is not a replacement for safety instruction in other

sections of this manual.

Injury or death can occur if the safety instruction is

not obeyed.

Learn how to operate the machine and how to use

the controls correctly.

Do not operate the machine if you do not know

how to operate the machine. Do not let persons

operate the machine that do not know how to

operate the machine.

Follow all safety instructions in the manuals and on

the safety signs on the machine, the implements,

and the attachments.

Use only approved attachments and implements.

Make sure that your machine has the correct

equipment that is necessary by the local

regulations.

WARNING:

Do not use alcohol or drugs that can

have an eect on alertness or

coordination. If you use prescription

or 'over the counter' drugs, get

medical advice about the safe

operation of machines.

CAUTION:

If attachments or implements used

with this machine have a dierent

operator manual, see that operator

manual for other important safety

instructions.

GUID-AC91CCF6-1FF8-4A85-97A1-2D1562806825-high.jpg [High]

Fig. 1

GUID-F38BCC9A-5A98-41F3-BA3C-2C5AB224EDFB [V7]

1. Safety

Application System 11

609142D1A

1.1.1 Safety symbol

The safety symbol tells you about an area that can

be dangerous.

Look for the safety symbol in this Operator's

Manual and on the machine. The safety symbols

tell you that there are important safety instructions

in the manual.

GUID-087C8B07-BA1A-4AC8-93FF-E28F097F1E16-high.jpg [High]

Fig. 2

1.1.2 Safety messages

The words DANGER, WARNING or CAUTION are

used with the safety symbol. Learn these safety

messages and obey the recommended

precautions and safety instructions.

DANGER:

If you do not obey the recommended

precautions and safety instructions,

DEATH OR INJURY will occur.

WARNING:

If you do not obey the recommended

precautions and safety instructions,

DEATH OR INJURY can occur.

CAUTION:

If you do not obey the recommended

precautions and safety instructions,

INJURY can possibly occur.

GUID-73F05026-C37B-415A-8140-AD939A283378-high.jpg [High]

Fig. 3

1.1.3 Messages

The messages important and note are not related to personal safety. They give information about the

operation and maintenance of the machine.

IMPORTANT:

If you do not follow the special instructions or procedures, you can cause damage to the machine. You can

also cause damage to the process, or the area around the machine.

NOTE: Information to help you do the procedure, or help you to understand.

GUID-5D9F270E-D748-4741-82B1-BE49B78685F2 [V7]

GUID-E54F7740-C021-42A8-8784-4287BE4356C8 [V4]

GUID-9A909F52-D57E-4C30-8CC7-6FDB6D7E9982 [V5]

1. Safety

12 Application System

609142D1A

1.1.4 Follow safety instructions

Carefully read, learn and understand all safety

messages and or information in this manual and

on machine's safety signs. Keep safety signs in

good condition. Replace missing or damaged

safety signs. Make sure the new equipment

components and or repair parts include current

safety signs. See local dealer for replacement

safety signs.

Never operate machine or equipment without

correct instruction and a complete understanding

of control operation.

Learn to operate the machine and how to use all

controls correctly before operation. Do not let

operator's not authorized operate the machine,

systems and or do service and or maintenance

procedures without correct instruction.

Keep machine, all components and systems, in

correct working condition. Modifications to the

machine not authorized by AGCO can decrease

functionality and or safety, decrease machine life

and void machine warranty.

IMPORTANT: Any modifications to machine or

systems not authorized by AGCO void the

warranty.

GUID-5ED2A984-22F3-401A-BF09-A1E6DFAC1922-high.jpg [High]

Fig. 4

1.1.5 Prepare for emergencies

Keep a first aid kit and a fire extinguisher handy.

Keep emergency numbers for doctors, ambulance

service, hospital, and the fire department readily

available always.

GUID-C89843AC-C77A-4DD7-8AC1-2A669AA59DB7-high.jpg [High]

Fig. 5

GUID-B1AC9269-352E-468C-93A7-DD6248A4DC53 [V2]

GUID-F7D2E4DE-89DA-40A4-89F2-2D29CE2096C0 [V2]

1. Safety

Application System 13

609142D1A

1.1.6 Exit the cab in an emergency

Before starting the procedure

Prior to machine operation, completely understand how to quickly exit the cab in an emergency.

Procedure

1. Remove the hammer (1) from the holder.

2. Use the hammer and break the best available

window.

3. Exit the cab through the window opening.

GUID-B4156BDF-EA21-4747-A7A0-790723BCEAF5-high.jpg [High]

Fig. 6

GUID-84374C1D-AD91-4281-A675-E6572267BBD0 [V1]

1. Safety

14 Application System

609142D1A

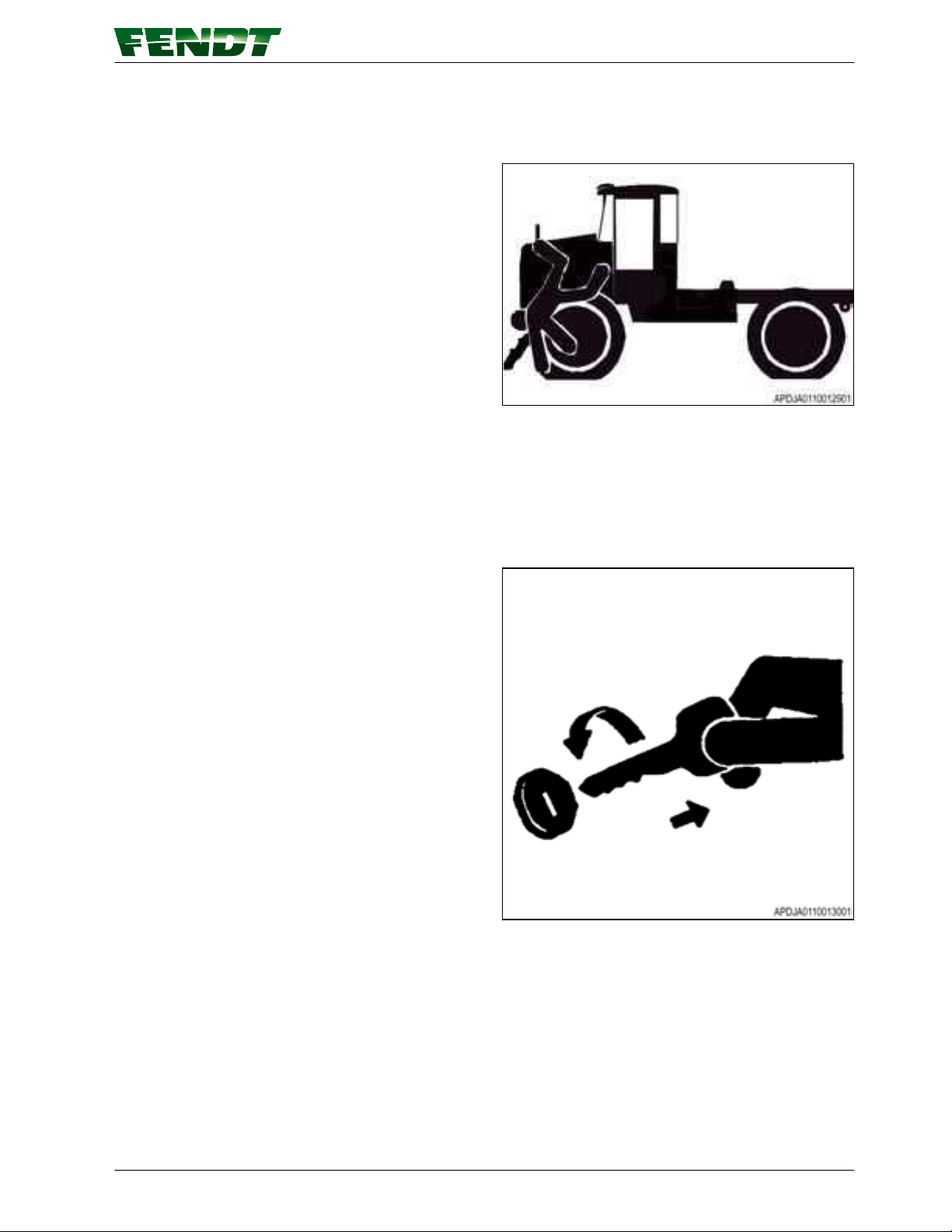

1.2 Operate the machine

Procedure

1. Make sure the operator and the ladder areas

are clean and dry to prevent personal injuries.

2. Make sure all wheel bolts are torqued to

correct specifications before operation.

3. Never permit any people on or in the

machine when in operation.

4. Engage park brake and put drive lever in

neutral before starting engine.

5. Stop the machine, turn o the engine, and

set the park brake if an accident occurs.

Remove the key and take the key with before

inspecting any damage.

6. Stop machine immediately if there is an engine, hydraulic system or any failure. Do not turn the key

o until the machine stops and turned o correctly.

7. The operator must not exceed the recommended speeds, loads, or tire inflation. These

recommendations are on the tires and the tire chart located in the operator manual.

8. Never get o a moving machine.

GUID-73472174-86BC-4C6D-8419-A538ECDE7947-high.jpg [High]

Fig. 7

9. When leaving machine unattended, set park

brake, turn o the engine, remove the key

and take the key with.

GUID-CCB62396-F09E-4ED4-B7E4-951AE4379F10-high.jpg [High]

Fig. 8

GUID-D599B6BC-38F2-4F90-9C0B-CBBEA33E77E1 [V5]

1. Safety

Application System 15

609142D1A

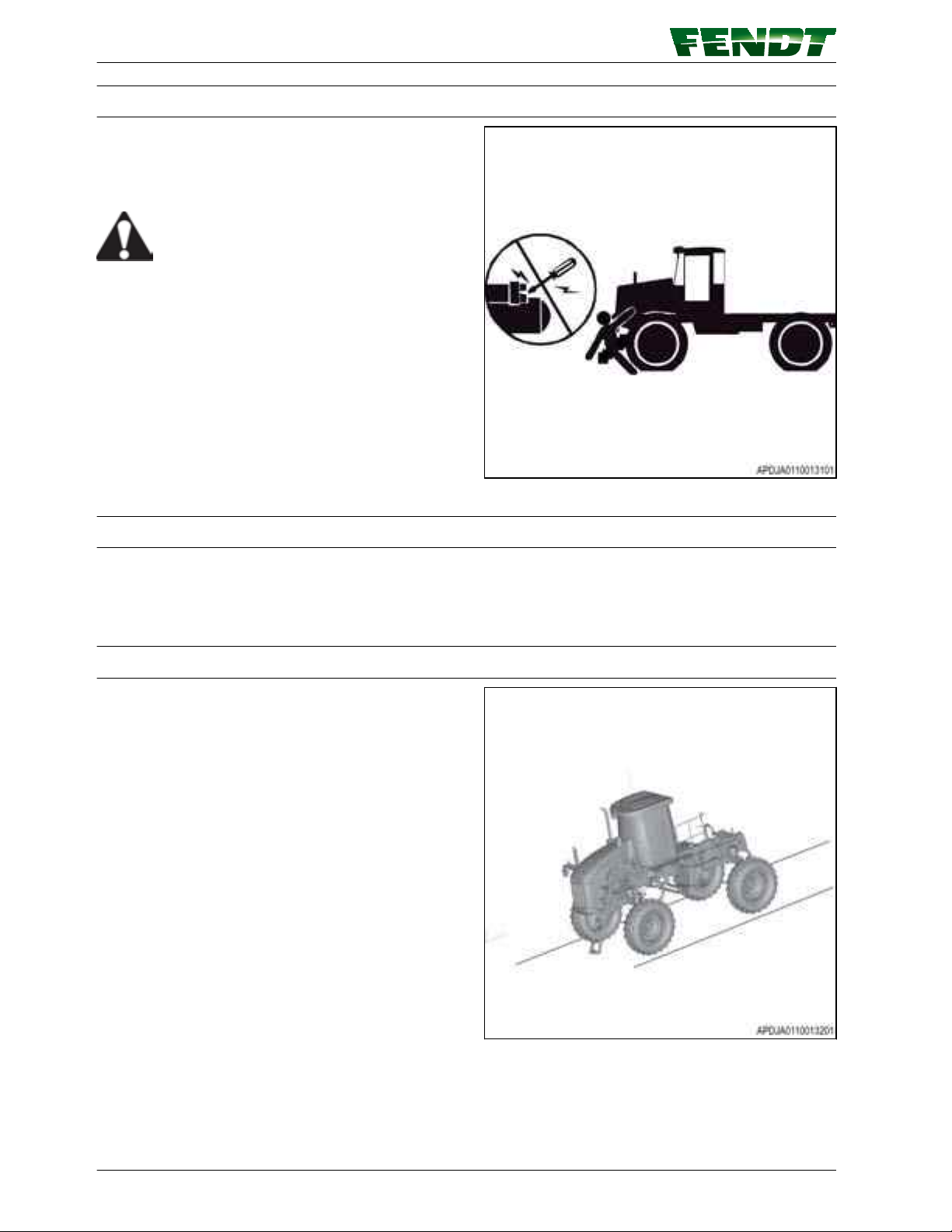

1.2.1 Prevent machine runaway

Never bypass start the engine by making a

connection across starter terminals. Engine will

start and machine will move if normal circuits are

bypassed.

WARNING:

Possible injury or death can result

from machine runaway. Never start

the engine while standing on the

ground. Start the engine only from

operator's seat with the seat belt on,

with the drive lever in neutral and

park brake engaged.

GUID-D6874892-5A2F-4157-8648-82F0F8160206-high.jpg [High]

Fig. 9

1.2.2 Use correct lamps and markers

To increase visibility, use the lamps and devices provided. Amber flashing warning lamps and rotating

beacon / strobe beacon, when installed, are recommended whenever driving on public roads unless

prohibited by law. Keep all lamps and markers clean and in correct working order. Replace any missing or

damaged components immediately.

1.2.3 Operation on slopes

Keep the machine in slow speed when going

down slopes. Avoid holes, ditches, and

obstructions to prevent a rollover, especially on

hillsides. Avoid sharp turns on hillsides.

Never drive near edge of a gully or steep

embankment.

GUID-52B4B828-88E8-4B45-ABDB-0AE4EA077D90-high.jpg [High]

Fig. 10

GUID-9D40BC10-B60E-4F53-BE16-720A78222FEA [V2]

GUID-17B8DDF0-8AFE-4842-A714-032776137B3F [V3]

GUID-263F56B3-7F72-4277-8020-0CC1C79793E2 [V3]

1. Safety

16 Application System

609142D1A

1.2.4 Travel on public roads

WARNING: Environmental transportation hazard.

Personal injury or chemical spill can occur.

A loaded machine driven on public roads has a high risk of tire failure. Do not use the

machine for transporting product on public roads.

Always walk around and visually inspect the machine before traveling on public roads. As a warning, honk

the horn twice before starting the engine. Check for damage and or faulty components that can fail and

create a hazardous condition. Make sure all machine systems operate properly including, but not limited to,

front road lights, tail and brake lights, hazard warning lights, park brake, horn, windscreen wiper and

washer, and rear view mirrors. Repair or replace any component not in proper working order.

Never drive at a speed causing the machine to bounce or lose control.

Obey all trac laws. Operate the machine with hazard warning lights or rotating beacon / strobe beacon, if

equipped, on, unless prohibited by law. The use of road lights while traveling on public roads is the

operator's responsibility.

1.2.5 Stop and park

Machine overturns, collisions, runaways, and crushing accidents can occur when an operator ignores safety

procedures.

Failure to signal before you stop, you turn or you slow on public roads, or anywhere can cause a possible

risk.

Pull to the side of the road before you stop.

Be very careful when you stop on slippery surfaces or with heavy loads.

Always engage the parking brake when the machine has stopped.

Remove the key to prevent any personnel not approved from operating the machine.

1.2.6 System boom operation

Make sure no personnel or objects are in the path

of booms before retracting or extending.

Know where the boom location is always.

Retract and lock booms and disengage hydraulic

enable switch before driving on public roads.

GUID-E4CDE4CA-3FCA-4C01-BB74-BE9EDD03B050-high.jpg [High]

Fig. 11

GUID-1297D337-508B-4FA7-88ED-BCB0577A38E5 [V5]

GUID-6D57EACC-87C0-486A-A753-AC474AE0AF05 [V4]

GUID-EC37065E-36E6-4167-94A7-21157086E8B3 [V2]

1. Safety

Application System 17

609142D1A

1.2.7 Avoid Eye Contact with Radar

Radar ground sensors emit a low intensity

microwave signal. The microwave signal will not

cause any ill eects during normal use. Although

the intensity is low, to avoid eye damage, never

look directly into the sensor while the sensor is in

operation.

GUID-11A2F16B-F74A-40CA-AA12-04E51A0AB69D-high.jpg [High]

Fig. 12

1.2.8 Exhaust fumes

Always work in a correct ventilated area.

Engine exhaust fumes can cause sickness or

death. If necessary to run engine in a closed area,

use correct equipment to safely remove exhaust

fumes from area.

Always open the doors and get outside air into

area.

GUID-14D1976F-1E03-40BF-8B7E-EBFFE3E03995-high.jpg [High]

Fig. 13

1.2.9 Noise prevention

Wear proper hearing protective devices such as

earmus or earplugs to prevent loss of hearing

due to high noise levels.

GUID-48B1B90D-20EB-42DB-A016-3CA0AB8AC168-high.jpg [High]

Fig. 14

GUID-4B8E0B85-0729-4BD2-82D3-C0FC9032F049 [V2]

GUID-7F41C7C3-DACC-46D2-ADC7-531D148964D3 [V2]

GUID-99732186-65C2-4EC3-8EDB-760F7ABE29B7 [V1]

1. Safety

18 Application System

609142D1A

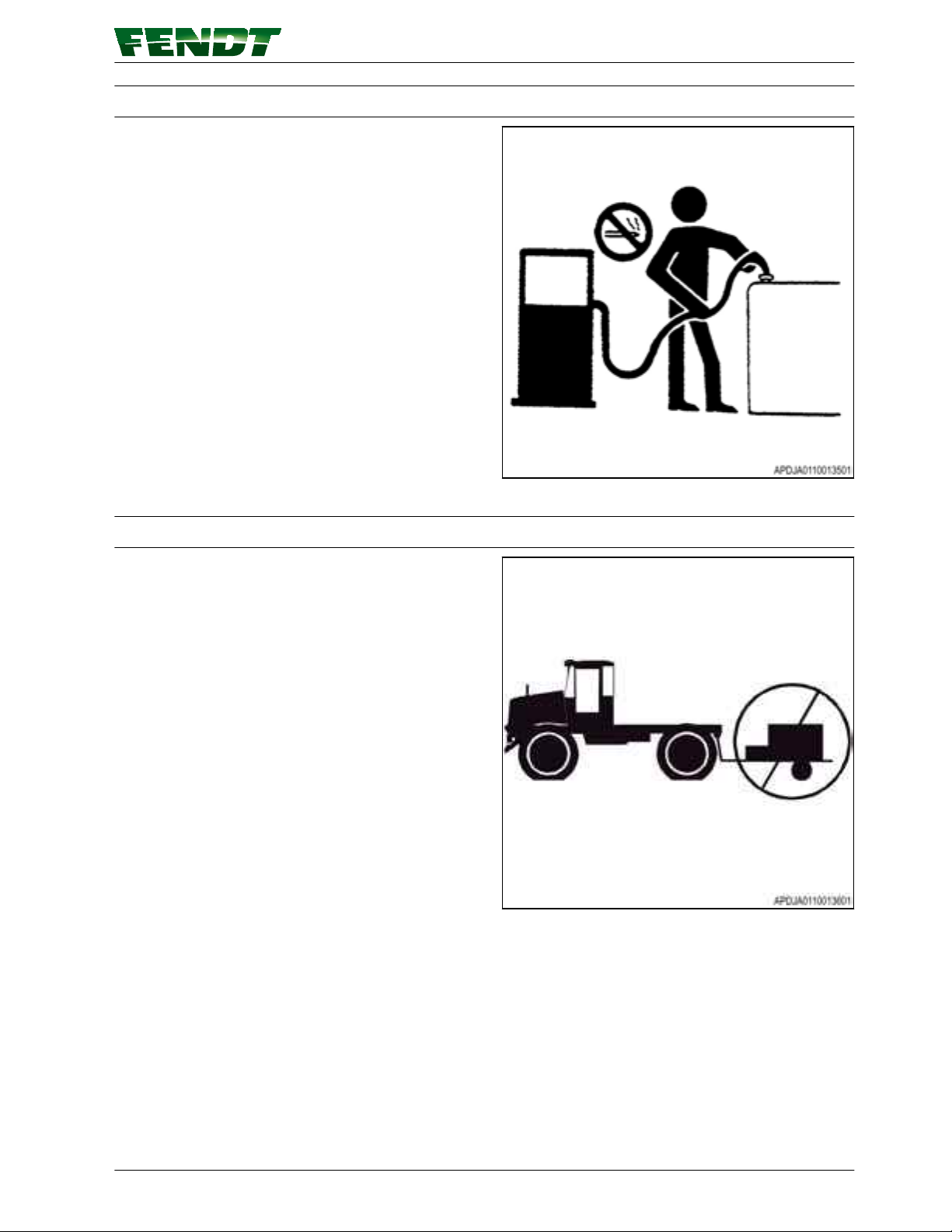

1.2.10 Handle fuel correctly

Fuel is very flammable. Handle carefully.

• Always stop the engine before refueling.

• Never refuel while smoking.

• Add fuel in a safe place, away from open

flames or sparks.

• Fill fuel tank outdoors.

• Never fill the fuel tank full.

• Cleanup any spilled fuel immediately.

• Never use diesel fuel, kerosene, gasoline, or

any flammable solvents for cleaning.

• Prevent fire hazards by keeping machine free of

any accumulated trash, grease, and debris.

• Always have, and be prepared to use, a

multipurpose dry chemical fire extinguisher

during operation and while refueling.

GUID-F973C46A-C6B9-4E58-A040-DDEFD6DBE1F9-high.jpg [High]

Fig. 15

1.2.11 Towing

Towing a trailer is not approved by AGCO.

Using machine for towing, creates a hazard and

can void machine and system warranty.

GUID-A62D1A6A-BFA9-4522-BCEF-F9E49172034F-high.jpg [High]

Fig. 16

GUID-9A178FCA-F53F-440E-A34E-657614BD6A29 [V2]

GUID-427BCFF3-65CA-400D-B9DD-40F839224B27 [V2]

1. Safety

Application System 19

609142D1A

1.3 Maintenance and service

Read and understand maintenance and safety

instructions before performing any maintenance

procedures.

Any maintenance procedures and or repairs must

only be done by trained personnel.

Never change any equipment or add attachments

not approved by AGCO.

GUID-7A2043D6-4BF0-4103-A043-7EAC2FF8C2D7-high.jpg [High]

Fig. 17

1.3.1 Modifications

Welding or changing the chassis in any way (such as adding implement towing hitches) can cause damage

and or failure of components. Modifications not approved by AGCO void machine and or system warranty.

1.3.2 Practice correct maintenance

Never lubricate, service, or adjust any systems or

components while machine is moving.

Never wear a necktie, necklace, scarf, or loose

clothing while working near machine tools or

moving parts.

Tie long hair behind head and wear a hair net.

Remove all jewelry to prevent electrical shorts and

or other personal injury when working with

machine tools or moving parts.

GUID-0AA66BCC-B5FC-46B5-82C2-01F2D748EA68-high.jpg [High]

Fig. 18

GUID-A68922CA-C2A0-4800-8263-852A6064FF48 [V2]

GUID-888E6A4B-BF15-42EB-865A-2080DC33551A [V2]

GUID-20D85144-D83B-41B5-9E2D-04BFDE7B300F [V3]

1. Safety

20 Application System

609142D1A

This manual suits for next models

2

Table of contents

Other FENDT Farm Equipment manuals