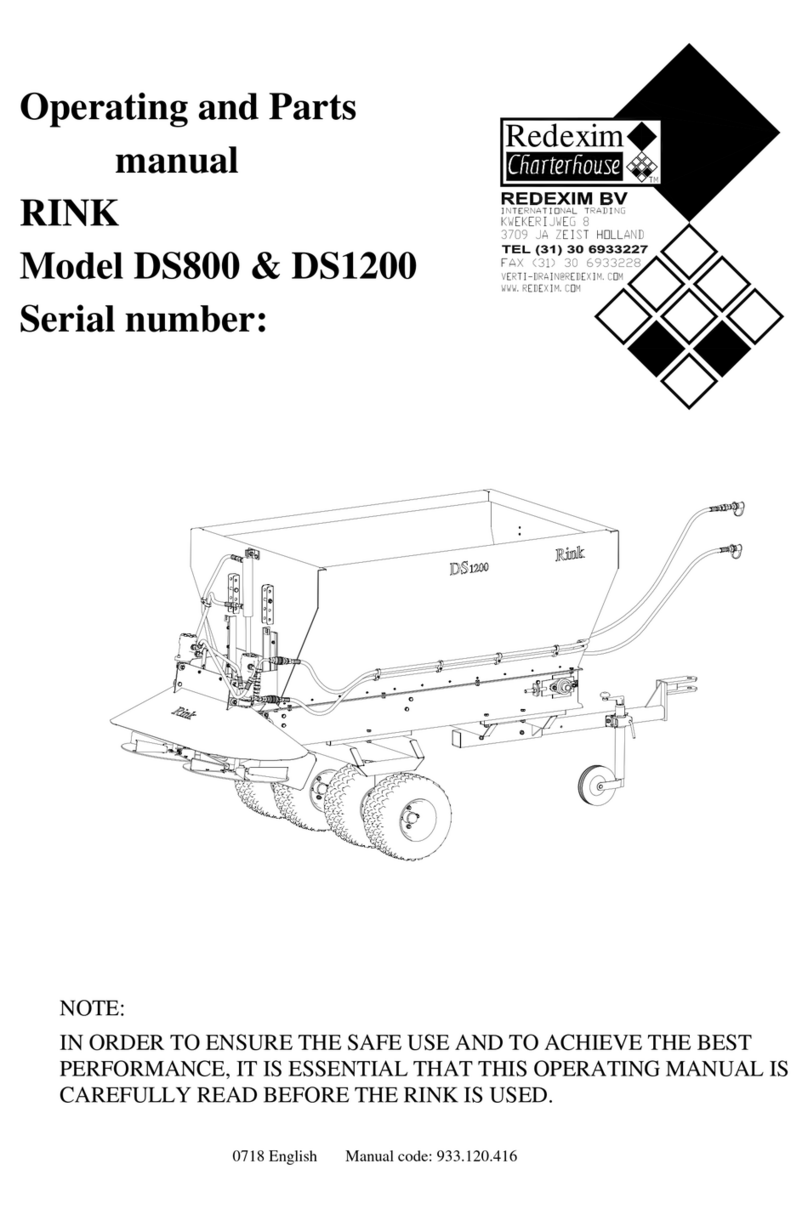

FENDT 1290 UD User manual

Workshop Service Manual

Large Square Baler

1290 UD

North America

4205 River Green Parkway, Duluth GA 30096 USA

FENDT is a worldwide brand of AGCO

© AGCO 2018

May 2018

79037317B

EME

English

1. General

1.1 Safety ................................................................. 1-5

1.1.1 Safety symbol ....................................................... 1-5

1.1.2 Safety messages ..................................................... 1-5

1.1.3 Information messages ................................................. 1-5

1.1.4 Safety signs .........................................................1-5

1.1.5 Safety warnings ...................................................... 1-6

1.1.6 A word to the technician ............................................... 1-6

1.1.7 The service manual ................................................... 1-7

1.1.8 The operator manual .................................................. 1-7

1.1.9 Tool box ........................................................... 1-8

1.1.10 Operation .......................................................... 1-8

1.1.10.1 General information ............................................ 1-8

1.1.10.2 Prepare for operation ........................................... 1-9

1.1.10.3 Personal protective equipment ....................................1-10

1.1.10.4 Seat instructions .............................................. 1-10

1.1.10.5 Shield and guards ............................................. 1-10

1.1.10.6 Exhaust warning .............................................. 1-11

1.1.10.7 Flying debris ................................................. 1-11

1.1.10.8 Handrails ................................................... 1-12

1.1.10.9 Agricultural chemicals .......................................... 1-12

1.1.11 Travel on public roads ................................................. 1-12

1.1.12 Maintenance ....................................................... 1-14

1.1.12.1 General maintenance information ..................................1-14

1.1.12.2 Fire prevention and first aid ...................................... 1-16

1.1.12.3 High pressure leaks ............................................1-17

1.1.12.4 Tire safety .................................................. 1-17

1.2 General information ................................................... 1-19

1.2.1 Introduction to this service manual ....................................... 1-19

1.2.2 Units of measurement ................................................ 1-19

1.2.3 Table of contents .................................................... 1-19

1.2.4 Page numbers ...................................................... 1-19

1.2.5 Remove a gib key .................................................... 1-19

1.2.6 Install a gib key ..................................................... 1-20

1.2.7 Remove a lock collar ................................................. 1-21

1.2.8 Install a lock collar ................................................... 1-21

1.3 Specifications ......................................................... 1-22

1.3.1 Specifications ...................................................... 1-22

1.3.1.1 Dimensions and weights ........................................ 1-22

1.3.1.2 Drive system specifications ...................................... 1-22

1.3.1.3 Shearbolt specifications ........................................ 1-23

1.3.1.4 Hydraulic specifications ......................................... 1-23

1.3.1.5 Pickup specifications ...........................................1-23

1.3.1.6 Packer specifications ...........................................1-24

1.3.1.7 Stuer specifications .......................................... 1-24

1.3.1.8 Plunger specifications .......................................... 1-24

1.3.1.9 Twine specifications ........................................... 1-25

1.3.1.10 Knotter and needle specifications ................................. 1-25

1.3.1.11 Bale chamber tension specifications ............................... 1-25

1.3.1.12 Ejector specifications .......................................... 1-25

1.3.1.13 Roller bale chute specifications ................................... 1-26

1.3.1.14 Lamp specifications ........................................... 1-26

Table of contents

Large Square Baler 1-1

79037317B

Find manuals at https://best-manuals.com

1.3.1.15 Knotter lubrication pump specifications ............................. 1-26

1.3.1.16 Chain lubrication pump specifications ...............................1-26

1.3.1.17 Lubricants and capacities ....................................... 1-26

1.3.1.18 Tire specifications ............................................. 1-27

1.3.1.19 Brake specifications ........................................... 1-28

1.3.1.20 Maximum speed ..............................................1-28

1.3.1.21 Tractor requirements ........................................... 1-28

1.3.1.22 Noise level .................................................. 1-28

1.3.2 Bolt torque values ................................................... 1-28

1.4 Machine indentification ................................................ 1-31

1.4.1 Location of the serial number plates and the statutory plates - if necessary .......... 1-31

1.4.2 Serial number description .............................................. 1-32

1.5 Machine component views ............................................ 1-33

1.5.1 Outside view - left side ............................................... 1-33

1.5.2 Outside view - right side .............................................. 1-34

1.5.3 Inner view - left side ..................................................1-35

1.5.4 Inner view - right side ................................................. 1-36

1.5.5 Outside view - top ...................................................1-37

1.5.6 Outside view - bottom ................................................ 1-38

1.6 Service and lubrication schedule ....................................... 1-39

1.6.1 Service schedule .................................................... 1-39

1.6.2 Lubrication procedures and general information .............................. 1-42

1.6.2.1 Drive chains ................................................. 1-42

1.6.2.2 Driveline lubrication and maintenance .............................. 1-43

1.6.2.3 Lubricate the hitch ball, if equipped ................................ 1-45

1.6.2.4 Do not lubricate the overrunning clutch ............................. 1-45

1.6.2.5 Do not lubricate the slip clutch for the main drive ...................... 1-46

1.6.2.6 Lubricate the connecting rods .................................... 1-46

1.6.2.7 Examine the packer crank bearings ................................ 1-46

1.6.2.8 Lubricate the bearing for the main drive sprocket ...................... 1-47

1.6.2.9 Lubricate the stuer drive ....................................... 1-47

1.6.2.10 Lubricate the knotter/needle clutch arm and the clutch arm roller .......... 1-47

1.6.2.11 Lubricate the brake linkages ..................................... 1-48

1.6.2.12 Lubricate the steering axle pivots and the steering axle tie-rods ............1-48

1.6.2.13 Lubricate the pivot bushings for the tandem axle springs ................ 1-49

1.6.2.14 Lubricate the center fitting for the six twine knotter .................... 1-49

1.6.2.15 Lubricate the linkages for the bale density cylinders .................... 1-49

1.6.2.16 Lubricate the packer clutch bushing and the splines .................... 1-50

1.7 Connect to the tractor - CE ............................................. 1-51

1.7.1 Hitch component identification .......................................... 1-51

1.7.2 Set the tongue height .................................................1-51

1.7.3 Tractor setup dimensions with an 80 mm (3.15 in) ball hitch, a CE spherical ball hitch, or

a 50 mm (2 in) ring hitch .................................................... 1-52

1.7.4 Connect a 50 mm (2 in) ring hitch to the tractor .............................. 1-52

1.7.5 Connect an 80 mm (3.15 in) ball hitch to the tractor ........................... 1-53

1.7.6 Operate a manual jack installed on the tongue ............................... 1-53

1.7.7 Operate a hydraulic jack installed on the tongue ..............................1-54

1.7.8 Install the safety transport chain ......................................... 1-55

1.7.9 Constant velocity implement driveline, if equipped ............................ 1-55

1.7.9.1 Check the constant velocity implement driveline for correct length ......... 1-55

1.7.9.2 Connect a constant velocity implement driveline to a power take-o (PTO) .... 1-57

1.7.9.3 Adjust the pedestal gearbox ..................................... 1-58

1.8 Checklists ............................................................ 1-59

1.8.1 Daily checklist ...................................................... 1-59

1.8.2 Examine after the first hour of operation ................................... 1-59

1.9 Lamps and Reflectors .................................................. 1-61

1.9.1 Lamps and reflectors ................................................. 1-61

Table of contents

1-2 Large Square Baler

79037317B

Find manuals at https://best-manuals.com

1.9.2 Lamps and reflectors ................................................. 1-63

1.10 Baler operation ........................................................1-67

1.10.1 Description of operation ............................................... 1-67

1.10.2 General terminal information ............................................1-67

1.10.3 Prepare to bale ..................................................... 1-67

1.10.4 Plunger position indication ............................................. 1-68

1.10.5 Start the machine ................................................... 1-68

1.10.5.1 Start the machine: determine the direction of plunger travel .............. 1-68

1.10.5.2 Start the machine: plunger on the retraction (green) stroke ............... 1-70

1.10.5.3 Start the machine: plunger on the compression (red) stroke .............. 1-71

1.10.5.4 Start the machine: machine does not start after four attempts .............1-71

1.10.6 Make the first bale ................................................... 1-72

1.10.7 Make bales ........................................................ 1-73

1.10.8 Stop the machine ....................................................1-73

1.10.9 Stuer cycle ....................................................... 1-74

1.11 Prepare to road the machine or move the machine on a trailer ............ 1-75

1.12 Tie down points, jack points, and lift points ............................. 1-77

1.12.1 Tie down points ..................................................... 1-77

1.12.2 Jack points ........................................................ 1-78

1.12.3 Lift points ......................................................... 1-78

1.12.4 Lift and move a machine correctly ........................................ 1-78

1.13 Disconnect the tractor ................................................. 1-80

Table of contents

Large Square Baler 1-3

79037317B

Find manuals at https://best-manuals.com

1.1 Safety

1.1.1 Safety symbol

The safety symbol tells you about a potentially

hazardous area!

Look for the safety symbol in this manual and on

the machine. The safety symbols tell you that

there is important safety instructions in the

manual.

GUID-4C201302-DBD2-4BFB-8D98-1DDED263BD6E-high.jpg [High]

Fig. 1

1.1.2 Safety messages

The words DANGER, WARNING or CAUTION are

used with the safety symbol. Learn these safety

messages and obey the recommended

precautions and safety instructions.

DANGER:

If you do not obey the recommended

precautions and safety instructions,

DEATH OR INJURY will occur.

WARNING:

If you do not obey the recommended

precautions and safety instructions,

DEATH OR INJURY can occur.

CAUTION:

If you do not obey the recommended

precautions and safety instructions,

INJURY can possibly occur.

GUID-73F05026-C37B-415A-8140-AD939A283378-high.jpg [High]

Fig. 2

1.1.3 Information messages

The words important and note are not related to personal safety, and are used to give information about

the operation and servicing of the machine.

IMPORTANT: Identifies special instructions or procedures which, if not followed, can cause damage to the

machine, the process, or the area around the machine.

NOTE: Information to make procedures easier.

1.1.4 Safety signs

WARNING:

Do not remove the safety signs. Replace safety signs that you cannot read, are damaged,

or are missing.

Clean the machine surface with a weak soap and water solution before you replace the safety signs.

Replacement safety signs are available from your dealer.

[V]

GUID-5D9F270E-D748-4741-82B1-BE49B78685F2 [V5]

GUID-E54F7740-C021-42A8-8784-4287BE4356C8 [V4]

GUID-9A909F52-D57E-4C30-8CC7-6FDB6D7E9982 [V3]

GUID-2FB17168-6A01-47C5-B298-234AF171520B [V6]

1. General

Large Square Baler 1-5

79037317B

Find manuals at https://best-manuals.com

Always make sure that safety signs are in the correct locations and that you can read the safety signs.

Illustrations of safety sign locations are at in this section.

Keep the safety signs clean. If necessary, use a weak soap and water solution.

1.1.5 Safety warnings

Before doing any unplugging, lubricating, servicing, cleaning, or adjusting:

•Park the machine on a solid level surface.

• Disengage the tractor power take-o (PTO).

• Put the tractor transmission in PARK and apply the tractor park brake.

• Turn o the terminal.

• Stop the tractor engine and take the key with you.

• Apply the baler flywheel brake.

• Apply the baler park brake, if equipped.

• Look and listen! Make sure all moving parts have stopped.

• Put blocks in front of and behind the wheels of the machine and the tractor before working on or under

the machine.

WARNING:

After lubrication, servicing, or adjusting the machine, make sure all tools and equipment

have been removed.

WARNING:

All shields and guards must be in position before operating the machine.

1.1.6 A word to the technician

Read and understand the safety section in this

service manual before operating or servicing the

machine. Read and understand the safety sections

in the manuals for all attachments before operating

or servicing attachments. The technician has the

key to safety. Good safety practices protect

everyone.

Study the safety information in this service

manual. Make the safety information a working

part of the safety program. The safety information

in this service manual applies specifically to this

type of machine. Always do all other usual and

customary safe working precautions. Remember -

The technician has the responsibility for safety.

Good safety practices can prevent serious injury or

death.

The safety section points out some basic safety

situations that can occur during the operation and

maintenance of the machine. The safety section

also suggests possible ways to deal with these

situations. The safety section does not replace

safety practices in other parts of this service

manual.

Practice good safety to help prevent injury or

death.

Learn how to operate the machine and how to use

the controls correctly.

GUID-AC91CCF6-1FF8-4A85-97A1-2D1562806825-high.jpg [High]

Fig. 3

GUID-37D29AF8-9B08-445B-8EFD-18840B91FE1D [V1]

GUID-3C35D58D-1F5D-4B85-A915-C7BB48F47262 [V1]

1. General

1-6 Large Square Baler

79037317B

Find manuals at https://best-manuals.com

Do not let other persons operate the machine without instruction and training.

Follow all safety precautions and instructions in the manuals and on safety signs axed to the machine and

all attachments.

Use only approved attachments and equipment.

Make sure the machine has the correct equipment needed by the local regulations.

WARNING:

An operator should not use alcohol or drugs which can aect their alertness or

coordination. An operator on prescription or 'over the counter' drugs needs medical advice

on whether or not they can properly operate machines. If any attachments used on this

equipment have a separate Operator Manual, see that manual for other important safety

information.

1.1.7 The service manual

Read the table of contents and basic layout. Become familiar with all parts of this service manual. This

service manual gives the technician very important information.

Machine movement when in normal use determines right-hand and left-hand.

This manual covers general safety practices for this machine.

The photos, illustrations, and data used in this manual were current at the time of printing. Inline

production changes can make machines vary from the information in the service manual. The manufacturer

reserves the right to redesign and change the machine as necessary without notification.

WARNING:

In some of the illustrations and photos used in this manual, shields or guards may have

been removed for clarity. Never operate the machine with any shields or guards removed.

If the removal of shields or guards is necessary to make a repair, they must be replaced

before operation.

1.1.8 The operator manual

Always keep the operator manual with the

machine.

Store the operator manual in the container (1)

located on the left-hand side of the machine.

GUID-9AA3CB91-F792-4B16-B055-8450B6C2E627-high.jpg [High]

Fig. 4

GUID-0CC50E5C-AD62-4FFD-9435-62214FEFA5F4 [V1]

GUID-19E4A4DB-A392-4939-8B62-4647AFBC71F1 [V1]

1. General

Large Square Baler 1-7

79037317B

Find manuals at https://best-manuals.com

1.1.9 Tool box

The machine has a toolbox (1) on the top of the

machine on the right side. Keep service parts and

the shear bolts in the tool box.

1

HAJHE0110179301

Original art: ~/Desktop/2018.01.09 MF NA 2370 UHD Baler/2018.03.27.01 UHD Tool box.svg

GUID-71D2DF4A-06EC-42FA-A6C8-CA33AF3AA23F-low.svg [Low]

Fig. 5

1.1.10 Operation

1.1.10.1 General information

When parking, park the machine and the tractor on

a solid level surface. put all controls in neutral and

apply the tractor park brake. Stop the tractor

engine and take the key with you.

Make sure the tractor and implement are in the

proper operating condition according to the

operator manuals. Make sure the tractor brakes

and the machine brakes are adjusted correctly.

The tractor must have enough weight and braking

capacity, especially when operating on roads and

terrain that is not even. Use a tractor of

recommended size and weight to tow the

machine.

Tractor must be equipped with rollover protective

structure (ROPS) and a seat belt. use seat belt

during operation.

Do not dismount from moving machinery.

Always operate the machine with the terminal

turned on.

Never start the tractor with the PTO engaged or

terminal turned on.

Stay o slopes too steep for operation.

Where possible avoid operating the machine near

ditches, embankments, and holes. Reduce ground

speed when operating on rough, slippery, or

muddy surfaces and when turning or crossing

slopes.

Be aware of the size of the machine and have

enough space available to allow for operation.

GUID-E77631FB-0DC0-4637-9090-88018315176E-high.jpg [High]

Fig. 6

GUID-158598AE-2E05-4B9D-B577-76F7B933BEE2 [V1]

[V]

GUID-A3ACB803-2E1D-4690-84C2-84FEDB4354EB [V5]

1. General

1-8 Large Square Baler

79037317B

Make sure all persons are clear of the rear of the bale chute when raising and lowering the chute, ejecting

or dumping a bale.

Do not stand between the tractor and the implement to install the hitch pin when the tractor engine is

running.

Avoid contact with electrical power lines. Contact

with electrical power lines can cause electrical

shock, resulting in very serious injury or death.

GUID-DB0A93E4-AEB5-49D5-AC5F-DD1454F1CFC6-high.jpg [High]

Fig. 7

Related Links

Tractor requirements page 1-28

1.1.10.2 Prepare for operation

Read and understand all operation instructions and precautions in this manual before you operate the

machine or do the servicing.

Make sure that you know and understand the positions and operations of all controls. Make sure that all

controls are in neutral and that the parking brake is applied before you start the machine.

Make sure that all persons are away from your area of work before you start and operate the machine.

Examine and learn the controls in an area that is clear of persons and obstacles before you start work.

Know the machine dimensions and make sure that you have sucient space available to operate the

machine. Do not operate the machine at high speeds in crowded areas.

It is important to know and use the correct procedures when you do work around and operate the

machine. Do not let children or unqualified persons operate the machine. Keep others, especially children,

away from your area of work. Do not let others to ride on the machine.

Make sure that the machine is in good condition for operation. Refer to the operator manual. Make sure

that the machine has the correct equipment required by local regulations.

All equipment has a limit. Make sure you understand the speed, brakes, steering, stability and load

characteristics of this machine and the tractor before you start.

GUID-A25B667B-D7CF-4C75-8AED-C10113104322 [V5]

1. General

Large Square Baler 1-9

79037317B

1.1.10.3 Personal protective equipment

Put on all personal protective equipment (PPE) and

protective clothes that are supplied to you or that

are necessary for the conditions and by applicable

laws. PPE includes equipment to prevent injury to

your eyes, lungs, ears, head, hands and feet.

Always keep hands, feet, hair, and your clothes

away from parts that move. Do not put on loose

clothing, jewelry, watches, or other items that can

tangle in parts that move. Tie up long hair that can

also tangle in moving parts.

GUID-1AEEBD1D-C71B-432C-9D23-52467D7C0BBF-high.jpg [High]

Fig. 8

1.1.10.4 Seat instructions

Put on the seat belt before you operate the

machine. Always sit in the seat and have the seat

belt on while you operate the machine. Replace

the seat belts when they become worn or broken.

Do not use a seat belt loosely. Make sure that

there is some tension on the seat belt. Do not

wear the seat belt in a twisted condition or

pinched between the structural parts of the seat.

Put on the seat belt if the instructional seat is

used. Use the instructional seat only to train new

operators or to find a problem. The instructional

seat is only for short periods of use.

Do not let children use the instructional seat or be

in the cab. Do not let other persons use the

instructional seat or be in the cab.

Drive the machine at slower speed and on level

ground when the instructional seat is used. Do not

start, stop, or turn quickly when the instructional

seat is used. Do not drive on highways or public

roads when the instructional seat is used.

GUID-5BA328EA-7732-4CE8-97B2-6511151E943C-high.jpg [High]

Fig. 9

1.1.10.5 Shield and guards

WARNING: Entanglement hazard.

Belts and components that rotate.

Severe personal injury or death can

occur.

Do not open, remove, or put your

hand behind shields if the engine is

running. Stop the machine before

doing service to the machine.

All shields and guards must be in the correct

position and in good condition. Keep away from

the components that rotate.

GUID-6163F2D6-39D6-48BF-871C-AC346EE022D2-high.jpg [High]

Fig. 10

GUID-7FEFA67B-E06F-4EFE-A23E-738FE96997E9 [V3]

GUID-F38524AD-E24F-4FCC-9154-E5357EFDE9D2 [V3]

GUID-9398BDE6-F83A-4855-B266-E86D0B48B9D7 [V9]

1. General

1-10 Large Square Baler

79037317B

DANGER: Entanglement hazard.

Rotating components.

Severe personal injury or death can

occur.

Do not make adjustments or repairs

to components while they are

moving. Stop the machine before

doing service to the machine.

Do not operate the machine with the drive shaft

shields open or removed.

Keep away from the components that turn.

Make sure guards that turn are free.

GUID-CEB32148-1F4C-457C-ADF7-595DFC51AC25-high.jpg [High]

Fig. 1

1

1.1.10.6 Exhaust warning

WARNING: Inhalation hazard. Exhaust

gases.

Death or serious illness can occur.

Do not operate the engine in a closed

building unless the exhaust is

ventilated to the outside.

Do not tamper with or modify the exhaust system

with unapproved extensions.

GUID-55072A39-D882-4355-8ABA-05660F3F6EDA-high.jpg [High]

Fig. 12

1.1.10.7 Flying debris

WARNING:

Be careful when you operate along

the side of a road or structures. Rocks

and other materials can be thrown

from the machine during operation

and can cause injury.

Stay away from the machine during operation.

Some materials can be thrown from the machine

during operation and cause injury.

GUID-1D480E10-339B-427D-9D05-37E84CC7A29A-high.jpg [High]

Fig. 13

GUID-AC6BA923-B398-43F4-BFAE-5130AFED6FC5 [V4]

GUID-3910D764-BEA7-4A1B-80BF-946E438C6212 [V5]

1. General

Large Square Baler 1-11

79037317B

1.1.10.8 Handrails

WARNING: Falling hazard.

Personal injury or death can occur.

Use appropriate safety precautions

when working o the ground.

Point your body in the direction of the ladder and

use the handrails when you are on the machine

ladders. Always keep three points of contact with

the ladder.

GUID-B4BF5956-B0F7-43A5-85C1-706D96BCA02B-high.jpg [High]

Fig. 14

1.1.10.9 Agricultural chemicals

Agricultural chemicals are very dangerous. Incorrect procedures with fertilizer, fungicides, herbicides,

insecticides and pesticides can cause injuries to plants, animals, soil and other persons property.

Always read and follow all manufacturers instructions before you open chemical containers.

Read and follow instructions each time you use a chemical.

Use the same precautions when you do adjustments, do servicing, clean or store the machine as used

when you put chemicals into the hoppers or tanks.

Tell all persons who are near chemicals of the possible dangerous results and the safety precautions that

are necessary.

Stay upwind and away from smoke from a chemical fire.

Keep or discard all chemicals that are not used as specified by the chemical manufacturer.

1.1.11 Travel on public roads

Always raise the bale chute before:

•Taking the machine across a road.

• Roading the machine.

• Moving the machine on a trailer.

See raising a bale chute for more information.

Make sure you understand the speed, brakes,

steering, stability, and load characteristics of this

machine and the tractor before you travel on public

roads.

Use good judgement when traveling on public

roads. Maintain complete control of the machine

at all times. Never coast down hills.

The maximum speed of farm equipment is

governed by local regulations. Adjust travel speed

to maintain control at all times. See Specifications

for the maximum speed for this machine.

Make sure the tractor is in the proper operating

condition according to the tractor operator manual.

Make sure the tractor brakes and the machine

GUID-657D3002-48DB-436B-9B56-D3750095397D-high.jpg [High]

Fig. 15

GUID-DAAB4281-F045-467E-97A1-20DFD2BB692C [V4]

GUID-A494D2FA-1956-40C4-9743-052166A2A431 [V4]

GUID-5D89E5D7-581C-41BB-8EB5-81C1804930D9 [V2]

1. General

1-12 Large Square Baler

79037317B

brakes, if equipped, are adjusted correctly. The tractor must have enough weight and braking capacity,

especially when operating on roads and terrain that is not even. To achieve proper braking capacity, use

tractor of recommended size and weight to tow the machine. See Specifications for the minimum tractor

weight.

Familiarize yourself with and obey all road regulations that apply to your machine. Consult your local law

enforcement agency for local regulations regarding movement of farm equipment on public roads. Use

headlights, flashing warning lights, taillights and turn signals, day and night, unless prohibited by local law.

Make sure all the flashers are operating prior to driving on the road. Make sure reflectors are correctly

installed, in good condition, and wiped clean. Make sure the Slow Moving Vehicle (SMV) emblem, if

equipped, is clean, visible, and correctly mounted on the rear of the machine.

Do not operate the baler on the road with a bale in the chamber.

Be aware of other trac on the road. Keep well over to your own side of the road and pull over, whenever

possible, to let faster trac pass.

Be aware of the overall width, length, height, and weight of the equipment. Be careful when transporting

the machine on narrow roads and across narrow bridges.

Always install the safety transport chain between the implement and the tractor drawbar.

• Use a safety transport chain with a strength rating equal to or more than the gross weight of the towed

machines.

• Connect the safety transport chain to the tractor drawbar and use a retainer on the hitch pin.

• Supply only enough slack in the safety transport chain to permit turning.

• Do not use the safety transport chain as a tow chain for towing.

Watch for overhead wires and other obstructions.

Avoid contact with electrical power lines. Contact

with electrical power lines can cause electrical

shock, resulting in very serious injury or death.

GUID-DB0A93E4-AEB5-49D5-AC5F-DD1454F1CFC6-high.jpg [High]

Fig. 16

Related Links

Tractor requirements page 1-28

Maximum speed page 1-28

Lift the roller bale chute page 8-3

1. General

Large Square Baler 1-13

79037317B

1.1.12 Maintenance

1.1.12.1 General maintenance information

Before you do maintenance, lubricate, do

servicing, clean, or make adjustments:

• Park the machine on a solid, level surface.

• Disengage the tractor power take-o.

• Make sure that all the controls are in the

neutral position and apply the parking brake.

• Make sure that the machine and the

attachments are lowered to the ground.

• Stop the engine and take the key with you.

• Apply the baler flywheel brake.

• If the baler has a parking brake, apply the baler

parking brake.

• Look and Listen! Make sure that all parts that

move are stopped.

• Put chocks in front of and behind the wheels of

the machine before you do work on or below

the machine.

GUID-DB4C2E27-9DAC-4734-83E4-BC4BB5C26EAF-high.jpg [High]

Fig. 17

Stay near the machine when the tractor is in operation.

Know the dimensions and the weights of parts when you do the servicing. Do not stand below or near a

part while it is moved with a hoist or other lift equipment.

After you do work on the machine, remove all tools from the machine.

Make sure that electrical connectors are clean before you connect them.

Do a check for loose, broken, missing, or damaged parts. Make sure that the machine is in good repair.

Make sure that all guards and shields are in position.

Do not do the servicing, examine or adjust chains

or belts while the engine is in operation.

GUID-7D1C9640-D737-4F38-8886-F1D2280DF613-high.jpg [High]

Fig. 18

[V]

GUID-93C8628D-B392-4191-80DB-7D54BDAAF61B [V17]

1. General

1-14 Large Square Baler

79037317B

Do not operate the machine with the drive shaft

shields open or removed. Entanglement in drive

shafts that rotate can cause injury or death.

Stay clear of components that rotate.

Make sure that guards that rotate can rotate freely.

A loose yoke can come o a shaft and result in

injury to persons or damage to the machine.

When you install a quick disconnect yoke, the

spring activated locking pins must move freely and

be in the groove on the shaft. Pull on the driveline

to make sure that the quick disconnect yoke can

not be pulled o the shaft. GUID-CEB32148-1F4C-457C-ADF7-595DFC51AC25-high.jpg [High]

Fig. 19

Remove spilled oil, antifreeze or fuel immediately

from the steps, platform, and other access areas.

Keep all access areas clean of unwanted materials.

GUID-3B306DB1-0777-4FA6-86F1-895652B4C1DB-high.jpg [High]

Fig. 20

Disengage the tractor PTO. Stop the tractor

engine. Remove the key. Take the key with you.

Apply the flywheel brake. Engage the knotter/

needle lockout before threading the needles,

threading the knotters or you adjust the twine

tensioners.

Injury can occur from threading the needles,

threading the knotters or adjusting the twine

tensioners with a baler in operation.

The needle frame and the knotters can move

when there is not hay in the baler.

When you do work with or around the needles or

knotters always engage the knotter/needle

lockout.

Do not try to remove twine from the bale chamber

or the knotter while the baler is in operation.

GUID-AFDF1E6C-62A8-4132-A343-CB74D561D430-high.jpg [High]

Fig. 21

1. General

Large Square Baler 1-15

79037317B

1.1.12.2 Fire prevention and first aid

Be prepared for emergencies.

Keep a first aid kit available for use on small cuts

and scratches.

Keep one or more fire extinguishers of the correct

type. Examine fire extinguishers regularly as stated

by the manufacturer. Make sure that the fire

extinguishers are charged and in operating

condition.

Crop material is flammable, there is a risk of fire.

Use a water type fire extinguisher or other water

source for a fire in crop.

For fires in material other than crop, such as oil or

electrical components, use a dry chemical fire

extinguisher with an ABC rating.

Keep fire extinguishers easy to access where fires

can occur.

Frequently remove crop material from the machine

and examine for components that are too hot. Do

checks on the machine each day for noises that

are not usual. Unusual noises can indicate a worn

out component that can cause too much heat.

If flame cutting, welding, arc welding, or grinding

is to be done on the machine or attachments, clear

crop material and unwanted material from around

the area. Make sure that the area below the work

area is clear of flammable material because falling

molten metal and sparks can cause ignition in the

material.

At the end of each season, or if the machine will

sit for more than 48 hours after baling high

moisture crops, do one of the following:

• If the machine has a bale ejector, use the bale

ejector to eject the bale.

• Fill the bale chamber with dry crop

GUID-FF34ACC9-D080-4CD5-9528-F426605803FF-high.jpg [High]

Fig. 22

If fire occurs, move upwind and away from the

smoke from the fire.

GUID-8FDCA67C-244A-40BA-967B-3FA4E7667A7E-high.jpg [High]

Fig. 23

GUID-9D716526-CF1A-4CD9-89A6-FD350D1B1E7A [V7]

1. General

1-16 Large Square Baler

79037317B

1.1.12.3 High pressure leaks

WARNING: Hydraulic fluid under

pressure can penetrate the skin or

eyes.

Serious personal injury, blindness, or

death can occur.

Relieve the pressure from the system

or component before disconnecting

components. Wear personal

protective gear while working on the

machine or equipment. Use a piece of

cardboard to check for leaks. Never

use your hand.

Fluid that leaks from the hydraulic system or the

fuel injection system is high pressure and is not

easily seen. The fluid can go into the skin causing

injury.

Fluid that is injected into the skin must be

surgically removed immediately. If not removed

immediately, infection and reaction can occur. Go

immediately to a physician who knows about this

type of injury.

GUID-CB450E2E-50DF-4D16-9E59-21C0B3E5B026-high.jpg [High]

Fig. 24

Use a piece of cardboard or wood to look for

possible leaks. Do not use your bare hand. Wear

leather gloves for hand protection and safety

goggles for eye protection.

Remove all pressure before you loosen hydraulic

lines. Lower equipment in the up position, close

the accumulator valve, and stop the engine.

Tighten all connections before you apply pressure.

GUID-9A83C5CD-95EC-445B-A3A7-1DCF8FACFE45-high.jpg [High]

Fig. 25

1.1.12.4 Tire safety

Examine tires for cuts, bulges, and correct

pressure. Replace worn or damaged tires. When

tire service is needed, have a qualified tire

mechanic service the tire. Tire changing can be

very hazardous and must be done by qualified tire

mechanic using proper tools and equipment.

Always use the correct tire size.

Tire explosion and/or serious injury can result from

over inflation. Do not exceed the tire inflation

pressures.

Do not inflate a tire that is seriously under inflated

or has been run flat. Have the tire examined by

qualified tire mechanic. GUID-CB65B01E-C8CB-43E0-A943-F2A9567A2E73-high.jpg [High]

Fig. 26

GUID-68111A90-0641-4B8F-9AB9-A5B05A044C46 [V4]

GUID-97EFADF3-87B3-455B-A330-9F02E232114E [V1]

1. General

Large Square Baler 1-17

79037317B

Table of contents

Other FENDT Farm Equipment manuals

FENDT

FENDT FORMER 12545 PRO User manual

FENDT

FENDT IDEAL Series User manual

FENDT

FENDT 5220 E User manual

FENDT

FENDT 4300 User manual

FENDT

FENDT 5270 C User manual

FENDT

FENDT IDEAL Series User manual

FENDT

FENDT 8380 P User manual

FENDT

FENDT 900 Gal Liquid System User manual

FENDT

FENDT BALER Series User manual