1 General

1.1 General information .................................................... 1-3

1.1.1 Introduction to this service manual .......................................1-3

1.1.2 Units of measurement ............................................... 1-3

1.1.3 Table of contents ................................................... 1-3

1.1.4 Page numbers ..................................................... 1-3

1.1.5 Intended use ...................................................... 1-3

1.1.6 How to correctly dispose of the waste ................................... 1-3

1.2 Safety ................................................................. 1-5

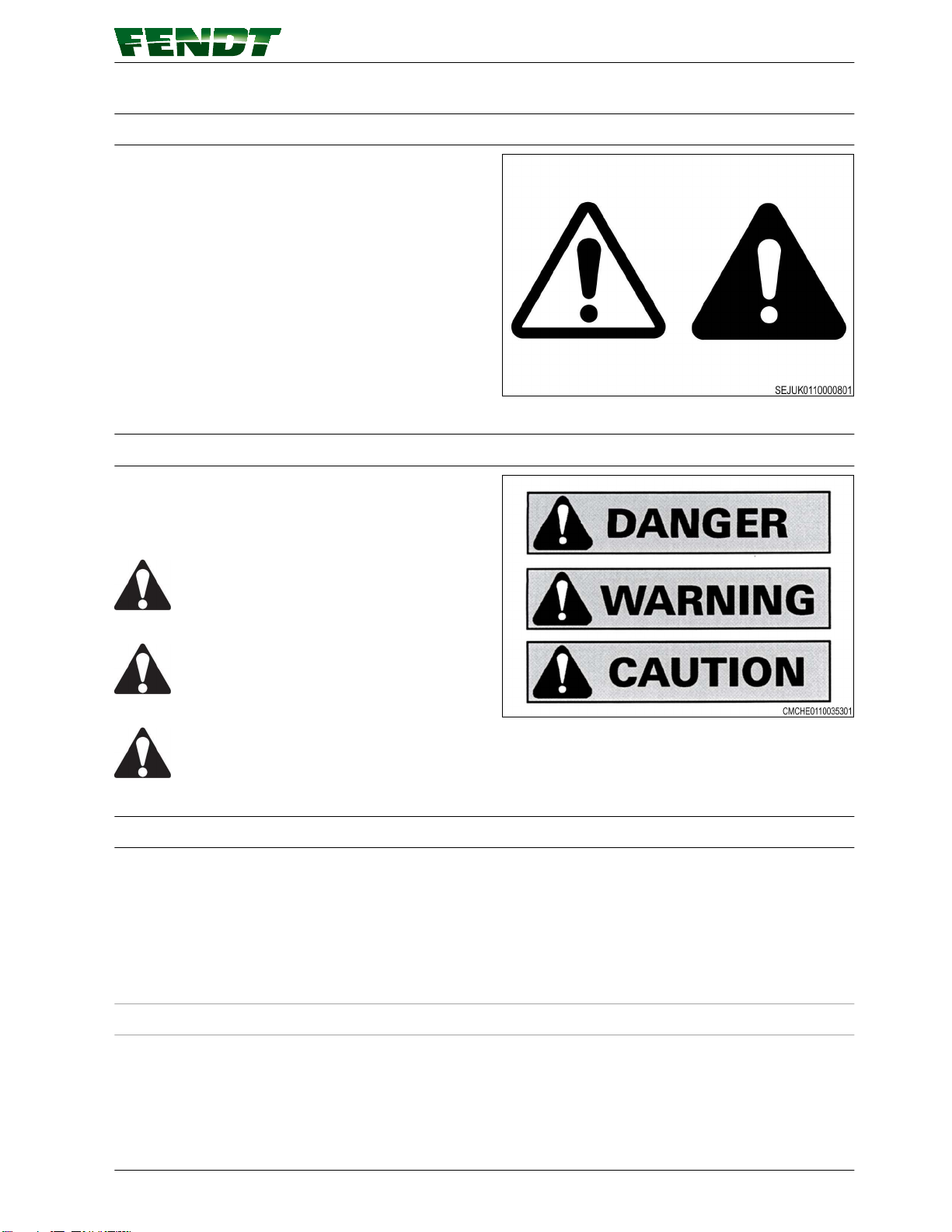

1.2.1 Safety symbol ...................................................... 1-5

1.2.2 Safety messages ................................................... 1-5

1.2.3 Messages ........................................................ 1-5

1.2.4 Safety signs ....................................................... 1-5

1.2.5 A word to the technician .............................................. 1-6

1.2.6 The service manual .................................................. 1-7

1.2.7 Operation ......................................................... 1-7

1.2.7.1 Prepare for operation ....................................... 1-7

1.2.7.2 General information ........................................ 1-7

1.2.7.3 Personal protective equipment ................................ 1-8

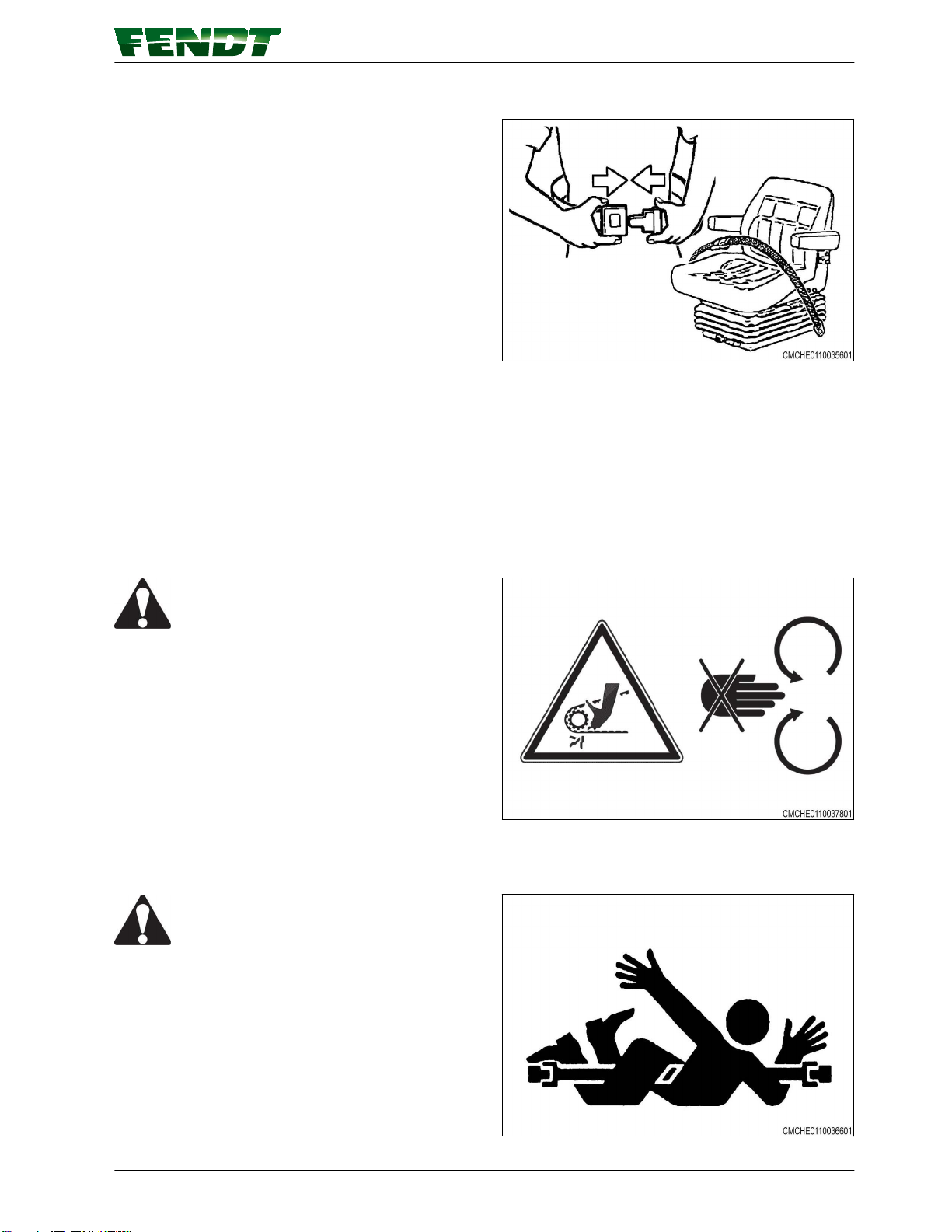

1.2.7.4 Seat instructions .......................................... 1-9

1.2.7.5 Shield and guards ..........................................1-9

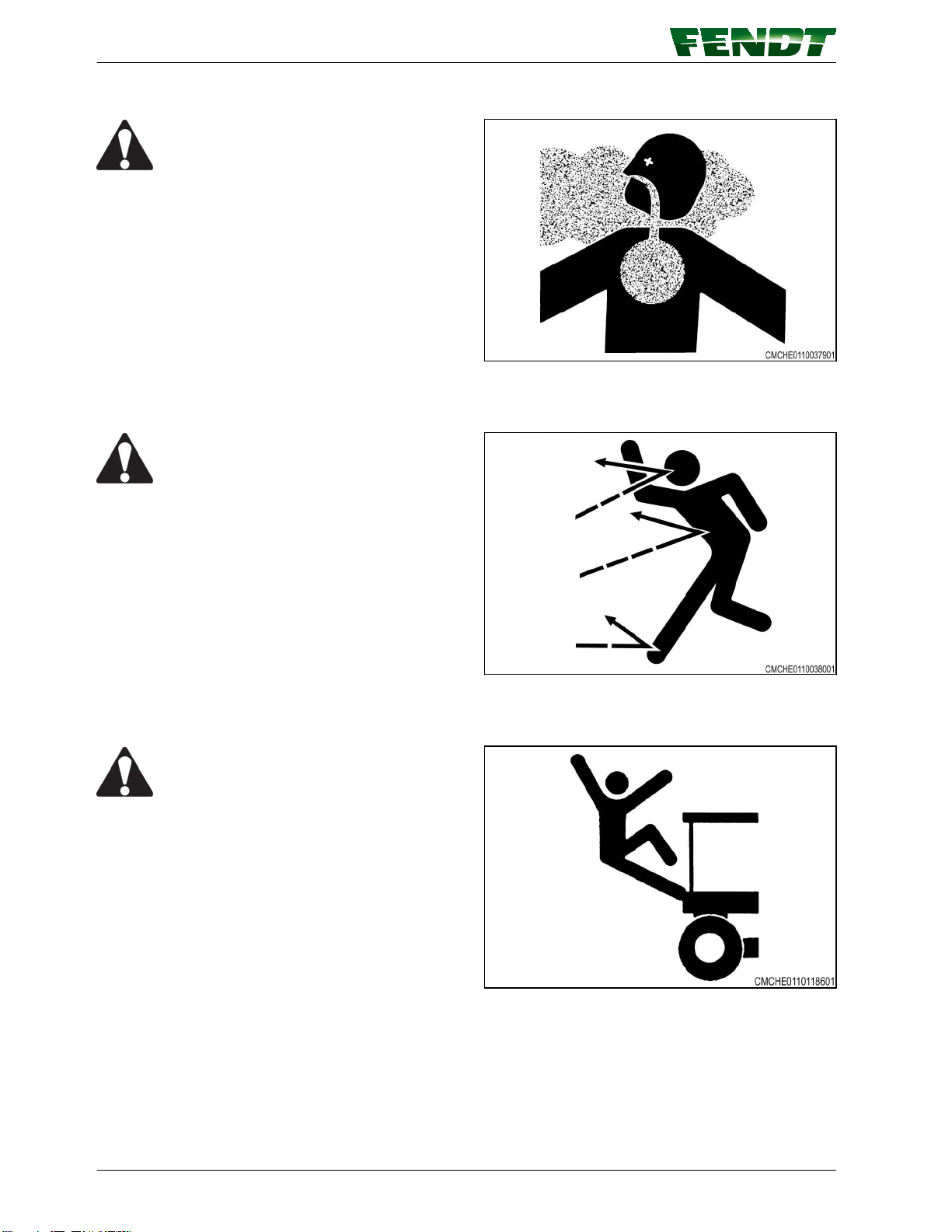

1.2.7.6 Exhaust warning .......................................... 1-10

1.2.7.7 Flying debris .............................................1-10

1.2.7.8 Handrails ............................................... 1-10

1.2.7.9 The agricultural chemicals .................................. 1-10

1.2.8 Travel on public roads ................................................1-11

1.2.9 Maintenance ...................................................... 1-12

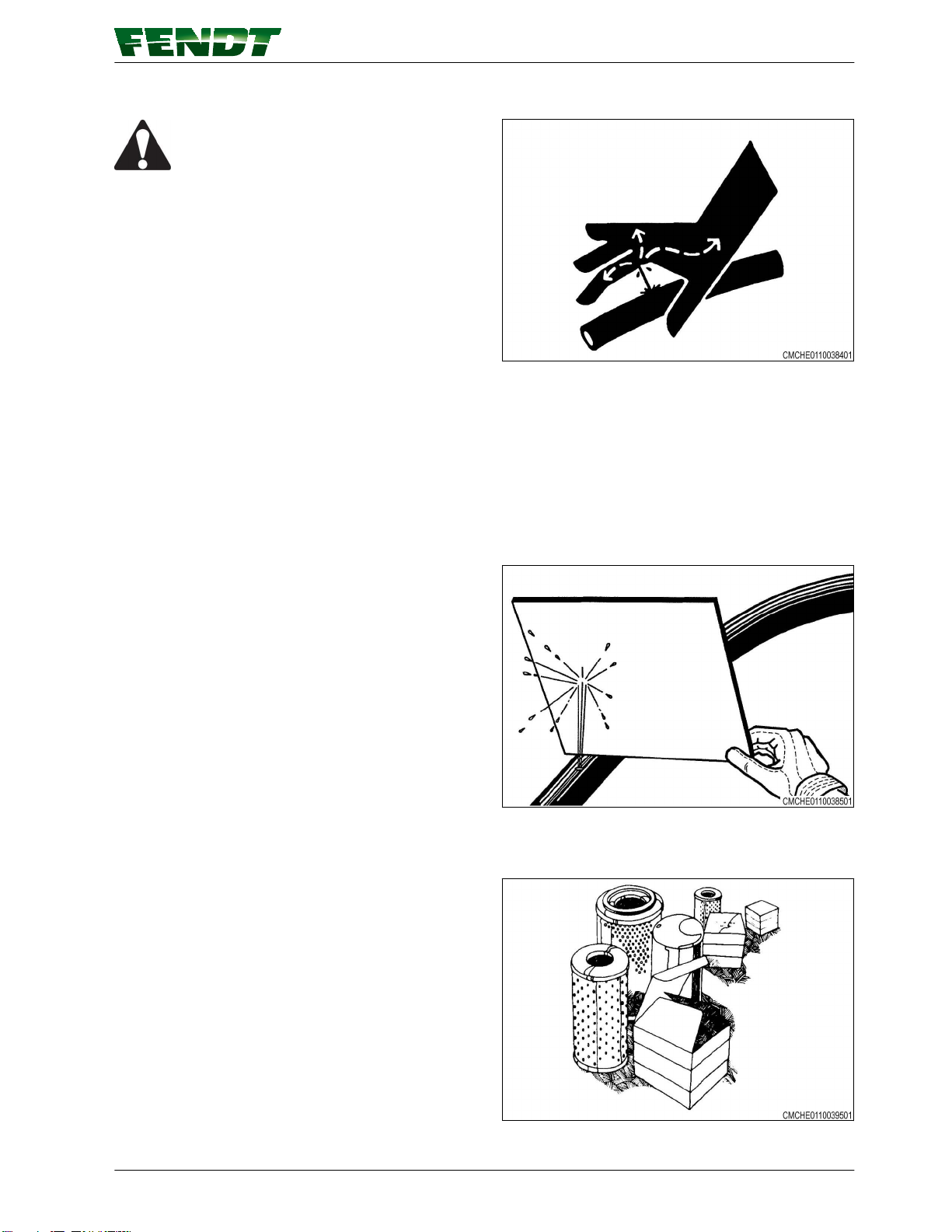

1.2.9.1 General maintenance information ............................. 1-12

1.2.9.2 Fire prevention and first aid .................................. 1-14

1.2.9.3 High pressure leaks ....................................... 1-15

1.2.9.4 Replacement parts ........................................ 1-15

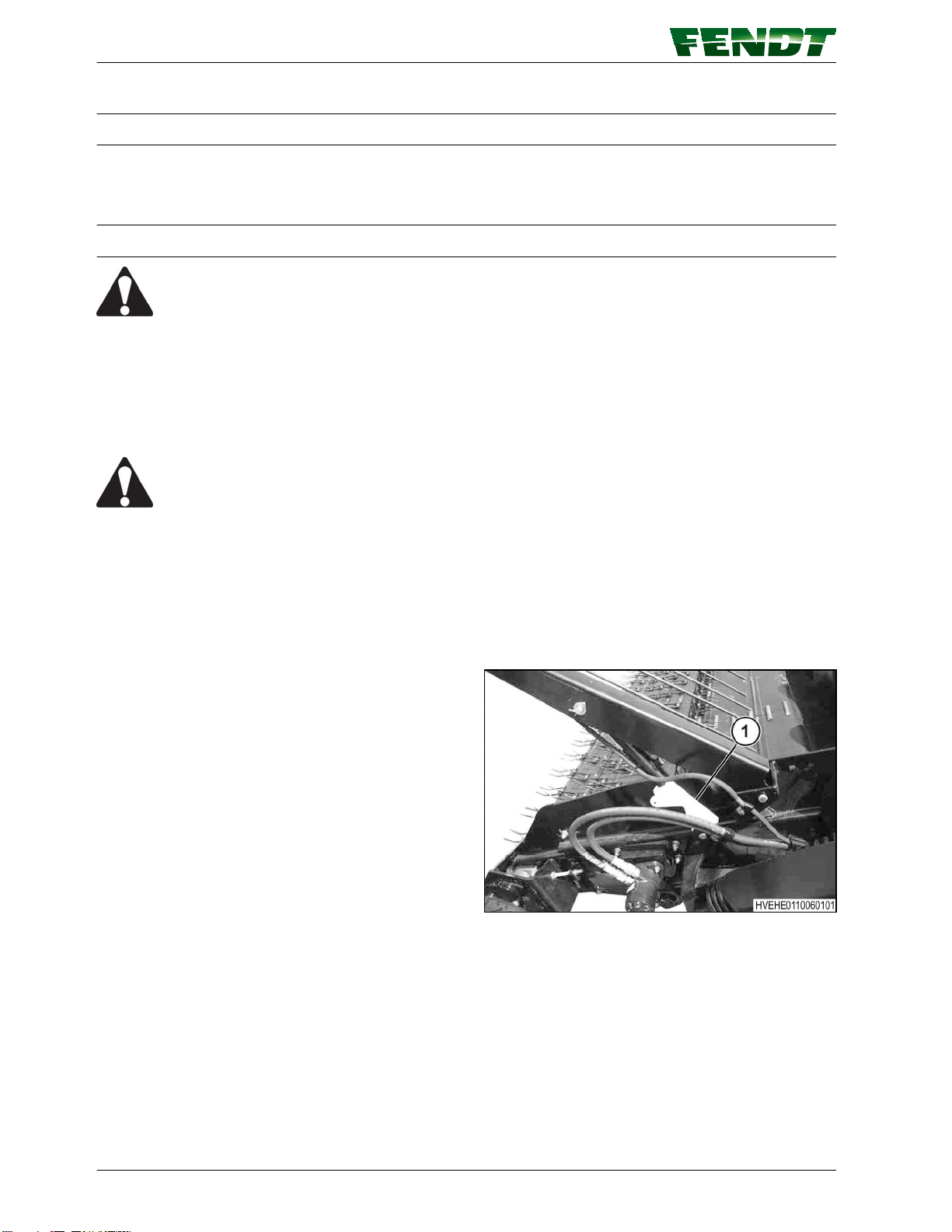

1.3 Cylinder stops .........................................................1-16

1.3.1 Header lift cylinder stop ............................................. 1-16

1.3.2 Hold-down cylinder support ........................................... 1-16

1.3.2.1 Engage the hold-down cylinder support ......................... 1-16

1.3.2.2 Disengage the hold-down cylinder support .......................1-16

1.4 Machine identification ................................................. 1-18

1.4.1 Serial number plate ................................................. 1-18

1.4.2 Serial number description ............................................ 1-18

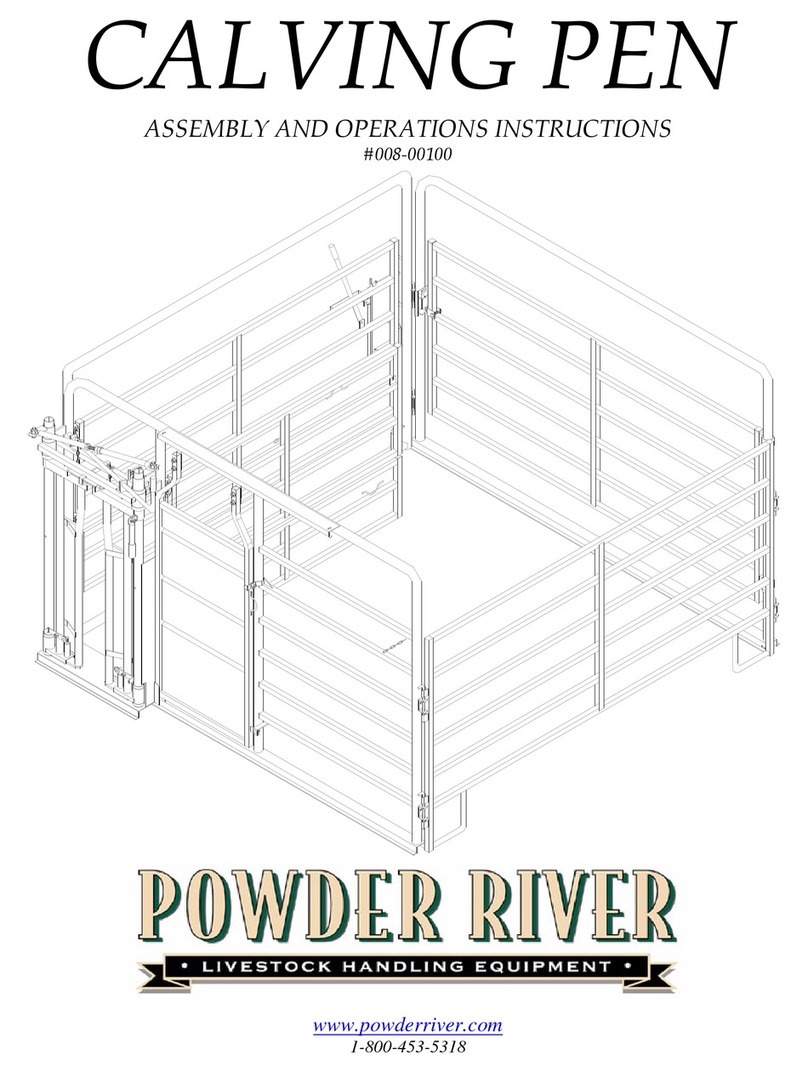

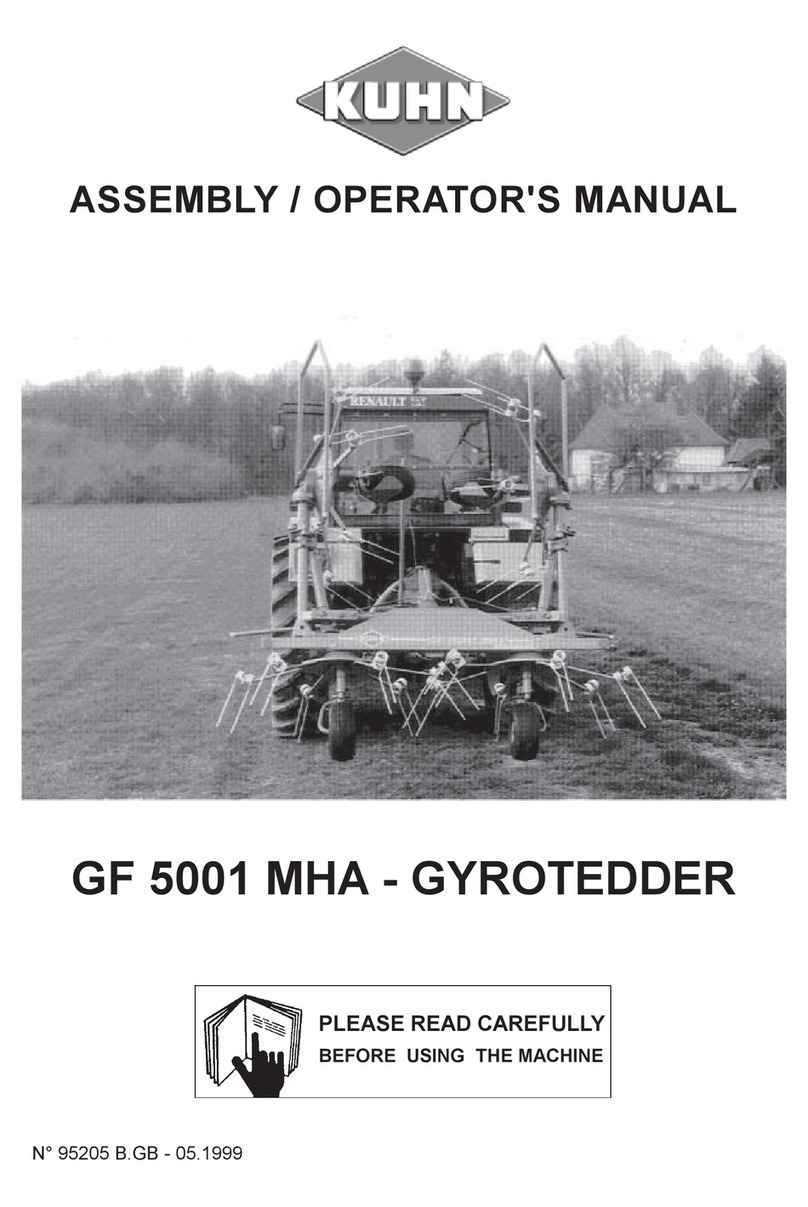

1.5 Component identification .............................................. 1-20

1.6 Specifications ......................................................... 1-23

1.6.1 Header specifications ............................................... 1-23

1.6.2 Header dimensions ................................................. 1-24

1.6.3 Lubrication specifications .............................................1-25

1.7 Troubleshooting ....................................................... 1-26

1.8 Connect and disconnect the header .................................... 1-29

1.8.1 Connect the header .................................................1-29

1.8.2 Disconnecting the header ............................................ 1-31

1.9 Connect and disconnect the header - Ideal .............................. 1-34

1.9.1 Connect the header .................................................1-34

Table of contents

Pickup Header 1-1

79037386D

Find manuals at https://best-manuals.com