FENDT 5270 C User manual

FENDT 5270 C

from serial No. 552310097

FENDT 5270 C-AL

from serial No. 552410055

FENDT 6300 C

from serial No. 563010120

FENDT 6300 C-AL

from serial No. 563410051

OPERATOR'S

MANUAL

TABLE OF CONTENTS

1. General Information

2. Operation - Controls and Instruments

3. Field Operations

4. Lubrication and Maintenance

5. Adjustments

6. Troubleshooting

7. Off-season storage

8. Optional Equipment

9. Technical Specifications

10. Alphabetical Index

Find manuals at http://best-manuals.com/search?&s=FENDT-327184015.PDF

CONTENTS

Section-Page

1

1. GENERAL INFORMATION

Customer information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Combine identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Ecology: information for the prevention of environmental pollution . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Emergency exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-31

Safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Machine lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-39

Noise level in the cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-40

Fire resistance inside the cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

Statutory regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

Vibrations in the cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-41

Hydraulic systems: hose safety requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

Scrapping and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-42

Electromagnetic emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-42

Notes for road transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-43

Weight distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-45

2. OPERATION - CONTROLS AND INSTRUMENTS

Operation - Crop Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Steering column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Control Pedals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Multifunction lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Gearshift lever and reversing lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Control panel (5270 C and 6300 C models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Control panel (5270 C-AL and 6300 C-AL models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Agritronicplus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Levelling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Access to combine components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-46

Engine: starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-49

Stopping the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

Driving the combine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

Operations to be carried out before road transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

Before using the combine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-53

Towing the combine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

Moving the machine in emergency situations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

3. FIELD OPERATIONS

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Starting and Stopping the Combine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Cutting table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Main Crop Elevator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Cylinder Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Concave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Rear beater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Multi Crop Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Straw walkers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Main Grain Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Fanning mill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Top sieve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Bottom sieve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Grain tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Find manuals at http://best-manuals.com/search?&s=FENDT-327184015.PDF

Section-Page

2

4. LUBRICATION AND MAINTENANCE

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Preliminary Service Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Scheduled Service Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Where and When to Carry Out Service Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Routine Service Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Scheduled Service Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Capacities and Specifications (5270 C - 6300 C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

Capacities and Specifications (5270 C-AL - 6300 C-AL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

5. ADJUSTMENTS

Belt and chain adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Belts and chains (left-hand side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Belts and chains (right-hand side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Slip clutches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-22

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

6. TROUBLESHOOTING

Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Threshing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Separation and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Hydrostatic Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Levelling Hydraulics System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Air conditioning circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Straw Chopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

7. OFF-SEASON STORAGE

8. OPTIONAL EQUIPMENT

9. TECHNICAL SPECIFICATIONS

Wheels and tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Combine Dimensions with Tyres (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Combine Dimensions with Tracks (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Tracks with runners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Clearance between unloading auger and table (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Technical specifications - 5270 C - 6300 C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-8

Dimensions of 5270 C-AL - 6300 C-AL models (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Technical specifications - 5270 C-AL and 6300 C-AL models . . . . . . . . . . . . . . . . . . . . . . . . . . .9-15

10. ALPHABETICAL INDEX

Find manuals at http://best-manuals.com/search?&s=FENDT-327184015.PDF

Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007 1-1

1. GENERAL INFORMATION

1.1 CUSTOMER INFORMATION

INTRODUCTION

Your new self-propelled combine is manufactured

for harvesting seed and cereal crops, for threshing,

separating, cleaning and conveying the grain into

the tank and depositing the straw on the ground.

This Operator's Manual contains all the necessary

practical information on the operation, adjustment

and maintenance of your new machine and should

be used as a practical reference guide.

The combine is designed and built to ensure

optimum performance, comfort and

ease-of-operation in a wide variety of crops and

conditions.

The combine has been thoroughly inspected prior

to delivery both at the factory and by your Dealer,

to ensure you receive it in perfect condition.

To keep the combine in perfect condition and to

ensure trouble-free performance, the periodical

maintenance operations listed in this manual

should be carried out at the recommended

intervals.

Before operating or driving the combine, read

this Operator's Manual carefully, paying

particular attention to the section on safety

rules. Always keep this manual on hand for

further reference.

The terms "left" and "right" are always used with

reference to the travelling direction.

Should you require further information about the

machine, please do not hesitate to contact your

authorised Dealer. Your Dealer provides specially

trained personnel, genuine quality spare parts and

the required tools to solve any problems that may

arise.

NOTE:

• This combine has been designed and built in

compliance with the Machine Directive

98/37/EC.

A CE Declaration of Conformity is supplied

with the machine.

The manufacturer disclaims all liability to any

claim resulting from unauthorised modification

or alteration.

• This manual is published for world wide

distribution, and the availability of equipment

shown as basic or accessory varies according

to the territory in which the combine is to be

used.

Specifications may differ from those contained

in this Operator's Manual according to the

customer's requirements.

• In order to provide a better view, certain

illustrations in this manual may show an

assembly with standard guards, or the guards

required by law in different countries, open or

removed. However, a machine should never

be operated in this condition. For your own

safety, always ensure all safety guards are

closed and correctly fitted before operating

the machine.

•This Operator's Manual, along with the

Operator's Manual for table and PTO shaft,

must always be kept in the pocket provided

on the right-hand side of the operator seat

for convenient reference..

Modifications and improvements

In accordance with the Company's policy of

continuous improvements to its products, the

Company reserves the right to modify and improve

its products whenever necessary and to the

required extent, without any obligation to apply

such modifications to previously sold products.

Find manuals at http://best-manuals.com/search?&s=FENDT-327184015.PDF

GENERAL INFORMATION

1-2 Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007

OPTIONAL EQUIPMENT

The machine has been designed to operate in a

wide variety of crops and conditions. However, in

certain cases it may be necessary to fit additional

accessories to improve machine performance and

adapt the machine to special crops or harvesting

conditions. A list of available accessories is

provided in the section "Optional Equipment".

SPARE PARTS AND ACCESSORIES

The genuine spare parts and accessories have

been specifically designed for this type of machine.

Only genuine parts supplied by your authorised

Dealer can guarantee correct operation and

optimum performance.

Never use non-genuine spare parts or accessories:

Some accessories (e.g. PTO shafts, straw

choppers, tables) require a CE certification, which

can be provided only by the manufacturer or his

qualified and recognised sub-suppliers.

Non-genuine spare parts have not been tested and

are not authorised by the manufacturer. The fitting

and/or use of such equipment may have a

damaging effect on the design features of the

machine and jeopardise operational safety.

The manufacturer disclaims all liability in the

event of loss or damage arising as a result of

non-genuine parts or accessories being fitted.

It is expressly prohibited to make any modification

to the combine without the prior written

authorisation by the manufacturer.

When ordering spare parts and/or optional

equipment, always quote combine model and serial

number (see section "Combine Identification").

WARRANTY

Your combine is warranted in compliance with the

regulations in force in your country and the

agreements made with your Dealer.

However, the warranty becomes void in the

following situations:

a.) If the machine has been used inappropriately.

b.) If adjustments and maintenance have not been

carried out according to the instructions in this

manual.

c.) If the failures are caused by the use of

non-genuine spare parts or accessories.

d.) If damage is the result of carelessness,

negligence, inappropriate use of the machine

or operational errors.

If the safety devices are removed, the warranty

becomes void automatically and the

manufacturer disclaims any liability. The

warranty also becomes void if non-genuine

spare parts are used.

The warranty applies only to repair or free

replacement of parts proving defective after a

careful inspection by the manufacturer (excluding

wear parts and tyres), as described in the Combine

Service Record Book. In the event that warranted

parts are replaced or repaired, warranty terms are

not extended. The customer can assert his

warranty rights only insofar as the warranty

conditions contained in the Service Record Book

have been observed.

LUBRICANTS

Your Dealer can provide a wide range of special

lubricants, produced according to the specific

technical specifications of the combine.

For these combines, we recommend the use of the

lubricants listed on page 4-33 (5270 C and 6300 C

models) and on page 4-37 (5270 C-AL and 6300

C-AL models).

Always use genuine AGCO parts.

Find manuals at http://best-manuals.com/search?&s=FENDT-327184015.PDF

GENERAL INFORMATION

Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007 1-3

1.2 COMBINE IDENTIFICATION

The combine and its main components are

identified by serial numbers and/or production

codes. The position of the different identification

data is described below.

NOTE: Always quote the combine serial number in

any communication to your Dealer.

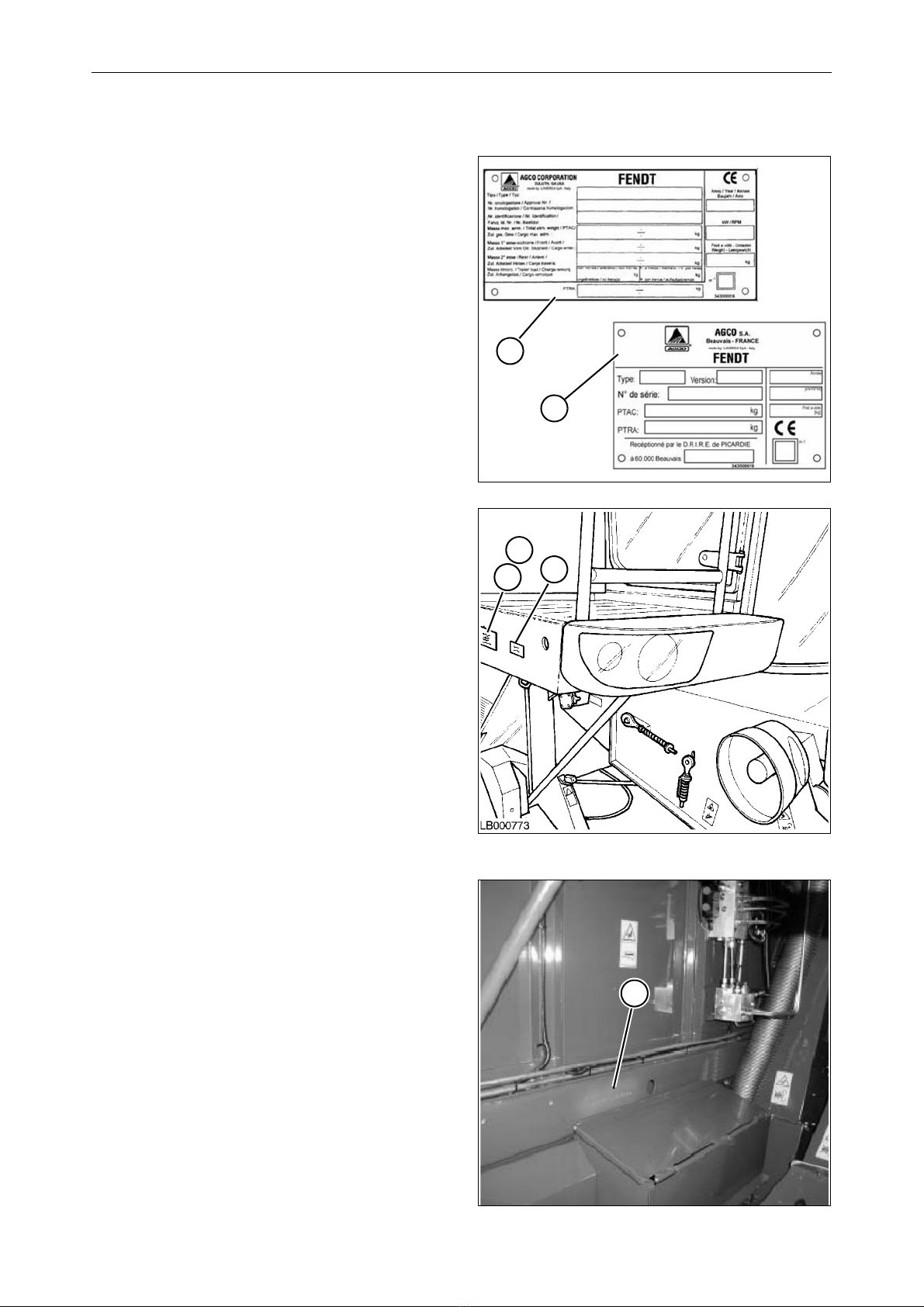

Combine type plate

Fig. 1 and Fig. 2

The manufacturer's type plate (1), statutory for all

countries (or (2), for France only), is positioned on

the outer right-hand side of the operator platform

and shows the following information:

• Combine type.

• Combine serial number.

• Manufacturing year.

•Weight.

• Engine power in kW and rpm according to

ISO/TR 14396.

•CEmarking.

• Road type approval number, where applicable.

For further details, please refer to the type approval

certificate.

In certain countries (e.g. Russia) the manufacturer's

type plate is positioned next to a decal/plate (3)

corresponding to the type approval.

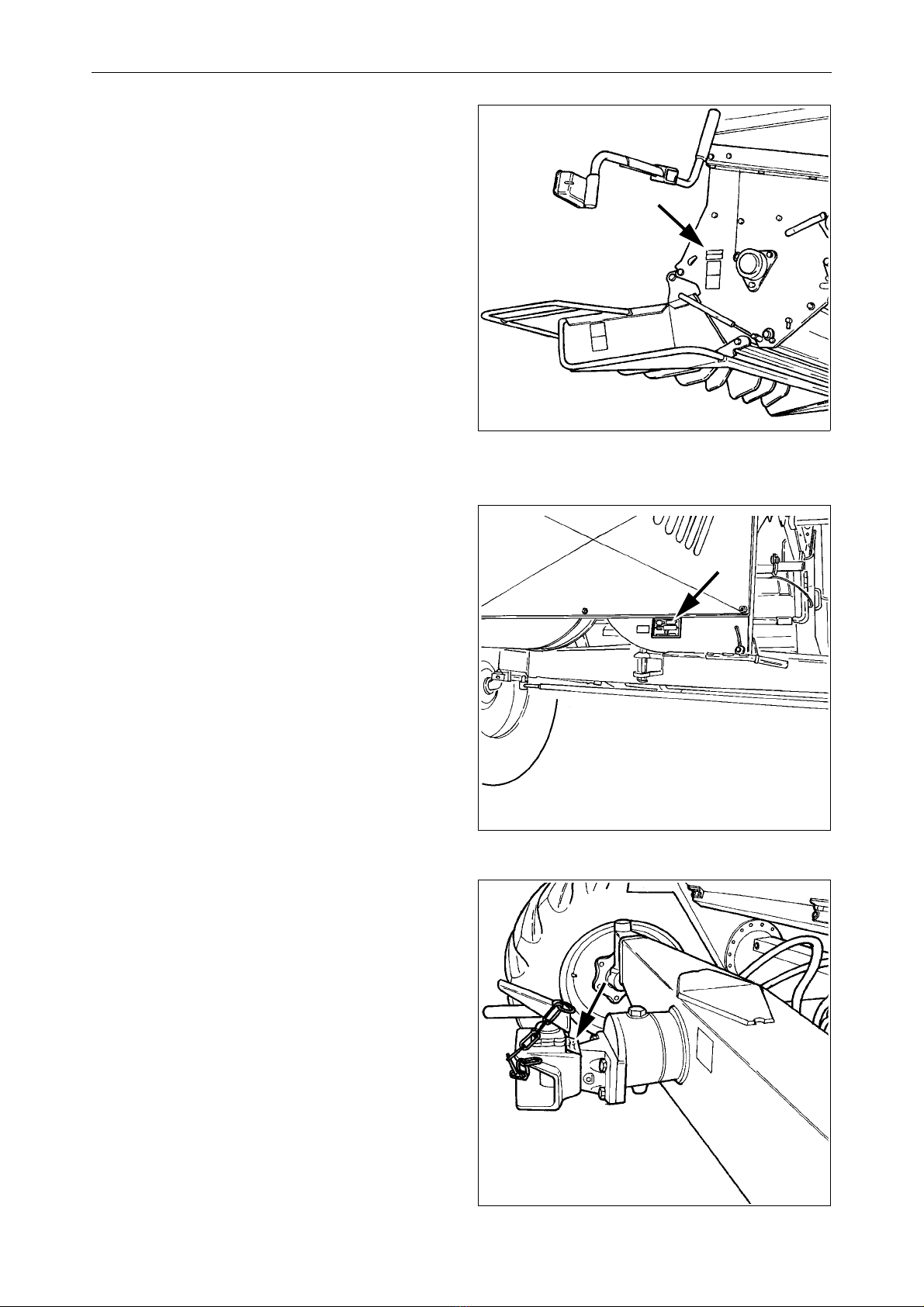

Combine identification details

Fig. 3

Combine type and serial number appear on the

plate and are also punched into the rear right-hand

side of the frame (1).

Fig. 1

Fig. 2

2

1

1

2

3

Fig. 3

1

Find manuals at http://best-manuals.com/search?&s=FENDT-327184015.PDF

GENERAL INFORMATION

1-4 Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007

Engine Identification

Fig. 4 and Fig. 5

The engine is identified by the type plate (1) in the

middle of the cylinder block.

The following information appears on the plate (1):

• Engine manufacturer

•Enginetype

• Engine power and rated speed

• Engine serial number

• Valve clearance

• Injection timing (static)

• Idling speed

• 97/68 EC approval engine family code

• EPA 40 CFR 89 approval family code

• 97/98/EC approval number

• Name of the engine assembler.

The engine serial number is always stamped on the

cylinder block as illustrated (black arrows).

Cutting table identification

Fig. 6

The cutting table is identified by a metal plate

positioned on the left-hand side of the table body.

Fig. 4

Fig. 5

1

1

Fig. 6

Find manuals at http://best-manuals.com/search?&s=FENDT-327184015.PDF

GENERAL INFORMATION

Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007 1-5

Cab identification

Fig. 7

The type plate is located on the outside of the cab,

in the bottom left-hand corner.

Hydrostatic pump identification

Fig. 8

Identification of the hydrostatic pump is facilitated

by means of a plate located on the pump body front

part.

Hydrostatic motor identification

Fig. 9

Identification of the hydrostatic motor is facilitated

by means of a plate located on the motor body

lower part.

Fig. 7

Fig. 8

Fig. 9

Find manuals at http://best-manuals.com/search?&s=FENDT-327184015.PDF

GENERAL INFORMATION

1-6 Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007

Straw chopper identification (if fitted)

Fig. 10

The straw chopper type plate is located on the

right-hand side next to the rotor support.

Chaff spreader identification (if fitted)

Fig. 11

The type plate is located on the right-hand side

next to the chaff spreader adjustment lever.

Rockinger trailer hitch identification (if

fitted)

Fig. 12

The plate is positioned on the top part of the

Rockinger trailer hitch.

Fig. 10

Fig. 11

Fig. 12

Find manuals at http://best-manuals.com/search?&s=FENDT-327184015.PDF

GENERAL INFORMATION

Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007 1-7

Please enter the identification details of your combine for convenient reference:

Combine model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Combine serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine type and serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cab serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Straw chopper serial number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cutting table serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Date of initial startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer's telephone number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE TYPES

C series combines can be equipped with a 4.80, 5.40, 6.00, 6.60 or 7.60 m cutting table.

NOTE: In this manual, the term "table/s" signifies both the cutting table and the maize header when used

generically. The term "cutting table" refers to the assembly consisting of reel, cutting bar, table auger, etc.

used to harvest cereal, rice, soya, etc. The term "maize header" refers to the assembly consisting of stalk

grippers, stripping blades, conveyor chains, etc. used for harvesting maize.

GENERAL INFORMATION

1-8 Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007

1.3 ECOLOGY: INFORMATION FOR THE PREVENTION OF

ENVIRONMENTAL POLLUTION

Soil, air and water are essential to agriculture and to

all life on earth. PROTECT THEM. In areas where

no local regulations impose standards for the use

and disposal of chemicals and petrochemical

products required by modern technology, all

necessary precautions must be adopted to avoid

any risk of pollution.

The following guidelines may be helpful:

• Find out about the legal requirements in your

country and comply strictly with them.

• If no regulations are in force, ask your Dealer

about the effects of lubricants, fuels, antifreeze

mixtures, cleaners, etc. on people and

environment; also ask how to store, use and

dispose of such products correctly. In most

cases, agricultural advisers will be able to

answer your questions satisfactorily.

Instructions:

1.) When refuelling the machine, take all

necessary precautions to avoid fuel spillage. In

particular, avoid using pressurised containers

or fuel supply systems, as these are unsuitable.

2.) As a rule, avoid any skin contact with liquid

fuels, lubricants, acids, solvents, etc.

Most of these products contain substances

potentially injurious to health.

3.) Do not dispose of lubricants by burning

(they contain substances which may evolve

gases injurious to health).

4.) Whenever possible, use biodegradable oil for

lubricating the chains, as this oil cannot be

collected.

In many countries, biodegradable rape oil and

other vegetable lubricants are available on the

market.

5.) Avoid spillage while draining oil, brake fluid,

coolant etc. from the engine, gearbox and

hydraulic system. Collect the fluids in suitable

containers and dispose of them properly,

according to regulations in force.

6.) Modern coolants and mixtures, e.g. antifreeze

and other additives, must be replaced every

two years. Never let them drain into the

ground; collect and dispose of them safely.

7.) Never open or modify the air-conditioning

system. It contains gases which must not be

released in the atmosphere. Contact your

Dealer or a specialist who has the correct

equipment for emptying and recharging the

system and for carrying out any required

maintenance or repair.

8.) Immediately repair any leaks or defects in the

engine cooling or hydraulic system to prevent

any risk of pollution.

9.) Never increase the pressure in a pressurised

system. This may cause the components to

burst.

10.) When welding, protect the hoses properly

against welding spatters that could damage or

weaken hoses and sleeves, resulting in oil and

coolant leaks.

GENERAL INFORMATION

Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007 1-9

1.4 SAFETY

Accidents can be prevented with your help.

All accident prevention depends on the full

cooperation of the persons using or involved with

service or maintenance of the machine.

Most accidents can be avoided by observing

simple safety rules.

The safety system is only as comprehensive as the

operator allows in practising caution whenever

running or servicing the machine.

Some of the illustrations contained in this manual

pertain to combine models of the same series,

which may be differently equipped. This means that

apparent discrepancies may result between any

particular combine and those depicted in this

manual.

¥

This symbol is used in this manual

whenever your safety is involved.

ATTENTION! BECOME ALERT! READ AND

FOLLOW THE INSTRUCTIONS!

YOU CAN NEVER BE TOO PRUDENT.

IN ORDER TO PROVIDE A BETTER VIEW,

CERTAIN PHOTOGRAPHS OR ILLUSTRATIONS

IN THIS MANUAL MAY SHOW AN ASSEMBLY

WITH THE SAFETY GUARDS OPEN OR

REMOVED.

ENSURE THAT ALL GUARDS ARE FITTED AND

CLOSED PRIOR TO MACHINE OPERATION.

WARNING SYMBOLS AND SAFETY

INSTRUCTIONS

Personal Safety

Three types of warning signs appear in this manual

and on the decals applied to the machine

("CAUTION", "WARNING" and "DANGER"),

followed by specific instructions or decals with

symbols clearly illustrating the type of hazard.

These instructions involve your safety and the

safety of people working nearby.

Pay particular attention to these warnings.

¥

CAUTION: Indicates a potentially

dangerous situation which, if not

avoided, may result in minor

injuries.

¥

WARNING: Indicates a potentially

dangerous situation which, if not

avoided, may result in serious

injuries.

¥

DANGER: Indicates a potentially

dangerous situation which, if not

avoided, may result in very

serious injuries or even death.

FAILURE TO FOLLOW THE INSTRUCTIONS

RELATED TO THE TERMS "CAUTION",

"WARNING" AND "DANGER" MAY RESULT IN

SERIOUS INJURIES OR EVEN DEATH.

Machine safety

Other types of advice (

"NOTE", "IMPORTANT"

and "ATTENTION"

) are followed by special

instructions referring to the safeguarding of the

machine.

NOTE: Highlights and describes correct techniques

or procedures to be adopted by the operator.

IMPORTANT: Informs the operator of procedures

that may prevent damage to the machine.

ATTENTION: Informs the operator that unless a

special procedure is followed, severe damage

could be caused to the machine.

GENERAL INFORMATION

1-10 Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007

SAFETY PRECAUTIONS

Most agricultural accidents can be avoided by

observing simple safety rules.

ROAD TRANSPORT

Combine road transport

1.) The combine may be operated only by

responsible personnel, trained and authorised

to work with the machine. Avoid operating the

combine when physically unfit; it is better to

interrupt work than to risk an accident.

2.) In many countries (e.g. Italy and France) a

driving licence is required if the combine is to

be driven on public roads.

3.) Operators should familiarise themselves with

the provisions of the Road Traffic Acts and of

the regulations thereunder in order to ensure

that, when taking the combine on public roads,

they comply with the relevant statutory

requirements. They should keep a suitable

speed for road and traffic conditions and

ensure that all the machine safety devices (if

required) are fitted and working properly.

The grain tank must be empty and the

unloading auger must be turned in.

4.) For safety reasons, the two brake pedals must

be latched when travelling on roads. To hold

the machine on inclined ground, the brakes

must be used (the braking effect of the

hydrostatic drive, only, is not sufficient).

5.) When travelling on roads, make sure that the

rotating beacons and the other additional

signals required to warn that the vehicle is

abnormally large and slow-moving, are

working properly.

6.) When driving on roads, turn the cab access

ladder forward.

When entering and leaving the combine always

use the ladders, handrails and the handles

provided. It is strictly forbidden to ride on the

access ladders to the cab, engine

compartment and grain tank when the machine

is moving.

7.) On the left-hand side of the operator seat there

is an additional seat that can be used by a

trainee during harvest. No other persons are

allowed on the machine.

¥

CAUTION: This seat is not intended for

children.

In road transport, one person employed for

agricultural jobs is allowed in the passenger

seat, provided this is permitted by local

regulations and provided that a seat for

transport of a passenger on public roads is in

accordance with the combine documentation.

GENERAL INFORMATION

Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007 1-11

8.) It is advisable to keep a first-aid kit on hand.

9.) Do not brake abruptly as this could cause the

machine to swerve.

10.) When driving downhill, never exceed 20 km/h

and always stay in gear; never change into

neutral.

On steep slopes, change into a lower gear:

please see relevant specifications on

page 1-37 of this section.

Gradually engage the multifunction lever.

Avoid abrupt turns when driving up or downhill

or across steep slopes.

11.) In countries where travelling on roads with the

table attached is allowed when circumstances

permit, the table must be secured against

lowering by engaging the safety stops on the

hydraulic cylinders and locking the main crop

elevator adapter.

¥

DANGER: Risk of electrocution.

12.) Beware of overhead lines and check that the

combine can easily pass under without

touching the lines, particularly if equipped with

an antenna. Take particular care when driving

through underpasses; make sure the machine

is able to pass through easily. In case of

contact between the machine and the power

supply line, the following procedure must be

adopted:

a) Disengage all drives.

b) Switch off the engine.

c) Apply the parking brake.

d) Ensure that you can leave the operator

seat safely without touching the electrical

cables.

e) Jump from the last step, making sure there

is no contact of body parts, ground and

machine.

f) Do not touch the machine until the power

has been cut off. Anyone approaching the

machine must be informed not to touch it.

g) Ask the power station to cut off the power.

13.) When driving on the road at night, the front

headlights must be dipped so that the low

beam line hits the ground no further than 10 m

in front of the vehicle. The rotating beacons

must always be operating, even when there is

no need for visual signalling and lighting

devices. Switch off the work lights.

14.) Before driving on public roads, ensure the

machine is equipped for road transport (see

page 2-51).

GENERAL INFORMATION

1-12 Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007

15.) When driving on public roads towing the

cutting table, ensure that the local traffic

regulations (lights, correctly fitted trailer hitch

etc.) are complied with. Ensure the cutter bar

protection shield is fitted.

Parking the Combine

¥

DANGER: Risk of squeezing, cutting or

getting trapped.

1.) Never leave the cutting table in raised position

when the combine is stationary.

2.) Always park the combine on level ground. If

parking on level ground is not possible, park

the combine across the slope, engage first

gear and apply the handbrake before stopping

the engine. If it is not possible to park as

described above, proceed as follows:

• Downhill parking: Engage the lowest

reverse gear. On machines with hydrostatic

drive, pull the multifunction lever slightly

backward until the drive engages, switch off

the engine and lock the parking brake. Get

off the machine and place sprags (if

available) or a solid object of a suitable size

in front of the traction wheels.

• Uphill parking: Engage the first gear, push

the multifunction lever forward until the

drive engages, switch off the engine and

pull the parking brake. Get off the machine

and place sprags (if available) or a solid

object of a suitable size behind the traction

wheels.

In any case, before leaving the combine

unattended, switch off the engine, remove

the ignition key and lower the cutting table.

Always keep the parking brake in good repair to

ensure it is capable of holding the machine on

inclinations up to 18-20% max. both uphill and

downhill when the grain tank is empty. Sprags

under the wheels will hold the machine uphill

and downhill provided the ground is sufficiently

firm. Sprags are supplied even for countries

where they are not required by law. The sprags

may be used only as additional safety not as

parking means, on inclinations of more than

18-20%.

GENERAL INFORMATION

Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007 1-13

FIELD OPERATIONS

¥

DANGER: To provide a better view, certain

illustrations in this manual show the

machine with the safety guards removed.

However, the machine should never

operate in this condition.

Keep all guards in place.

1.) Before starting work the operator should

familiarise himself thoroughly with all machine

controls.

2.) Always drive the combine at a speed which,

depending on ground conditions, provides the

necessary safety. When working on rough

ground proceed with greatest care reducing

speed to ensure stability.

¥

DANGER: Risk of overturning.

3.) When taking the combine to work on slopes,

the operator must be thoroughly familiar with

machine controls and with working on sloping

grounds. Drive at slow speed, in particular

while turning and when the grain tank is full.

Ensure that the ground is sufficiently firm

with no sudden surface changes and that

the tyres have enough grip on the ground.

¥

DANGER: Risk of electrocution.

4.) Beware of overhead lines and check that the

machine can easily pass under without

touching the lines, particularly if the unloading

tube is turned out (see page 1-11).

5.) Proceed with greatest care when working with

the wheels close to the edge of ditches or

steep drops.

6.) If the machine tends to tilt forward when

working on slopes, lower the cutting table

completely.

7.) Avoid turning at high speeds.

¥

DANGER: Risk of squeezing, cutting or

getting trapped.

8.) If any moving part becomes blocked or

jammed, release it only when the engine is

switched off and all drives have come to a

complete stop. Never push the crop into the

main crop elevator by hand or feet. This

could result in danger to life or severe injury.

¥

DANGER: Risk of breathing in dust.

9.) Threshing dust may cause allergic lung

diseases. The dust may also contain residues

of pesticides injurious to health. Keep the cab

door shut when threshing. Wear a protection

mask when carrying out service work involving

exposure to dust (cab filters, rotary screen etc.)

and when working with compressed air.

10.) Keep a fire extinguisher within easy reach.

Check the extinguisher at the intervals

prescribed by national law. Replace or

recharge it whenever it has been used, even if

only partially.

The type of extinguisher approved for Europe

contains 6 kg of extinguishing agent and

belongs to fire class ABC.

A 160 mm Ø extinguisher is recommended

since a suitable bracket is already fitted on the

machine, near the hydraulic control valve.

GENERAL INFORMATION

1-14 Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007

MAINTENANCE WORK

Work on the Machine

1.) Before inspecting, cleaning, adjusting or

servicing combine and table (grain or maize),

always ensure that the engine is stopped, the

brakes are applied and all moving parts have

come to a complete stop.

2.) To lift one side of the machine (for example to

remove a wheel), use lifting equipment with

suitable capacity, e.g. a column hydraulic jack

or a lift with a minimum capacity of 10,000 kg.

3.) Pay special attention while removing

preloaded parts.

¥

DANGER: Risk of shocks.

It is strictly forbidden to loosen the nut

fastening the cylinder variator pulley

without using proper tools. This operation

may be carried out only by your Dealer's

skilled staff.

4.) Work on tyres requires correct tools and expert

knowledge. An incorrect assembly can

seriously compromise your safety. When in

doubt, refer to specialised staff.

5.) Before refitting the wheels, ensure that the

contact surfaces of wheel rim and final drive

hub are perfectly clean (remove paint); check

that the thread of bolts and nuts is in perfect

condition. The front wheel nuts must be

tightened to 550 Nm (56 kgm) crosswise and

the rear wheel nuts to 304 Nm (31 kgm).

Check that the nuts are sufficiently tightened

after the first working hours and then at least

every 80 hours. It is advisable to check, at least

once a day, that no parts are loose.

6.) Do not carry out any work (inspection or

maintenance) on the machine when the wheels

have been removed, unless the machine is

properly supported.

¥

DANGER: Risk of high pressure fluid

splashes.

7.) The hydraulic, hydrostatic and diesel oil

injection systems can be pressurised.

Maintenance work on the systems may be

carried out only by specially trained staff.

8.) Before working on any part of the electrical

system, remove the battery ground cable or

switch off the main battery switch.

GENERAL INFORMATION

Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007 1-15

9.) When carrying out welding on the machine,

heat and welding splatters may cause serious

damage. If possible, have this work carried out

by skilled staff.

To prevent damage to the engine electronic

components, remove the specific

component from the combine and weld it

separately.

If the component cannot be removed,

proceed as follows:

a) Stop the engine.

b) Disconnect the negative cable from the

battery.

c) Detach the ECU shield.

d) Disconnect all of the harnesses from

the ECU.

e) Tie up the harnesses to the machine so

that they cannot touch the ECU.

f) Connect the welder ground cable as

close as possible to the area where the

welding is to be carried out.

g) Protect hydraulic and electric

components exposed to welding

spatters.

10.) After any maintenance or repair work, collect

all tools used and store them in the toolbox on

the combine. Always check the combine for

loose parts, and ensure all guards have been

correctly reinstalled.

11.) Before starting the combine, make sure all

guards are fitted and that safety guards with

locks are properly secured.

These guards can be opened with a tool or with

the suitable key supplied with the ignition key.

Also check table, grain tank and sieves for

loose/disassembled parts.

¥

DANGER: Risk of shocks, squeezing or

getting trapped.

Always sound the horn three times to warn

persons nearby of your intention to start

the engine.

12.) Before starting the engine, make sure no one is

carrying out service or inspection on the

machine or standing in the combine operating

range.

13.) Always keep children away from the combine.

14.) Check wheel nut torque after the first hours in

operation, as described in section

"PRELIMINARY SERVICE INSPECTION"

(page 4-2) and after any maintenance work

involving dismounting of wheels. It is good

practice to check daily that the nuts have

not loosened or become defective in any

way.

¥

DANGER: Risk of shocks, squeezing or

getting trapped.

15.) It is strictly forbidden to enter the grain tank

without stopping the engine and removing the

ignition key from the switch. Before inspecting,

cleaning, adjusting or servicing combine and

table (grain, maize etc.), always ensure that the

engine is stopped, the brakes are applied and

all moving parts have come to a complete stop.

¥

DANGER: Risk of squeezing.

16.) Never work under the cutting table without

securing it firmly and/or engaging the safety

stops on the crop elevator lifting rams.

GENERAL INFORMATION

1-16 Operator's Manual Combines FENDT 5270-6300- EN - LA327184015 - 11/2007

¥

DANGER: Risk of getting trapped.

17.) Never work on the machine wearing loose

clothing that could get caught in a moving part.

Check that all rotating parts are protected with

safety guards.

18.) Keep clear of all moving parts on the machine

and particularly on the table.

19.) After any lubrication, adjustment or repair

work, always refit all safety guards.

Replace or repair missing or damaged safety

guards immediately.

¥

DANGER: Risk of falling.

20.) Do not step onto the grain tank cover or cab

roof. To reach high areas (for example

inspection lids on the unloading tube) use the

access ladder for the engine area.

21.) While operating the combine, pay special

attention to correct function and the efficiency

of the braking system, checking the oil level in

the tank and replacing friction pads before they

wear out completely.

¥

DANGER: Risk of explosion.

22.) It is strictly forbidden to modify a hydraulic

accumulator by mechanical machining,

welding, etc. For the accumulator inspection or

replacement, refer to your local Dealer.

Engine

1.) Never start the engine if battery recharging

equipment is connected to the machine.

2.) Always keep the engine and the engine

compartment clean. Dust, diesel oil, oil and

accumulated straw are highly flammable. For

the same reason, also keep the transmission

housing and the brake system clean.

¥

DANGER: Risk of breathing in toxic gases.

3.) Never operate the engine in an enclosed area

without ensuring proper ventilation, since

highly toxic exhaust gases are generated.

This manual suits for next models

7

Other FENDT Farm Equipment manuals

FENDT

FENDT 4300 User manual

FENDT

FENDT FORMER 12545 PRO User manual

FENDT

FENDT 900 Gal Liquid System User manual

FENDT

FENDT 8380 P User manual

FENDT

FENDT 5220 E User manual

FENDT

FENDT IDEAL Series User manual

FENDT

FENDT BALER Series User manual

FENDT

FENDT IDEAL Series User manual

FENDT

FENDT 1290 UD User manual

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions