6

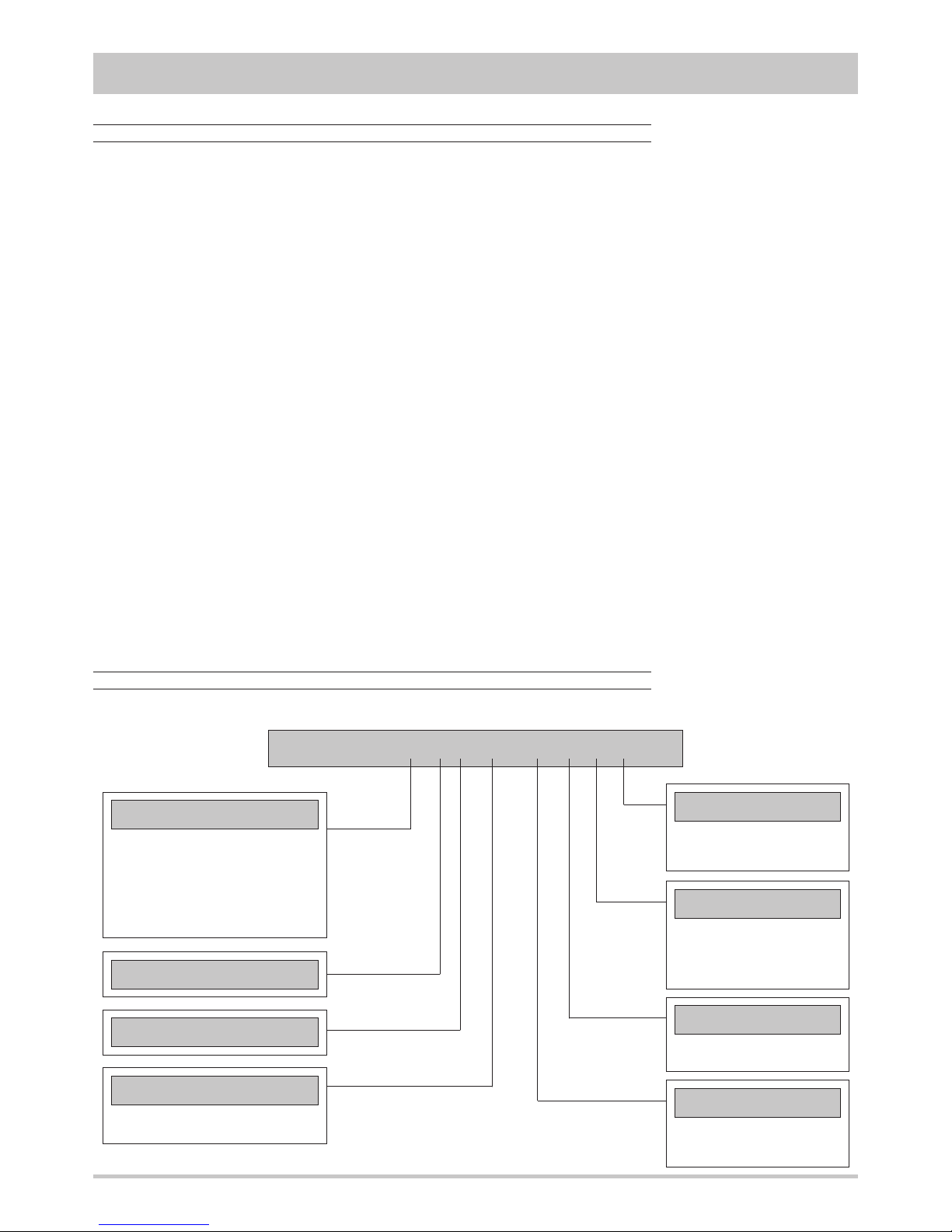

GENERAL FEATURES

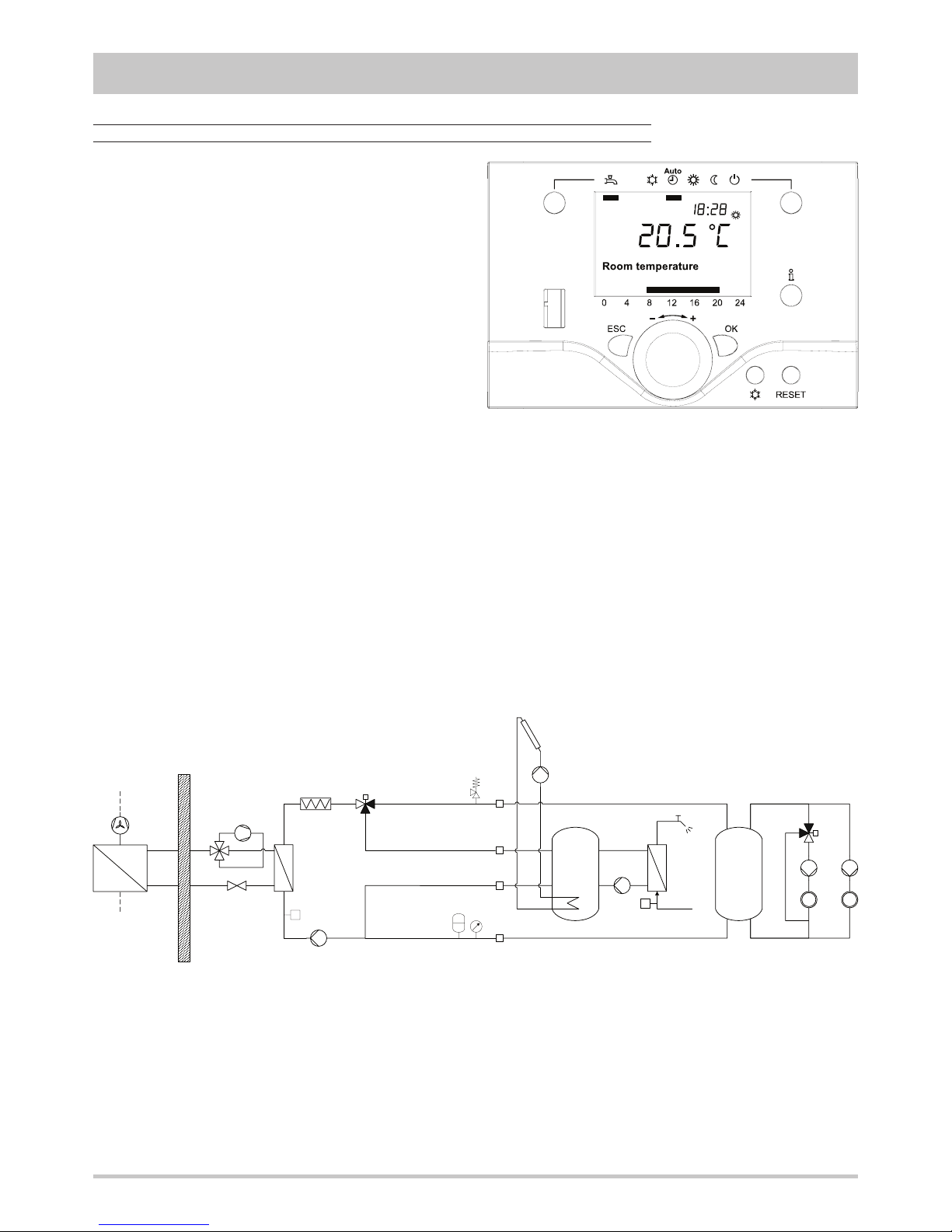

Description of components

Indoor unit structure Basement, lateral panels and frontal

panel, are completely thermally and acoustically insulated in

order to minimize thermal losses and noise emissions in the

surroundings. Accessibility to internal parts is possible removing

the frontal panel and the upper panel. For extraordinary

manteinances also the rear panel can be removed.

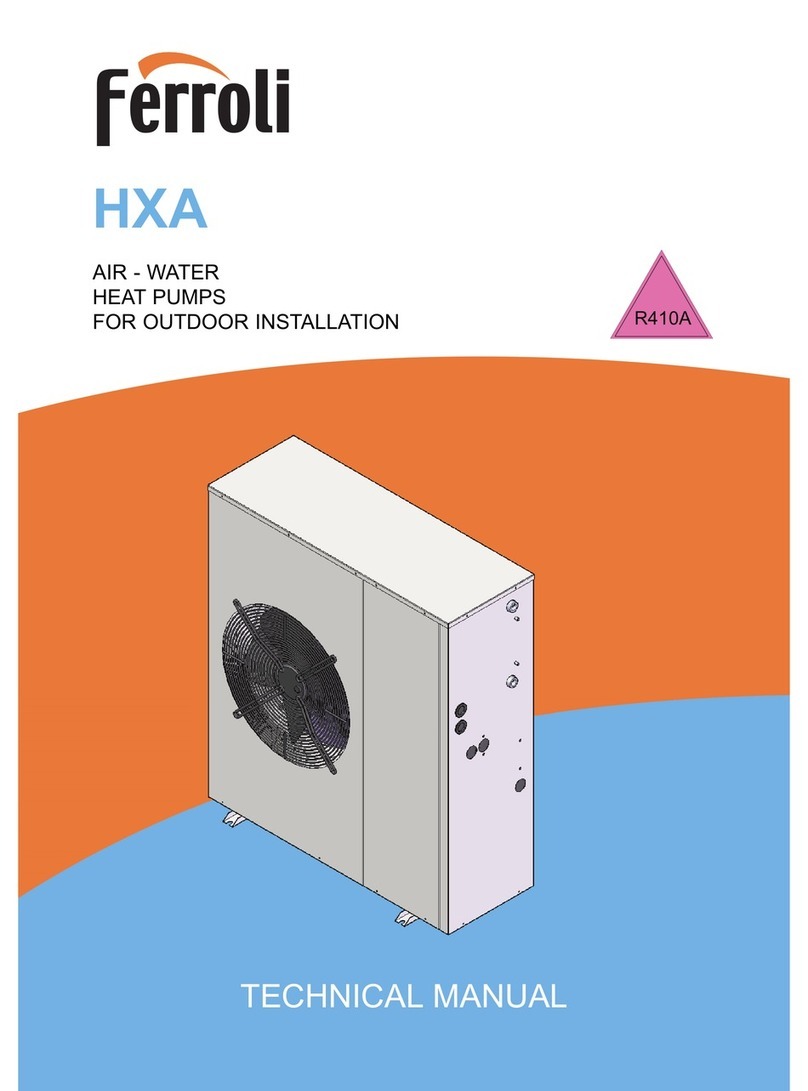

Outdoor unit structure Basement, supporting structure and

lateral panels are made of galvanized and painted sheet-steel to

guarantee good resistance to atmospheric agents. Accessibility

to internal parts is possible removing the frontal panel. For

extraordinary manteinances also the other panels can be

removed.

Refrigerant circuit All the components of the refrigerant circuit,

except the finned coil, are contained inside an extractable box

placed in the indoor unit to simplify the maintenance operations.

The box is placed on rubber vibration dampers and is connected

to the hydraulic circuit through flexible pipes in order to avoid

the propagation of the vibrations generated by the compressor

outside the unit. The hermetic rotary compressor (1) is mounted

on damper supports and is protected against overtemperatures

and overcurrents. The heat exchangers on the plant side (2) is

a brazed stainless steel plate heat exchanger, properly insulated

to avoid condensate generation and to minimize thermal losses,

and protected by a flow switch that detects whatever water

flow lack. The source side heat exchanger (3) is a finned coil

realized with grooved copper pipes and hydrophilic aluminium

fins with waved profile to increase the heat exchange coefficient.

A tray is placed under the coil to collect the condensate generated

in heating mode. The expansion device (4), an electronic

expansion valve, allows the unit to adjust itself to the different

operating conditions keeping steady the set superheating. The

refrigerant circuit of each unit contains moreover solid core

hermetic filter dryer (5) to restrain impurity and moisture

residuals that could be present in the circuit, high and low

pressure switches in order to assure the compressor to operate

inside the permitted limits, 4 way reverse cycle valve (6) to

allow operating mode change reversing the refrigerant flow,

pressure connections SAE 5/16” - UNF 1/2” - 20 equipped

with pin, gasket and blind nut, as required for the use of R410A

refrigerant (they allow the complete check of the refrigerant

circuit : compressor inlet pressure, compressor outlet pressure,

thermostatic expansion valve upstream pressure and pressure

drops accross the filter). All the pipes of the refrigerant circuit

are properly insulated to avoid condensate generation and to

minimize thermal losses.

The axial fan (8) is equipped with an high efficiency electronically

commutated (EC) motor, is contained ia a sheet nozzle and is

equipped with a safety grille.

Hydraulic circuit All the pipes are thermally insulated to avoid

condensate generation and minimize thermal losses. The circuit

is equipped with a three speed glandless pump, expansion

vessel, safety valve, pressure gauge and air vents.

Electrical panel. It contains all the power, control and security

components necessary to guarantee the unit to work properly.

The unit is managed by a microprocessor controller to which

all the electrical loads and the control devices are connected.

The user interface, placed on the frontal panel of the unit, allows

to view and to modify, if necessary, all the parameters of the unit.

All the units are supplied with an outdoor temperature sensor,

to be installed outside, in order to realize the climatic control.

1

72

6

4

5