selected fabric must be strong enough and the correct length for the manner

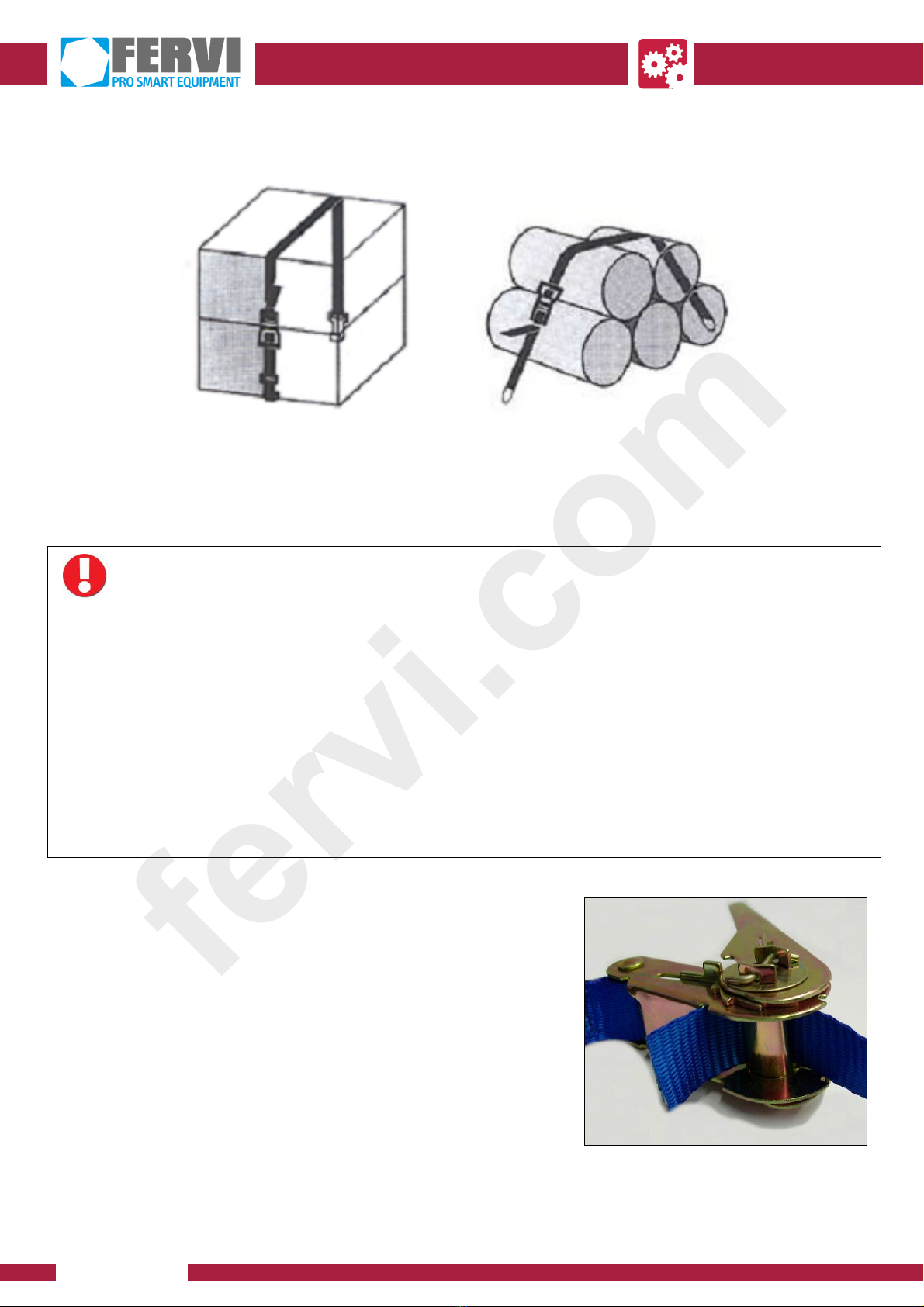

Determine the mass, shape and centre of gravity for the load to be anchored;

Determine the fixing points for the straps;

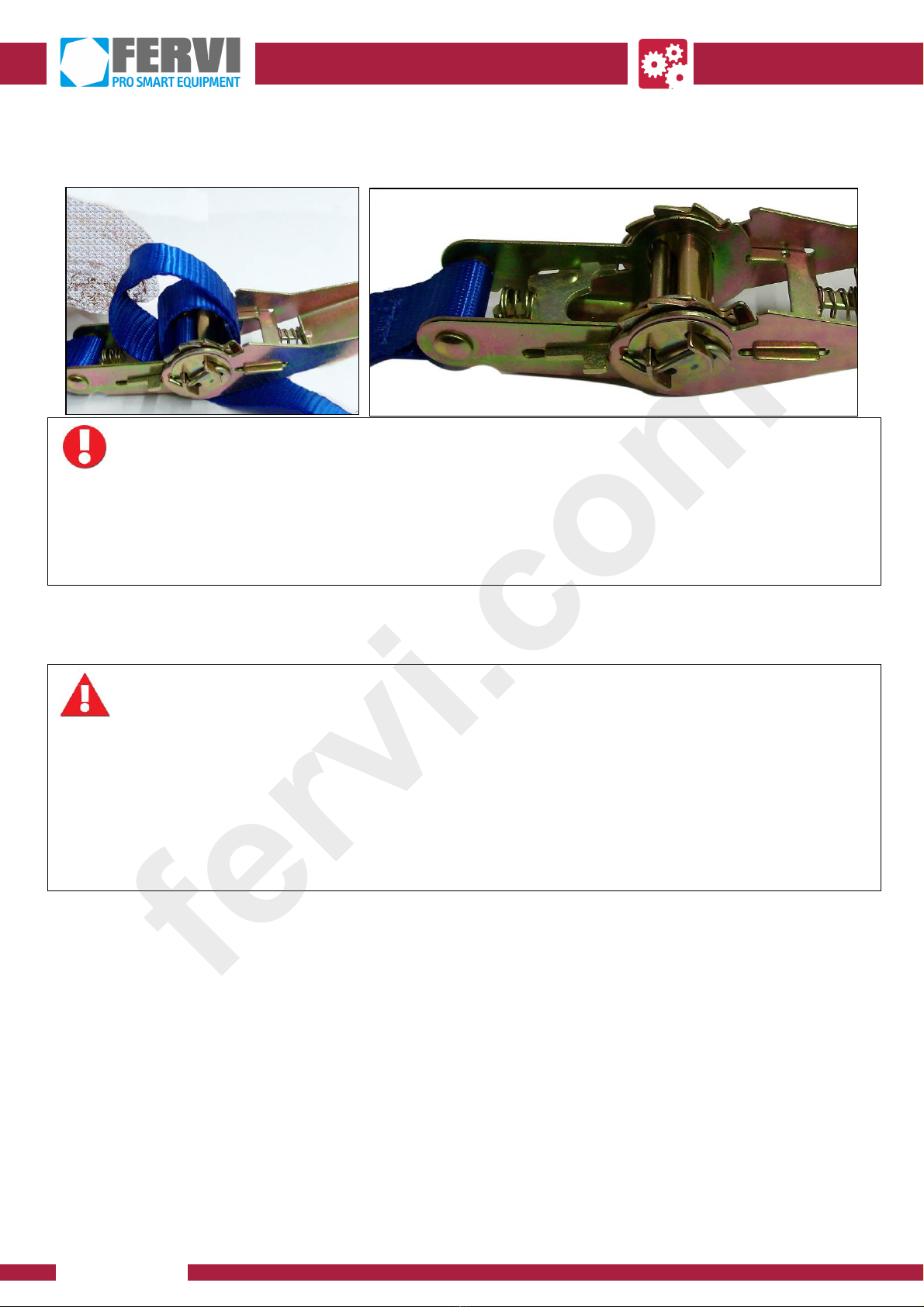

Check the tensile strain capacity (LC) of the straps before tightening;

Check that the load is stable in t

he absence of a tie down;

Plan the mounting and removal of the strap before moving;

Remember that while moving, it may be necessary to unload parts of the load;

Calculate the number of fabric straps in accordance with UNI EN 12195

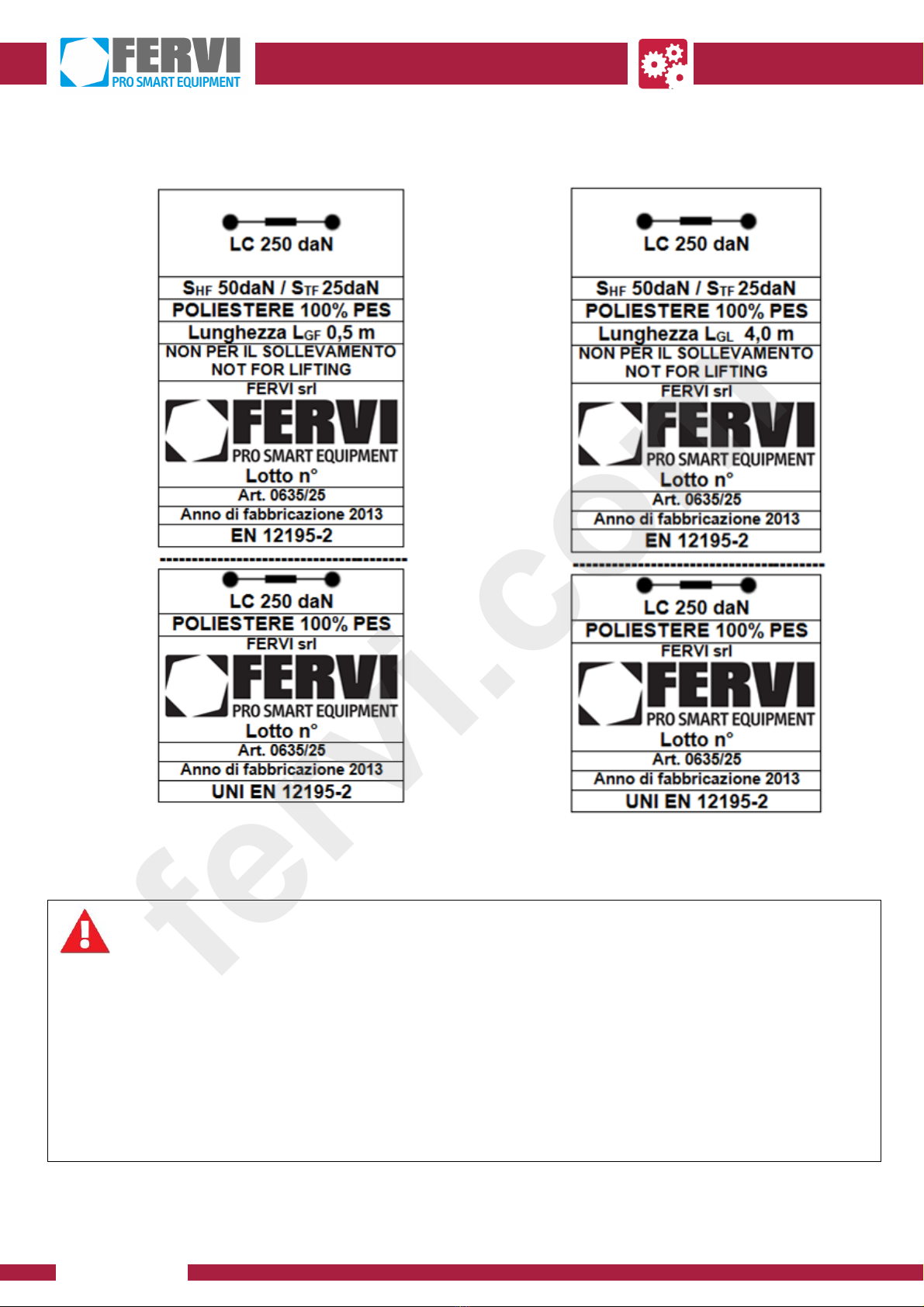

ic straps designed for friction securing and with the label that carries the

must be used for friction anchoring;

Periodically check the tensile load, especially immediately after initial

Selecting and Using the Stra

While selecting and using the fabric straps, one must take into account the required payload

of the strap, taking into account the mode of use and the nature of the load to be fixed. The

size, shape and weight of the load, together with the method of i

ntended use, transportation

environment and the nature of the load, affect the correct choice. For reasons of stability, the

supporting units must be secured with at least a pair of fabric straps for friction

anchoring and two pairs of fabric s

traps for diagonal anchoring.

The fabric straps should not be overloaded: The maximum manual load of 500 N should be

applied (50 daN on the label; 1 daN =

1 kg). Mechanical aids (such as

should not be used as extensions, except in th

e case where they form part of the t

Selecting and Using the Straps

Due to the different behaviour and

of load conditions, different anchoring or tie down

equipment should not be used (for example, tie down chains and fabric st

same load. Attention should also be given to the fact that the auxiliary hooks (components)

and tie down devices within the load's tie down device are compatible with the fabric strap.

Before using the strap, chec

k that it has been properly stored away from UV light sources

(direct sun exposure) and without deep wrinkles, twists or knots that may have weakened the