TABLEOFCONTENTS

Identification.................................................................................................................................................1

Productbrandandtypedesignation:........................................................................................................1

Nameandmanufacturercontact:.............................................................................................................1

Declarationofconformitytoproductstandards:......................................................................................1

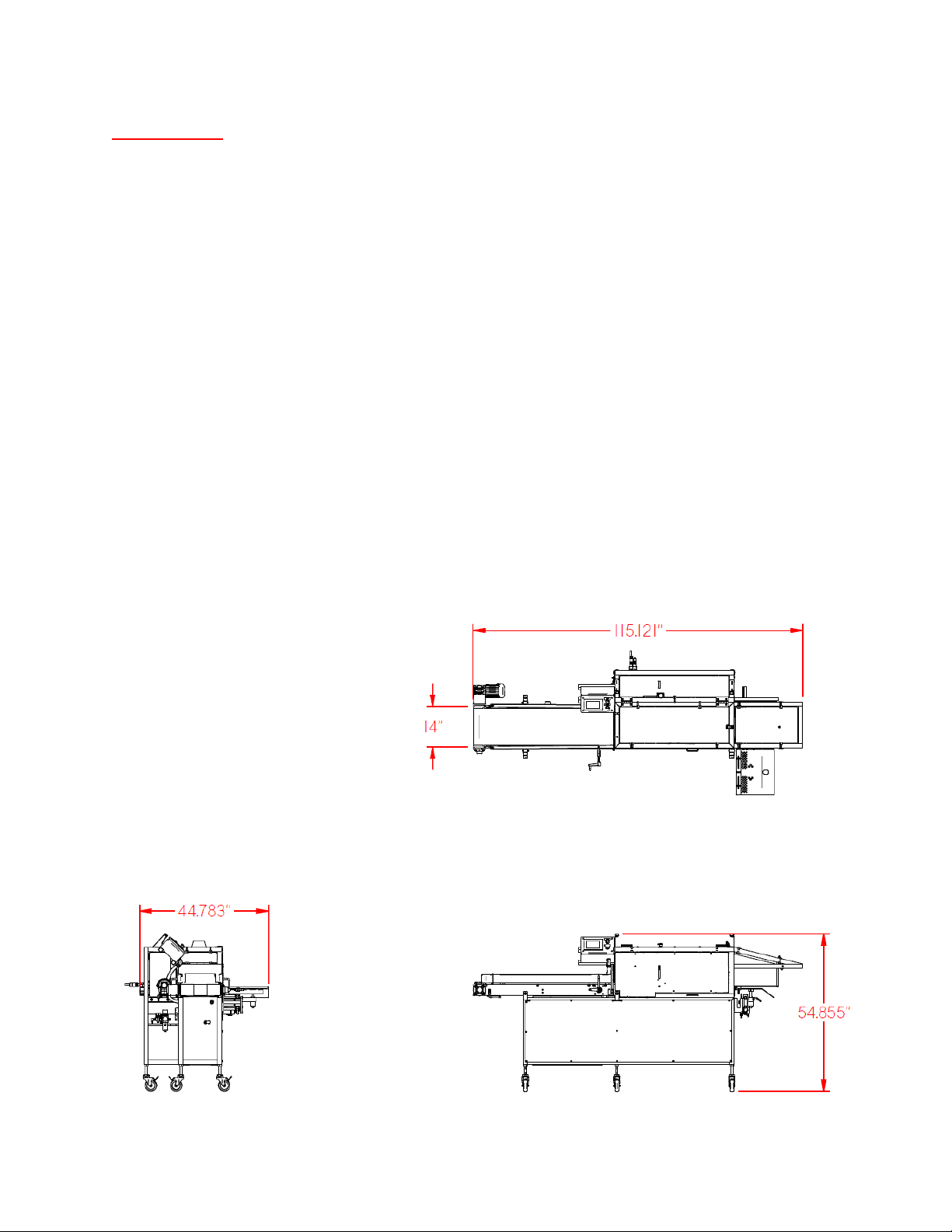

ProductSpecification.....................................................................................................................................2

Generalfunctionsintendeduse:...............................................................................................................2

Dimensionsandweight:............................................................................................................................2

Powerdata–ElectricityandPneumatic....................................................................................................2

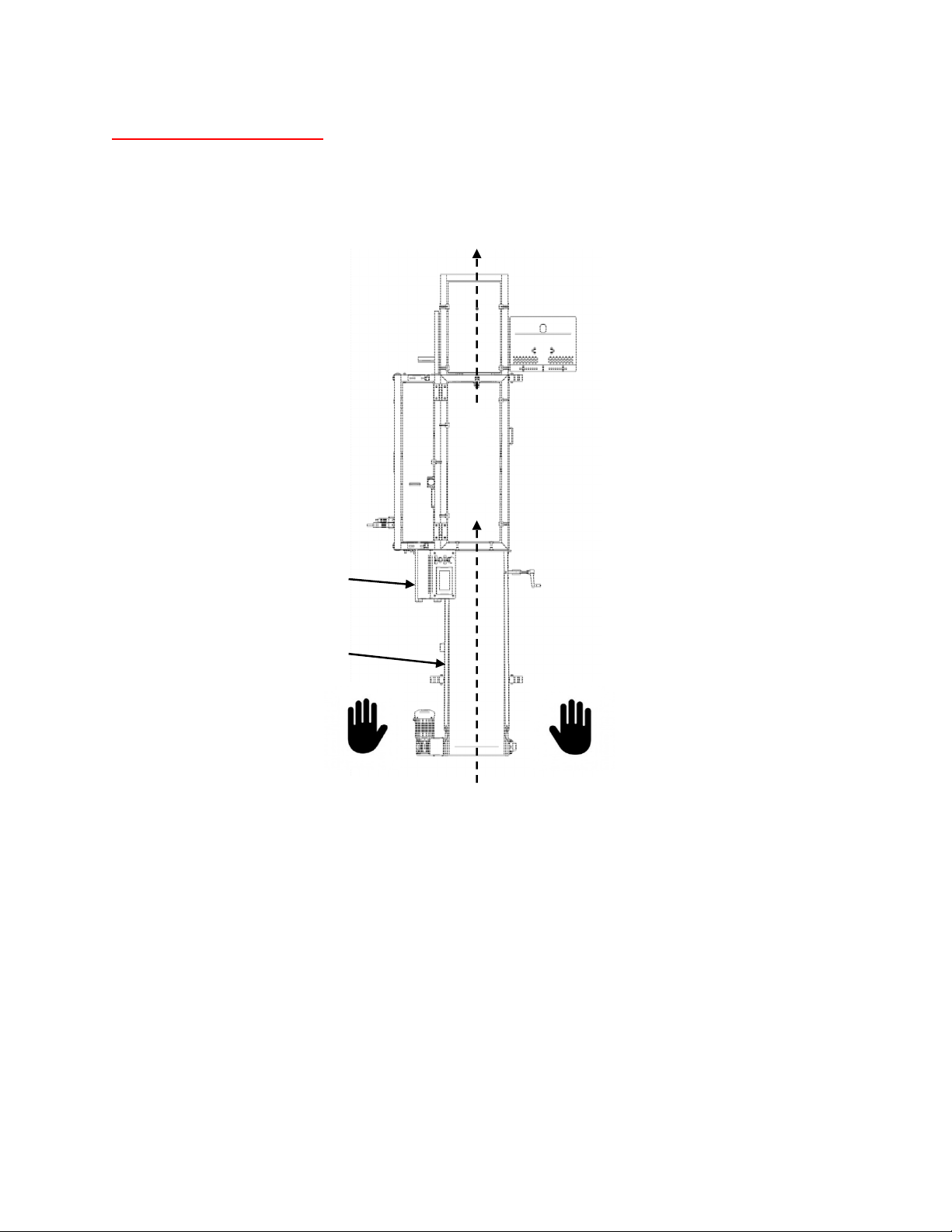

Installation.....................................................................................................................................................3

Locationofinstructions.............................................................................................................................4

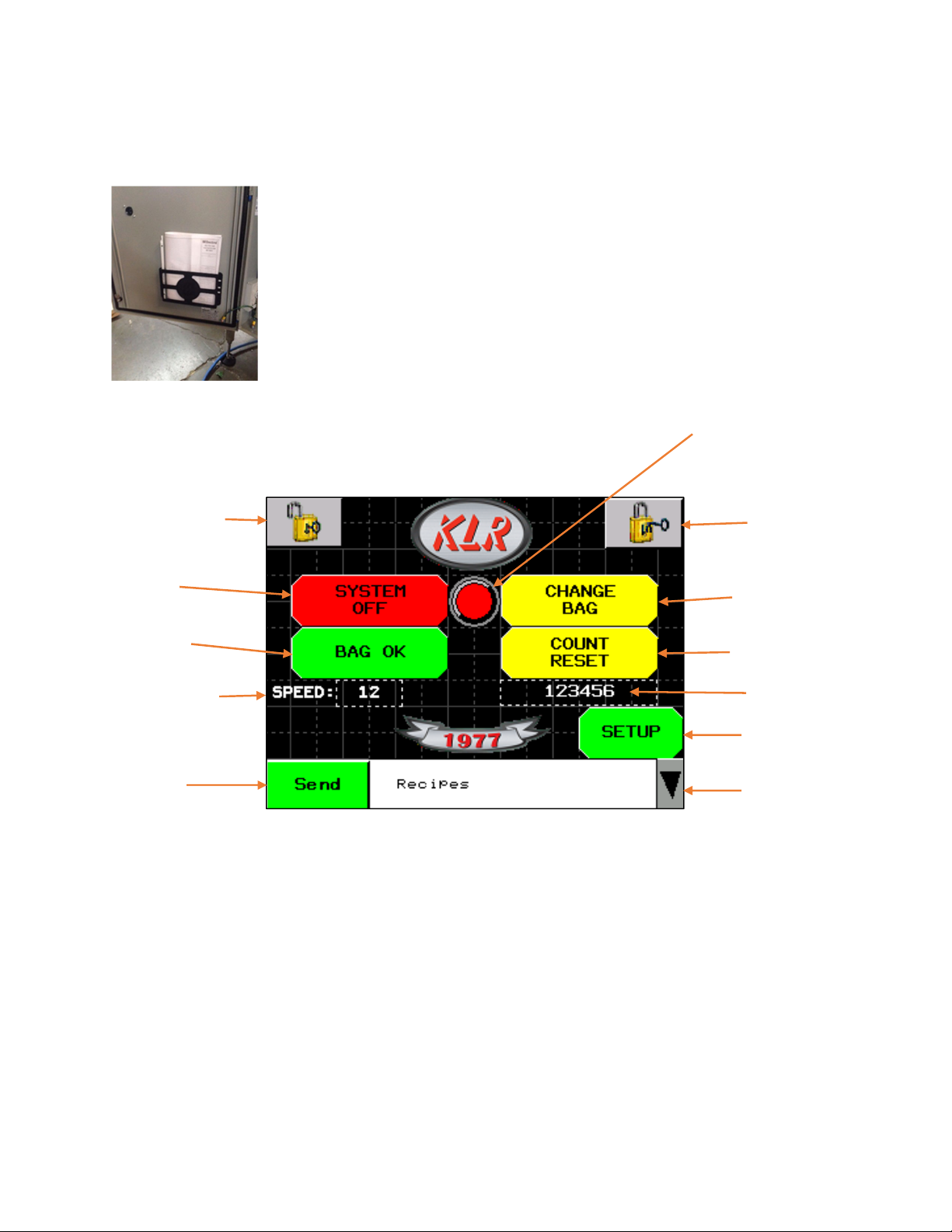

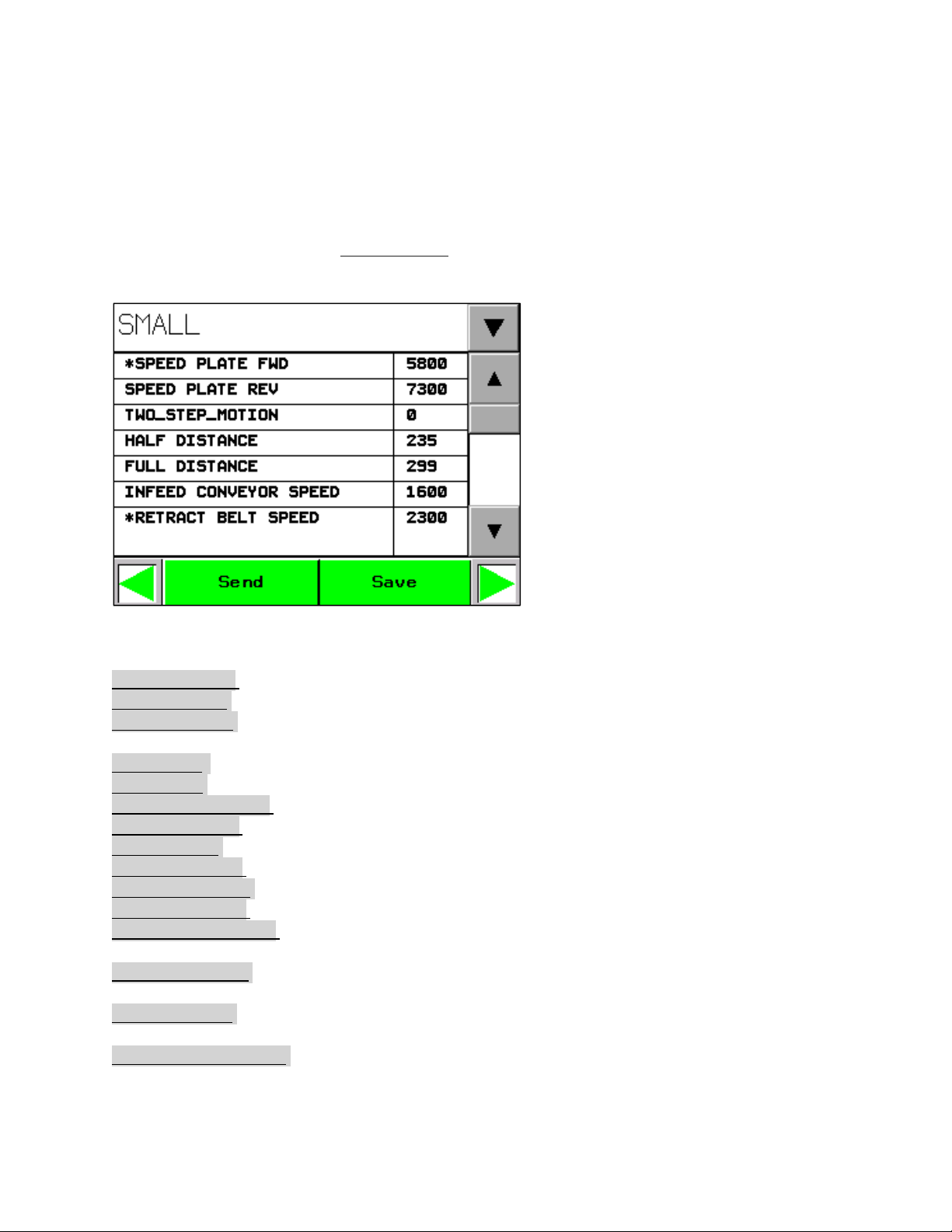

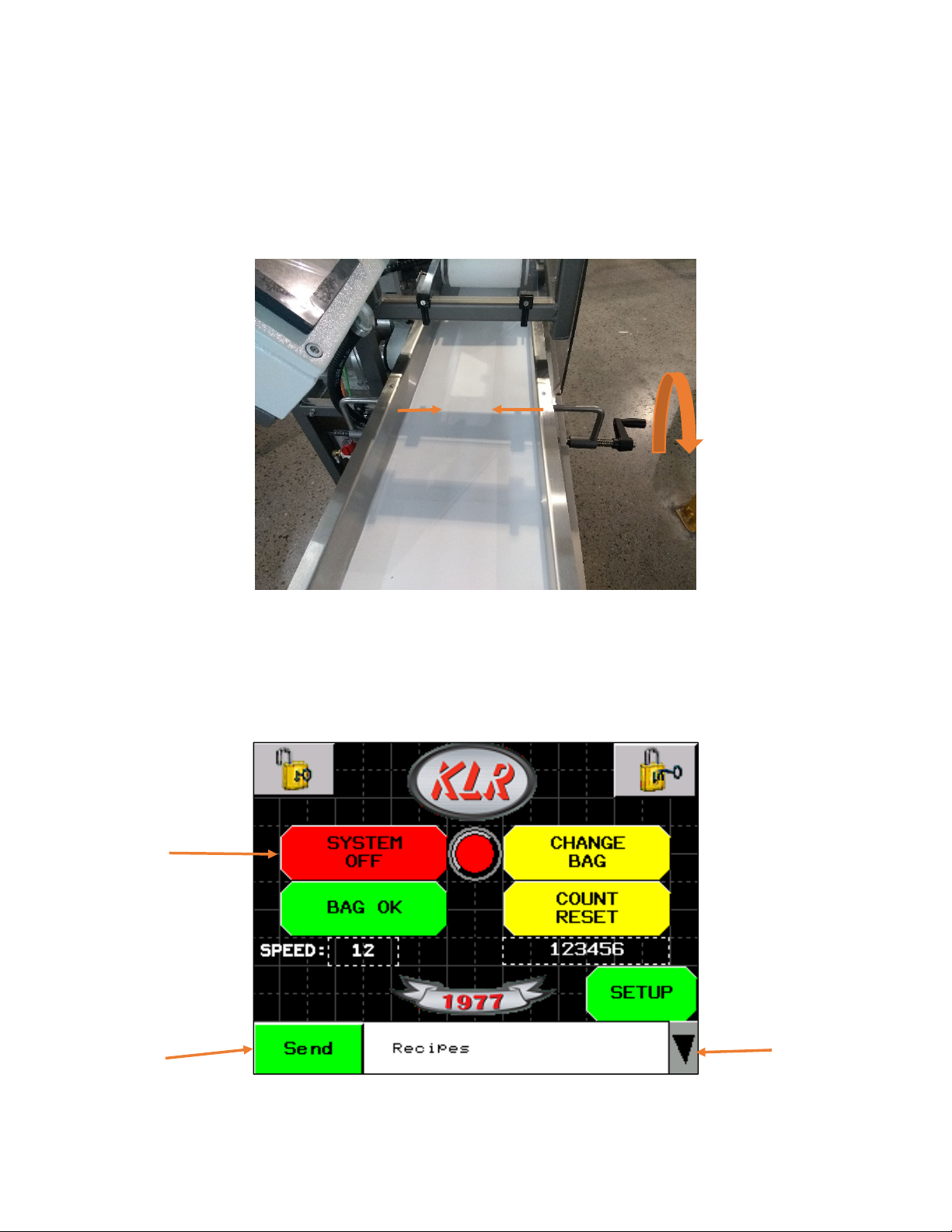

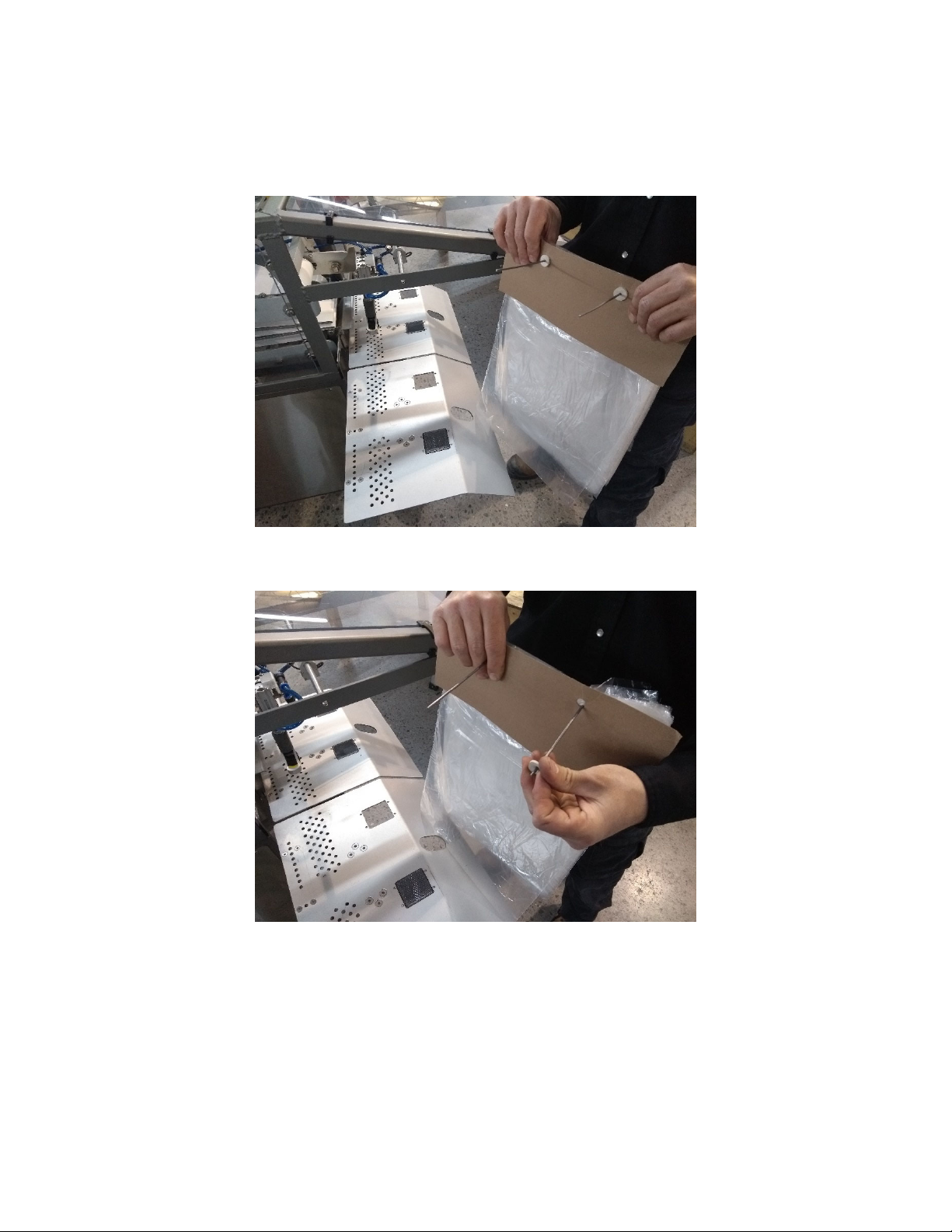

OPERATION...................................................................................................................................................4

SAFETYPRECAUTIONS.................................................................................................................................14

Security....................................................................................................................................................14

Personalprotection.................................................................................................................................14

SecurityLabels........................................................................................................................................14

Safetycomponents.................................................................................................................................15

MAINTENANCE............................................................................................................................................16

Preventivemaintenanceschedule..........................................................................................................16

Maintenancesteps..................................................................................................................................17

Cleaning...................................................................................................................................................24

LISTSOFSPAREPARTSANDCONSUMABLES..........................................................................................2526

CHECKLIST..............................................................................................................................................2627

MaintenanceandrepairsbyspecializedtechniciansfromKLRSystemsInc...........................................2829

Contactinformation............................................................................................................................2829

LISTSOFSPAREPARTSANDFURNITURE(ANNEXE).................................................................................2829

DECOMMISSIONINGOFTHEMACHINE...................................................................................................2829