Battery-operated Hand Tool LGT260 for Plastic Strapping User Manual

16 17

Battery-operated Hand Tool LGT260 for Plastic Strapping User Manual

Object(simulation)

d.Weld and cut off the strap:

Weld and cut off the strap to

finish the strapping operation

by referring to the Method for

Basic Settings.

The purple indicator light will be

on during the welding process.

Strap Welding & Cutting Completed

Remarks:

5.2.4 Operation Methods for Three Modes

e. Remove the machine and

complete the operation:

After the welding is finished,

the buzzer rings for 3 seconds

and stops, indicating that the

strap welding and cutting work

is completed. At this time, you

can remove the machine by

lifting the rocker lever and

moving the tool rightward and

wait for a next operation.

Manual Mode (MAN):

Semi-Automatic(SEM):

1. In the Automatic (AUT) Mode, only Steps a, b, c, e are required.

2. Remove the battery and then install it again, if the tool fails

to work normally due to misoperation or other reasons.

3. When the strap is stuck by the machine, the battery must be

pulled out first, then cut off the strap, remove the Left Guard

(side cover), and then remove the strap.

4.The tension protection function will start by pressing the

button Tensioning “1” continuously for 8 times, and at this time,

the protection function can be cancelled by lifting the rocker

lever once.

5. Note: If the rocker lever is lifted immediately after welding,

the machine will give rapid sound alarms for 5 seconds due to

a lack of cooling time.

Long press the button Tensioning “1” until the set tension level is

reached, and the machine will stop automatically. Then press the

button Welding “2”, and strap welding and cutting will be finished after

three short sounds of "Beep", and at this time, hold the rocker lever to

retract the strap and remove the tool.

Long press the button Tensioning “1” until the set tension level is

reached, and the machine will automatically weld and cut off the strap.

The strap welding will be finished after three short sounds of "Beep",

and at this time, hold the rocker lever to retract the strap and remove

the machine.

Fully Automatic(AUT): Short press the button Tensioning “1” until the set tension level is reached,

and the tool will automatically weld and cut off the strap. The strap welding

will be finished after three short sounds of "Beep", and at this time, hold the

rocker lever to retract the strap and remove the machine.

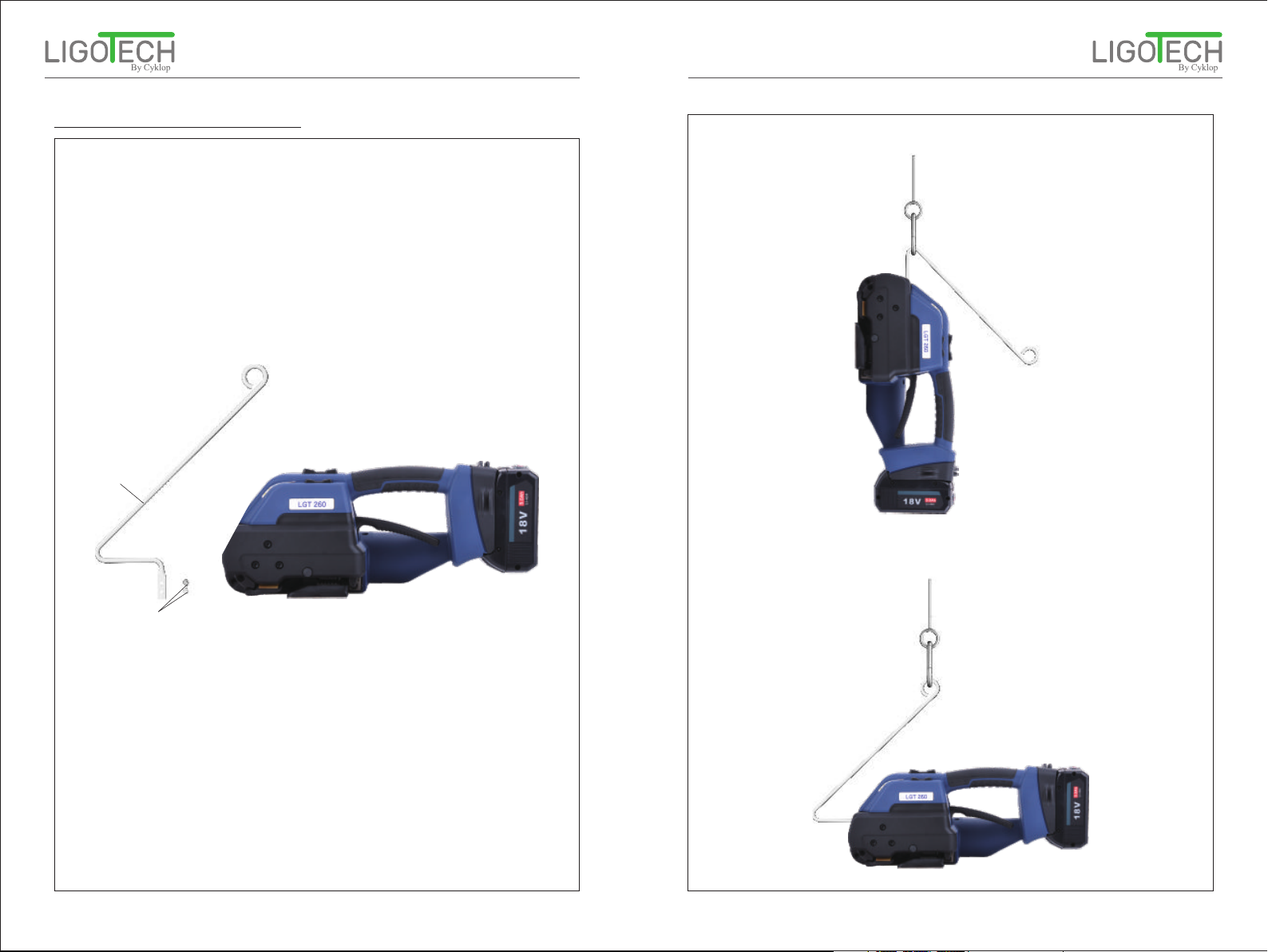

a. wrap the PP/PET straps around

the object to be packed:

The operator faces the tool, holding

the machine in his right hand, and the

machine is on the right side of the

operator. Place the strap around the

object to be strapped in the order of

upper side->front side->lower side-

>back side, as shown in the figure.

Warning: Please keep the

PP/PET strap away from oil,

grease and other dirt when

welding it, as a dirty strap cannot

be welded well.

5.2.3 Strapping Operation Steps

b. Put the straps into the tool:

After feeding the strap around

the object to be strapped

properly, lift the rocker lever of

the machine with your right

hand, and insert the parallel

overlaid straps into the tool

smoothly with your left hand, and

then release the rocker level.

Note: Please tension the

strap around the object as

much as possible and then

insert it into the tool, which can

reduce the strap tensioning

time of the tool, avoiding

wasting electric energy.

c. Tension the strap:

Tension the strap to finish the

strapping operation by referring

to the Method for Basic Settings.

Note:

Manual(MAN) and Semi-

Automatic(SEM) Mode: Press

the tension button “1” until the

indicator light shows purple, and the

tension protection does not affect

the next-step operation.

Automatic(AUT) Mode:

Press the tension button in a short

time and release.

Warning: Keep the movement

of the tool in balance during the

tensioning process. Lift the

rocker lever to stop working

when an emergency stop is

required during the tensioning

process. Therefore, do not

block the movement direction

of the strapping tool.

Object(simulation)

Correct Feeding Direction

Object(simulation)

Wrong Feeding Direction

Object(simulation) Object(simulation)

Proper Length of Strap Left Excessive Length of Strap Left

Object (simulation)

Tension Completed