9

Edge router

Technical data OFK 500 Q

Wattage 450 W

Drive shaft rotating speed 28,000 rpm

Max. Diameter of milling tool 27 mm

Weight 1.5 kg

Degree of protection / II

The specifi ed illustrations can be found at the

beginning of the operating instructions.

Symbols

Warning of general danger

Wear ear protection!

Read the Operating Instructions/Notes!

1 Intended use

The OFK 500 Q is intended for fl ush trimming and

profi ling of wood, plastic and similar materials.

The user is liable for damage and injury

resulting from incorrect usage!

2 Safety instructions

2.1 General Safety

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings

and instructions may result in electric shock, fi re

and/or serious injury.

Save all warnings and instructions for future

reference.

The term „power tool“ in the warnings refers

to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

2.2 Tool-specifi c safety rules

- Hold the power tool by insulated gripping

surfaces only, because the cutter may contact

its own cord. Cutting a “live” wire may make

exposed metal parts of the power tool “live” and

could give the operator an electric shock.

- Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holding the work by your hand or against the

body leaves it unstable and may lead to loss of

control.

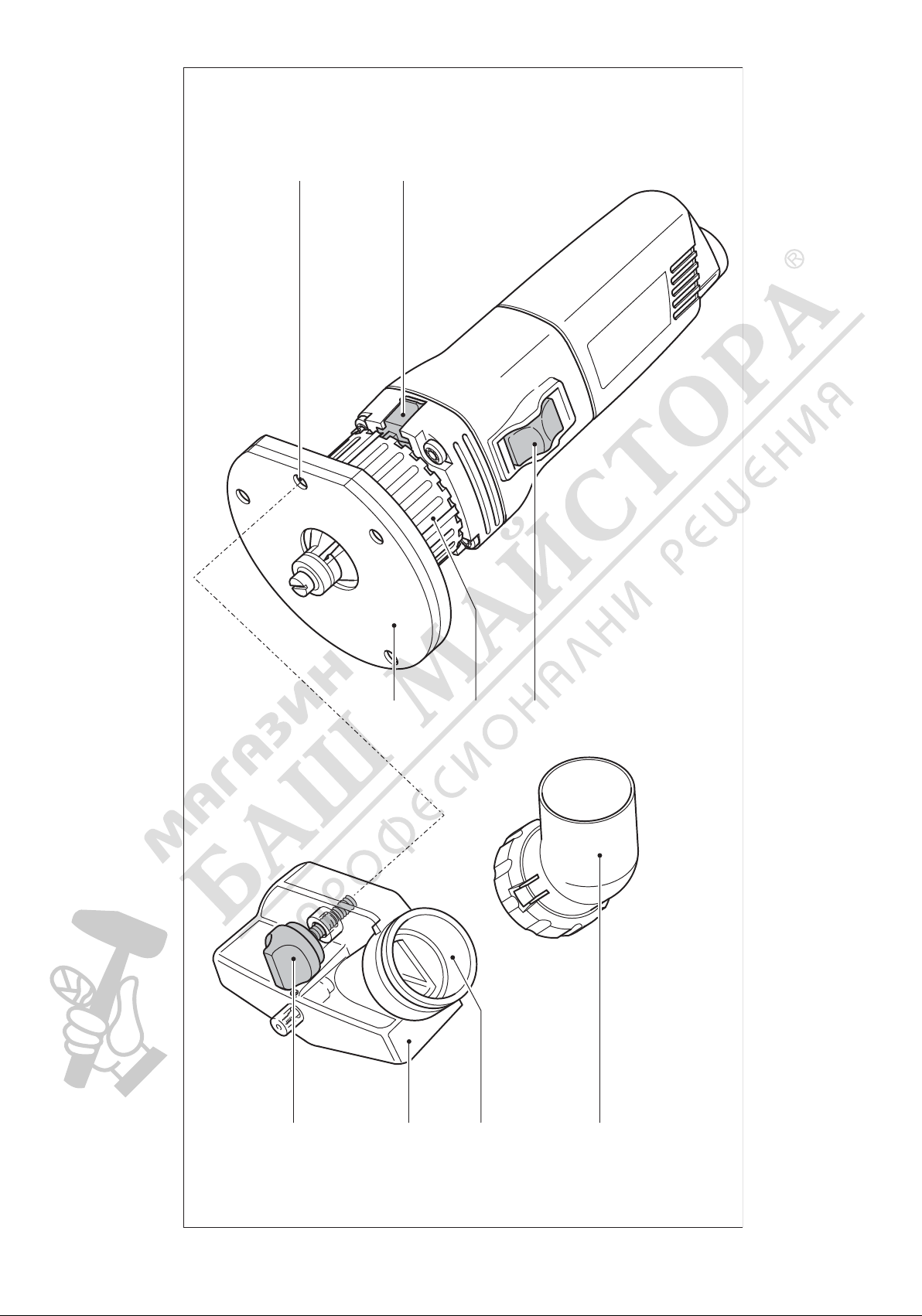

- Do not operate the machine unless the guiding

table (1.5) and the safety hood (1.2) have been

correctly installed.

- Do not operate the machine unless the setting

ring gauge is locked (see chapter 4.2).

- Only use milling tools that are EN 847 certi-

fi ed for rotating speeds of at least 30.000 rpm.

Tools that are cracked or misshapen must not

be used.

- Ensure that the milling tool is fi rmly seated and

check that it runs smoothly.

- Only use original Festool accessories.

- Only for AS/NZS: The tool shall always be sup-

plied via residual current device with a rated

residual current of 30 mA or less.

2.3 Safety instructions Cutter

a) Technical data

See imprint on tool.

Tool manufactured to comply with EN 847-1.

b) Correct use

Type of feed: MAN (manual feed).

Speed: Do not exceed the maximum speed speci-

fi ed on the tool and/or keep to the speed range.

Materials: Wood, plastic.

Warning: The operator is liable for damages and

accidents caused by incorrect use!

c) Safety instructions

Pay attention to the safety instructions included

with your tool.

Pay attention to the safety regulations applicable

on your country.

Do not use tools with noticeable cracks, blunt or

damaged cutting edges ---> danger to live!

The clamping surfaces must be free of dirt,

grease, oil and water.

Clamp the tool so that it cannot come loose dur-

ing work.

Insert the router into the clamping collet as far

as possible or as far as the mark on the router

shank.

Only mill in the opposite direction of rotation of

the tool (counter-rotation).

c) Maintenance and care

Use only original Festool spare parts.

Repairs and grinding work may only be carried out

by Festool service centres or qualifi ed experts.

Do not alter the construction of the tool.

Clean tool regularly and remove all resin (use

detergents with a pH value between 4.5 and 8).

Blunt cutting edges can be re-ground to a mini-

mum cutting edge thickness of 1 mm on the

face.