Festool LR 32-SYS User manual

Other Festool Power Tools manuals

Festool

Festool Trion PS-300Q Installation instructions

Festool

Festool BHC 18 Installation instructions

Festool

Festool PS420EBQ Owner's manual

Festool

Festool OF 2200 EB-F User manual

Festool

Festool VS-600 User manual

Festool

Festool PSC 420 EB Installation instructions

Festool

Festool Trion PS-300Q Guide

Festool

Festool OF 2200 EB User manual

Festool

Festool OF 2200 EB User manual

Festool

Festool ROTEX RO 90 DX FEQ User manual

Festool

Festool Domino DF 500 Q Installation instructions

Festool

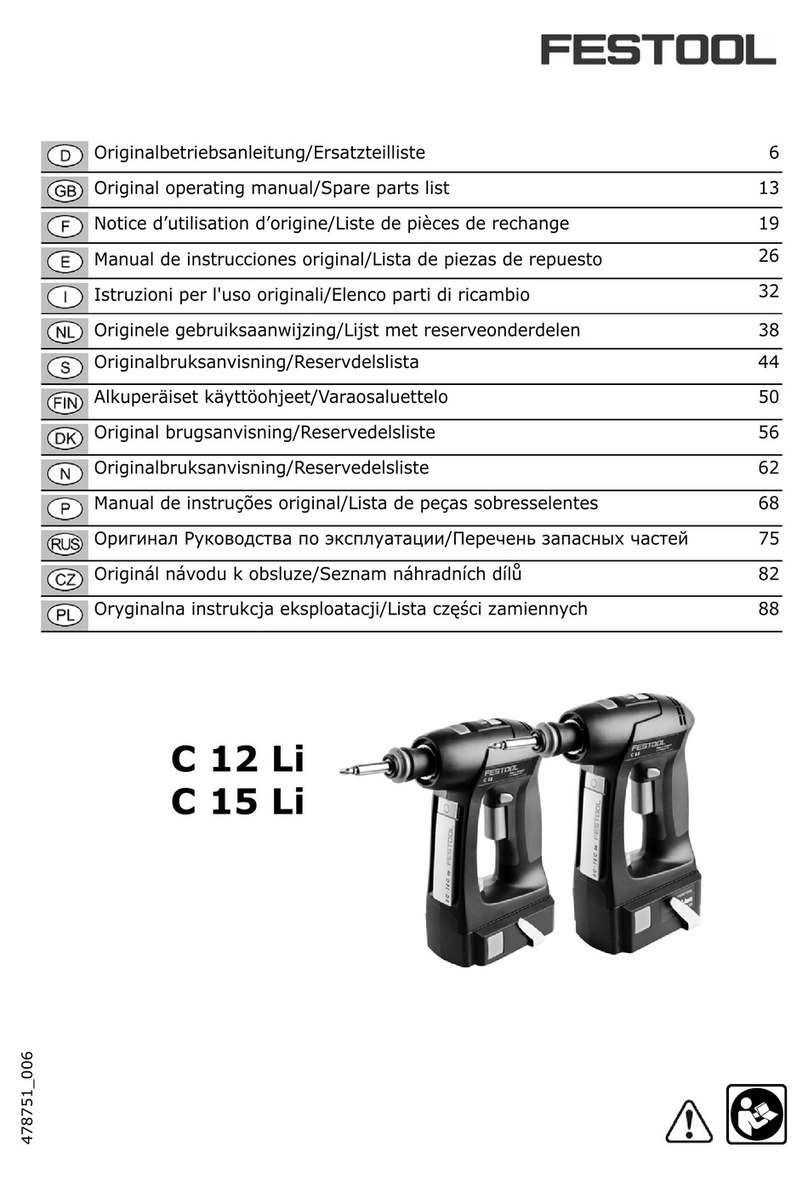

Festool C 12 Li Installation instructions

Festool

Festool ETS EC 150/3 A EQ Installation instructions

Festool

Festool MFK 700 EQ User manual

Festool

Festool Domino DF 500 Owner's manual

Festool

Festool Domino XL DF 700 Owner's manual

Festool

Festool Carvex PS 420 EBQ User manual

Festool

Festool Trion PS 300 EQ User manual

Festool

Festool TI 15 Guide

Festool

Festool VECTURO OS 400 EQ Owner's manual