FFS Brands Vizu 400 Pass Through Multi Stack User manual

Page 1of 28

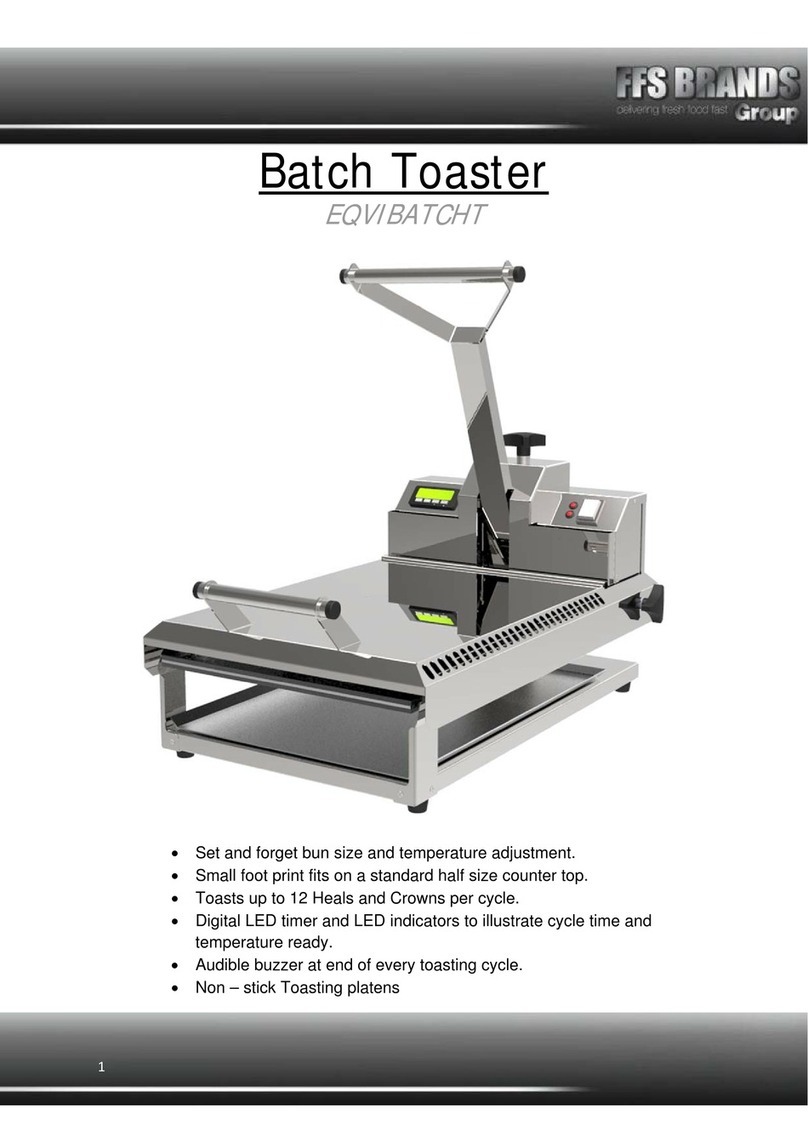

VIZU®400 Pass Through

Multi Stack

VI400PTMS

Counter top ‘Pass Thru’ With a small footprint

Cooked food holding with multi-level racks (multi stack)

Front and rear flap access for quick loading and unloading

Thermostatically controlled environment

Automatic water fill for humid environment

Illuminated interior

Page 2of 28

Contents

VIZU® Multi Stack Pass Thru.........................................................................................1

MULTI STACK PASS-THRU SPECIFICATION PAGE .........................................................3

Model VIMSPT...........................................................................................................3

Assembly and Installation Instructions.........................................................................6

Instructions for use ...................................................................................................7

Description of Multi Stack Auto Fill Pass Thu machines ..................................................8

Use of Auto Fill Pass-Thru machines..........................................................................11

Cleaning of Auto Fill Pass-Thru machines ...................................................................12

Exploded View ........................................................................................................13

Wiring Diagram .......................................................................................................14

Spare Parts List.......................................................................................................15

Cleaning instructions - Daily .....................................................................................19

FAULT FINDING ......................................................................................................20

Terms and Conditions .................................................................................................22

Claims....................................................................................................................22

Returns ..................................................................................................................22

Damage Claim Form ...................................................................................................23

Warranty ...................................................................................................................24

Page 3of 28

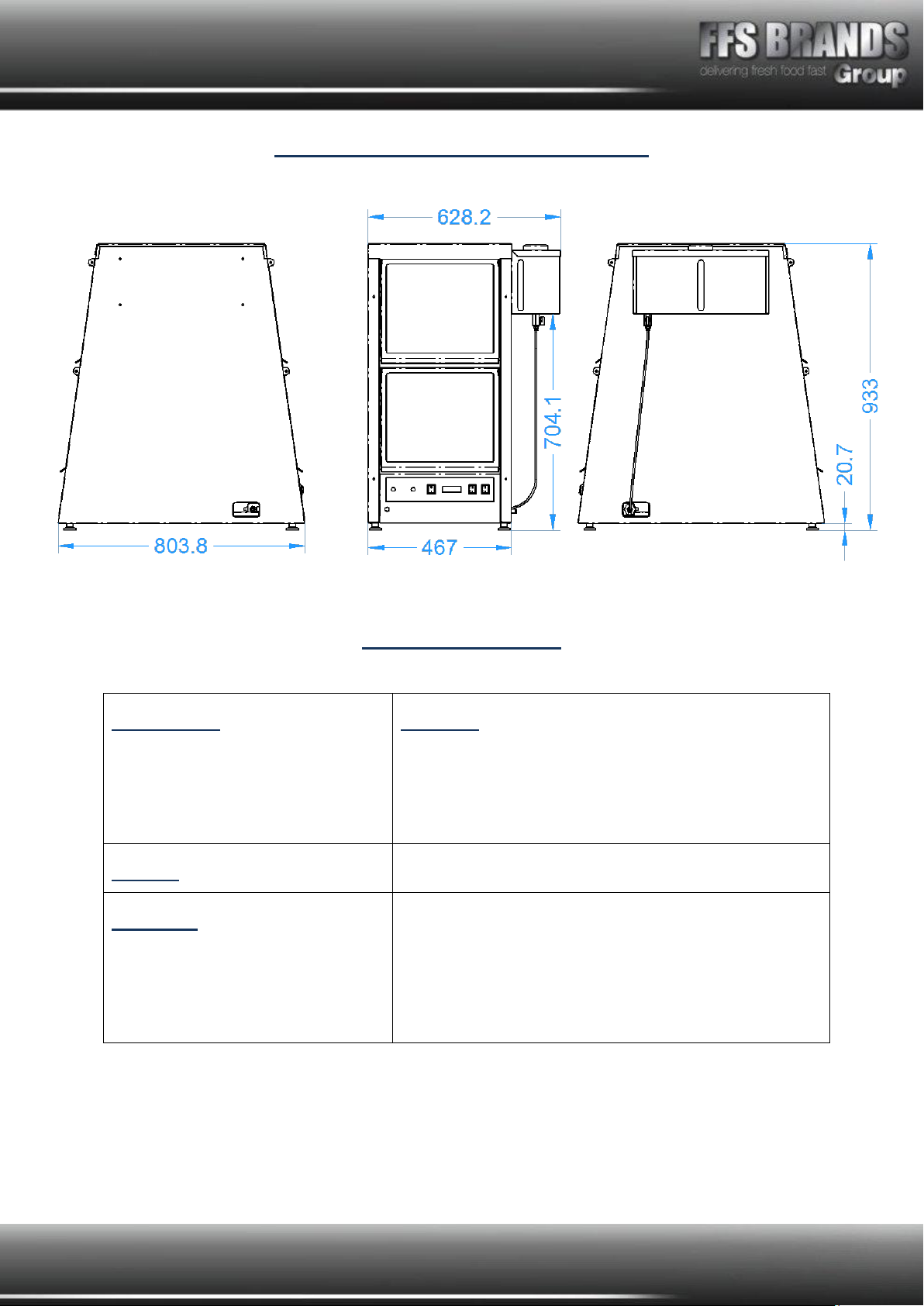

VI400PTMS SPECIFICATION PAGE

Model VI400PTMS

Dimensions

Height

Width

Depth

Machine

935.00 mm

630 / 470 mm

805 mm

Weight

kg

Electrical

Running Amps

Connection Type

International Option

1400w, 1 phase, 50Hz ac

230v, 6 Amps

BSCHUKO 2/3 PIN PLUG

N/A

Page 4of 28

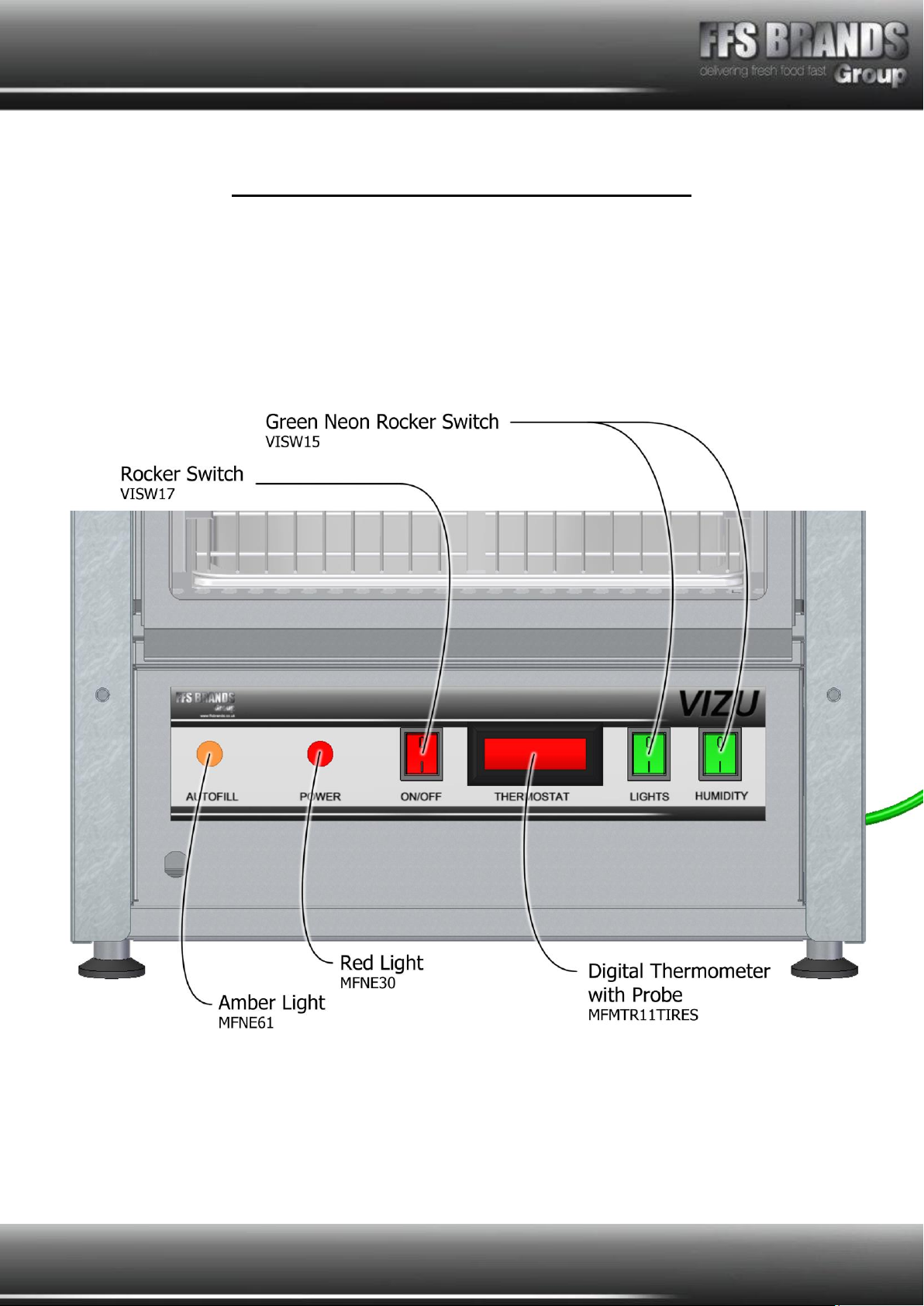

VI400PTMS Control Panel- Labelled Views

The below image shows the individual parts and part names for the ‘Multi Stack

Pass-Thru’ Control Panel situated on the back of the machine. Please refer to this

image for more information regarding the product installation as well as use

instructions.

Page 5of 28

Page 6of 28

All

Vizu 400 Pass Through Multi Stack’s

have been tested and checked for proper

operation before leaving the factory.

Upon delivery please check the unit for damage. If the unit is damaged, contact the carrier,

or Fast Food Systems, immediately and file a damage claim (found in the back of the

manual) Please retain all packing materials.

Damage must be reported within 7 days of delivery

General Description

The unit has been designed to hold cooked foods in a humid atmosphere. Being a pass-thru

unit the machine can be loaded from one side and unloaded from the other.

Assembly and Installation Instructions

1. Unpack machine from packaging

2. Peel all surfaces of plastic film and wipe down with warm soapy water

3. Position machine on a level surface

4. Machine must be affixed to a fresh mains water supply, or side mounted bottle filled

daily with fresh water

5. Machine must be plugged into a 13Amp power supply.

6. Install all removable parts including; Element Cover, Side mounted ‘Rack Supports’,

Gastro Pans and wire racks.

7. Install racking by sliding it into the ‘Rack Supports’

8. Make sure all parts are seated correctly by checking all parts at both sides of the

machine.

Page 7of 28

Switch Controls

Red Switch –‘ON/OFF’

-Controls the temperature within the cabinet via the digital thermostat

Green Switch - ‘LIGHTS’

-Operates the lights within the unit

Green Switch –‘HUMIDITY’

-Operates humidity system within the unit –Can work with main supply or

supplied bottle

Instructions for use

1. Ensure Mains power is on –The red ‘POWER’ light should be lit

2. Ensure either Mains water is on and connected, or the bottle is filled and connected

3. Turn red ‘ON/OFF’ switch to ‘ON’

4. Turn green ‘LIGHTS’and ‘HUMIDITY’ switches to ‘ON’

5. Leave the machine for 20 minutes to heat and humidify

6. Turn on load food as required, from the ‘Control Side’ and unload from the ‘Draw

Side’

7. If using the bottle, please make sure to keep an eye out for the water level in the

bottle.

LED Indication

When the unit is on the red POWER LED indicator with be lit.

When the ON/OFF switch is lit, the unit has power to the heating system, this is

also be indicated by the Digital display being lit

When the GREEN LIGHTS switch is lit, power will be going to the lighting system

When the GREEN HUMIDTY switch is lit, power will be going to the humidity

system

When the AMBER LED indicator is lit, the machine will be filling the internal water

tray to the correct water level

Page 8of 28

Description of Multi Stack Auto Fill Pass Thu machines

The Multi Stack Auto Fill Pass Thru unit must only be used to keep cooked food hot and

moist; it must not be used to re-heat cooked foods.

The machine is suitable for holding cooked meats and fish.

This unit is more complex machine than a standard Pass-Thru and as such there are a few

more rules of use.

When the machine is placed in the position that it will be used in it is important to

ensure that it is level. Ensure that the surface the Pass-Thru is mounted on is flat

and well supported.

The machine can be either connected to a Mains water supply or the supplied water

tank (which must be refilled by the machine operator).

The unit is supplied as standard with the remote water tank. The water pressure

reducing valve is pre-set, however if the location the machine is being installed in

has a different water pressure this may need to be adjusted.

If the tank is to be re-positioned, OR mains feed is to be made the water feed

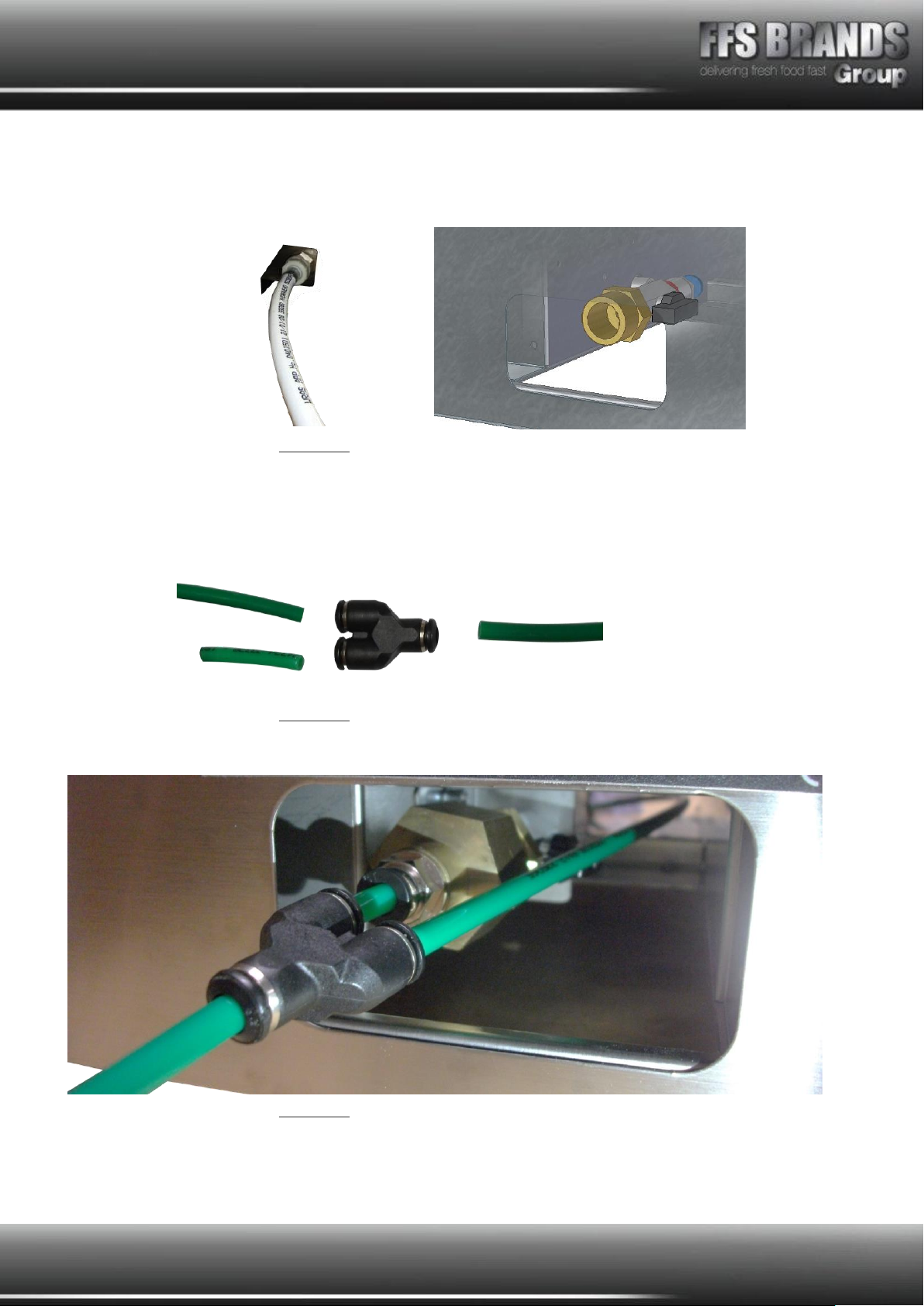

connection to the machine must be dis-connected. See Fig. 1 & Fig. 2 below.

Figure 1 Figure 2

The standard plumbing fitting used for a washing machine can be fitted to the

remaining threaded piece shown in Fig 2

The tank can be mounted on the opposite side of the unit if desired, alternatively the

tank can be placed on an up-stand or other location –If this is the case it is

important that the tank is NOT at a lower position than it would be if it were

mounted on the side of the machine, otherwise the water flow will be adversely

affected.

Page 9of 28

1. To connect the mains supply, simply screw the mains inlet pipe into the thread on

the fitting, as shown in Fig. 3. Ensure a tight waterproof seal - use PTFE tape.

Figure 3

2. When two VIMSPT’s are next to each other these can be connected together (Only

when using the Bottle), using the Supplied ‘Green Tube’. Cut a piece 1 inch long

(make sure to use a sharp knife to result in a clean cut) and then arrange the parts

as shown in Fig 4.

Figure 4

3. Now connect all the parts together as shown in Fig 5.

Figure 5

Page 10 of 28

4. When installing the machine to a mains water supply the pressure regulating valve

within the machine must be adjusted to reduce the pressure. This is done by winding

the thumb screw in until the desired pressure is achieved, see Fig. 6.

Figure 6

5. Ensure that the water tray is pushed in to the unit fully (it should lock in position –

pull gently to check). The water filling sequence can now begin. Switch the ‘ON/OFF’

switch for ‘HUMIDITY’ to the ‘ON’ position. The float of the machine will sense that

the water tray is empty and it will begin to fill the machine. (If this does not happen

please check that the draw is fully pushed in (activating the micro-switch) and that

the water supply is connected and able to flow). The amber light on the panel will

light during filling stage, (this is a slow process). The correct pressure should see the

water flow in to the water tray without causing splashing –see Fig 7.

Figure 7

6. It is important that the machine fills slowly so that the water can be heated by the

under pan heater, allowing the machine to fill too quickly will cause the temperature

to drop.

The machine is factory set to 70C. This is adequate to hold cooked food at a safe

and legal temperature (i.e. above 63C)

Page 11 of 28

Use of Auto Fill Pass-Thru machines

1. Switch the machine on (red switch), then switch the auto-fill and lights on (green

switches).

2. The machine should be left for 20 minutes to allow it to reach the correct operating

temperature. By having an automatically filling water system the internal atmosphere

of the unit will be humid, improving the “hold time” that products can be kept for.

3. Whenever the flaps are raised on the Pass Thru unit they should also be lowered in a

controlled manner and not allowed to drop and bang against the side of the

machine. Allowing the flaps to hit the machine can result in damage to the doors but

more importantly weaken the bulbs and reduce their life.

4. Ensure that the water supply is maintained –otherwise the machines humidity will

be affected.

Page 12 of 28

Cleaning of Auto Fill Pass-Thru machines

1. The water drawer should be removed daily for cleaning.

TAKE CARE WHEN REMOVING THE WATER DRAWER

Gently lift the front of the water drawer and then slide drawer out of machine, the water will

cut-off automatically when the drawer is removed. Next drain water in to a sink. The water

pan can be removed from the drawer by carefully lifting the float and then removing the pan.

Be careful not to damage float and mechanism.

With the water draw removed the rest of the removable pieces can be removed, Once the

parts have all been removed these can be cleaned in warm soapy water (soak the parts in

warm soapy water if required).

CARE MUST BE TAKEN WHEN CLEANING THE INTERIOR OF THE MACHINE

BECAUSE ELEMENTS, PANELS ETC. MAY REMAIN HOT FOR SOMETIME AFTER THE

HEATING HAS BEEN SWITCHED OFF.

Page 13 of 28

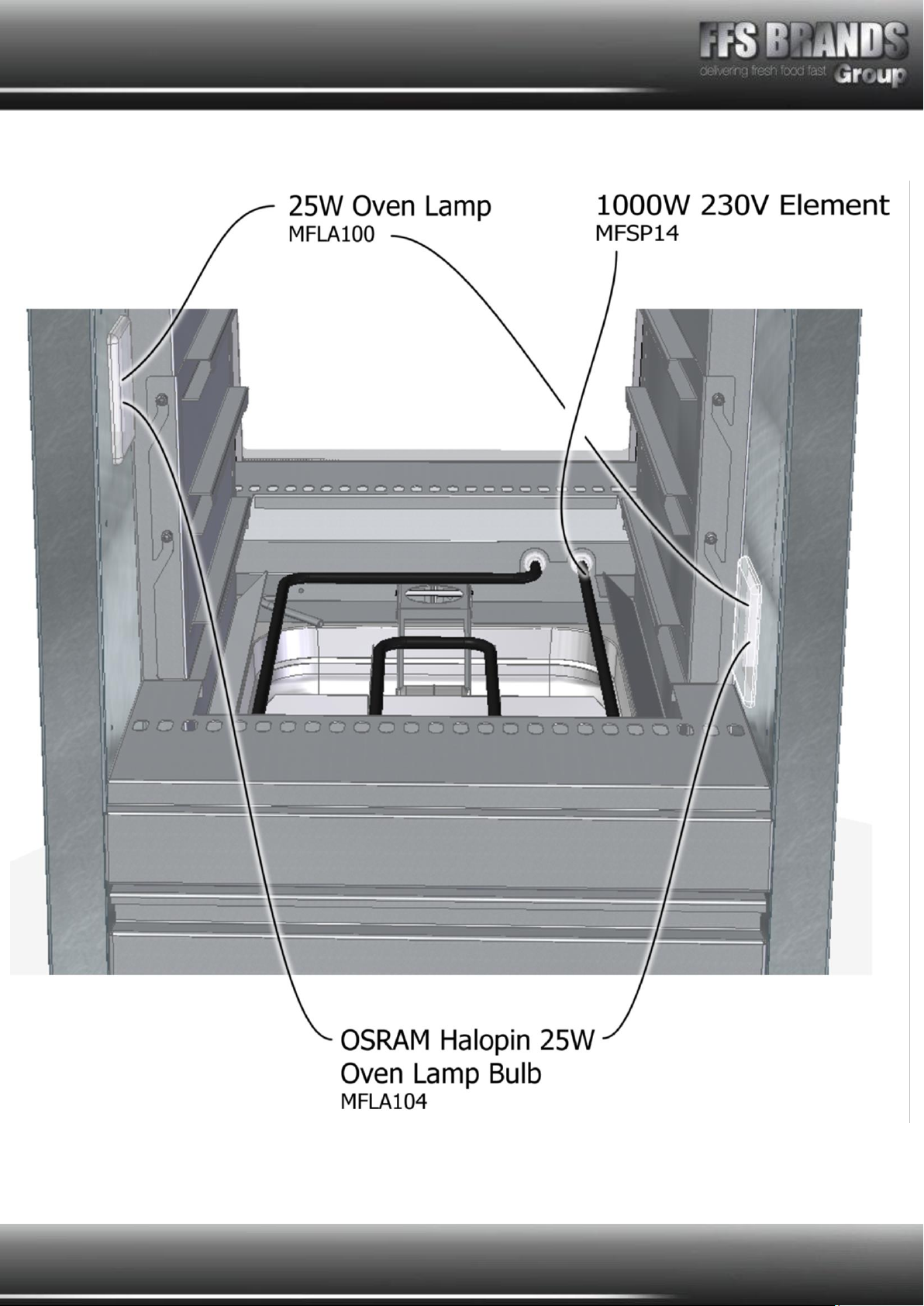

Exploded View

This page can be used as a reference when communicating with FFS Brands Manufacturing

team to help describe parts and locations in the machine.

Page 14 of 28

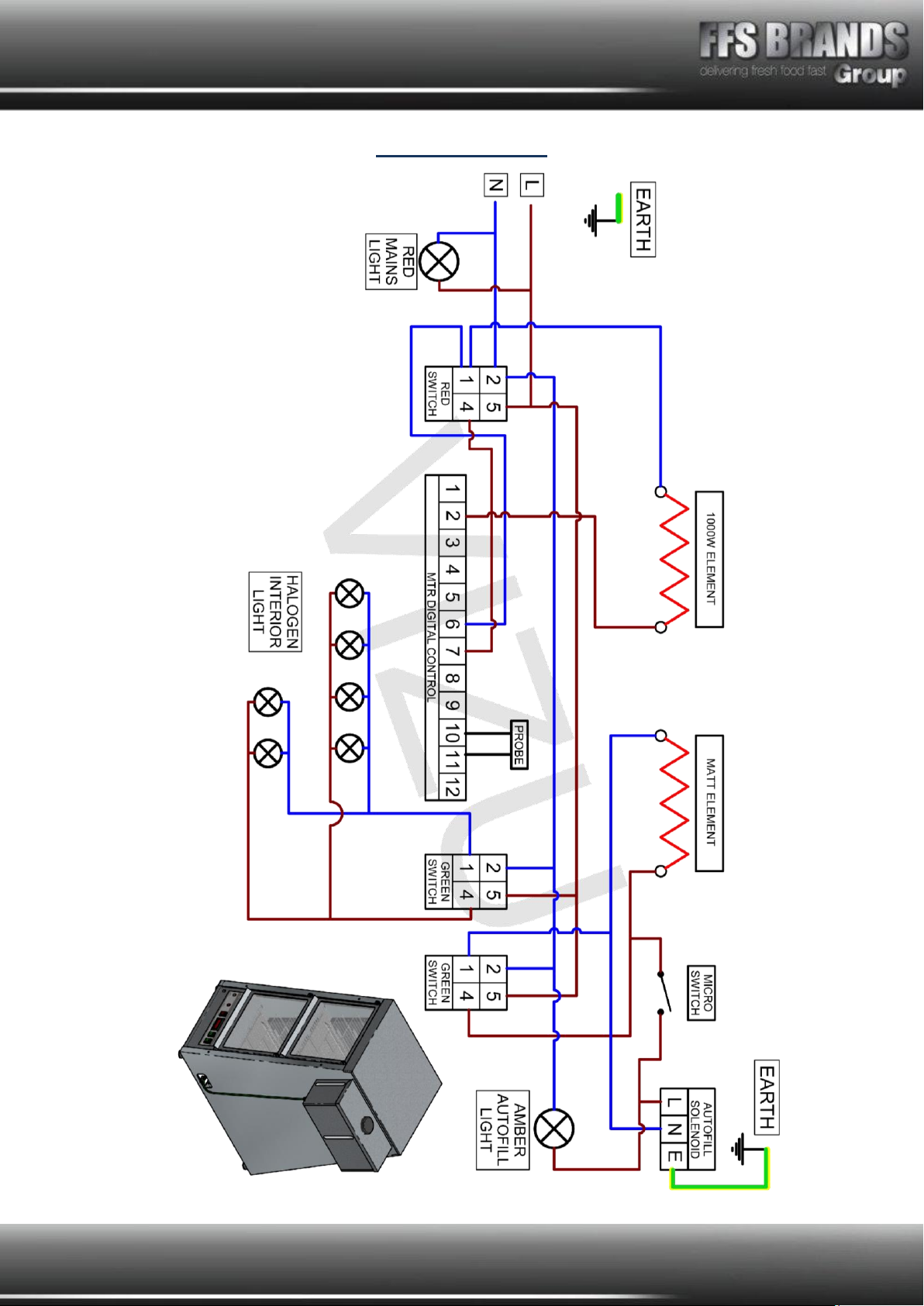

Wiring Diagram

Page 15 of 28

Spare Parts List

PART NO.

PART NAME

QTY.

MFSP14

1000W 230V HEATING ELEMENT

1

MFNE30

RED LIGHT

1

MFNE61

AMBER LIGHT

VISW17

ROCKER SWITCH REVOLVA MFC1553ALR

1

VISW15

GREEN NEON ROCKER VIZU

BURGER/PASSTHRU

2

VILE14

SWITCH COVER BEVEL MF1026

3

MFMTR11TIRES

LTR-5TSRE-A(P) DIGI THERM. WITH PROBE

1

MFLA100

OVEN LAMP ASSEMBLY 25W

6

BESCHUKO

H05RR-F 2MTR RUBBER C032

1

MFEUROCONVERT

EURO TO UK CONVERTER PLUG BLACK 19-1032

1

MFOHSL01

HIGH TEMPERATURE SLEEVING

0.8

Page 16 of 28

PART NO.

PART NAME

QTY.

MFLA104

HALOPIN OSRAM OVEN 25W 230V G9

6

MF285-100

FLAP WINDOW 375mm wide x 5mm deep x 321mm

high

4

MF285-101

FLAP RUBBER

4

C07911/100

GN 1/1 GRID / SHELF STAINLESS

6

GSGAST90002

1/1 GASTRONORM PAN - 20mm DEEP

2

GSGAST?????

GASTRONORM PAN 1/4 65mm DEEP

1

MF51LHSPRING

LH TORSION SPRING (PLATED PIANO WIRE)

2

MF51RHSPRING

RH TORSION SPRING (PLATED PIANO WIRE)

2

MF817-8877

NYLON STRAIGHT RELIEF CABLE BUSH

1

MF354Z

2 POLE 5 AMP TERM BLOCK

3

MFFFR12/04

BRASS F-F ADAPTER 3-4 BASPT 1-4 BSPT

1

Page 17 of 28

PART NO.

PART NAME

QTY.

MFRC12/04

BRASS M-M ADAPTER 3-4 BSPT –1-4 BSPT

2

MFVM04

Mini Ball Valve 1/4'' Bspp Brass

2

MFMCU7061/4

Mcu706 1/4 Flow Control

1

MF20231/4-1/4

2023 1/4''-1/4'' Flow Control Concection Ring

1

MFF4PB6-1/4

Union (Male) Bspp

3

MFPU22001-

230V1/8

1/8A Solenoid Valve With Coil

1

MFWADE-

ME106/083

6MMx1/8 Bspt Male Stud Elbow 20X20X10MM

2

MF51FLOAT

Magnetic Float Switch S/S Floating Ball

1

MF515-767

Microswitch Used On Float VI1100/700PT

1

MF12LTRTANKQTR

OUT

12L Tank With 1/4Bsp Female 150X420X200

1

Page 18 of 28

PART NO.

PART NAME

QTY.

MFLTR035G04S

180 Degree S/S Torsion Spring

1

MF483-4964a

Green Standard Nylon Tube 30m x 6mm

1.5 + 0.8

MF605-649

Grommet

2

MF55310-6

6mm push fit plastic y connector

1

MF225WELEMENT

225W mat element 0.75Amps 0.225Kw 230V

1

MF0A074

TONG STORE CLIP LOCK ASSY

4

Page 19 of 28

Cleaning instructions - Daily

1. Disconnect the machine from the power supply before cleaning and allow to cool.

2. Remove food as well as gastronorme pans and wire racks, wash thoroughly in warm

soapy water, rinse and dry.

3. Remove the side racks and wash in warm soapy water, rinse and dry.

4. Remove the element cover and wash in warm soapy water, rinse and dry

5. Doors may be wiped with a soft damp cloth, dry thoroughly taking care not to

damage the plastic.

6. Remove the water tray assembly, lift the float and take out water gastronome plan

and clean thoroughly, (take care not to damage float assembly).

NEVER use wire wool, scourers, abrasive cleaners, acids or bleach.

DO NOT flood or allow electrical parts to become wet.

NEVER handle the lamps; if they become dirty they should be wiped with a soft, damp,

grease free cloth.

DO Dry all surfaces thoroughly removing all moisture.

A stainless steel cleaner/polish may be applied to the exterior.

N.B - For Hard Water Areas

To avoid the risk of scale build up, we advise to either fit an in-line softener if using the

mains supply or use a water softener. If the unit is being used with a remote water tank,

use de-ionised water.

Please be aware of these guidelines as scale is not covered by our warranty, as noted earlier

in this manual

Page 20 of 28

FAULT FINDING

Any servicing must only be carried out by qualified personnel. Unit must be removed from

electrical supply before servicing.

Problem

Probable Cause

Solution

1. Indicated ON/OFF

switch does not light

up

No power to machine.

ON/OFF switch faulty

Check machine is plugged in and switched

on.

Check fuse in 13a plug, replace if faulty.

Check circuit breaker at main supply board

is in (ON) position.

Check Switch, replace if faulty.

2. Digital thermostat

does not indicate

temperature reading.

ON/Off switch OFF

Unit overheated

ON/OFF switch faulty

Digital thermostat faulty

Switch ON

Allow to cool.

Replace switch

Replace if thermostat faulty

3. Lamps do not work

No power

Green switch OFF

Lamp not correctly seated.

Faulty lamp

See section 1

Switch ON Red switch

Switch ON Green switch.

Check fitted correctly

Replace lamp/bulb

4. Unit does not heat

up.

No power to machine

ON / OFF switch OFF

ON / OFF switch faulty

Digital thermostat faulty

Thermocouple faulty

Switching relay faulty

Heat element faulty

See section 1.

Switch ON

Replace Switch

Replace thermostat

As indicated on controller replace

thermocouple

Replace relay

Replace element

This manual suits for next models

1

Table of contents

Other FFS Brands Commercial Food Equipment manuals