Banquet trolleys, refrigerated

Content

About this product Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Conditions of use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Standard model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Options and accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Functional principle Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About this product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Initial use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Shutting down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cleaning and care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Product marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Transport Checking for/reporting on damage incurred during transportation. . . . . . . 8

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Packaging material disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

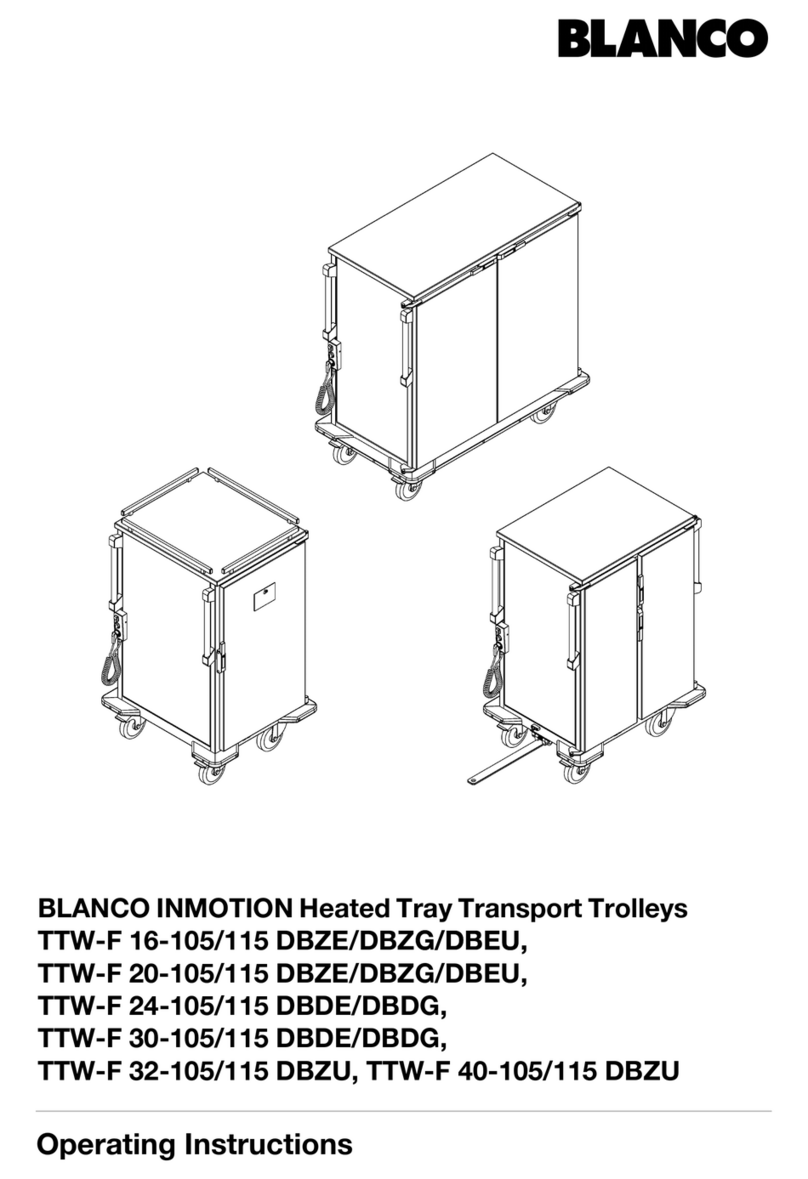

Overview Unit overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Temperature control – overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Initial use Conditions of operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Initial cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Selecting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Initial use after a long period of disuse. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connecting the unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation Switching refrigeration on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the setpoint temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Locking and unlocking keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Displaying/deleting maximum/minimum temperature . . . . . . . . . . . . . . . 15

Defrosting unit automatically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Starting defrost cycle manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Accelerated defrosting of the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Defrosting the unit by switching off refrigeration . . . . . . . . . . . . . . . . . . . 17

Pre-cooling unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Opening a unit door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Locking back the unit door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Closing the unit door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Turning door lock into transport locking position . . . . . . . . . . . . . . . . . . . 19

Loading the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Moving the unit to a new location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Traversing ramps, recesses, slanted surfaces . . . . . . . . . . . . . . . . . . . . . 22

Keeping food cool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Removing food . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23