Fibaro Roller Shutter provides three association groups:

1

association

group

is

triggered through a momentary swltch clic

k,

or a toggle switch position change.

II

association

group

is triggered through a momentary switch hold

NOTE

II

association group is inactive when toggle switches

are used or in Gate Controller mode (parameter 10).

In

case of controlling Venetian Blinds, control

commands are sent in Fibar Command Class

standard.

III

association

group

reports the module status. Only one device

may

be

assigned to this group, main controller by default.

Jt's

not

recommended to modify this group's settings.

Fibaro Roller Shutter allows for commanding other Roller Shutters,

associated into I or ll assoclation group, through clicking

or

holding a

switch key. For example, this mechanism atlows for operating a

Roller Shutter connected to the switch with a button click, and

operating the devices associated

in

II

association group by a button

hold.

In

addition, when operating Venetian Blinds, it's possible to

synchronize many devices.

USING ASSOCIATIONS TO OPERATE ANOTHER

ROLLER SHUTTER OR ANY OTHER Z-WAVE

DEVICE.

1ASSOCIATION GROUP:

Clicklng

Ä

button

, connected to

S1

terminal will inltiate up

movement

in

associated Roller Shutters, or send Turn

On

command

frame to the devices associated

in

l-st association group.

Clicking

...

button

, connected to S2 terminal will initiate down

movement in associated Roller Shutters, or send Turn Off command

frame to the devices associated

in

1-st

associatlon group.

II

ASSOCIATION GROUP:

Holding

Ä

button,

connected to

S1

terminal will move the

connected roller blind

up,

and after 1 second delay initiale up

movement in associated Roller Shutters, or send Turn

On

command

frame to the devices associated

in

11-nd

association group.

Holding

...

button,

connected to S2 terminal will move the

conected rolled blind down, and after 1 second delay initiale down

movement

in

asSociated Roller Shutters,

or

send Turn Off command

frame to the devices associated

in

11-nd

association group.

USING ASSOCIATIONS TO OPERATE ROLLER

SHUTTERS CONNECTED

TO

VENETIAN BUNDS.

Using association mechanism to operating venetian blinds require&

configuring both, l-st and

11-nd

association groups.

1ASSOCIATION GROUP

Clicking

A

button

, connected to

S1

terminal will initiate up

movement of the connected venetian blind and other device~

associated in

1-st

association group.

Clicking

...

button,

connected to S2 terminal will initiate down

movement of the connected venetian blind and other devices

associated in

1-st

association group.

II

ASSOCIATION GROUP (relevant for momentary switches only)

Holding

A

button

, connected to

S1

terminal will initiate slats

rotation up, of the connected venetian blind as well

as

the other

devices associated in

11-nd

association group.

Holding

...

button,

connected to S2 terminal will initiate slats

rotation down, of the connected venetian blind as well as the other

devices associated in ll-nd association group.

& NOTE

Once the assoclated devices are already moving,

they will

be

stopped ifany

of

the buttons is pressed

and held

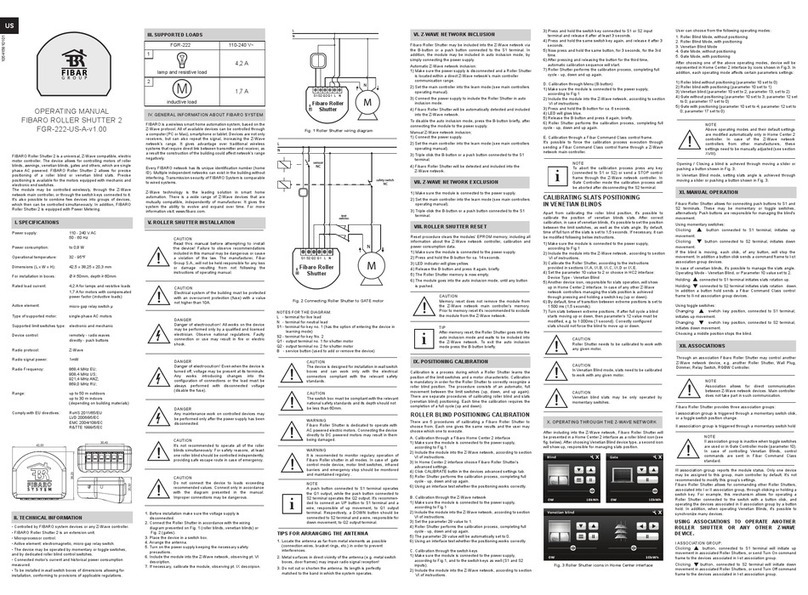

XIII. OPERATING GATE MOTORS

Fibaro Roller Shutter allows for operating gate motors. Gate motor

should be connected to

01

and

02

terminaJs according to Fig.2.

In

the Gate Mode, a momentary switch may

be

connected to

S1

terminal. lt's recommended

to

connect

an

IR barrier, an emergency

stop button or any alarm mechanism to S2 terminal. Opening a

contact in a device connected to S2 terminal will always result in

stopping a motor in current position (see Fig. 2).

Clicking a push button connected to

S1

terminal will initiate opening

the gate. Nextclick ofa button will stop the gate.Yet another cllck of

a button will close the gate. According to following seaquence;

OPEN -STOP -GLOSE -STOP -OPEN.

G;ite

'<.

X

D

DD

-0

ow

10kWh

Fig. 5

Roller

Shutter

icon

In Horne

Center

interface

&NOTE

In

Gate Mode, by default, the

S1

terminal

is

set to

operate

w1th

a momentary switch, ignoring the

parameter 14 settings

Full opening the

ga

te initiales a Ro

ll

er Shutter COUNTDOWN.After

the COUNTDOWN the gate will start closing. COUNTDOWN length

is

set through the

pa

rameter 12.

In

addition, if

th

e IR barrier is cut (S2

contact opened) at the gate fully open, the gate will start closing after

a time period specified

in

parameter 17.

NOTE

In

both Gate Modes, with and without positioning,

parameters 12 and 17 are automatically set to

0.

At

these settings the gate will open, but will not

automatical!y close. Relevant times need to be set

manually in parameters 12 and 17 (see section

XVIII).

NOTE

Parameters 12 and 17 settings are automatically

modified only in Horne Center 2 controller, when

choosing one

of

Gate Modes. ln case ofcontrollers

from other manufacturers·these parameters need to

be

set manuaHy (see section XVIII).

NOTE

Installation ofthe gate driver may

be

performed only

by certified professionals. The motor must

be

equipped with the appropriate limit switches (see Fig

2). lt's recommended

to

connect a NC (normally

closed) contact

of

an

IR

barrier to S2 terminal.

Opening the contact will stop the gate.

In

addition,

it's recommened to connect an emergency stop

button to the motors neutral (N) wire.

In

emergency,

pushing the emergency stop button will cut the

power and stop the gate. ltls recomended to monitor

regulary operation

of

Fibaro Roller shutter

in

all

modes. Also it

is

recomended to regulary verificate

and maintenance connectors.

NOTE

S1

and S2 terminals react to mains voltage only.

Using

IR

barriers with

NC

contacts operating

an

lower voltages require using an additional relay (see

Fig. 2)

XIV. LED INDICATOR

Fibaro Roller Shutter has a MENU. Each MENU level is signaled

through a LED lndicator colour.

Ta

enter MENU press and hold the

B-button for at least 2 seconds.

While the B-button

is

being held, LED lndicator colours will change

in

the following sequence:

BLUE -Roller Shutter calibration procedure (see section IX)

VIOLET -initiale the Z-Wave network range tester

GREEN -reset energy consumption data memory (see section XVI)

YELLOW

-Roller Shutter reset (see section VIII)

Release the B-button

to

choose the desired function and confirm

your choice with the B-button click.

XV

. Z-WAVE RANGE TESTER

Fibaro Roller Shutter has a built in mechanism, allowing to roughly

estimate

the

Z-Wave network range.

CAUTION

To

allow for the Z-Wave network range test, the

Z-Wave network controller needs

to

support the

functionality and the module needs to be included

in the network. Z-Wave range test puts heavy strain

on

the network,

so

it's recommended to use the

function only in special cases.

In

order to test the Z-Wave network range:

1) Press and hold the 8-button for ca. 6 seconds, until the LED

lndicator glows violet.

2) Release the B-button.

3) Click the B-button.

4) LED lndicator will signal the Z-Wave network range (see

description

be

low).

5)

Click the B-button to exit the Range Tester.

Network range signaling modes:

Z-Wave network range is signaled by LED illumination colour and

behaviour. Blinking each 1-second means the modules tries to

establish a direct communication with the main controller, while 2

seconds glowing means the test result. The test is pelionned in a

loop, until being stopped by the user. Z-Wave range test is

peliormed in three steps, signaled with green, yellow, violet and

red:

1) Blinking in GREEN means the modute tries to establish a direct

communication with the main controller. Positive test result is

signaled by a 2 second glowing

in

GREEN, after which the test is

repeated (step 1

).

In

practice, if the module

is

able to establish a

dlrect communication with the main contro!ler, the LED will glow

GREEN, without blinking.

2)

lf

the module

is

notable to establish a direct connection with the

main controller, it will try to establish a routed connection, through

another, intermediary, Z-Wave network devices. LED indicator will

change the illumination colour to RED. Positive test result is

signa!ed with glowing

in

YELLOW. After 2 seconds the module will

retry establishing a direct communication (step 1

).

[I]

NOTE

The module may

mod1fy

the main controller

commumcat1

on

from direct

to

routed and vice

versa, espec1alty

1f

1t's

located at the direct

commun1cat1on range hmit

3)

lf

the module

is

notable to establish a routed connection with the

main controller, LED lndicator colour will change from YELLOW to

VIOLET. After few seconds test will end and the LED lndicator will

glow RED for two seconds. Whole procedure will start again and

the module will try to establish a direct connection with the main

controller (step 1).

XVI.

CU

RRENT AND HISTORICAL

POWER CONSUMPTl0 N MEASURING

Fibaro Roller Shutter allows for the current load and power

consumption monitoring. Data

is

sent to the main controller, e.g.

Horne Center

2.

Measuring is carried out by an independent microprocessor

dedicated exclusively for the purpose, assuring maximum accuracy

and precision. The microprocessor is factory calibrated.

Electric

power-

power consumed by an electric device in an instant,

in Watts

f;N)

.

ElectriC

energy

-energy consumed

by

a device through a time

period. Most commonly measured in kllowatt-hours (kWh). One

kilowatt-hour

is

equal to one kilowatt

of

power consumed over a

period

ofone

hour, 1kWh • 1000 Wh. ·

RESETTING ELECTRICITY CONSUMPTION MEMORY

Fibaro Roller Shutters electricity consumption memory may

be

cleared in one ofthe following ways:

1)

Through the module reset (see section VIII)

2) Through the main controller menu (see main controllers

operating manual

3) Manually using the following instructions:

a) Make sure the device is connected to voltage supply.

b) Press and hold the B-button for ca. 10 seconds, until LED 1

ndicator glows GREEN.

c) Release the B-button.

d) Click the 8-button.

e) Energy consumption memory has been erased.

NOTE

1) Please contact your local supplier for the current

rates

2) Fibaro Roller Shutter stores consume.d electricity

data on its memory, which means disconnecting the

modu1e

from voltage supply does not erase the

data.

XVII. PROTECTION MODE

Fibaro Roller Shutter uses the Protection Command Class v2 to

prevent from unintended motor movement.

1) Local Protection

Local Protection State:

n·

:.

rio protectiori.

ROiier

Shutter'responds

t'o

pUsh

büttons.

1 -

not

supported

2 - Local protection active. Roller Shutter does not respond to

push buttons.

Once the Local Protection

is

activated, the module stops

responding to

S1

and

S2

push buttons. SCENE

10

and association

commands will not

be

sent as weil.

The

only exception

is

the

B-button. Menu and

Z~Wave

network inclusion, after the 8-button

or

S1

push button triple click, are still active.

WARNING

In

Protection Mode it will not be possible to control

Fibaro Roller Shutter from buttons. lt

is

not

recomended to control all Fibaro Roller Shutters

in

this mode.

CAUTION

There's one more exception in Local Protection.

In

Gate Mode, S2 (IR Barrier) is still active. lt means

if

the obstacle is detected, the gate will stop,

regardless the Local Protection State set.

2)

RF

Protection (radio protection)

RF

Protectlon State:

0 - No protection. Roller Shutter responds to command frames.

1 -

RF

Protection active. Roller Shutter does not respond to the

Z-Wave control frames.

2 - not supported.

Once the

RF

Protection is activated, the module stops responding

to command frames setting the blind position. lt's still possible

however to configure the device (advanced configuration

parameters, protection modes) and checking it's current state

through polling (position, power. energy).

~VIII. ADVA.NCED CONFI

GURA

TION

GENERAL SETTINGS:

3.

Reports

type

0 - Blindposition reports sent to the maln controller using Z-Wave

Command Class.

1 - Blind position reports sent to the main controller using Fibar

Command Class.

Parameters value shoud be set to 1 if the module operates

in

Venetian Blind mode.

Default setting: O

Parameter size: 1

[byte]

NOTE

&

To

make sure whether Fibar Command Class is

supported by

Z~Wave

network main controllers

from other manufacturers, please contact the

controllers manufacturer.

10.

Roller

Shutter

operating

modes:

0

~

Roller Blind Mode, without positioning

1 - Roller Blind Mode, with positioning

2 - Venetian Blind Mode, with positioning

3 - Gate Mode, without positioning

4 - Gate Mode, with positioning

Default settng: 1

Parameter size: 1 [byte]

12. In Venetian

Blindmode

(parameter

10

s·

et

to

2)

the

parameter

determines

time

of

full

turn

of

the

slats

.

In

Gate Mode (parameter 10 set to 3 or 4) the parameter defines the

COUNTDOWN time, i.e. the time period after whi'ch an open gate

starts closing.

In

any other operating mode the parameter value is

irrelevant.

Value of Omeans the gate will not close automatically.

Available settings: 0-65535

(0

-655,35s)

Default setting: 150 (1,5 s)

Parameter size: 2

[bytes]

13.

Set

slats

back

to

previous

positlon.

In Venetian Blind Mode (parameter 10 set to 2) the parameter

influences slats positioning

in

various situations. In any other

operating mode the parameter value is irrelevant.

0 - Slats return to previously set position only in case

of

the

main controller operation.

1 - Slats return to previously set position

in

case ofthe main

controller operation, momentary switch operation, or when the

limit switch

is

reached.

2 - Slats retum to previously set position

in

case ofthe main

controller operation, momentary switch operation, when the limit

switch

is

reached

or

after receiving a "STOP" control frame

(Switch Multilevel Stop).

Default setting: 1

Parameter size: 1

[byte]

14.

Switch

type.

The parameter settings are relevant for Roller Blind Mode and

Venetian Blind Mode (parameter 10 set to

0,

1,

2).

0

~

Momentaryswitches

1 - Toggle switches

2 - Single, momentary switch. (The switch should be connected to

S1

terminal)

Default setting: D

Parameter size: 1

[byte]

17. In

Roller

Blind

Mode

or

Venetian

Blind

mode

(parameter

10

set

to

0,

1, 2)

the

parameter

determines

when

the

Roller

Shutter

relays

are

turned

off

after

reaching

a

limit

switch.

In

Gate Mode (parameter 10 set to 3 or 4) the parameter determines

a time period after which a gate will start closing after a S2 contact

has been disconnected.

In

this mode, time to turn off the Roller

Shutter relays after reaching a limit switch

is

set to 3 seconds and

cannot be modified.

Value of Omeans the gate will note close automatically.

Available Settings: 0 • 255 (0,1-25,5s).

Default setting: 10 (1s).

Parameter size: 1

[byte]

18.

Motoroperation

detection.

Power threshold to be interpreted as reaching a limit switch.

Available settings: O• 255 (1-255 W)

The value of Omeans reachlng a limit switch will not be detected

Default setting: 10 (10W).

Parameter size: 1

[byte]

22.

Motoroperation

time.

Time perlod for the motor to continue operation.

Available settings: O- 65535

(0-

65535s)

The value of Omeans the function

is

disabled.

Default setting: 240 (240s.

-4

minutes)

Parameter size: 2

[bytes]

29.

Forced

Roller

Shutter

callbration.

By modifying the parameters setting from O to 1 a Roller Shutter

enters the calibration mode. The parameter

re

levant only if a Roller

Shutter is set

to

work in positioning mode {parameter 10 set to 1, 2

or4)

.

1 - Start calibration process

Default setting: 0

Parameter size: 1

[byte]

ALARM

SETTINGS:

30

.

Response

to

general alarm

O- No reaction.

1 - Open blind.

2 - Glose blind.

Default setting: 2

Parameter size: 1

[byte]

31.

Response

to

flooding

alarm

0 - No reaction.

1 - Open blind.

2 - Glose blind.

Default setting: 0

Parameter size: 1 [byte)

32.

Response

to

smoke,

CO

or

C02

alarm

0 - No reaction.

1 - Open blind.

2 - Glose blind.

Default setting: 1

Parameter size: 1

[byte]

33.

Response

to

temperature

alarm

0 - No reaction.

1 - Open blind.

2 - Glose blind.

Default setting: 1

Parameter size: 1

[byte]

35.

Managing

slats

in

response

to

alarm

.

In

Venetian Blind Mode (parameter 10 set to 2), the parameter

determines how the slats will react upon alarrn detection.

In

any

other modes, the parameter value

is

not relevant.

0 -

Da

not change slats position - slats return to the last set

position.

1 - Set slats to their extreme position.

Default setting: 1

Parameter size: 1

[byte]

POWER

AND

ENERGY REPORTS SETTINGS:

40.

Power

reports.

Power level change that will result

in

new power value report being

sent. The parameterdefines a change that needs to occur

in

orderto

trigger the report.The value is a percentage ofthe previous report.

Power report threshold available settings: 1-100 (1-100%).

Value of Omeans the reports are turned off.

Oefault setting: 10 (10%).

Parameter size: 1

[byte]

42.

Periodic

power

or

energy

reports.

The parameter defines a time period between consecutive reports.

Available settings: 1-65534 (1-65534 seconds)

Value ofOmeans the reports are turned off.

Default setting: 3600 (3600 seconds / 60 minutes).

Parameter size: 2 [bytes]

43.

Energy

reports.

Energy level change which will result

in

new energy value report

being sent. The parameter defines a change that needs

to

occur ln

order to trigger the

report

Energy threshold available settings: 1-254 (0,01

-2

,54kWh).

Value

of

Omeans the reports are tumed off.

Default setting 10 (0,1kWh).

Parameter size: 1

[byte]

44.

Self

.measureme~t.

A Roller Shutter may include power and energy used by itself in

reports sent to the main controller.

0 - Self-measurement inactive.

1 - Self-measurement active.

Default setting: O

Parameter size: 1

[byte]

SCENES

AND

ASSOCIATIONS SETTINGS:

50. Scenes I

Associatlons

activation

.

Par~me!er determines whether scenes or associations are activated

by the switch keys.

0 - Associations activation

1 - Scenes activation

Default setting: O

Parameter size: 1

[byte]

XIX. GU

ARA

NTEE

1. The Guarantee is provided by FIBAR GROUP S.A. (hereinafter

"Manufacturer"), based in Poznan, ul. Lotnicza

1;

60-421 Poznan,

entered

in

the register

cf

the National Court Register kept

by

the

District Court in Poznari, VIII Economic Department

ofthe

National

Court Register, no. 553265, NIP 7811858097, REGON:

301595664.

2. The Manufacturer is responsible for equipment malfunction

resulting from physical defects (manufacturing or material)

cf

the

Device for 12 months from the date

of

its purchasing.

3. During the Guarantee period, the Manufacturer shall remove

any defects, free

of

charge, by repairing or replacing (at the sole

discretion

of

the Manufacturer) any defective components

cf

the

Device with new or regenerated components that are free

of

defects. When the repair impossible, the Manufacturerreserves the

right

to

replace the device with a new or regenerated one, which

shall

be

free

cf

any defects and its condition shall not be worse than

the original device owned by the Customer.

4. ln special cases, when the device cannot be replaced with the

device

of

the same type (e.g. the device is no langeravailable in the

commercial offer), the Manufacturer may replace it with a different

device having technical parameters similar to the faulty one. Such

activity shall

be

considered as fulfilling the obligations

of

the

Manufacturer. The Manufacturer shall not refund money paid for

the device.

5.

The holder ofa valid guarantee shall submit a guarantee claim

through the guarantee service. Remember: before you submit a

guarantee claim, contact our technical support using telephone or

e-mail. More than 50%

of

operational problems is resolved

remotely, saving time and money spent to initiating guarantee

procedure.

lf

remote support

is

insufficient, the Customer shall fill

the guarantee claim form (using our website -www.fibaro.com) in

orderto obtain claim authorization. When the guarantee claim form

is

submitted correctly, the Customer shall receive the claim

confirmation with a unique number (Return Merchandise

Authorization -RMA).

6.

The claim may

be

also submitted

by

telephone.

In

this case, the

call

is

recorded and the Customer shall

be

informed about it

by

a

consultant before submitting the claim. lmmediately after

submitting the claim, the consultant shall provide the Customerwith

the claim number (RMA-number).

7. When the guarantee claim fom, is submitted correctly, a

representative of the Authorised Guarantee Service (hereinafter

as

"AGS") shall contact the Customer.

8.

Defects revealed within the guarantee period shall be removed

not later than 30 days from the date of delivering the Device to

AGS. The guarantee period shall be extended by the time in which

the Device was kept byAGS.

9.

The faulty device shall

be

provided

by

the Customer with

complete standard equipment and documents proving its

purchase.

10. Parts replaced under the guarantee are the property of the

Manufacturer. The guarantee for all parts replaced

in

the guarantee

proc.ess shall

be

equal to the guarantee period of the original

device. The guarantee period

of

the replaced part shall

not

be

extended.

11. Costs of delivering the faulty device shall

be

borne by the

Customer. For unjustified service calls, the Service may charge the

Customer with travel expenses and handling costs related to the

case.

12. AGS shall not accept a complaint claim only when:

• the Device was misused or the manual was not observed,

• the Device was provided by the Customer incomplete, without

accessories or nameplate,

• itwas determined that the fault was caused by other reasons than

a material or manufacturing defect

of

the Device

• the guarantee document

is

not valid

or

there is no proof of

purchase,

13. The Manufacturer shall not be liable for damages to property

caused by defective device. The Manufacturershall not be liable for

indirect, incidental, special, consequential

or

punitive damages, or

for any damages, including, inter alia, loss of profits, savings, data,

lass

of

benefits, claims by third parties and any property damage or

personal injuries arising from orrelated to the use ofthe Device.

14. The guarantee shall not cover:

• mechanical damages (cracks, fractures, cuts, abrasions, physical

deformations caused by impact, falli[lg or dropping the device or

other object, improper use or not observing the operating manual);

• damages resulting frorn extemal causes, e.g.; flood, storm, fire,

lightning, natural disasters, earthquakes, war, civil disturbance,

force majeure, unforeseen accidents, theft, water damage, liquid

leakage, battery spill, weather conditions, sunlight, sand, moisture,

high or low temperature, air pollution;

• damages caused by malfunctioning software, attack

of

a

computer virus, or by failure to update the software as recommen-

ded by the Manufacturer;

•damag

es

resulting from: surges in the powerand/ortelecommuni-

cation network, irnproper connection to the grid in

~

manner

inconsistent with the operating manual, or from connecting other

devices not recommended by the Manufacturer.

• damages caused by operating or storing the device in extremely

adverse conditions, i.

e.

high humidity, dust, too low (freezing) or too

high ambient ternperature. Detailed permissible conditions for

operating the Device are defined in the operating manual;

• damages caused by using accessories not recommended

by

the

Manufacturer

• damages caused by faulty electrical installation of the Customer,

. including the use of incorrect fuses;

• damages caused by Customer's failure to provide maintenance

and servicing activities defined in the operating manual;

• damages resulting from the use of spurious spare parts or

accessories improper for glven model, repairing and introducing

alterations by unauthorized persons;

• defects caused by operating faulty Device er accessories.

15. The scope

cf

the guarantee repalrs shall not include periodic

maintenance and inspections,

in

particular cleaning, adjustments,

operational checks, correcti

on

of

errors or parameter programming

and other activities that should be performed by the user (Buyer).

The guarantee shall not cover natural wear and tear

of

the Devi

ce

and its components listed in the operating manual and in technical

documentation as such elements have a defined operational life.

16.

lf

a defect is not covered by the guarantee, the Manufacturer

reserves the right to remove such defect

at

its sole discretion,

repairing the damaged or destroyed parts or providing components

necessary for repair or replacement.

17. This guarantee shall not exclude, limit or suspend the Customer

rights when the provided product is inconsistent with the purchase

agreement.

CE:

This

Device

may

be

used

with

all

devices

certified

with

Z-Wave

certificate

and

should

be

compatible

with

such

devices

produced

by

other

manufacturers

.

Any device compatible with 2-Wave may

be

added

to

Fibaro system.

Hereby, Fibar Group S.A. declares that this Fibaro

Roller Shutter 2 is

in

compliance with the essential

requirements and other relevant provisions

of

Directive 1999/5/EC.

FIBARGROUP

FIBARO

In

case of any technical questions contact customer servlce centre

in your country.

www

.

fibaro

.

com