Filtec FT-50 Assembly instructions

Cross Beam

Label Detectors

Installation and Setup Guide for

Models FT-50 and FT-70

3003-0395

Cross Beam Label Detectors

Installation and Setup Guide for Models:

• FT-50

• FT-70

Document 3003-0395

Industrial Dynamics Company, Ltd.

Document 3003-0395 Copyright. All rights reserved.

No part of this publication may be reproduced or used in any form or by any means (graphic,

electronic, or mechanical including photocopying, recording, taping, or information storage

and retrieval system) without written permission of Industrial Dynamics Company, Ltd.

Filtecand Industrial Dynamicsare registered trademarks of Industrial Dynamics Company,

Ltd. All other trademarks are the property of their respective owners.

Contact Information

Corporate Headquarters: 3100 Fujita Street,

Torrance, California

90505-4007

U.S.A.

Telephone:(310) 325-5633

FAX: (310) 530-1000

Internet: www.filtec.com

Mailing Address: P.O. Box 2945,

Torrance, California

90509-2945

U.S.A.

Shipping Address: 3100 Fujita Street,

Torrance, California

90505-4007

U.S.A.

Customer Service: (800) 733-5173

Contents

System Descriptions

................................................

1

Bottle Specifications

................................................

4

Function Descriptions

...............................................

4

InstallationRequirementsand Instructions

..............................

7

SensorMechanical Alignment

........................................

9

SensorCalibration

.................................................

10

FT

-

50 Trigger to Label Detector Center Point Distance

(Label Detector

P/N

22353

only)

......................................

11

Fine Adjustment of Distance (Trigger to Label)

..........................

13

Adjustment of Sensor Look Distance (Label)

...........................

15

Maintenance. Troubleshooting. and Replacement

........................

16

Sensor Assembly Replacement

......................................

19

Drawings and Parts Lists

...........................................

22

Industrial

Dynamics

Company.

Ltd.

Document3003-0395

Industrial

Dynamics

Company,

Ltd. Document 3003-0395

CROSS

BEAM LABEL DETECTORS

P/N

22353

P/N

32769

Kit,

Label Inspection,

Cross

Beam

Kit,

X

-

Beam, Head Mounted

System

Descriptions

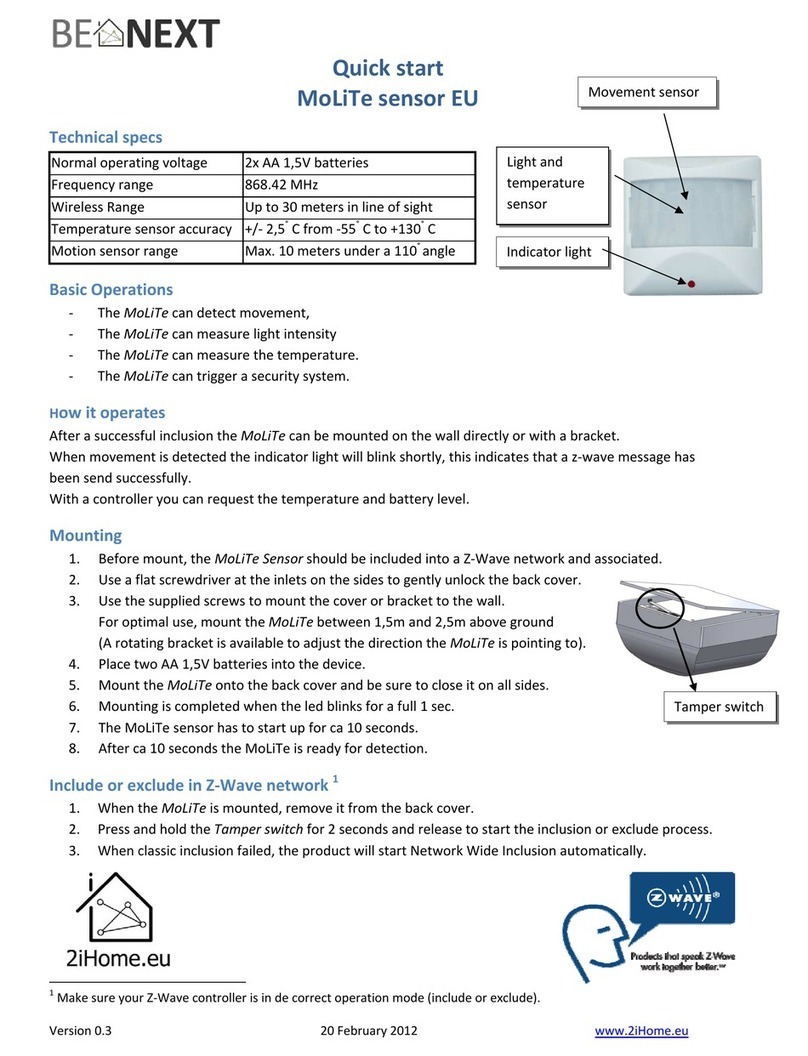

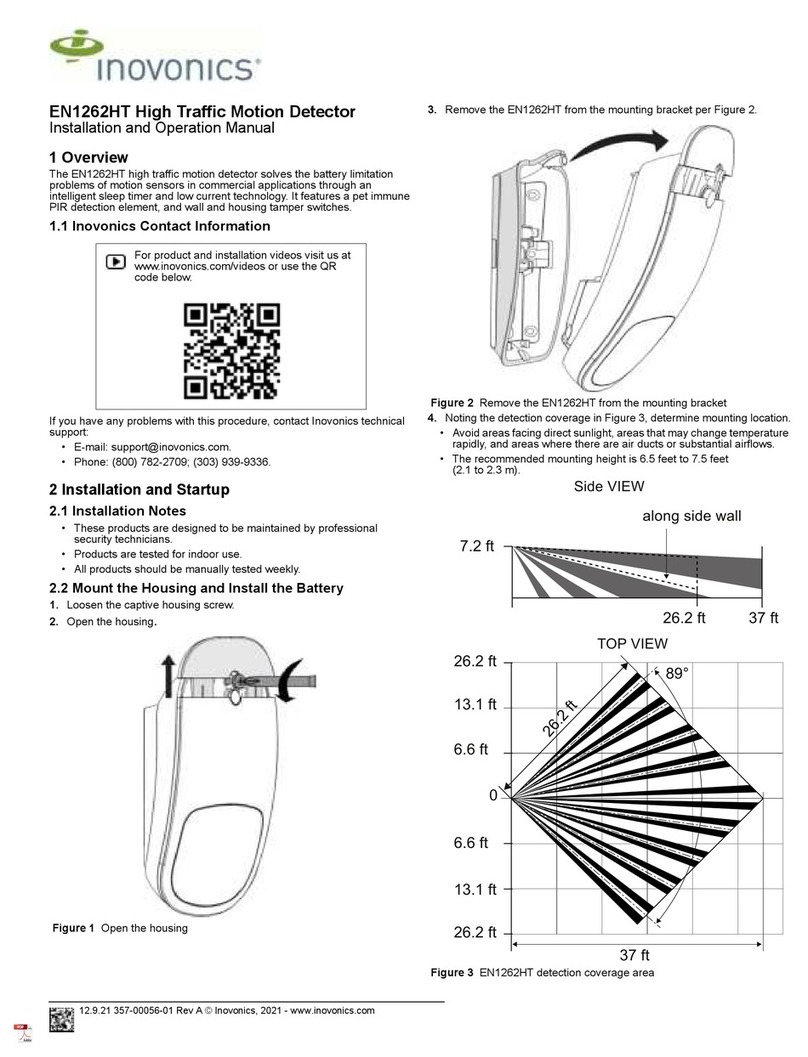

The Cross Beam Label Detector, P/N 22353, (Figure

1),

and the

Head

-

Mounted Cross Beam Label Detector, P/N 32769, (Figure

2),

are optional accessories for the FT

-

50 system. The Cross

Beam Label Detector is mounted on the Kit, Mounting Bracket,

Inspection Station,

P/N

22344. The Head Mounted Cross Beam

Label Detector is mounted on blocks bolted to the FT

-

50's

bottom. Both Label Detectors are operated by the FT

-

50. Both

Label Detectors check bottles that are transparent

to

infrared

radiation for the presence of body labels.

Each Label Detector uses two infrared photoelectric transmitters

and

two

infrared receivers, placed diagonally

at

45°

to

the flow

of bottles on the conveyor. Each transmitter transmits across the

Production Conveyor to its receiver. When

a

liquid

-

filled

transparent unlabeled bottle passes between

a

transmitter and its

receiver, the transmitter's light beam refracts away from the

receiver, except during

a

brief interval when the beam

is

passing

straight through the bottle's centerline.

If

the bottle

has

a

body

label, no infrared light reaches the receiver during this

centerline

interval. Each transmitter

-

receiver

pair

is connected

to

a

Photo Amplifier

(P/N 19140).

Both Label Detectors each

have two Photo Amplifiers; they are located either in the

Inspection Station Electronic Enclosure (Label Detector P/N

22353) or in the

FT

-

50

(Label Detector P/N 32769).

In

the Label

Detector

P/N

22353, the outputs from both Photo Amplifiers are

combined (logically OR’ed) onto

a

single FT

-

50 Sensor input

line. In the Label Detector P/N 32769, each Photo Amplifier

output is connected to

a

separate FT

-

50 Sensor input line. The

FT

-

50 compares the logic state of the Sensor input line (Label

Detector P/N 22353) or the logic state of each of the two Sensor

input lines (Label Detector P/N 32769) to an internal table to

determine if the bottle should be accepted

or

rejected.

Power

(+20 VDC)

and a Ground reference are supplied by the

FT

-

50 Main Terminal Block

TB1,

through the cable connecting

the FT

-

50

to

the Inspection Station JunctionBox.

Both Label Detectors require that

a

High Resolution Encoder

(Assembly

P/N

24997, Installation

Kit

P/N

24444), driven by the

Production Conveyor, be connected

to

the FT

-

50. The High

Resolution Encoder is installed per Installation Drawing I-00425.

The Encoder enables the FT

-

50 to precisely track when each

bottle's centerline is passing through the cross beam measure

-

Industrial Dynamics Company

Ltd. Document 3003-0395

I

ment point.

This

enables the

FT

-

50

to accept only those bottles

with

body labels, instead

of

unlabeled bottles (which would

appear

to

have body labels by being measured early

or late).

Top View

2

Figure

1.

Cross

Beam Label Detector,

P/N

22353

Industrial

Dynamics

Company,

Ltd. Document 3003-0395

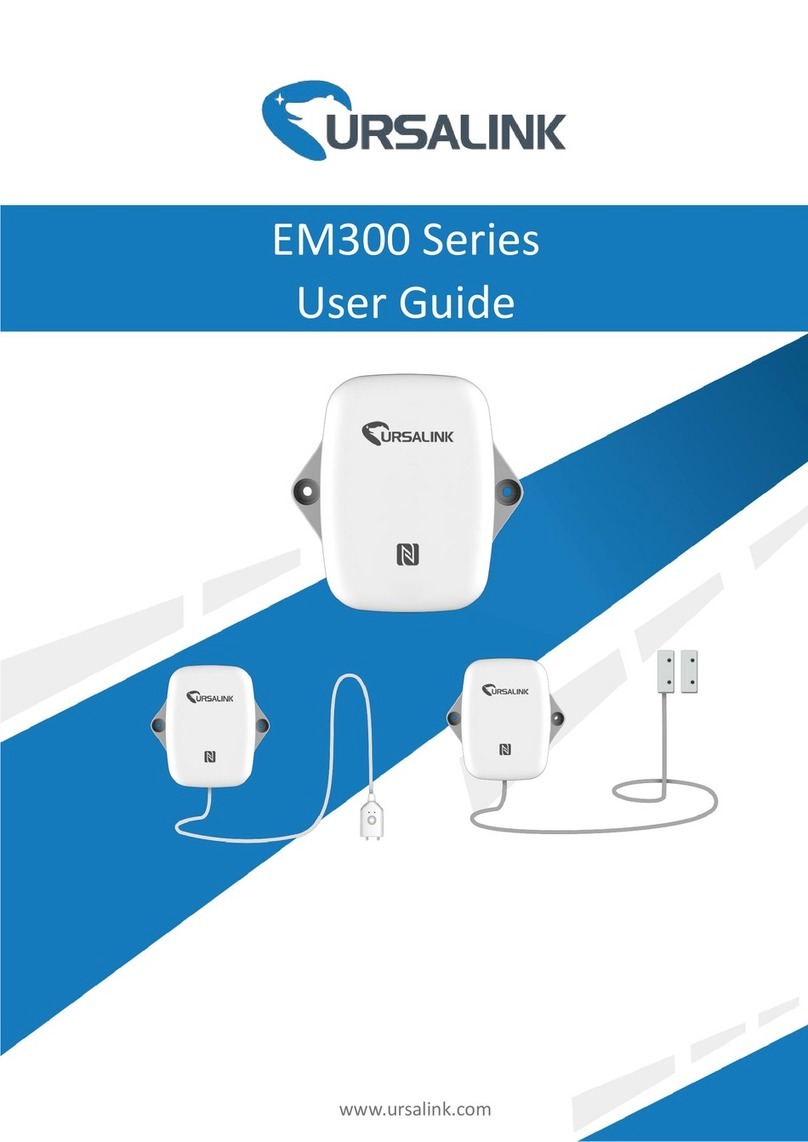

Side View

Isometric

View

Figure

2.

Head

-

Mounted X

-

Beam Label

Detector

P/N

32769

Industrial

Dynamics

Company

Ltd. Document 3003-0395

3

Bottle Specifications

Maximum Bottle Diameter:3.25 inch

(85.0

mm)

Minimum Bottle Spacing:1.00 inch

(25.4

mm)

NOTE

A

minimum

1

inch bottle spacing

on

the Production Conveyor

is

required.

Failure to maintain this spacing may result in

bottles being falsely accepted or rejected.

Function Descriptions

The

FT

-

50

software contains specific functions that define the

inspection parameters for the Label Detector Sensors and

Display, and reset the contents of the Reject Counters. These

functions are:

BOTTLE FINISH

Function Key: MISSING BODY STATUS

TRIGGER TO LABEL (Label Detector

P/N

LOOK DIST LABEL

ADJUST DIST LABEL

22353

only)

COUNTERS

Function Key: TOTAL MISSING BODY

RESET MISSING BODY

LBL

These functions can be either Status functions (displaying output

to the operator), Command functions (accepting input from the

operator, or Status/Command functions (displaying output and

accepting input).

MISSING

BODY

STATUS

-

(STATUS/COMMAND)

Toggles inspection for body labels ON or

OFF.

Enables the

function to be turned ON or OFF

in

both the OPERATE and the

CALIBRATE modes.

(Range: ON or OFF, Default: OFF)

4

Industrial Dynamics Company, Ltd. Document 3003-0395

TRIGGER TO LABEL

-

(STATUS/COMMAND)

The distance, in millimeters, between the center point of the

Inspection Trigger Beam and the center point of the Label

Detector. This distance is used by the processor to establish the

proper timing for label inspection.

For Label Detector P/N 22353, the Default distance is 150

mm,

and

a

user message to enter the measured distance

appears on

the Display.

For Label Detector P/N 32769, the Default distance is 102

mm,

and

a

user message does

not

appear on the Display.

LOOK DlST LABEL

-

(STATUS/COMMAND)

Adjusts the distance, in millimeters, during which the label

sensor output will be evaluated by the processor. This

gate

is

centered

on

the center point of the Label Detector.

(Range: 1

-

25

mm,

Default 12 mm)

ADJUST DlST LABEL

-

(STATUS/COMMAND)

For Label Detector 22353, adjusts the distance set in TRIGGER

TO LABEL, using the

FT

-

50

Display as

a

monitor.

For Label Detector P/N 32769, enables adjustment of the 102

mm default Trigger

to

Label distance.

This function is used in Calibrate Mode. Refer

to

Sensor

Mechanical Alignment

(page 9), and

Sensor Calibration

(page

10).

TOTAL MISSING BODY

-

(STATUS)

Displays the total number

of

containers that failed inspection for

the Body Labels since the last time the counter was reset.

(Range:

0

-

99,999,999)

RESET MISSING BODY

-

(COMMAND)

When selected and executed by pressing either

UP

or

DOWN

arrow key, resets the

TOTAL

MISSING

BODY

Reject counter.

If

the previous count value

is

to

be saved,

it

must be recorded

externally; there is

no

storage for the counter value once

it

is

reset.

Industrial

Dynamics

Company

Ltd. Document 3003-0395

5

LAST REJECT DETECTED

-

(STATUS)

Displays the cause for the last reject.

If

caused by

a

missing

label, the bottom line of the Liquid Crystal Display

shows MISSING BODY. Following either

of

these

messages, there will be up

to

six

numbers (example: MISSING

BODY

-

4,5,6,

1),

corresponding to the number or numbers for

the Sensors which saw

a

label.

ALARM MISSING BODY LBL

-

(STATUS/COMMAND)

Sets the number of consecutive MISSING BODY rejects that

cause an alarm condition. Rejects must be consecutive. Each

good

container that passes through the

FT

-

50

will reset the

Alarm Counter to zero.

(Range:

OFF,

1

-

250,

Default:

OFF)

6

Industrial Dynamics Company,

Ltd. Document 3003-0395

Installation Requirements and Instructions

The X

-

Beam Label Detector

P/N

32769 is already installed as an

integral

part

of the FT

-

50. User installation is not required.

Perform the following steps to install Label Detector

P/N

22353:

1.

Double

-

check the indents of the upstream positioning Guide

Rails.

Measure,

and adjust both Guide Rail indents as

required to

ensure

that

the upstream Guide Rails position

the Production Bottles

exactly

on

the FT

-

50 and Inspection

Station

(P/N

22353

only)

centerline, as shown in Installation

Drawing

1

-

00412.

NOTE

This Guide Rail measurement is

critical

for

proper Label

Detector operation.

Ensure

that the Guide Rails are positioned

correctly.

If,

due to Guide Rail positioning error, the bottles

flow

on

one side

of

the

FT

-

50

and Inspection Station

centerline,

the

Label Detector

P/N

32769

cannot

be adjusted

to operate correctly, and the Inspection Station Vertical Tubes

supporting Label Detector

P/N

22353

must be offset

to

compensate

for

the

error.

CAUTION

Shut down and lock out drive power

to

the Production

Conveyor and Takeaway Conveyor

2. Install the Inspection Station and the wiring from the

Inspection Station‘s JunctionBox to the FT

-

50 per Installation

Drawing 1

-

00399.

Industrial

Dynamics

Company

Ltd. Document 3003-0395

7

NOTE

For best results, the Label Detector centerline should be at

least

18

in. downstream from the outside edge

of

the FT

-

50.

This allows approximately

13

in. working space between

the

FT

-

50 and the Label Detector, should the FT

-

50 require service.

Similarly, the Label Detector centerline should

be

at least

10

in. upstream from the Proline rejector's centerline, to ensure

that bottles have approximately

3

in. clearance from the Label

Detector's outermost edge when they are rejected.

The correct position of the Inspection Station Horizontal and

Vertical Tubes relative

to

the centerlines

of

the Production

Conveyor and bottles, as shown in Installation Drawing

I

-

00399,

is

critical

in determining inspection accuracy. When

installing the Inspection Station:

The Production Bottle's center must be placed exactly

on

the Production Conveyor Centerline, and

The Inspection Station must be installed

so

that the

Centering

Tool's

point

(0,0

point

on

the Horizontal Tube's

scales) is suspended directly over the center of the

Production Bottle's

cap.

2.

Using the Production Bottle on the Production Conveyor's

centerline as

a

reference aid, install the Label Detector

Assembly on the Inspection Station. Position the Label

Detector Assembly approximately

1

in.

(25

-

30

mm) above

the labels to be inspected.

8

Industrial

Dynamics

Company,

Ltd. Document 3003-0395

Sensor Mechanical Alignment

CAUTION

Shut

down and

lock

out

drive power

to

the

Production

Conveyor

and

Takeaway Conveyor prior

to

servicing

Prerequisites from FT-50 Manual

For both Label Detectors

(P/N

22353 and

P/N

32769), ensure

that:

1.

The FT

-

50 Trigger, High Resolution Encoder and Rejector are

set

up

and calibrated per the FT

-

50 Manual, Chapter

2.

2.

The FT

-

50 Container Parameter Table and System Parameter

Settings Table contain the most recent values for the bottle

type to be inspected in the User Defaults and System

Settings memory, per the FT

-

50 Manual, Chapter

2.

Label Detector

P/N

32769 does not require mechanical

alignment.

Perform mechanical alignment of Label Detector

P/N

22353 per

Drawing 22353, Item

7.

Industrial

Dynamics

Company

Ltd. Document 3003-0395

9

Sensor Calibration

CAUTlON

Shut down and lock

out

drive power

to

the Production

Conveyor and Takeaway Conveyor before proceeding.

Perform the following procedures

to

calibrate Label Detector

P/N 22353 and Label Detector P/N 32769. A fully filled

unlabeled Production Bottle is required.

1.

Ensure

that

no bottles are between the Label Detector

Sensors.

2.

a.

For Label Detector P/N 22353, open the Inspection

Station JunctionBox.

b. For Label Detector P/N 32769, remove the

FT

-

50

cover.

3.

Set

each

of

the

two

Amplifier Gain potentiometers fully

counterclockwise (minimum Gain).

4.

Adjust each Amplifier's potentiometer the same amount

clockwise until each LED flashes steadily.

5.

Place the filled unlabeled Test Bottle exactly on the FT

-

50

and Inspection Station (P/N 22353 only) centerline.

6.

Verify that both LEDs flash

at

the same time and

at

the same

rate.

If

not:

a.

For Label Detector

P/N

22353

1.

Verify that the FT

-

50, the Inspection Station, and the

Test Bottle are

all

on the Production Conveyor

centerline.

2. Verify

that

the Label Detector is symmetrically

positioned about the centerline.

3.

Perform

steps

5. and 6. again.

If

the

LEDs

still

do

not

blink

at

the same rate, contact

IDC

Customer Service.

b.

For

Label Detector P/N 32769, contact

IDC

Customer

Service.

10

Industrial

Dynamics

Company,

Ltd. Document 3003-0395

7.

a.

For Label Detector P/N 22353, close the Inspection

Station JunctionBox.

b.

For

Label Detector P/N

32769,

install the FT

-

50 cover.

FT

-

50 Trigger to Label Detector Center Point Distance

(Label Detector P/N 22353 only)

Activate Label Logic

Perform the following procedures for Label Detector P/N 22353

only:

NOTE

The Production and Takeaway Conveyors

are

still shut

down and locked out.

If other Label Detectors

on

the Inspection Station

Mounting Bracket Kit require alignment and calibration

(example: Crossbeam Label Detector), perform their set

-

up

before proceeding.

1.

Press the BOTTLE FINISH function key repeatedly until

the Display's

top

line shows MISSING BODY STATUS.

2. Press the UP

or DOWN arrow keys

as

required until the

Display's bottom line shows ON.

The Radioisotope Source Manual Shutter Rod MUST be

pushed into the FT

-

50

(NO

Red Paint Shows) BEFORE

Inserting Hands

Into

Inspection Tunnel. Failure

to

Comply

Will Result in Radiation Exposure.

NOTE

If the

Label Detector

P/N

22353

is

the

first

Label Detector

to

be set up

on

this Inspection Station, then perform this

procedure.

If

not,

go

to

Fine Adjustment

of

Distance

(Trigger

to

Label)

(page

13).

The distance from the FT

-

50 Trigger to the Label Detector

center point is the initial approximation

of

the Trigger to

Label Distance.

Industrial

Dynamics

Company

Ltd. Document 3003-0395

11

CAUTION

1.

Measure the distance in millimeters from the FT

-

50 Trigger

Beam to the Centering

Tool's

point (Label Detector center

point); note the value.

2.

Press the BOTTLE FINISH function key until the Display's

top line shows INSP TRIG TO LABEL.

3.

Press the

UP

or

DOWN arrow keys as necessary until the

Display's bottom line shows the distance from the FT

-

50

Inspection Trigger Beam to the Label Detector center point in

millimeters.

4.

When measurement

is

complete, pull out the Radioisotope

Source Manual Shutter

Rod.

12

Industrial

Dynamics

Company,

Ltd. Document 3003-0395

Fine Adjustment

of

Distance (Trigger to Label)

For both Label Detector models, perform the following

procedure:

1.

Remove the Production and the Takeaway Conveyor lock

-

outs and energize the Conveyors. Allow Production Bottles

to flow past the FT

-

50 and the Inspection Station.

2.

Press the

BOTTLE

FINISH function key until the Display

shows ADJUSTDISTNCE LABEL. The bottom line shows

EXECUTE.

3.

Press the

UP

or DOWN arrow keys as necessary until the

Display shows:

NOTE

The first

two

messages are displayed for approximately

four

seconds each.

"

Run

only

'one' container

at

a

time

"

means

run

only one

type

of

container

at

a

time.

Normal

Production Bottles are acceptable for this procedure.

The last message

is

a

prompt which waits

for

the Sensor

number

(1

or

2)

to be entered.

For Label Detector

22353,

enter

1.

For Label Detector

32769,

enter

1

or

2.

4.

Press the

UP

or

DOWN

arrow keys until the Display's

bottom

line shows

1.

Industrial

Dynamics

Company

Ltd. Document 3003-0395

13

5.

The Display changes to:

6.

Observe the Display for one

of

the following four possible

patterns:

a. The Distance (Trigger to Label) is correct:

(Ideal display

-

no

pattern)

(Acceptable display

-

small pattern around center)

b. The Distance (Trigger

to

Label)

is

too short:

c. The Distance (Trigger to Label)

is

too

long:

7.

Determine

if

the Distance (Trigger to Label) is set correctly

and

adjust as necessary:

a.

Observe the Display as bottles pass through the Label

Detector. Note the bottles' pattern on the display.

b.

If

the bottles' pattern is centered, the Distance (Trigger

to

Label)

is

correct.

c.

If

the bottles' pattern

is

located

to

the left, press the

UP

arrow key to

center the pattern.

d.

If

the bottles' pattern

is

located

to

the right, press the

DOWN arrow key to center the pattern.

NOTE

When

the

average distance

is

changed using the

UP

or

DOWN

Arrowkeys, the Display's bottom line will change to

"

LABEL

DIST

=

nnn

MM

"

,

where

"

nnn

"

is the current changed

value, and

"

MM

"

is

the unit (millimeters).

14

Industrial

Dynamics

Company.

Ltd. Document 3003-0395

8.

Press the DIAGNOSTICS key to

exit

the ADJUST

DISTNCE LABEL function. The Display shows:

9.

a.

For

Label Detector P/N 22353, go to

Adjustment

of

Sensor

Look

Distance (Label)

below.

b.

For

Label Detector P/N 32769, return to Step

1.

to test

and adjust Sensor

2.

Adjustment

of

Sensor

Look

Distance (Label)

For

both model Label Detectors, perform the following

procedure with the Production Conveyor moving, but with

no

bottles passing through the Label Detector:

1.

Press the BOTTLE FINISH function key

until

the Display

shows LOOK DIST LABEL,

or

the particular

text

assigned

to

this

FT

-

50.

2. Press the

UP

or

DOWN arrow keys until the Display's

bottom line shows

12.

3.

Insert one

good

(labelled) Production Bottle and one

missing (Body) label

Production Bottle onto the Production

Conveyor upstream

of

the bottle positioning guide rails.

If

the good bottle is accepted and the missing label bottle

is

rejected, the Look Distance function

is

correct.

If

not, adjust

the FT

-

50

a.

For Production Bottles

of

less than

50

mm

diameter,

press the

UP

or

DOWN arrow keys

to

decrease the

value shown on the Display's bottom line by

1

(mm).

b. For Production Bottles greater than 50 mm Diameter,

press the

UP

or

DOWN arrow keys to increase the

value shown on the Display's bottom line by

1

(mm).

4.

Repeat step 3.

until

the good bottle

is

accepted and the

missing label bottle

is

rejected.

If

the value

of

the

Look

Distance (Label) function decreased

to

1

mm

or increased to

25

mm,

contact the Industrial Dynamics' Customer Service

Department.

Industrial

Dynamics

Company

Ltd. Document 3003-0395

15

Other manuals for FT-50

3

This manual suits for next models

1

Table of contents

Other Filtec Security Sensor manuals

Popular Security Sensor manuals by other brands

LUXOMAT

LUXOMAT PD4-M-DALI/DSI-1C-FC Installation and operating instruction

Magnum Innovations

Magnum Innovations M EOSW Series manual

SSS Siedle

SSS Siedle BMM 611-0 Product information

Satel

Satel AQUA manual

Honeywell

Honeywell Satronic IRD 1010 manual

Bircher Reglomat

Bircher Reglomat Jupiter operating instructions

System Sensor

System Sensor InnovAir DH100ACDCI Installation and maintenance instructions

Rotech

Rotech FJC-DL001 user manual

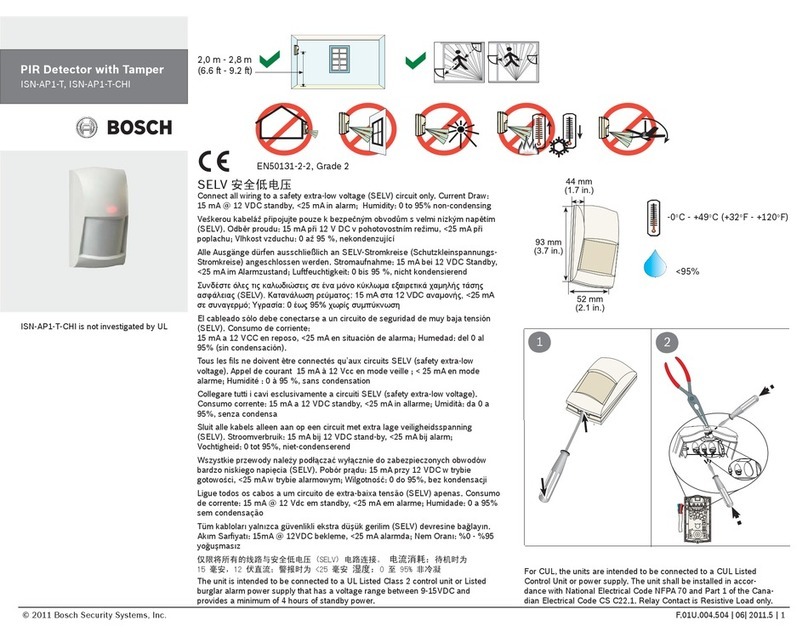

Bosch

Bosch ISN-AP1-T installation guide

Dalsa

Dalsa Rad-icon 1520 user manual

HD Electric

HD Electric V-WATCH Operating instructions manual

Conrad Electronic

Conrad Electronic 182622 operating instructions