Page 7

Informaon About the Sprayer

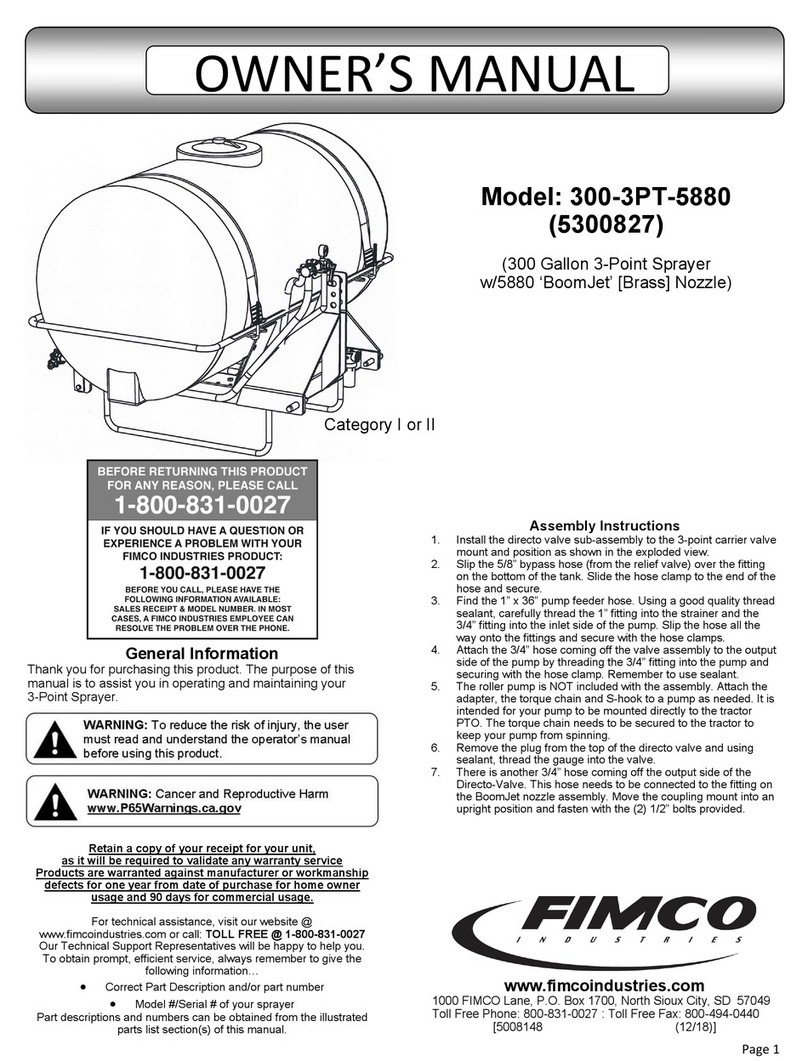

Roller pumps are posive displacement pumps, which means that the enre soluon being pumped must go somewhere or the

pump will break. In this roller pumping system, soluon is drawn from the tank and forced to a planned source, such as boom

nozzles or handgun. The pressure is controlled by a pressure relief valve, which is a spring-loaded device that controls the amount

of uid bypassed (recirculated) to the tank. The gray handle is to be ghtened to increase pressure and loosened to decrease

pressure. The ‘directo-valve’ is the on/o control which allows the operator to manually control the soluon going to the boom.

Tesng the Sprayer

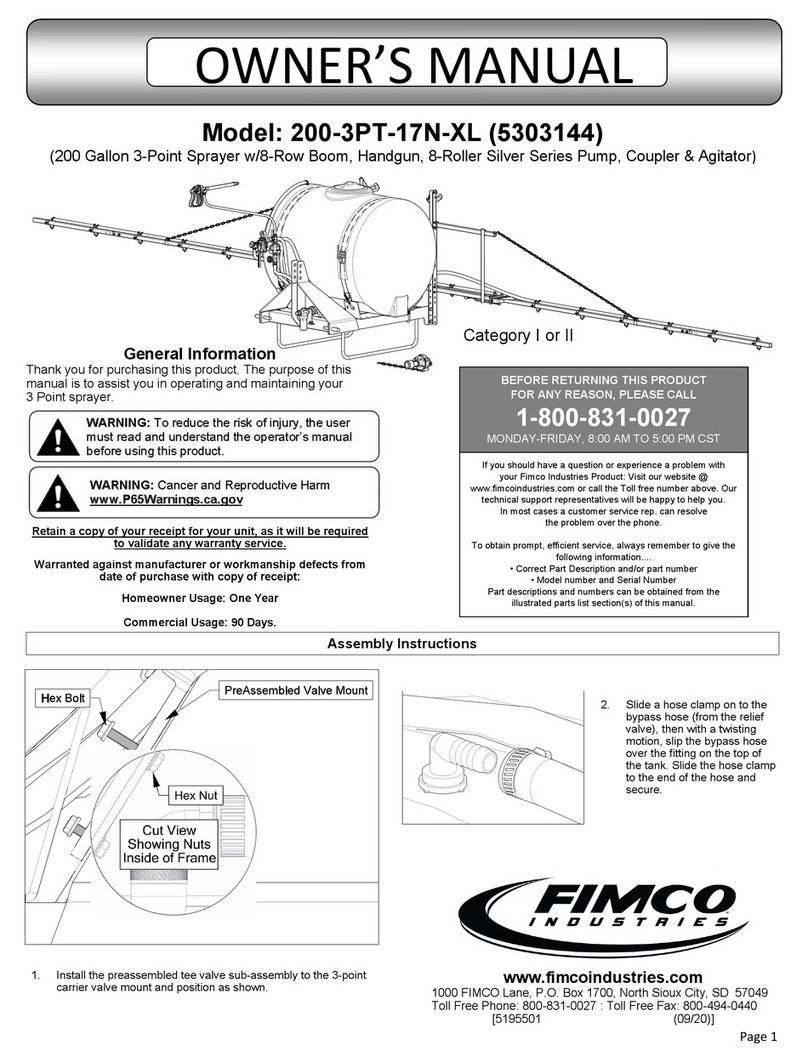

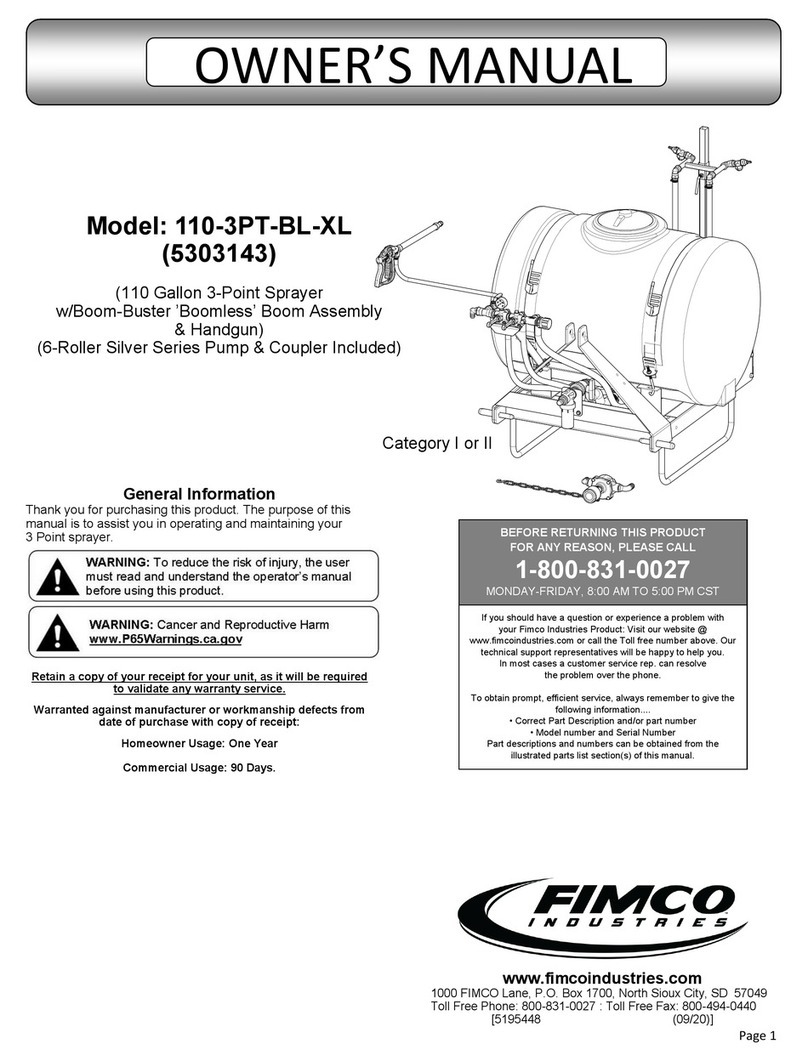

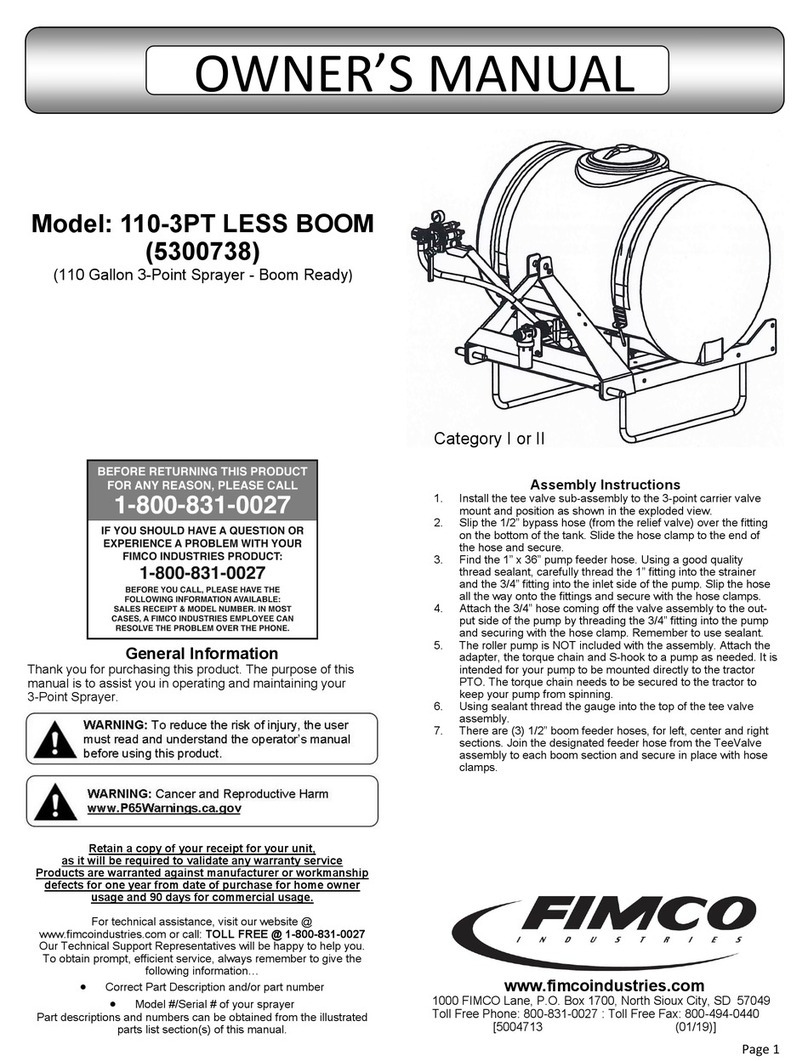

Aach the sprayer to the tractor 3 point hitch. Mount the pump to the PTO and ax the torque chain. Open the tank lid and be

sure the tank is clean and free of foreign material.

NOTE: It is VERY important to test the sprayer with plain water before actual spraying is aempted. This will enable you to check

for leaks without the possibility of losing any expensive chemicals.

Fill the tank about 1/2 full with plain water.

Before starng, open the sucon line valve (located underneath the

carrier frame), turn the relief valve handle out to lower the line pressure.

This will help prime the pump.

CAUTION:

Always be sure that the water (or soluon) has reached the pump before starng your sprayer. If the pump is allowed to run dry,

serious damage to the pump will result.

Always have the pressure line open to the ps so that the air which may be trapped in the line will be forced (or purged) out.

Start the tractor PTO. Check the enre system for leaks. Once the pump is primed, the pressure may be increased by turning the

handle of the pressure relief valve in. Keep the pressure line open to the ps when seng the pressure. Set the pressure and then

lock the relief valve handle in place. Shut o the directo-valve and check for leaks again. Pressure will increase when the pressure

line valve is closed and then return to the preset pressure when the valve is opened again.

During the tesng period, be sure to observe the spray paern given by the spray nozzles. If there is any paern distoron, it will

be necessary to remove and clean the aected ps.

Cauon: Never use a metal object or other sharp item for cleaning a nozzle p. It is beer to use a nozzle brush (NOT wire brush)

or compressed air for p cleaning.

Condions of weather and terrain must be considered when seng the sprayer. Do not spray on windy days. Protecve clothing

must be worn in some cases

Be sure to read the chemical label(s) before applicaon!

Operaon & Calibraon

The performance of any agricultural chemical depends upon the proper applicaon.

The ps supplied as standard with the sprayer can be used for a wide variety of spraying applicaons. Other p sizes are available

for dierent coverages. The speed and pressure charts shown indicate the rates can be changed considerably by changing speed

and pressure. The pumping system draws soluon from the tank through the strainer/lter and to the pump. The pump forces the

soluon under pressure to the boom nozzles.

WARNING: Some chemicals will damage the pump valves if allowed to soak untreated for a length of me! ALWAYS ush the

pump as instructed aer each use. DO NOT allow chemicals to sit in the pump for extended mes of idleness. Follow the chemical

manufacturer’s instrucons on disposal of all waste water from the sprayer.

When you are ready to spray, mix chemicals as follows. Add the proper amount of water to the tank.

Only ll the tank with what you’re going to spray in a day, never leave chemicals sit in tank.

Run the sprayer while adding chemical to the water. Do NOT spray through the boom at this me. This will allow the soluon to

return (‘bypass’) to the tank. The movement of soluon through the bypass will aid in mixing the water and chemicals. If this water

movement is not enough to keep the chemical in suspension, it may be necessary to add an oponal agitator kit. You should now

be ready to spray.