Fimer TT165 AC/DC User manual

Instruction Manual

TT165 AC/DC - TT205 AC/DC

TT165 AC/DC - TT205 AC/DC

Istruzioni Originali

Original instructions

Übersetzung der Originalbetriebsanleitung

Notice originale

Manual original

20050 RONCO BRIANTINO (MI) Italy

Via Brigatti, 59

Tel. +39 039 6079326 - Fax. +39 039 6079334

www.fimer.com - info@fimer.com

TT165 AC/DC - TT205 AC/DC

1

2

3

4

14

7

5

15

6

16

17

18

19

10

812 13

911

ITALIANO ENGLISH DEUTSCH FRANÇAIS ES AÑOL

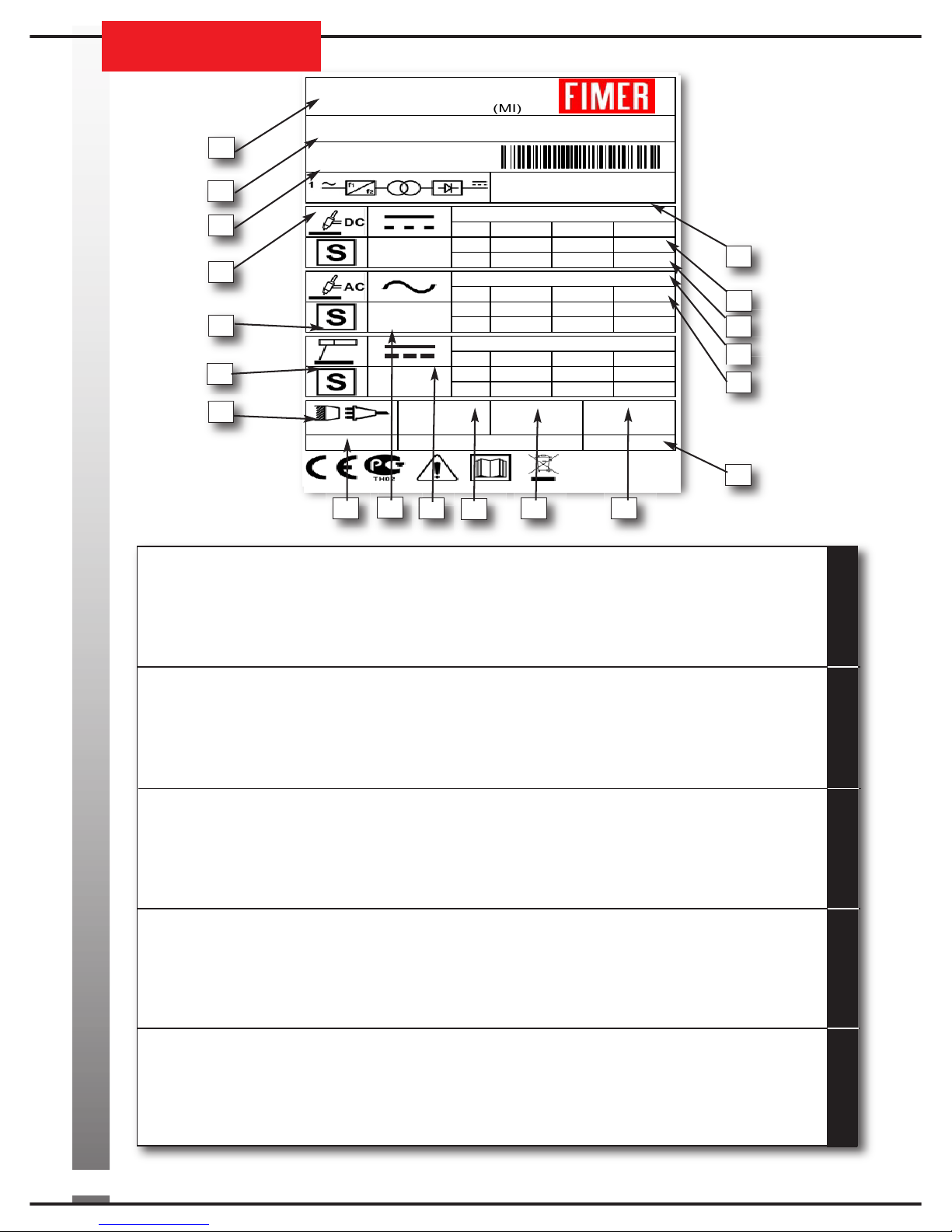

1. NOME, INDIRIZZO E LOGO COSTRUTTORE

2. MODELLO

3. NUMERO DI SERIE

4. SCHEMA BLOCCHI

5. USCITA DI SALDATURA

6. UTILIZZABILE IN AMBIENTE

A MAGGIOR RISCHIO DI SCOSSA ELETTRICA

7. ALIMENTAZIONE

8. GRADO DI ROTEZIONE

9. TI O DI CORRENTE DI SALDATURA

10. TENSIONE NOMINALE A VUOTO

11. TENSIONE NOMINALE DI ALIMENTAZIONE

12. MASSIMA CORRENTE NOMINALE DI ALIMENTAZIONE

13. MASSIMA CORRENTE EFFETTIVA DI ALIMENTAZIONE

14. NORME DI RODOTTO

15. RANGE CORRENTE TENSIONE DI SALDATURA

16. CICLO DI INTERMITTENZA

17. CORRENTE NOMINALE DI SALDATURA

18. TENSIONE CONVENZIONALE DI CARICO

19. ANNO DI FABBRICAZIONE

1. MANUFACTURER’S NAME,

ADRESS AND COM ANY LOGO

2. MODEL

3. SERIAL NUMBER

4. BLOCK DIAGRAM

5. WELDING OUT UT

6. SUITABLE FOR USE IN HIGH-VOLTAGE AREAS

7. OWER SU LY

8. DEGREE OF ROTECTION

9. TY E OF WELDING OUT UT CURRENT

10. IN UT VOLTAGE

11. RATED IN UT VOLTAGE

12. MAXIMUM RATED IN UT CURRENT

13. MAXIMUM EFFECTIVE IN UT CURRENT

14. A LICABLE STANDARDS

15. RANGE OF WELDING VOLTAGE-CURRENT

16. DUTY CYCLE

17. RATED WELDING CURRENT

18. CONVENTIONAL LOAD VOLTAGE

19. YEAR OF CONSTRUCTION

1. NOM, ADRESSE ET LOGO CONSTRUCTEUR

2. MODELE

3. NUMERO DE SERIE

4. SCHEMA FONCTIONNEL

5. SORTIE DE SOUDURE

6. UTILISABLE EN MILIEU À RISQUE D’ELECTRIFICATION

ÉLEVÉE

7. ALIMENTATION

8. DEGRE DE ROTECTION

9. TY E DE COURANT DE SOUDAGE

10. TENSION NOMINALE A VIDE

11. TENSION NOMINALE D’ALIMENTATION

12. COURANT NOMINAL D’ALIMENTATION MAXIMUM

13. COURANT EFFECTIF D’ALIMENTATION MAXIMUM

14. NORMES DE RODUIT

15. LAGE DE COURANT/TENSION DE SOUDAGE

16. CYCLE INTERMITTENT

17. COURANT NOMINAL DE SOUDAGE

18. TENSION CONVENTIONNELLE DE CHARGE

19. ANNÉE DE RODUCTION

1. NOMBRE, DIRECCIÓN Y LOGOTI O DEL FABRICANTE

2. MODELO

3. NÚMERO DE SERIE

4. ESQUEMA BLOQUES

5. SALIDA DE SOLDADURA

6. SE UEDE UTILIZAR EN AMBIENTES CON MAYOR

RIESGO DE DESCARGAS ELÉCTRICAS

7. ALIMENTACIÓN

8. GRADO DE ROTECCIÓN

9. TI O DE CORRIENTE DE SOLDADURA

10. TENSIÓN NOMINAL EN VACÍO

11. TENSIÓN NOMINAL DE ALIMENTACIÓN

12. MÁXIMA CORRIENTE NOMINAL DE ALIMENTACIÓN

13. MÁXIMA CORRIENTE EFECTIVA DE ALIMENTACIÓN

14. NORMAS DE RODUCTO

15. ÁMBITO DE LA CORRIENTE DE TENSIÓN DE SOLDADURA

16. CICLO DE INTERMITENCIA

17. CORRIENTE NOMINAL DE SOLDADURA

18. TENSIÓN CONVENCIONAL DE CARGA

19. AÑO DE FABRICACIÓN

1. NAME, ADRESSE UND LOGO DES HERSTELLERS

2. MODELL

3. SERIENNUMMER

4. BLOCKSCHALTBILD

5. SCHWEISSAUSGANG

6. IN UMGEBUNG MIT HÖHERER

STROMSCHLAGGEFAHR VERWENDBAR

7. S EISUNG

8. SCHUTZART

9. SCHWEISSSTROMTY

10. LEERLAUFNENNS ANNUNG

11. NENNS EISES ANNUNG

12. HÖCHSTER NENNS EISESTROM

13. HÖCHSTER EFFEKTIVER S EISESTROM

14. RODUKTNORMEN

15. SCHWEISSS ANNUNGSSTROMBEREICH

16. AUSSETZBETRIEB

17. SCHWEISSNENNSTROM

18. KONVENTIONELLE LASTS ANNUNG

19. BAUJAHR

TARGA DATI, NOMINAL DATA, LEISTUNGSCHILDER LAQUE DON

TARGA DATI, NOMINAL DATA, LEISTUNGSCHILDER LAQUE DONÉ

ÉES, LACA DE CARACTER

ES, LACA DE CARACTERÌ

ÌSTICAS

STICAS

VI

Fimer SpA

Via Brigatti, 59

20050 Ronco Briantino

I)

TT 165 AC/DC

Serial Number :

090775305

EN.60974-1

EN.60974-10

Model :

V0=85V

da 5A / 10,2V a 165A / 16,6V

X

I2

U2

35%

165A

16,6V

60%

165A

16,6V

100%

140A

15,6V

V0=85V

da 5A / 10,2V a 165A / 16,6V

X

I2

U2

35%

165A

16,6V

60%

165A

16,6V

100%

130A

15,2V

V0=85V

da 5A / 20,2V a 112A / 24,48V

X

I2

U2

35%

112A

24,48V

60%

112A

24,48V

100%

93A

23,72V

MADE IN ITALY

1 - 50/60 Hz

V1=230V

I1max=18,5A

I1ass=14,8A

IP 21S 2009

TT 165 AC/DC

ESO:

DIMENSIONI:

CARATTERISTICA STATICA:

DIS OSITIVO DI ROTEZIONE DI RETE:

TENSIONE DI INGRESSO:

ROTEZIONE TERMICA:

TEM . INTERVENTO:

Le prove di riscaldamento sono state effettuate alla temperatura di 40°

FUNZIONE ARC FORCE E ANTI-STICKING:

DIAMETRI DEGLI ELETTRODI UTILIZZABILI:

WEIGHT:

DIMENSIONS:

STATIC CHARACTERISTIC:

OWER SU LY ROTECTION:

IN UT LOAD:

THERMAL ROTECTION:

INTERVENTION TEM ERATURE:

Overheating tests run at 40° C

ARC FORCE AND ANTI-STICKING FUNCTIONS:

MAX ELECTRODE DIAMETERS:

GEWICHT:

ABMESSUNGEN:

STATISCHE EIGENSCHAFTEN:

NETZSCHUTZVORRICHTUNG:

EINGANGSS ANNUNG :

WÄRMESCHUTZ:

EINSATZTEM ERATUR:

Die Erhitzungsprüfungen wurden bei einer Temperatur in Höhe von 40° durchgeführt

ARC FORCE UND ANTISTICKING FUNKTION:

VERWENDBARE ELEKTRODENDURCHMESSER:

OIDS:

DIMENSIONS:

CARACTÉRISTIQUE STATIQUE :

DIS OSITIF DE ROTECTION DE RÉSEAU :

TENSION D’ENTREE :

ROTECTION THERMIQUE :

TEM . INTERVENTION :

Les essais de chauffe ont été effectués à la température de 40°

FONCTION ARC FORCE ET ANTICOLLANT :

DIAMETRES DES ELECTRODES UTILISABLES :

ESO:

DIMENSIONES:

CARACTERÍSTICA ESTÁTICA :

DIS OSITIVO DE ROTECCIÓN DE RED :

TENSIÓN DE ENTRADA:

ROTECCIÓN TÉRMICA :

TEM . INTERVENCIÓN :

Las pruebas de calentamiento se han realizado con una temperatura de 40 ºC.

FUNCIÓN FUERZA ARC Y ANTISTICKING :

DIÁMETROS DE LOS ELECTRODOS UTILIZABLES :

ITALIANO ENGLISH DEUTSCH FRANÇAIS ES AÑOL

ALTRI DATI TECNICI

ALTRI DATI TECNICI

ADDITIONAL TECHNICAL INFORMATION

ADDITIONAL TECHNICAL INFORMATION

WEITERE TECHNISCHE DATEN

WEITERE TECHNISCHE DATEN

CARACTERISTIQUES TECHNIQUES

CARACTERISTIQUES TECHNIQUES

OTROS DATOS TÉCNICOS

OTROS DATOS TÉCNICOS

13.8 g.

270x600x450

cadente

230V +/- 30%

termostato tipo “thermic SO1”

Fusibili 20A Ritardati

Int. Bipolari: 20A Curva o C

13.8 g.

270x600x450

drooping

230V +/- 30%

Thermostat : “Thermic SO1”

20A Delay-Fuses

Two-Pole 20A - or C-Standard Switch

13.8 g.

270x600x450

fallend

230V +/- 30%

Thermostat Typ „thermic SO1”

verzögerte 20A Sicherungen

Int. zweipolig: 20A - oder C- urve

13.8 g.

270x600x450

cadente

230V +/- 30%

Thermostat type “thermic SO1”

Fusées Retardées 20A

Int. Bipolaires 20A Courbe o C

13.8 g.

270x600x450

cadente

230V +/- 30%

termostato tipo “thermic SO1”

Fusibles 20A Retardados

Int. Bipolares: 20A Curva o C

VII

TECHNICA SPECIFICATION

TECHNICA SPECIFICATION

TECHNISCHE SPEZIFIKATIONEN

TECHNISCHE SPEZIFIKATIONEN

SPÉCIFICATIONS TECHNIQUES

SPÉCIFICATIONS TECHNIQUES

ESPECIFICACIONES TÉCNICAS

ESPECIFICACIONES TÉCNICAS

SPECIFICHE TECNICHE

SPECIFICHE TECNICHE

Ø 1.5-3.25/4.0

Ø 1.5-3.25/4.0

Ø 1.5-3.25/4.0

Ø 1.5-3.25/4.0

Ø 1.5-3.25/4.0

1

2

3

4

14

7

5

15

6

16

17

18

19

10

812 13

911

ITALIANO ENGLISH DEUTSCH FRANÇAIS ES AÑOL

1. NOME, INDIRIZZO E LOGO COSTRUTTORE

2. MODELLO

3. NUMERO DI SERIE

4. SCHEMA BLOCCHI

5. USCITA DI SALDATURA

6. UTILIZZABILE IN AMBIENTE

A MAGGIOR RISCHIO DI SCOSSA ELETTRICA

7. ALIMENTAZIONE

8. GRADO DI ROTEZIONE

9. TI O DI CORRENTE DI SALDATURA

10. TENSIONE NOMINALE A VUOTO

11. TENSIONE NOMINALE DI ALIMENTAZIONE

12. MASSIMA CORRENTE NOMINALE DI ALIMENTAZIONE

13. MASSIMA CORRENTE EFFETTIVA DI ALIMENTAZIONE

14. NORME DI RODOTTO

15. RANGE CORRENTE TENSIONE DI SALDATURA

16. CICLO DI INTERMITTENZA

17. CORRENTE NOMINALE DI SALDATURA

18. TENSIONE CONVENZIONALE DI CARICO

19. ANNO DI FABBRICAZIONE

1. MANUFACTURER’S NAME,

ADRESS AND COM ANY LOGO

2. MODEL

3. SERIAL NUMBER

4. BLOCK DIAGRAM

5. WELDING OUT UT

6. SUITABLE FOR USE IN HIGH-VOLTAGE AREAS

7. OWER SU LY

8. DEGREE OF ROTECTION

9. TY E OF WELDING OUT UT CURRENT

10. IN UT VOLTAGE

11. RATED IN UT VOLTAGE

12. MAXIMUM RATED IN UT CURRENT

13. MAXIMUM EFFECTIVE IN UT CURRENT

14. A LICABLE STANDARDS

15. RANGE OF WELDING VOLTAGE-CURRENT

16. DUTY CYCLE

17. RATED WELDING CURRENT

18. CONVENTIONAL LOAD VOLTAGE

19. YEAR OF CONSTRUCTION

1. NOM, ADRESSE ET LOGO CONSTRUCTEUR

2. MODELE

3. NUMERO DE SERIE

4. SCHEMA FONCTIONNEL

5. SORTIE DE SOUDURE

6. UTILISABLE EN MILIEU À RISQUE D’ELECTRIFICATION

ÉLEVÉE

7. ALIMENTATION

8. DEGRE DE ROTECTION

9. TY E DE COURANT DE SOUDAGE

10. TENSION NOMINALE A VIDE

11. TENSION NOMINALE D’ALIMENTATION

12. COURANT NOMINAL D’ALIMENTATION MAXIMUM

13. COURANT EFFECTIF D’ALIMENTATION MAXIMUM

14. NORMES DE RODUIT

15. LAGE DE COURANT/TENSION DE SOUDAGE

16. CYCLE INTERMITTENT

17. COURANT NOMINAL DE SOUDAGE

18. TENSION CONVENTIONNELLE DE CHARGE

19. ANNÉE DE RODUCTION

1. NOMBRE, DIRECCIÓN Y LOGOTI O DEL FABRICANTE

2. MODELO

3. NÚMERO DE SERIE

4. ESQUEMA BLOQUES

5. SALIDA DE SOLDADURA

6. SE UEDE UTILIZAR EN AMBIENTES CON MAYOR

RIESGO DE DESCARGAS ELÉCTRICAS

7. ALIMENTACIÓN

8. GRADO DE ROTECCIÓN

9. TI O DE CORRIENTE DE SOLDADURA

10. TENSIÓN NOMINAL EN VACÍO

11. TENSIÓN NOMINAL DE ALIMENTACIÓN

12. MÁXIMA CORRIENTE NOMINAL DE ALIMENTACIÓN

13. MÁXIMA CORRIENTE EFECTIVA DE ALIMENTACIÓN

14. NORMAS DE RODUCTO

15. ÁMBITO DE LA CORRIENTE DE TENSIÓN DE SOLDADURA

16. CICLO DE INTERMITENCIA

17. CORRIENTE NOMINAL DE SOLDADURA

18. TENSIÓN CONVENCIONAL DE CARGA

19. AÑO DE FABRICACIÓN

1. NAME, ADRESSE UND LOGO DES HERSTELLERS

2. MODELL

3. SERIENNUMMER

4. BLOCKSCHALTBILD

5. SCHWEISSAUSGANG

6. IN UMGEBUNG MIT HÖHERER

STROMSCHLAGGEFAHR VERWENDBAR

7. S EISUNG

8. SCHUTZART

9. SCHWEISSSTROMTY

10. LEERLAUFNENNS ANNUNG

11. NENNS EISES ANNUNG

12. HÖCHSTER NENNS EISESTROM

13. HÖCHSTER EFFEKTIVER S EISESTROM

14. RODUKTNORMEN

15. SCHWEISSS ANNUNGSSTROMBEREICH

16. AUSSETZBETRIEB

17. SCHWEISSNENNSTROM

18. KONVENTIONELLE LASTS ANNUNG

19. BAUJAHR

TARGA DATI, NOMINAL DATA, LEISTUNGSCHILDER LAQUE DON

TARGA DATI, NOMINAL DATA, LEISTUNGSCHILDER LAQUE DONÉ

ÉES, LACA DE CARACTER

ES, LACA DE CARACTERÌ

ÌSTICAS

STICAS

VIII

Fimer SpA

Via Brigatti, 59

20050 Ronco Briantino

I)

TT 205 AC/DC

Serial Number :

090775305

EN.60974-1

EN.60974-10

Model :

V0=85V

da 5A / 10,2V a 200A / 18V

X

I2

U2

35%

200A

18V

60%

175A

17V

100%

145A

15,8V

V0=85V

da 5A / 10,2V a 200A / 18V

X

I2

U2

35%

200A

18V

60%

180A

17,2V

100%

155A

16,2V

V0=85V

da 5A / 20,2V a 140A / 25,6V

X

I2

U2

35%

140A

25,6V

60%

115A

24,6V

100%

100A

24V

MADE IN ITALY

1 - 50/60 Hz

V1=230V I1max=26,6A

I1ass=17,2A

IP 21S 2009

TT 205 AC/DC

ESO:

DIMENSIONI:

CARATTERISTICA STATICA:

DIS OSITIVO DI ROTEZIONE DI RETE:

TENSIONE DI INGRESSO:

ROTEZIONE TERMICA:

TEM . INTERVENTO:

Le prove di riscaldamento sono state effettuate alla temperatura di 40°

FUNZIONE ARC FORCE E ANTI-STICKING:

DIAMETRI DEGLI ELETTRODI UTILIZZABILI:

WEIGHT:

DIMENSIONS:

STATIC CHARACTERISTIC:

OWER SU LY ROTECTION:

IN UT LOAD:

THERMAL ROTECTION:

INTERVENTION TEM ERATURE:

Overheating tests run at 40° C

ARC FORCE AND ANTI-STICKING FUNCTIONS:

MAX ELECTRODE DIAMETERS:

GEWICHT:

ABMESSUNGEN:

STATISCHE EIGENSCHAFTEN:

NETZSCHUTZVORRICHTUNG:

EINGANGSS ANNUNG :

WÄRMESCHUTZ:

EINSATZTEM ERATUR:

Die Erhitzungsprüfungen wurden bei einer Temperatur in Höhe von 40° durchgeführt

ARC FORCE UND ANTISTICKING FUNKTION:

VERWENDBARE ELEKTRODENDURCHMESSER:

OIDS:

DIMENSIONS:

CARACTÉRISTIQUE STATIQUE :

DIS OSITIF DE ROTECTION DE RÉSEAU :

TENSION D’ENTREE :

ROTECTION THERMIQUE :

TEM . INTERVENTION :

Les essais de chauffe ont été effectués à la température de 40°

FONCTION ARC FORCE ET ANTICOLLANT :

DIAMETRES DES ELECTRODES UTILISABLES :

ESO:

DIMENSIONES:

CARACTERÍSTICA ESTÁTICA :

DIS OSITIVO DE ROTECCIÓN DE RED :

TENSIÓN DE ENTRADA:

ROTECCIÓN TÉRMICA :

TEM . INTERVENCIÓN :

Las pruebas de calentamiento se han realizado con una temperatura de 40 ºC.

FUNCIÓN FUERZA ARC Y ANTISTICKING :

DIÁMETROS DE LOS ELECTRODOS UTILIZABLES :

ITALIANO ENGLISH DEUTSCH FRANÇAIS ES AÑOL

ALTRI DATI TECNICI

ALTRI DATI TECNICI

ADDITIONAL TECHNICAL INFORMATION

ADDITIONAL TECHNICAL INFORMATION

WEITERE TECHNISCHE DATEN

WEITERE TECHNISCHE DATEN

CARACTERISTIQUES TECHNIQUES

CARACTERISTIQUES TECHNIQUES

OTROS DATOS TÉCNICOS

OTROS DATOS TÉCNICOS

16 g.

270x600x450

cadente

230V +/- 30%

termostato tipo “thermic SO1”

Fusibili 20A Ritardati

Int. Bipolari: 20A Curva o C

16 g.

270x600x450

drooping

230V +/- 30%

Thermostat : “Thermic SO1”

20A Delay-Fuses

Two-Pole 20A - or C-Standard Switch

16 g.

270x600x450

fallend

230V +/- 30%

Thermostat Typ „thermic SO1”

verzögerte 20A Sicherungen

Int. zweipolig: 20A - oder C- urve

16 g.

270x600x450

cadente

230V +/- 30%

Thermostat type “thermic SO1”

Fusées Retardées 20A

Int. Bipolaires 20A Courbe o C

16 g.

270x600x450

cadente

230V +/- 30%

termostato tipo “thermic SO1”

Fusibles 20A Retardados

Int. Bipolares: 20A Curva o C

IX

TECHNICA SPECIFICATION

TECHNICA SPECIFICATION

TECHNISCHE SPEZIFIKATIONEN

TECHNISCHE SPEZIFIKATIONEN

SPÉCIFICATIONS TECHNIQUES

SPÉCIFICATIONS TECHNIQUES

ESPECIFICACIONES TÉCNICAS

ESPECIFICACIONES TÉCNICAS

SPECIFICHE TECNICHE

SPECIFICHE TECNICHE

Ø 1.5-4.0

Ø 1.5-4.0

Ø 1.5-4.0

Ø 1.5-4.0

Ø 1.5-4.0

X

1

USE AND MAINTENANCE MANUAL

USE AND MAINTENANCE MANUAL

Fimer S.p.a. thanks you for selecting this unit, it will prove to be a useful, problem-free

tool for many years to come if the instructions contained in this manual are followed scru-

pulously.

This manual must be considered as an integral part of the unit and must accompany it

when it change location or is resold.

The user must assume responsability for maintaining this manual intact and legible at all

times.

Fimer S.p.a. reserves the right to modify this manual at any time without notice.

All rights of translation and total or partial reproduction by any means whatsoever (inclu-

ding scanner, photocopy, film, and microfilm) are reserved and reproduction is prohibited

without the express written consent of Fimer S.p.a.

INDEX

INDEX

• WARNING .............................................................................................................

............................................................................................................... pag. 3, 4, 5

1. GENERA INFORMATION ......................................................................... pag. 6

2. DESCRIPTION OF WE DER ..................................................................... pag. 6

3. CONNECTION TO POWER SUPP Y .............................................................. pag. 8

4. OUTPUT CONNECTIONS .......................................................................... pag. 9

4.2 TIG WE DING CONNECTIONS................................................................. pag. 9

5. GAS CY INDER AND GAS PRESSURE REGU ATOR CONNECTIONS ..................... pag. 9

6. WE DING METHODS ................................................................................ pag. 10

6.1 MMA Welding ......................................................................................... pag. 10

6.1.1 Description............................................................................................. pag. 10

6.1.2 MMA WE DING FEATURES.................................................................... pag. 10

6.1.3 MMA WE DING...................................................................................... pag. 10

6.2 DC Welding........................................................................................... pag. 11

6.2.1 Description......................................................................................... pag. 11

6.2.2 Arc Generation Mode ( ift or HF)....................................................... pag. 11

6.2.3 Welding Mode Selection (2T, 4T or 4T Bi- evel)................................ pag. 11

6.2.4 Welding Process Selection (Normal or Pulsed) .................................... pag. 13

6.2.5 TIG Welding.......................................................................................... pag. 13

6.2.6 Welding Parameter Setting .................................................................. pag. 14

6.3 AC- TIG Welding....................................................................................... pag. 15

6.3.1 Description......................................................................................... pag. 15

6.3.2 Arc Generation Mode ( ift or HF)....................................................... pag. 15

6.3.3 Welding Mode Selection (2T, 4T or 4T Bi- evel)................................ pag. 15

6.3.4 Welding Process Selection (Normal or Pulsed) .................................... pag. 17

6.3.5 TIG Welding.......................................................................................... pag. 17

6.3.6 Welding Parameter Setting .................................................................. pag. 18

7. REMOTE CONNECTIONS.................................................................................. pag. 19

7.1 MMA WE DING.................................................................................................. pag. 19

7.2 TIG Welding....................................................................................................... pag. 19

7.3 TIG WE DING (Pedal-controlled).................................................................... pag. 19

8. TROUB E SHOOTING........................................................................................ pag. 19

9. B OCK DIAGRAM............................................................................................... pag. 19

3

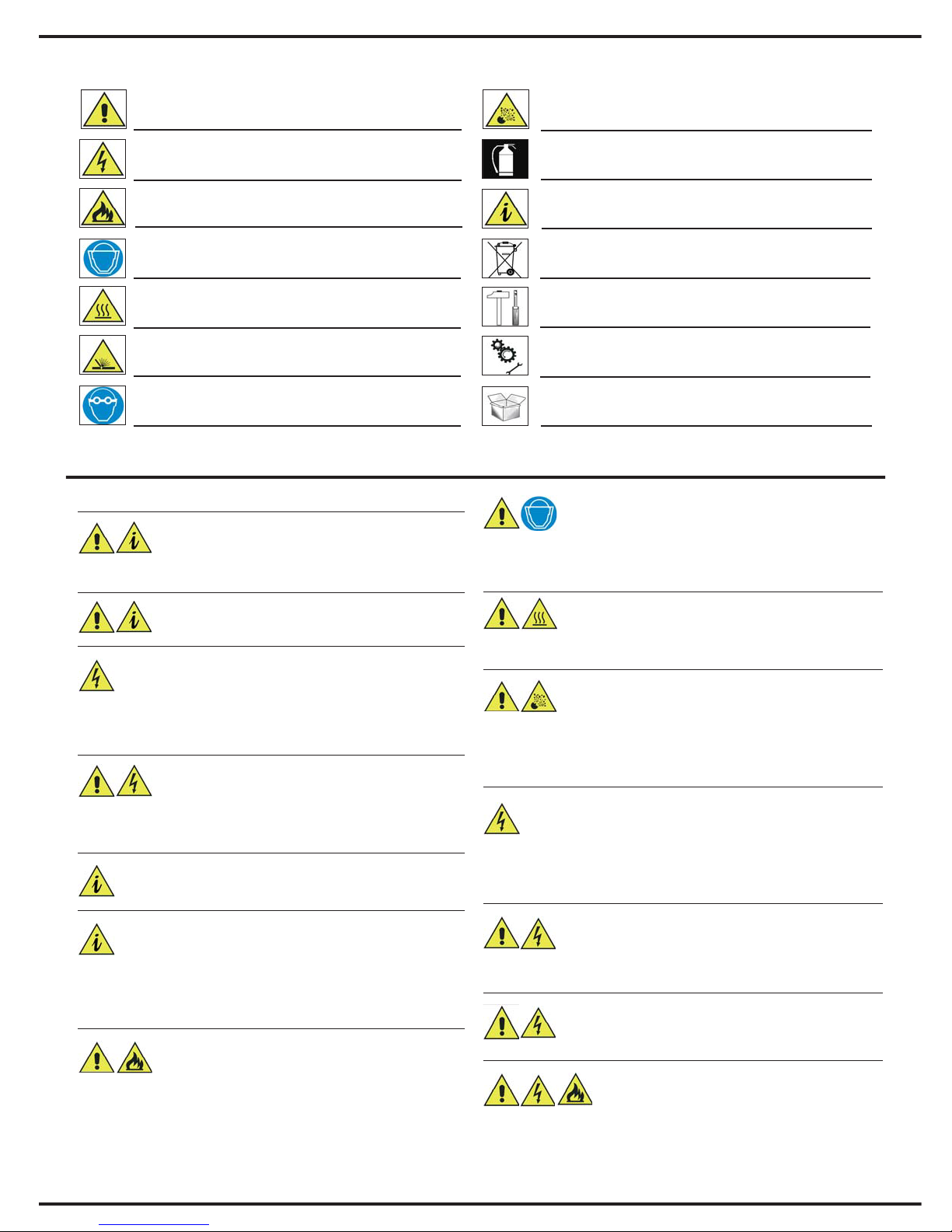

WARNING SYMBOLS

WARNING SYMBOLS

CAU TION

CAU TION

DANGER

(Indicating a hazard that could cause injury or damage)

DANGER

OF FIRE OR EXPLOSION.

Indicating that eye protection is required to avoid

burns and eye damage.

TOXIC GAS

Indicating the risk of toxic gas hazards

HOT SLAG

Indicating the risk of being burned by hot slag

EYE PROTECTION

Indicating that eye protection is required to avoid flying debris

ELECTRIC SHOCK

(Indicating the danger of electric shock)

DANGER COMPRESSED GAS

Indicating the risk of injury or death in the event of improper hand-

ling or maintenance of compressed gas cylinders or regulators

IMPORTANT INFORMATION

Indicating the precautions to be taken when installing and

using the unit.

DISPOSAL

INFORMATION

FIRE

PRECAUTIONS

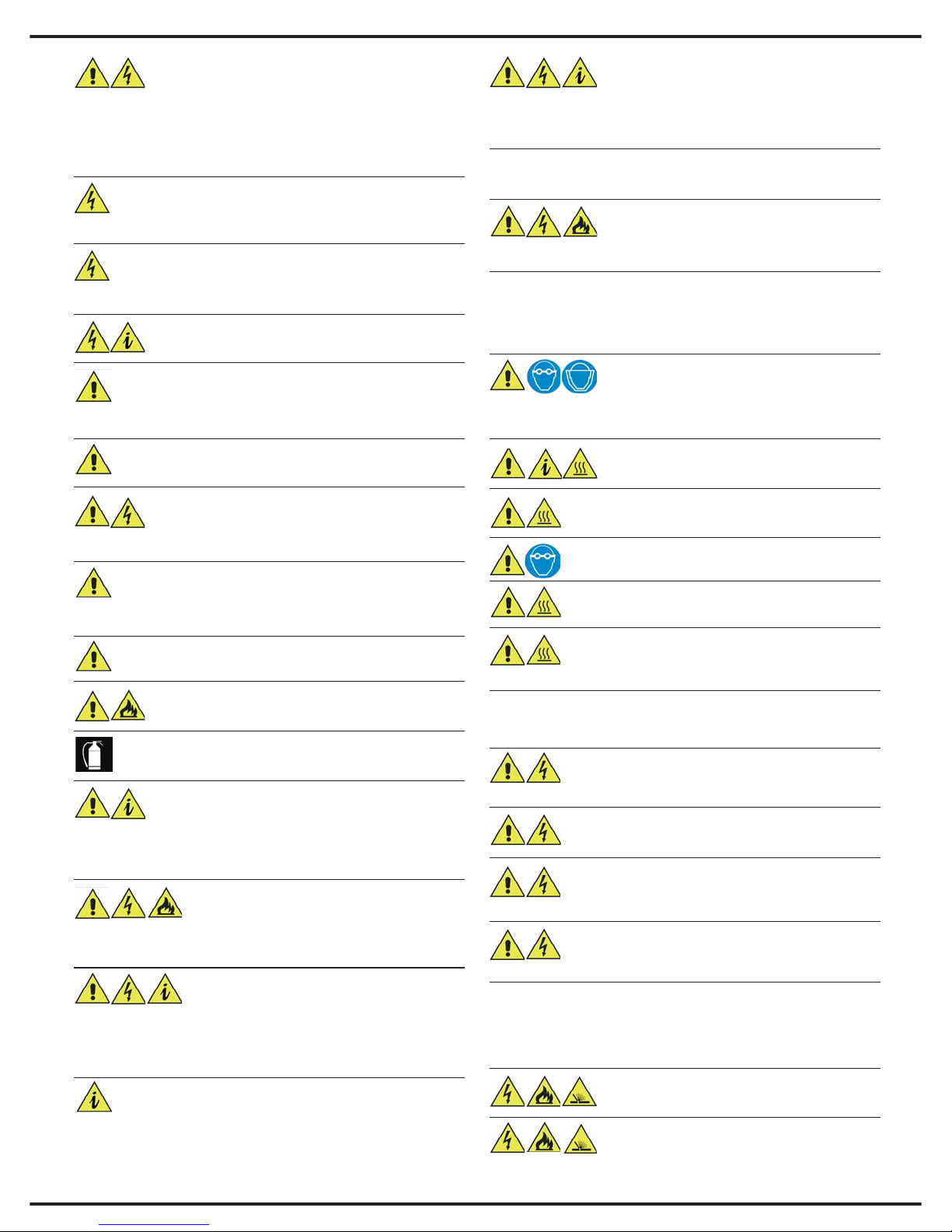

SAFETY WARNINGS

This equipment is designed solely for industrial or

professional use. As such, only experienced or ful-

ly-trained people should use the equipment. The user

and/or owner is responsible for ensuring inexperienced person-

nel does not have access to the equipment.

The safety information contained in this manual is a guide to

ensure you are not subjected to unnecessary risks. However,

the operator must be competent and careful at all times.

Fimer SpA declines all responsibility for injury or dama-

ge caused by inexperienced, improper or neglectful use

of its equipment.

A workman must look after his tools carefully ! Remember that

any tool or equipment can become a hazard if it is not looked

after properly.

Equipment in a state of disrepair or neglect can be dangerous. If it

does not operate properly or overheats, the electricity supply should

be removed immediately and the unit should be returned to the sup-

plier for repair.

All equipment connected to electric power supplies can be dan-

gerous if the manufacturers instructions are not read and obser-

ved. Read, understand and observe these safety instructions

to reduce the risk of death or injury from electric shock. Ensure that

even bystanders are aware of, and understand, the dangers that exi-

st in the welding area.

Read this manual carefully before using your Welder.

You can then do a better and safer job.

By reading this manual you will learn more about the

possibilities, limitations and potential dangers of welding.

Retain this manual for the entire life of the equipment. It should be

kept within the operator’s reach at all times.

Fires and explosions can seriously injure or cause dama-

ge ! Read, understand and observe all safety warnings

to reduce the risk of death or injury from fire or explo-

sion. Pay particular attention to the fact that even bystanders should

be aware of, and understand, the dangers existing in the welding area.

Remember that welding, by nature, produces sparks, hot spatter, mol-

ten metal drops, hot slag and hot metal parts that can cause fires, can

burn skin and damage eyes.

Arc rays can damage your eyes and burn your skin ! Read,

understand and observe all safety warnings to avoid dama-

ge from arc rays. Pay particular attention to the fact that

even bystanders should be aware of, and understand, the dangers exi-

sting in the welding area. Wear a protective mask and make sure bystan-

ders do the same.

Fumes, toxic gases and vapours can be harmful ! Read,

understand and observe all safety warnings to avoid harm

from toxic welding gases. Pay particular attention to the fact that even

bystanders should be aware of, and understand, the dangers.

Carelessness while using or maintaining the compres-

sed gas cylinders or regulators can injure or kill the

operator and/or bystanders ! Read, understand and observe all safety

warnings to avoid the dangers of compressed gas. Pay particular

attention to the fact that even bystanders should be aware of, and

understand, the dangers.

HIGH VOLTAGE

The unit carries potentially lethal voltage.

The high voltage areas of the equipment have been segregated

and can be reached only by using tools that are not provided with the

Welder.

All maintenance or repair operations requiring access to such areas may

only be performed by Fimer-trained technicians.

FOREIGN OBJECTS

Never block the air vents with foreign objects and avoid

any contact with liquids. Clean using just a dry cloth. The-

se safety precautions apply even when the unit is switched off.

CABLE GAUGES

Check that all cables are appropriately gauged for

the input power required by your specific Welder.

This precaution applies also to extension cables, if used. All extension

cables must be straight. Coiled cables can overheat, becoming dange-

rous. Twisted or coiled cables can also cause Welder malfunction.

WEIGHT LOADS

The upper part of the Welder was not designed to with-

stand heavy loads. Never stand on the unit.

INSTALLATION

INSTRUCTIONS

OPERATING

INSTRUCTIONS

UNPACKING

INSTRUCTIONS

4

WE LD IN G O PE RATI ON

WE LD IN G O PE RATI ON

SA FE TY I NS TRU CT IO NS

SA FE TY I NS TRU CT IO NS

PERSONNEL PROTECTION

PERSONNEL PROTECTION

LOCATION

Place the Welder well away from heat sources. Place the

Welder in a well-ventilated environment. Place the Welder in

a safe, protected area. It must not be installed outdoors. Do not install the

Welder in dusty environments. Dust can get into the inner parts of the unit

and inhibit cooling. The Welder must be positioned on a flat, stable surfa-

ce that extends further than the units own dimensions in all directions.

CLEAN LOCATIONS

The installation area must be kept clean and dry to be sure the Welder

fans do not draw in small objects or liquids. Not only could the equip-

ment malfunction but a serious risk of fire outbreak could be created.

REPAIRS

Never attempt to repair the Welder yourself.Always

refer to the manufacturer or an authorized repairer.

All warranty provisions will immediately become null and void if any repair,

or attempt to repair, not specifically authorized in writing or handled by

Fimer S.p.A. is carried out. Furthermore, Fimer S.p.A. will accept no

responsibility for any malfunction or damage resulting as a consequen-

ce of such unauthorized action.

SPARE PARTS

Use only manufacturer-recommended spare parts.

Other spare parts could cause equipment mal-

function. The use of non-original spare parts will also result in the war-

ranty provisions becoming null and void, releasing the manufacturer

from any responsibility for malfunction or damage resulting as a con-

sequence of such action.

CAUTION !

Welding processes can be dangerous for the operator and bystanders

if the safety warnings and instructions are not heeded.

WORK-AREA FLOORING

The work-area flooring MUST be fireproof.

WORK-AREA SURFACES

Work benches or tables used during welding

MUST have fireproof surfaces.

PROTECTION MASK

Wear a protective non-flammable welding mask

to protect your neck, your face and the sides of

your head. Keep the front lens clean and replace it if it is broken

or cracked. Place a transparent protection glass between the mask

and the welding area.

CLOTHING

Wear close-fitting, closed, non-flammable, pocke-

tless clothing.

EXTINGUISHER

Always place an approved fire extinguisher in the immediate vicinity

of the work area. Fire extinguishers should be checked regularly.

EYE PROTECTION

NEVER look at the arc without appropriate eye protection.

FUMES AND GASES 1

Clean away paint, rust or any other dirt from the item to

be welded to avoid the creation of dangerous fumes.

FUMES AND GASES 2

NEVER weld on metals containing zinc, mercury, chro-

mium, graphite, heavy metals, cadmium or beryllium unless

the operator and the bystanders use appropriate air-supplied respirators.

CONFINED SPACES

When welding in small environments, leave the power

source outside the area where welding will take place and

attach the grounding clamp to the part to be welded.

HUMIDITY

Never weld in wet or humid environments.

DAMAGED CABLES

Never use damaged cables. (This applies to both

the power and the welding cables.)

DAMAGED CABLES

Never remove the unit side panels. If the side panels

can be opened, always checked they are closed

tightly before starting any work.

HIGH VOLTAGE PROTECTION

HIGH VOLTAGE PROTECTION

Together with the previous instructions, the following pre-

cautions should be strictly observed

FI RE P RE VE NTI ON

FI RE P RE VE NTI ON

Together with the previous instructions, the following pre-

cautions should be strictly observed.

Welding operations require high temperatures therefore

the risk of fire is great.

TECHNICAL ASSISTANCE

The Welder must be taken to an authorized Technical Assi-

stance Centre if the equipment has been damaged in any way

or if any one of the following events occurs : liquid infiltration; dama-

ge caused by falling objects; exposure to rain or humidity (exceeding

the specified limits); malfunction; performance failure or if the equip-

ment has been dropped.

OVERLOAD PROTECTION

Check that the power source supplying the Welder carries the

correct voltage and is safety-protected. The power switch must open all the

power supply circuits. (If a single-phase connection is used, both the live and

the neutral poles must be open. If a three-wire connection is used , all three

poles must be open. Four-wire circuits require all poles and neutral open).

Time-delayed fuses or K-standard circuit breakers should be used.

CABLE COLOURS

The green-yellow wire is for earthing. (Don’t use it for

anything else !)

INSTALLATION ENVIRONMENT

The equipment is not suitable for use in washrooms,

shower cubicles, pool areas or similar environments. If

you are obliged to use the unit in such areas, turn off all water sup-

plies and check the area has been evacuated.

OPERATING AND/OR INSTALLATION ENVIRONMENT 3

Never use the Welder in an explosive, corrosive, abra-

sive or saline environment.

VENTILATION

Weld in a well-ventilated environment that does not have

direct access to other work areas.

EARTHING

If the Welder was not already supplied with a plug, connect the

earth wire first. When removing the plug, disconnect the earth

wire last.

PLUG AND POWER SUPPLY

If the Welder already has a plug attached, check that it is appro-

priate for the wall-socket you intend using. Never tamper with

the power cable.

RELOCATION 1

Some Welders are extremely heavy therefore care should be

taken when relocating the unit. Check the floor or platform wei-

ght load limitations before relocating the unit if the Welder is to be used,

even only temporarily, in a non-industrial environment

OPERATING AND/OR INSTALLATION ENVIRONMENT 1

The Welder was not designed for installation or use in areas where it

could be subject to blows or vibration, such as road-vehicles, railway

carriages, cable-cars, aircraft, ships or boats or similar environments (including

cranes, conveyor-carriers or any other mobile equipment prone to vibration)

OPERATING AND/OR INSTALLATION ENVIRONMENT 2

The Welder should never be used or stored in the rain or in snow.

RELOCATION 2

Never store or move the Welder in an inclined position or on its

side.

Together with the previous instructions, the following

precautions should be strictly observed

5

CLEAN ENVIRONMENT

Remove all flammable materials away from

the work environment.

SERIOUS DANGER ! 1

NEVER weld in confined spaces (e.g. in a con-

tainer vehicle, a cistern or a storeroom etc.) where toxic, inflamma-

ble or explosive materials are, or have been, located or stored.

Cisterns, in particular, may still contain toxic, flammable or explosi-

ve gases and vapours years after they have been emptied.

SERIOUS DANGER! 3

NEVER use the Welder to melt frozen water

pipes.

SERIOUS DANGER ! 2

NEVER weld a cistern that contains (or has stored)

toxic, inflammable or explosive materials. They could

still contain toxic, flammable or explosive gases and vapours years

after they have been emptied. If you are obliged to weld a cistern,

ALWAYS passivate it by filling it with sand or a similar inert sub-

stance before starting any work.

WELDING ENVIRONMENT VENTILATION

Ventilate the welding environment carefully. Maintain

sufficient air-flow to avoid toxic or explosive gas accumulation.

Welding processes on certain kinds or combinations of metals can

generate toxic fumes. In the event of this happening, use air-sup-

ply respirators. BEFORE welding, read and understand the wel-

ding alloy safety provisions.

GAS TYPES

These welders use only inert (non-flammable) gases for welding

arc protection. It is important that the appropriate type of gas is

chosen for the type of welding being performed.

UNIDENTIFIED GAS CYLINDERS

NEVER use unidentified gas cylinders.

PRESSURE REGULATOR 1

NEVER connect the cylinder directly to the Welder.

Always use a pressure regulator.

PRESSURE REGULATOR 2

Check the regulator is performing its function properly.

Read the regulator instructions carefully.

PRESSURE REGULATOR 3

Never lubricate any part of the regulator.

PRESSURE REGULATOR 4

All regulators are designed for a specific type of gas.

Check the regulator is appropriate for the protective

gas to be used.

VE NT IL AT IO N

VE NT IL AT IO N

Together with the previous instructions, the following pre-

cautions should be strictly observed

PR OT EC TI VE WE LD IN G GA SE S

PR OT EC TI VE WE LD IN G GA SE S

Together with the previous instructions, the following

precautions should be strictly observed when welding

with protective gases

WALL AND FLOOR PROTECTION

The walls and flooring surrounding the welding

environment must be shielded using non-flammable materials. This

not only reduces the risk of fire but also avoids damage to the wal-

ls and floors during welding processes.

EXTINGUISHER

Place an approved and appropriately-sized fire extinguisher in

the work environment.

Check its working order regularly (carry out scheduled inspections)

and ensure that all parties involved know how to use one.

DAMAGED GAS CYLINDERS

NEVER use damaged or faulty cylinders.

CYLINDER RELOCATION

NEVER lift a gas cylinder by holding the regulator.

GAS CYLINDERS

Do not expose gas cylinders to excessive heat sour-

ces, sparks, hot slag or flames.

GAS HOSE 1

Check the gas hose is not damaged.

GAS HOSE 2

Always keep the gas hose well away from the work

area.

ELECTRIC SHOCK

Together with the previous instructions, the following pre-

cautions should be strictly observed to reduce the risk of

electric shock

ELECTRIC SHOCK INJURY

DO NOT touch a person suffering from electric shock if

he/she is still in contact with the cables. Switch the mains power

source off immediately THEN provide assistance.

CABLE CONTACT

Do not tamper with power cables if the mains power is still

switched on. Do not touch the welding circuitry. Welding cir-

cuitry is usually low voltage, however, as a precaution, do not tou-

ch the welder electrodes.

CABLE AND PLUG PRECAUTIONS

Check the power supply cable, plug and wall-socket regularly.

This is particularly important if the equipment is relocated often.

REPAIRS

Never attempt to repair the Welder yourself. The result would

not only cause warranty cancellation but also high danger risks.

MAINTENANCE PRECAUTIONS

Always check that the electric power supply has been discon-

nected before performing any of the maintenance opera-

tions listed in this manual ( e.g. before replacing any of the fol-

lowing: worn electrodes, welding wires, the wire feeder etc.)

Never point the welding gun or the electrode towards yourself

or others.

Check no power supply cables, telephone cables or other

electrical items (e.g. computer cables, control lines etc.) are

in the vicinity of the Welder.

Check there are no telephones, televisions, computers or other

transmission devices close to the Welder.

ELECTROMAGNETIC COMPATIBILITY

Make sure that people with pace-makers are not in the imme-

diate vicinity of the Welder.

Do not use the Welder in hospitals or medical environments

(including veterinary surgeries). Make especially sure there

is no electrical medical equipment being used close to whe-

re welding is being done.

Should the Welder interfere with other apparatus, take the fol-

lowing precautionary measures:

1. Check the Welder’s side panels are securely fastened.

2. Shorten the power supply cables.

Place EMC filters between the Welder and the power source. (Con-

tact Fimer Technical Dept. in this respect )

EMC compatibility : CISPR 11, Group 1, Class A.

6

1. GENERA INFORMATION

Models TT165 AC/DC and TT205 AC/DC are

portable, single-phase Welders based on

INVERTER technology. They are extremely

compact, versatile units and can be used in all

circumstances where a compact design needs

to be flanked by high performance. They can

be used for TIG (AC or DC) or MMA welding.

Lift or HF arcs can be generated.

Thanks to the advanced microprocessor

techniques, reliable high-quality results (that

could previously only be provided by bigger,

more expensive welders) can be achieved on

a wide variety of materials, such as steel, iron,

wrought iron, copper, nickel and alloys.

WARNING: The unit should only be used for

the operations described in this manual. It

should not be used to melt frozen pipes.

Manual consultation suggestions: The

most frequently consulted diagrams (Figs.1

and 2) are grouped together on page 6.

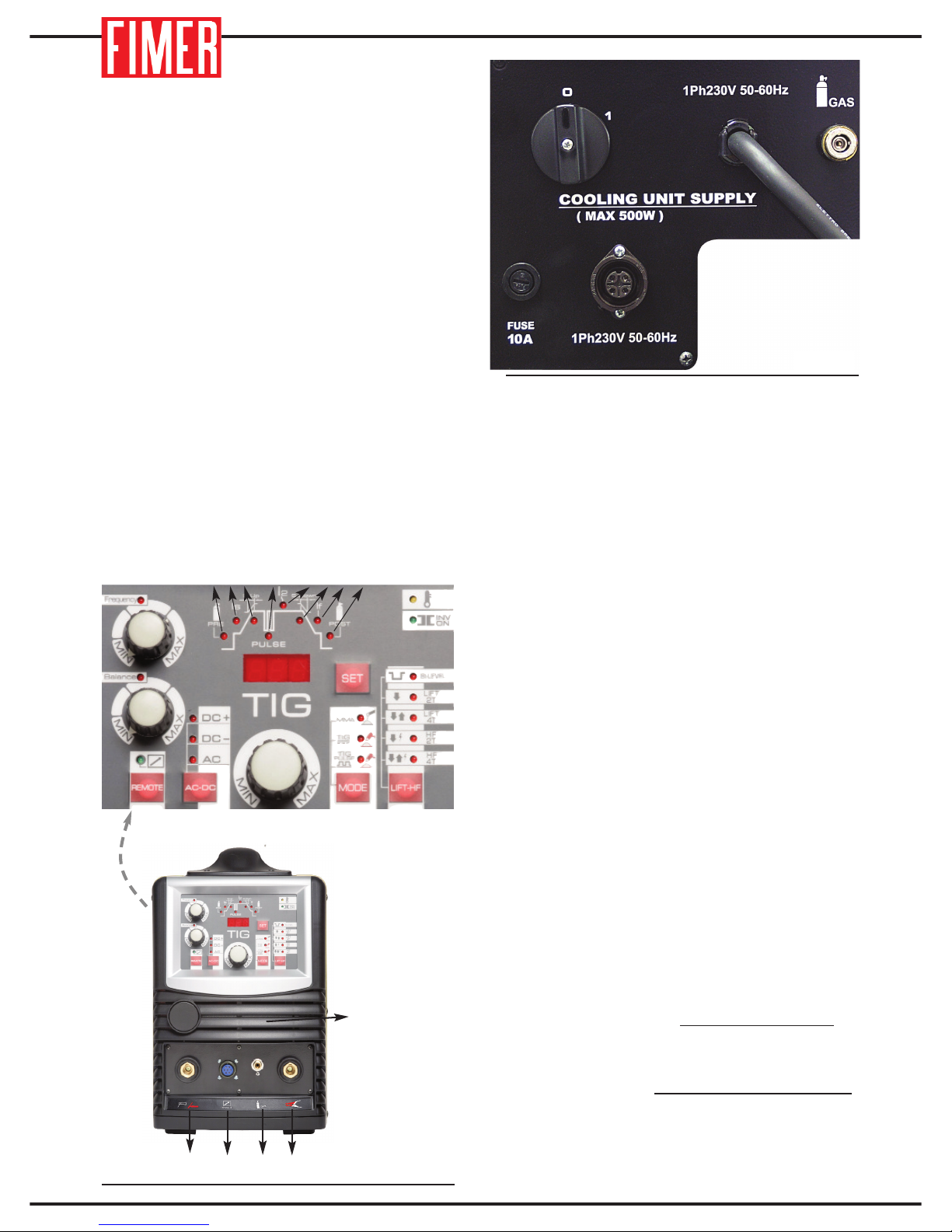

2. DESCRIPTION OF WE DER

Warning: The unit should only be used for

operations described in this manual.

It should not be used to melt frozan pipes.

FIGURE 1:

1. Frequency Knob

TIG AC welding:

The AC output current frequency can be set

using this nob.

MMA + TIG DC welding: Not used

2. Frequency Confirmation:

TIG AC Mode : This lights up for app. 4

seconds for each setting selected using

nob 1.

MMA and TIG DC welding: Not used

EDs 3 to 10: Welding Setting Indicators

Lit when a welding parameter has been

changed using button 14.

Adjust the settings using nob 25. The

new setting will be shown on the

display panel (13).

Memorise the new setting pressing button

14 (or wait 1.5 seconds).

Indicator details:

3. Setting Indicator: Pre-Gas Indicat r:

Lit when the pre-gas duration has been set

using button 14.

4. Setting Indicator: Initial Current Indicat r (Is):

Lit when the initial current value has been

set set using button 14.

34 5 67 8 9 10

11

12

14

20

30

31

32

24

25

26 33

27

28

29

1

2

13

38

37

3635

34

Fig.1

43

42

39

41

40

Fig.2

15

16

17

18

19

21

22

23

7

5. Setting Indicator: Sl pe-Up Indicat r:

Lit when the Slope-Up time, increasing

from the Initial Current (Is) value to I2.

6. Setting Indicator: Pulse Frequency

Indicat r:

Lit when the pulse frequency has been set

using button 14.

7. Setting Indicator: Welding current.(I2)

Lit when the welding current value has

been set using button 14.

8. Setting Indicator: Sl pe-D wn Time.

Lit when the Slope-Down time, decreasing

from I2 to final welding current value (If),

has been set using button 14.

9. Setting Indicator: Final Welding Curent (If)

Lit when the final current value has been

set set using button 14.

10. Setting Indicator: P st-Gas Time:

Lit when the Post-Gas duration has been

set using button 14.

11. Thermal Protection Signal and low

mains voltage:

this lights up when the unit overheats.

Usually this occurs when the welder duty-

factor has been exceeded. Check that the

air-intake grills (34) on the frontand back of

the welder are not clogged. Leave the

welder switched on to allow the internal

components to cool down. When the LED

goes off, normal welding operations can be

resumed.

Should the letters ‘E.Ln’ appear on the

display panel 13 and the LED 11 lights up,

it means the power supply is below the

standard required.

12. Power Inverter Runnig ED:

MMA welding: This lights up when the unit

is ready to weld.

TIG welding: This lights up as soon as an

arc is created.

13. Display panel: Shows welding current

value during normal operations.

During the setting of TIG welding (button

14) shows the value of the parameter.

The following information will also be

displayed:

- When unit is switched on, welder model

and firmware version.

- Should the letters ‘E.Ln’ appear on the

display and the LED 11 lights up, it means

the power supply is below the standard

required.

14. Welding Parameter Selector

The parameter to be adjusted can be

selected. The button is used together

with nob 25 to select the required

setting, and the settings can be checked

via LEDs 3 to 10.

EDs 15 to 19:

Arc Generation and 2T - 4T mode indicator:

Lit when arc generation (2T or 4T) has

been selected, pressing button 20

repeatedly.

Indicator details:

15. Bi- evel Arc Mode Indicator:

Lit when Bi-Level 4T (Lift or HF) arc

generation has been selected.

16. 2T ift-Arc Indicator :

Lit when 2T Lift-Arc generation has been

selected.

17. 4T ft-Arc Indicator :

Lit when 4T Lift-Arc generation has been

selected.

If LED 15 is not lit it means normal 4T Lift-

Arc generation has been set. If lit, 4T

Bi-Level Lift-Arc generation has been set.

18. 2T HF Arc Generation Indicator

Lit when 2T HF arc generation has been

selected.

19. 4T HF Arc Generation Indicator

Lit when 4T HF arc generation has been

selected.

If LED 15 is not lit it means normal 4T HF

arc generation has been set. If lit, 4T HF

Bi-Level arc generation has been set.

EDs 21, 22 and 23: Welding Mode

Indicators.

Lit when a welding mode has been

selected pressing button 24 repeatedly

21. MMA Welding indicator.

22. Non-Pulse TIG Welding Indicator.

23. Pulsed TIG Welding Indicator.

24. MMA/TIG Mode Selector:

Repeatedly pressing this button

alternates the welding mode, ie. MMA

mode (LED 21 on). normal TIG mode

8

(LED 22 on) or pulsed

TIG mode (LED 23 on).

25. WE DING CURRENT KNOB.

Further Function: Turning this knob, while

using button 14 and LEDs 3 to 10, the

welding parameters can be set.

26. OCA / REMOTE SE ECTOR:

Local (LED 27 off) or Remote (LED 27 on)

use of the welder can be selected pressing

this button.

When in local use the welding current is set

turning knob 25.

During remote use the welding current is set

using a remote unit (optional accessory).

27. REMOTE USE INDICATOR

28. BA ANCE KNOB:

TIG AC welding: The balance of the DC

component of the AC output welding current

can be set using thes nob.

TIG DC/MMA welding: Not used

29. Balance Current Confirmation:

TIG AC welding: This lights up for app. 4

seconds at each setting selected using of

nob 28.

MMA + TIG DC welding: Not used

30. Direct polarity indicator

31. Reverse polarity indicator

32. AC mode indicator

33. Polarity selector: Repeatedly pressing

this button alternates the output polarity .

MMA Mode: switch between direct polarity

(LED 30 ON) (usual selection) and Reverse

polarity (LED 31 ON)

TIG Mode: switches between Reverse

polarity DC mode(LED 31 ON) and AC

mode (LED 32 on).

34. Air-intake grills

35. Welding front socket

MMA welding: Electrode clamp

TIG welding: Welding Torche

36. Remote Control Connector

MMA welding: Using a dedicated (optional)

accessory, the welding current can be

remote adjusted.

TIG welding: A “start” or “stop” command is

relayed from the torch to the unit.

If a welding pedal (optional accessory) is

used, a suitable current level command is

also sent. (In the latter case, the torch button

is automatically disabled.).

37. Gas Hose Connector:

MMA welding: Not used

TIG welding: Torch hose connection.

38. Earth Clamp

MMA welding: Earth Clamp

TIG welding: Earth Clamp

FIGURE 2:

39. Fuse

40. ON/OFF SWITCH Switches ON or OFF

the unit

41. Power supply cable: Input cable

provided with plug.

42. GAS INPUT: (Paragraph 5)

MMA welding: Not used

TIG welding: elding torch hose connection.

43. iquid-Cooling System Connector

(optional accessory): Beware !!

The connector uses dangerously high

voltage: NEVER use it for any other use than

as described in this Manual.

3. CONNECTION TO POWER SUPP Y

Before plugging the unit in, check the power

supply voltage, phase and voltage

frequency.

The permissible voltage is shown in the

“Technical Specification” chapter of this

manual and on the unit nameplate. Ensure

the welder is earthed appropriately. Also

check that the plug provided with the unit is

compatible with the local power grid socket.

Make sure that the power supply is sufficient

to operate the welder.

The types of power supply protection

devices to be used are listed in the

“Technical Specification” section of this

manual.

The power cable supplied with the welder

should not be extended but, if that becomes

necessary, either an identical or greater

cross-section cable should be used

according to the final cable length. The

TT165 AC/DC and TT205 AC/DC models

9

require a three-wire cable (2 phases and

earth) with a minimum cross section area

equal to 2.5 mm².

4. OUTPUT CONNECTIONS

The welding cables are connected using

fast-connector plugs.

4.1 MMA Welding connections

1) Connect the electrode clamp to the

special socket on the front panel of the unit

(Fig 1 – 35). Lining up the peg and the

groove, insert the plug and screw it in well

clockwise. Do not over-tighten.

Check the direct polarity Led (Fig. 1 - 30) is

ON.

2) Connect the earth cable to the special

socket on the front panel of the unit (Fig 1 –

38) Lining up the peg and the groove, insert

the plug and screw it in well clockwise. Do

not over-tighten.

WARNING: Some electrodes require

negative polarity on the electrode clamp

and positive polarity on the earth cable. In

that case, invert polarity using the Fig. 1 -

35 button. Always check the electrode

packaging for instructions regarding the

required polarities!

4.2 TIG WE DING CONNECTIONS

1) Connect the earth cable to the special

socket on the front panel of the unit (Fig. 1

– 38). Lining up the peg and the groove,

insert the plug and screw it in well

clockwise. Do not over-tighten.

2) Connect the torch to the appropriate

socket (Fig 1 – 35).

Lining up the peg and the groove, insert the

plug and screw it in well clockwise. Do not

over-tighten.

Connect the torch remote signal connector

to socket 36 (Fig.1) on the front panel of the

unit. Do not over-tighten.

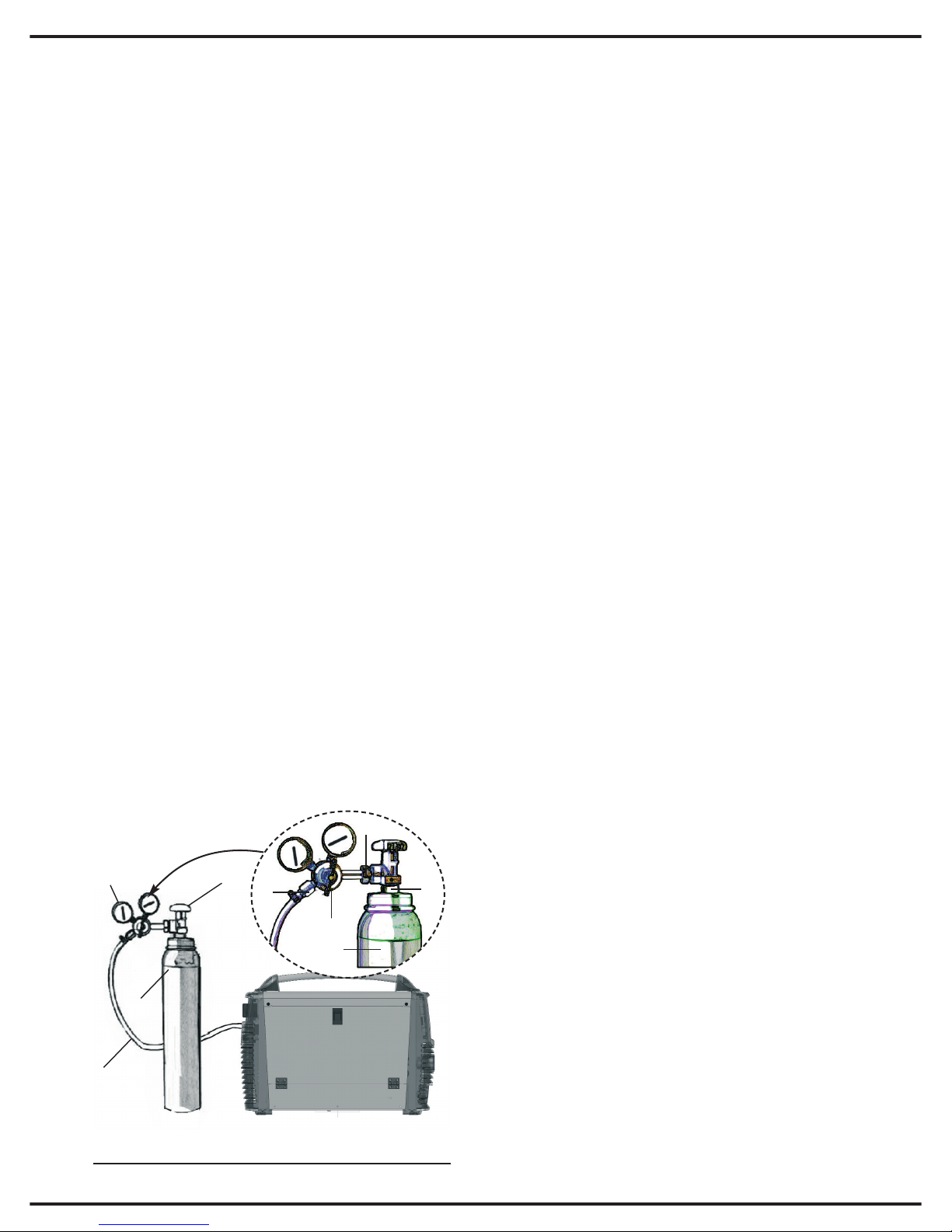

5. GAS CY INDER AND GAS

PRESSURE REGU ATOR

CONNECTIONS

Only for TIG Welding: Skip this charter

entirely if the welder is to be used for MMA.

Before connecting the gas cylinder, check

it contains pure Argon gas.

Always use welding torches with control

buttons.

While referring to Figure 3, follow these

instructions carefully:

1. Connect the pressure regulator (2) to the

gas cylinder (3). Tighten the bolt (6)

between the regulator (2) and the cylinder

(3). Do not overtighten to avoid damaging

the cylinder valve (1).

2. Connect the gas hose of the torch (4) to

the pressare regulator (2) and clamp

securely using a clasp (5). (Alternatively

use cylinder and hose fast connectors).

3. Connect the other end of the gas hose

(6) to the socket on the rear panel of the

welder unit (Fig.2 – 42).

4. Connect the gas hose from the torch to

the appropriate socket (7) on the front panel

of the unit (37 di fig 1).

4

3

2

1

6

2

5

1

3

Fig.3

10

5. Open the gas cylinder

valve (1). Press the torch button and check

that gas is flowing through correctly.

WARNING: Cylinders contain high

pressure gas. Handle them with care.

Inappropriate treatment can cause serious

accidents. Do not pile gas cylinders up and

never expose them to excessive heat,

flames or sparks. Do not bang cylinders

against each other. Contact your supplier

for more information regarding the use and

maintenance of gas cylinders.

WARNING: Never use cylinders that are

damaged or show signs of oil or grease

leakage. Contact your supplier immediately

of any such circumstances.

6. WE DING METHODS

The welding mode is selected pressing

button 24 (Fig.1) repeatedly. Check the

correct mode has been selected, i.e. MMA

(LED21 on), normal TIG (LED22 on) or

pulsed TIG (LED23 on).

6.1 MMA Welding ( ED 21, Fig 1 ‘on’)

Select this mode pressing button 24

repeatedly until LED21 lights up.

6.1.1 Description

Electric MMA (Metal Manual Arc) and

SMAW (Shielded Metal Arc Welding) are

both manual procedures exploiting the

heat generated by an electric arc that is

produced when covered welding

electrodes make contact with the

workpiece. It is commonly used due to

its versatility. In fact, welding jobs can

be performed anywhere: in a workshop,

in the open, in confined spaces or hard

to reach areas. A wide range of

electrodes are available, suiting all

requirements.

The arc is generated touching the electrode

to the workpiece.

The potentiometer knob (Fig. 1 –25)

regulates the welding current (thicker

workpieces require higher current settings).

6.1.2 MMA WE DING FEATURES

While welding the following features come

into effect:

Arc Force: Whenever the arc tends to

drop the microprocessor automatically

increases the welding current in order to

maintain and stabilise the arc.

Hot Start: The arc is generated touching

the electrode to the workpiece. To ensure

the arc is generated efficiently, the

microprocessor increases the welding

current for app. one second, , guaranteeing

fast, safe arc generation.

Antisticking: Stops the welding current if

the operator makes a mistake causing the

electrode to stick to the workpiece. The

electrode can be removed from its clamp

without causing damaging sparks.

6.1.3 MMA WE DING

Proceed as follows for MMA welding:

1. Using the button 33 (Fig. 1) set the right

polarity of the welding current. Usually

direct polarity (LED 30 ON).

Always check the suitable polarity indicated

in the electrode manufacurer’s instruction.

2. According to the type of electrode and the

thickness of the workpiece, set the welding

current using nob 25 (Fig.1). (The welding

current value is shown on display 13). Figure

4 provides guidelines according to the

diameter of the specific electrode being used.

However, the electrode manufacturer’s

instructions should also be heeded.

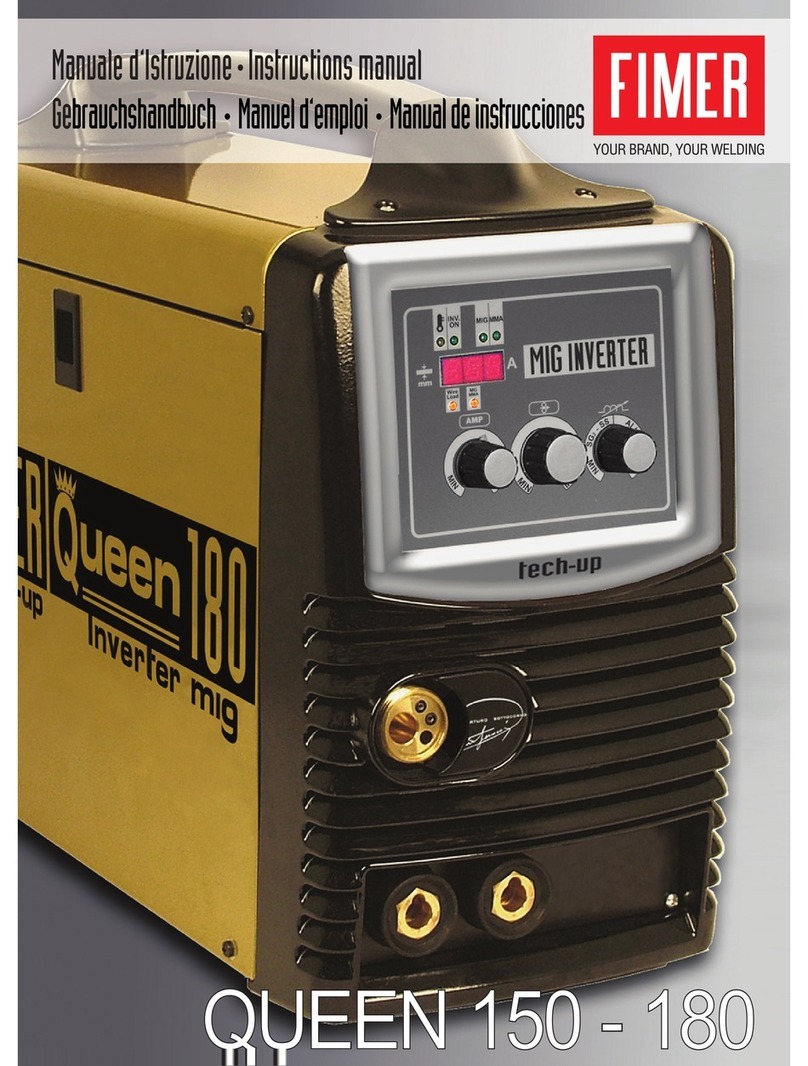

DIAMETRO (mm) CORRENTE (A)

35-50

40-70

60-100

80-140

120-170

180-250

1.6

2.0

2.5

3.25

4.0

5.0

Fig. 4 Electrode Diameter vs Welding

Current Considerations

This manual suits for next models

1

Table of contents

Other Fimer Welding System manuals

Fimer

Fimer TM 215 User manual

Fimer

Fimer QUEEN 210 User manual

Fimer

Fimer King 320 User manual

Fimer

Fimer Tp 72 User manual

Fimer

Fimer TT205 DC User manual

Fimer

Fimer QUEEN 180 User manual

Fimer

Fimer T252 User manual

Fimer

Fimer QUEEN 212EVO User manual

Fimer

Fimer King 350 User manual

Fimer

Fimer TM 236 User manual

Popular Welding System manuals by other brands

Hypertherm

Hypertherm powermax 350 Operator's manual

Parkside

Parkside PESG 120 A1 Assembly, operating and safety instructions

iWeld

iWeld CUT 50 CNC PILOT user manual

Miller Electric

Miller Electric Maxstar 150 S Specifications

Lincoln Electric

Lincoln Electric MAGNUM PRO 400A Series Operator's manual

djm direct

djm direct DJMMIG130 manual