Fimet NEO User manual

Fimet Neo®

Technical Manual

Ver. 1.8 – 19.12.2018

2 • Technical Manual

Contents

1Introduction..................................................................................................................................................4

1.1 Manufacturer ............................................................................................................................................4

1.2 Models Covered by this Manual...............................................................................................................4

1.3 Directives and Standards.........................................................................................................................4

1.4 Terms and Abbreviations .........................................................................................................................4

1.5 Symbols and Markings.............................................................................................................................5

1.6 Referred Documents ................................................................................................................................6

1.7 General.....................................................................................................................................................7

1.8 Transportation, Storage and Packaging...................................................................................................7

1.9 Environmental Specifications.................................................................................................................10

1.10 Maximum lifting capacity........................................................................................................................10

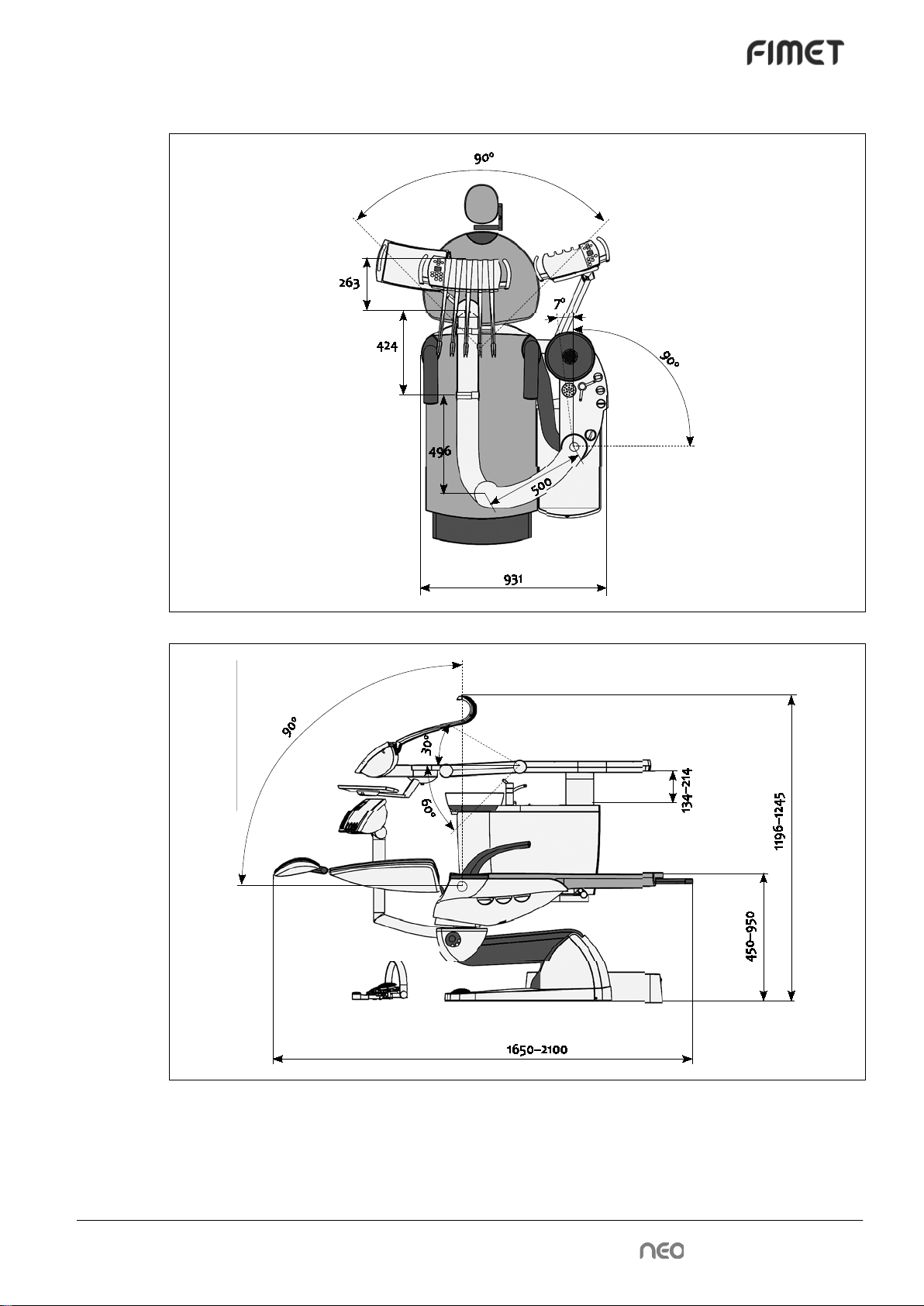

1.11 Movement Ranges .................................................................................................................................11

2Installation..................................................................................................................................................12

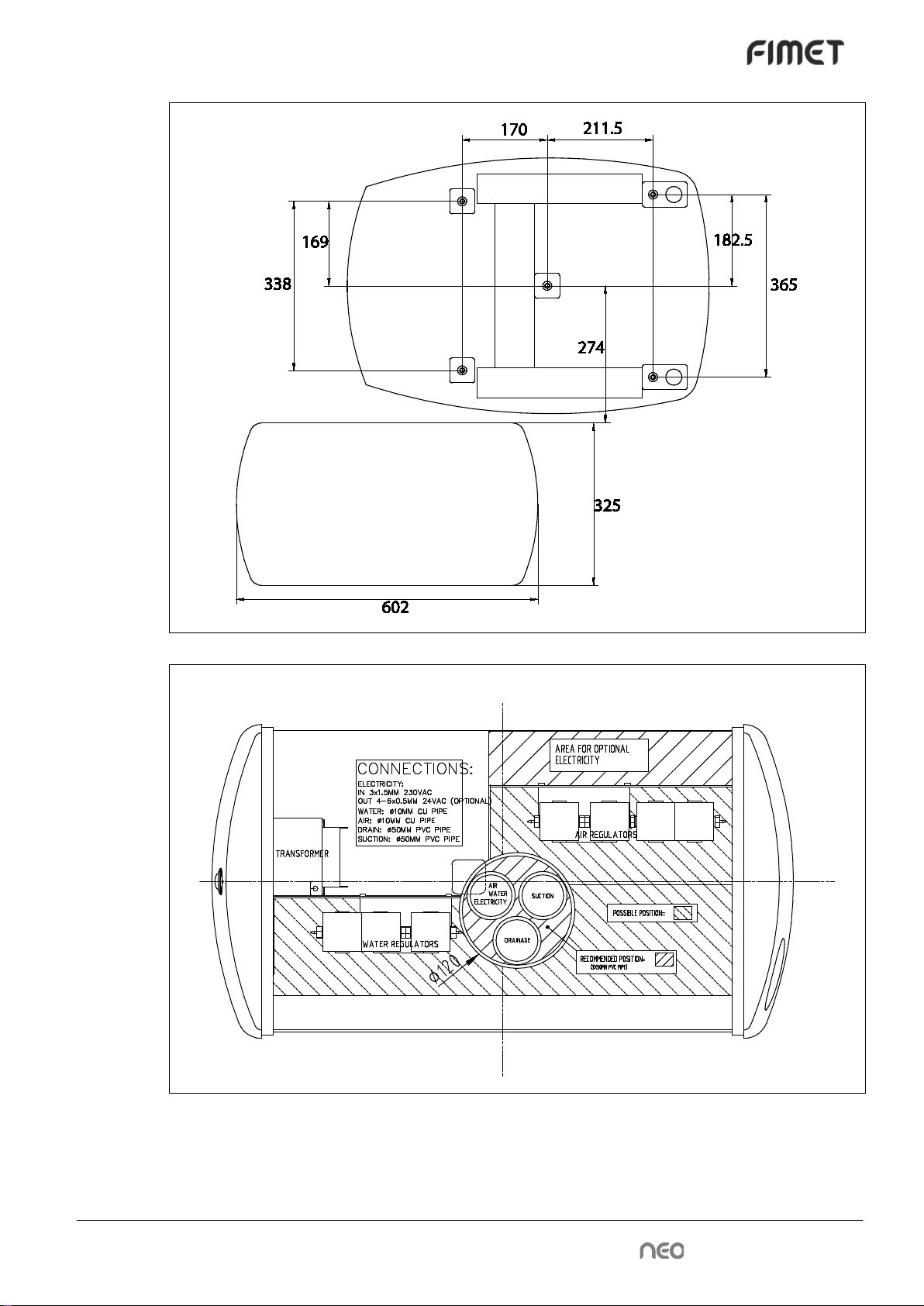

2.1 Space Requirements..............................................................................................................................12

2.2 Unpacking...............................................................................................................................................14

2.3 Attaching Backrest .................................................................................................................................14

2.4 Attachment to floor .................................................................................................................................15

2.5 Floor materials........................................................................................................................................17

2.6 Attaching unit to the chair.......................................................................................................................17

2.7 Adapter adjustments ..............................................................................................................................18

2.8 Connecting the cables............................................................................................................................18

2.9 Removing transport screw......................................................................................................................19

2.10 Adjusting the instrument arm spring.......................................................................................................19

2.11 Adjusting the stiffness of tray rotation ....................................................................................................20

2.12 Headrest lock tightness adjustment.......................................................................................................20

2.13 Setting Air and Water Pressures............................................................................................................21

2.14 Connection to Mains...............................................................................................................................21

3Annual service...........................................................................................................................................22

3.1 Service steps..........................................................................................................................................22

3.2 Greasing the Lift Motor Screw Spindle...................................................................................................23

3.3 Safety measurements ............................................................................................................................24

4Repairs and adjustments..........................................................................................................................27

4.1 Replacing Fuses.....................................................................................................................................27

4.2 Replacing Electric Circuit Boards...........................................................................................................28

4.3 Replacing rechargeable batteries of remote foot control .......................................................................28

4.4 Error, warning and info messages .........................................................................................................28

4.5 Setting the chair movement soft limits ...................................................................................................30

4.6 Remote foot control settings...................................................................................................................31

4.7 Remote foot control lever calibration......................................................................................................32

4.8 Pairing the transmitter and the receiver.................................................................................................32

4.9 Unpairing the transmitter and the receiver.............................................................................................32

4.10 Setting the parameters of joysticks ........................................................................................................33

4.11 Replacing the MST.................................................................................................................................33

4.12 Faro Alya operating light On/Off mode change......................................................................................34

5User interface - service menu ..................................................................................................................36

6Electronics .................................................................................................................................................39

Technical Manual • 3

6.1 General Description............................................................................................................................... 39

6.2 System overview.................................................................................................................................... 39

6.3 Data communication.............................................................................................................................. 41

6.4 Status LEDs........................................................................................................................................... 41

6.5 Connection Box...................................................................................................................................... 41

6.6 Unit/Cuspidor......................................................................................................................................... 42

6.7 Chair ...................................................................................................................................................... 42

6.8 Instrument Bridge .................................................................................................................................. 42

6.9 Suction Head ......................................................................................................................................... 42

6.10 User interference devices...................................................................................................................... 43

6.11 Radio devices ........................................................................................................................................ 43

6.12 I/O cards ................................................................................................................................................ 43

7PCB descriptions...................................................................................................................................... 44

7.1 ALA - Unit bottom safety switch............................................................................................................. 44

7.2 ALB - Suction arm safety switch............................................................................................................ 44

7.3 ALC - Chair lift safety switch.................................................................................................................. 44

7.4 ALD - Chair back safety switch.............................................................................................................. 45

7.5 ALE – Chair movement limiter switch, lift .............................................................................................. 45

7.6 ALF - Chair movement limiter switch, tilt ............................................................................................... 46

7.7 BRI – Instrument bridge main board...................................................................................................... 46

7.8 BUI – Instrument bridge user interface.................................................................................................. 47

7.9 BVA - Instrument bridge valve board A ................................................................................................. 48

7.10 BVB - Instrument bridge valve board B ................................................................................................. 49

7.11 BVD - Instrument bridge valve board .................................................................................................... 50

7.12 CNA - Connector card ........................................................................................................................... 50

7.13 CUI – Chair user interface ..................................................................................................................... 51

7.14 DSW – Doriot tool switch....................................................................................................................... 52

7.15 GUI – Graphical user interface.............................................................................................................. 52

7.16 HSW - Hanging hose switch.................................................................................................................. 53

7.17 JOY - Joystick........................................................................................................................................ 53

7.18 MDR - DC motor driver.......................................................................................................................... 54

7.19 MST – Master device controller............................................................................................................. 56

7.20 PWRA - Power Supply - Mains.............................................................................................................. 56

7.21 PWRB Power Supply - Secondary ........................................................................................................ 57

7.22 PWRC Power Supply - Multimedia........................................................................................................ 58

7.23 RFB – Remote foot control battery PCB................................................................................................ 58

7.24 RFC – Radio foot controller ................................................................................................................... 59

7.25 RFT - Foot control lever switch.............................................................................................................. 59

7.26 RLY – Relay card for external connections ........................................................................................... 60

7.27 RXC - Radio receiver............................................................................................................................. 60

7.28 SUI – Suction head user interface......................................................................................................... 61

7.29 UMB – Bien Air micromotor adapter...................................................................................................... 62

7.30 UMF – Micromotor driver....................................................................................................................... 63

7.31 UNT – Unit main module ....................................................................................................................... 64

7.32 UNV - Unit valves .................................................................................................................................. 65

7.33 X1N10A - Pressure relief....................................................................................................................... 66

8Pneumatics................................................................................................................................................ 67

9Materials used in maintenance................................................................................................................ 91

4 • Technical Manual

1 Introduction

1.1 Manufacturer

This product has been manufactured by:

Fimet Oy

Teollisuustie 6

FI-07230 Monninkylä

Finland

Tel: +358 19 521 6600

Fax: +358 19 521 6666

fimet@fimet.fi

http://www.fimet.fi

1.2 Models Covered by this Manual

This manual covers the Fimet-manufactured dental treatment system models:

Neo

Neo Cart

Neo City

Neo Ceiling

1.3 Directives and Standards

The product complies with the requirements of:

IEC 60601-1:2005 Medical electrical equipment - Part 1: General requirements for basic

safety and essential performance

ISO 14971:2012 Medical devices - Application of risk management to medical devices

ISO 6875:2011 Dental patient chair

ISO 7494-1:2011 Dentistry - Dental units - Part1: General requirements and test meth-

ods

ISO 7494-2:2015 Dentistry - Dental units – Part2: Water and air supply

This product bears the CE marking in accordance with the provisions of the Council Di-

rective 93/42/EEC of June 14, 1993 concerning medical devices.

1.3.1 Quality Standards

Fimet Oy is a responsible dental manufacturer. The company’s quality management system

is certified by notified body (VTT) according to the standards:

SFS-EN ISO 13485:2012 Medical devices - Quality management system - System re-

quirements for regulatory purposes

1.4 Terms and Abbreviations

Accessible conductive part Part of the system (other than an applied part) that can be

touched without opening an access cover.

Technical Manual • 5

Applied part Part of the equipment that in normal use necessarily comes

into physical contact with the patient to perform its function.

Applied parts in Neo system are: seat, backrest, headrest,

footrest, handles, instruments, and suction tips.

System Dental Treatment System, consisting of Dental Unit, Dental

Chair, Operating Light, Foot Control, and Hand Control.

Dental Unit Part of the System consisting of Cuspidor, Instrument

Bridge, Display, Suction Head, Connection Box, and

Tray(s).

Dental Chair Part of the System consisting of patient chair including

seat, backrest, headrest, armrests, footrest, display and

joysticks.

Connection Box An enclosure consisting of power supply and connections

to drainage, pressurised air, mains power, suction, and wa-

ter.

Operating Light Light source with swivel arms and optional power supply.

Display Flat panel display with swivel arm.

Cuspidor Main body of the unit consisting of pneumatic centre,

spittoon bowl, clean water bottle, water heater, filter(s),

amalgam separator, and water taps for glass filling and

bowl flushing.

Instrument Bridge Device consisting of instrument holders, hoses with whip

arms or hanging hoses, swivel arms, control buttons, and

display.

Suction Head Device consisting of hanging hoses with holders, swivel

arms, control buttons, and display.

Tray Metallic or plastic tray with a supporting arm.

Foot Control Radio operated control device with batteries or pneumatic

remote control.

Hand Control Radio operated control device with batteries.

Joystick Four-way control device for controlling the chair

PCB Printed Circuit Board

1.5 Symbols and Markings

Follow instructions for use

The information provided is important and must be read.

Note!

The information provided is important and should be read before use.

6 • Technical Manual

Warning!

This symbol warns against possible operating errors or hazards to the product, user, patient

or maintenance personnel.

Warning: High Voltage!

This symbol warns against high voltage. The system has to be separated from mains volt-

age before maintaining. Only qualified personnel may open the enclosure provided with this

symbol.

Type B classified applied part. It is a part which is in contact with the patient,

and might be protectively earthed or not conductive.

Type BF classified applied part. Offers better electrical protection than type B

applied part. BF applied parts are electrically separated from earth, ‘floating’.

2011 Manufacturing year.

RF transmitter, a symbol for non-ionising radiation. There is a low power

close-range RF transmitter in the remote foot control.

IPX1 Ingress protection code, class 1 means that the product is protected against

vertically falling water drops.

Italics mean a term or abbreviation with an explanation defined in the section 1.4

Terms and Abbreviations.

Bold text is a reference to another document.

1.6 Referred Documents

Registration Form – Supplied with the device.

Service Book – Located in the pouch on the backside of the unit door

Technical Manual • 7

1.7 General

Warning!: If this equipment is modified, appropriate inspection and testing

must be conducted to ensure continued safe use of the equipment.

Contact the manufacturer for detailed descriptions on printed circuit boards, component

lists, and other information and spare parts required to repair and service the equipment.

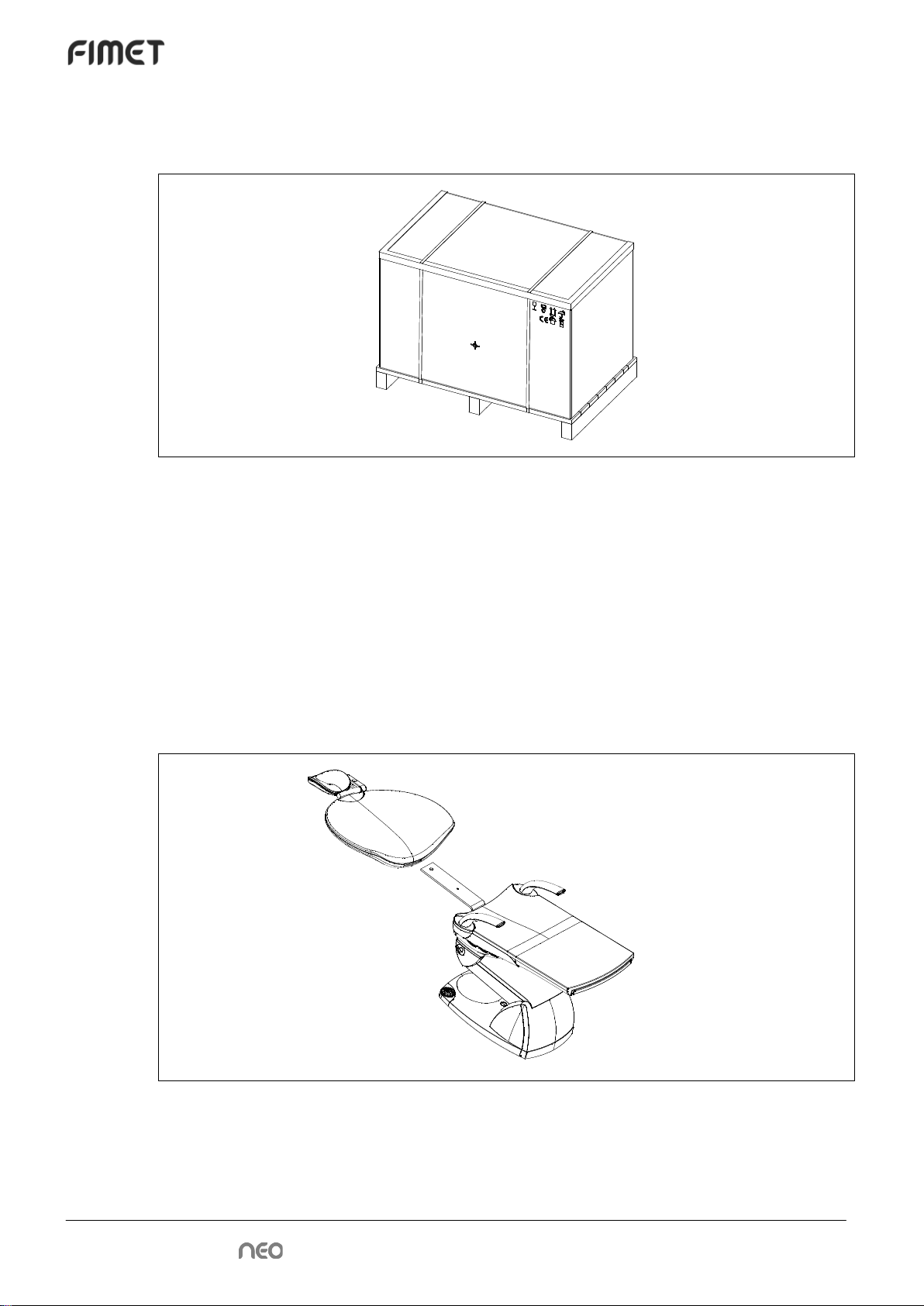

1.8 Transportation, Storage and Packaging

The patient chair and unit are delivered in separate packages.

Check the condition of the transport package before accepting the delivery. If the package

is damaged, please contact the carrier and report of the transport damage.

During transportation, the chair and unit packages may be stacked in piles of two. During

storage, piles of three are acceptable.

1.8.1 Symbols used in packages

Symbol

Instruction

Fragile, handle with care

Use no hand hooks

This way up

Keep away from rain

Stacking limit, number of packages allowed to be

stacked

Do not roll

Beware of scrathing the contents while opening the

package

0537

CE-mark with notified body number

8 • Technical Manual

1.8.2 Contents of the chair package

Item Order code Quantity

Neo Chair

1 pc

Seat upholstery

1 pc

Backrest

1 pc

Handle, right

1 pc

Handle, left

1 pc

Headrest

1 pc

Remote foot control

1 pc

Chair seat bottom back part

1 pc

Accessory box (+ other order specific items):

1 pc

Arm rest hole cover

59201011

2 pcs

Head rest lock tightening tool

59203610

1 pc

Chair bottom foot

59203660

5 pcs

PS Wafer 18*25*1,0

97601810

2 pcs

Screw 3 X 8

2 pcs

Screw 3 X 10

2 pcs

Screw 3 X 12

2 pcs

Screw 3 X 16

2 pcs

Screw 3 X 20

2 pcs

1.8.3 Contents of the unit package

Item Order code Quantity

Neo unit

1 pc

White spittoon bowl

C20171W

1 pc

Transparent spittoon bowl

C20171

1 pc

Technical Manual • 9

Item Order code Quantity

O-ring for spittoon bowl

OR7504

1 pc

Spittoon bowl sieve, lower

C20173

1 pc

Spittoon bowl sieve, upper

C20174

1 pc

All instrument flushing –holder

C10686

1 pc

Suction arm joint cap

C10548M

1 pc

Clean water bottle, 1l

32322301

1 pc

Unit accessory box

Adapter attachment screws, hex socket, M8x40

-

6 pcs

Adapter adjustment screws, hex socket, M8x30

-

6 pcs

Allen keys, 5 mm & 3 mm

-

2 pc

Suction hose, small volume, 2.03 m

99000010

1 pc

Suction hose, high volume, 1.96 m

99000009

1 pc

Suction hand piece, small volume

DU220 /

CA140 /

59205130

1 pc

Suction hand piece, high volume

DU210 /

CA150 /

59205090

1 pc

Suction tips for small volume suction

DU225

3 pcs

Suction hand piece tip

CA160

1 pc

Suction reduction piece, large

59204390

1 pc

Suction reduction piece, small

CA130

1 pc

General hose connector, white

59205471W

1 pc

Suction hose end piece, small, white

59205242W

1 pc

Suction hose end piece, large, white

59205241W

1 pc

Light pole via cover ring, white

59204274

1 pc

Block adjustment key

59204204

3 pc

PVC tube, Ø25mm x 100mm

-

2 pc

PVC connector 90° 32mm

PV03290

2 pc

Metal clamp for tube, 30mm

3333660

2 pcs

Compression fitting nut

3333190

2 pcs

Compression fitting ring

3333200

2 pcs

Lubricant for tube fittings

-

1 pc

Operating light pole cap

C10617

1 pc

Spring adjustment key

590208030

1 pc

Suction head attachment screw M8x18

-

1 pc

O-ring

OR156178

2 pcs

O-ring

OR12015

2 pcs

Tray arm stopper, white(*) (w. double tray)

59205200W

1 pc

Documents

Fimet Neo User Guide

1 pc

Instrument instruction manuals

n pc(s)

Neo Quick Guide

1 pc

10 • Technical Manual

Item Order code Quantity

Neo Registration card

1 pc

Neo Service book

1 pc

Neo monitor and camera power cable connections(*)

1 pc

* optional

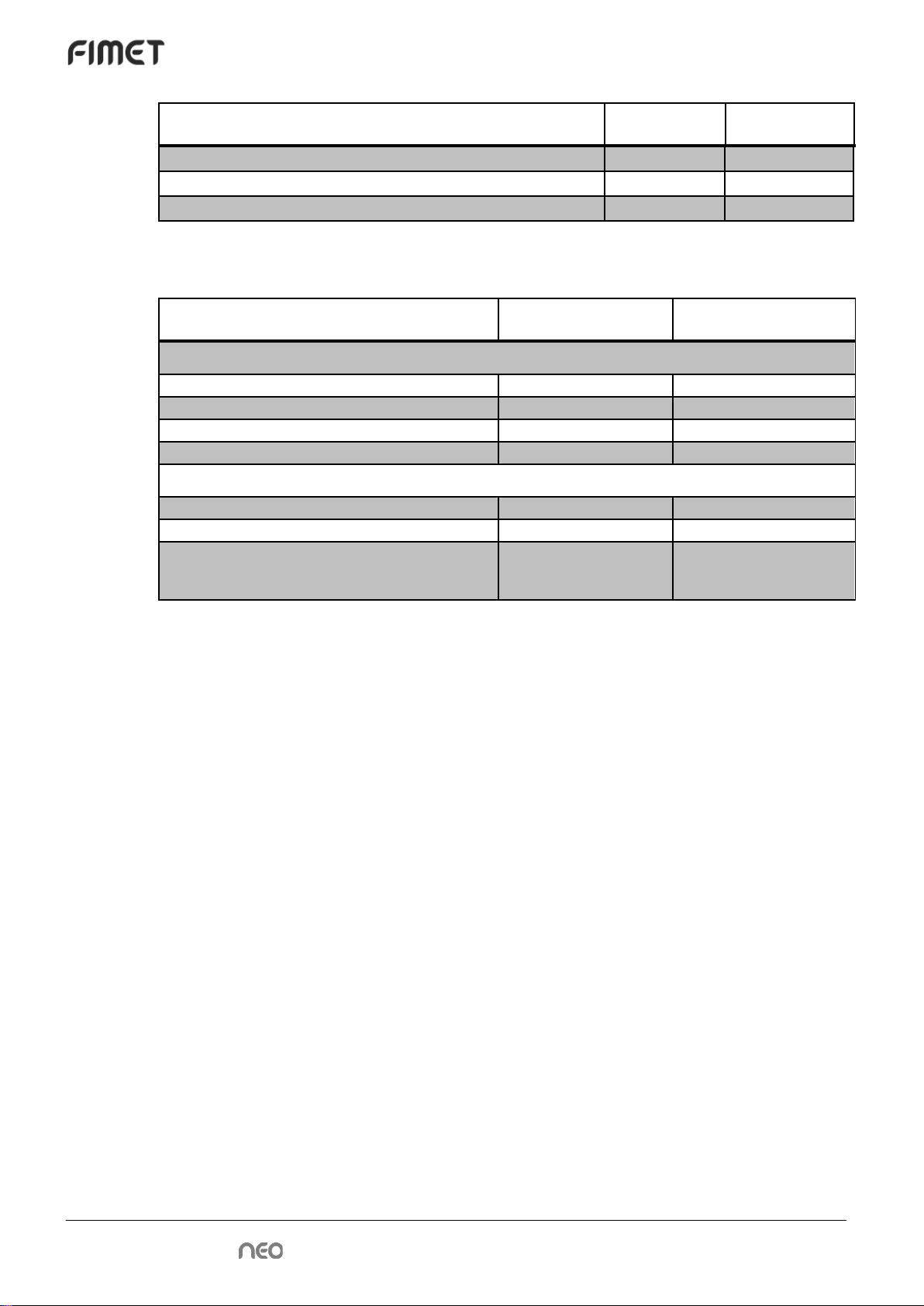

1.9 Environmental Specifications

Variable Min Max

During storage and transport

Humidity

10%

95%

Temperature

-40°C

70°C

Temperatures for display

-20°C

60°C

Air pressure

50 kPa (0.5 bar)

106 kPa (1.06 bar)

During use

Humidity

30%

75%

Temperature

10°C

35°C

Air pressure

80 kPa (0.8 bar, ca.

2000 m above sea

level)

102 kPa (1.02 bar, ca.

60 m below sea level)

Using the product in a moving vehicle is not allowed.

1.10 Maximum lifting capacity

The chair is designed to lift patients weighting 135 kg maximum. The total lifting capacity

(including the chair, patient, and other parts of the system) is 250 kg.

Maximum weight of the Display is 8 kg.

Technical Manual • 11

1.11 Movement Ranges

12 • Technical Manual

2 Installation

2.1 Space Requirements

Technical Manual • 13

14 • Technical Manual

2.2 Unpacking

2.2.1 Unpacking the chair

After cutting the bands, lift the cardboard hood away.

Lift both of the trays away. Then lift the cardboard collar away. Unscrew the fixing screws.

The chair is now ready to be positioned to the final location. The side of cardboard box can

be used as a slide to ease up the positioning of the chair.

2.2.2 Unpacking the unit

Cut the bands and open the cardboard box. Remove the cardboard box. Detach the wood-

en frames around the unit. The unit is now ready to be attached to the chair.

2.3 Attaching Backrest

Slide the backrest in its place. Make sure the locking mechanism locks the backrest.

Technical Manual • 15

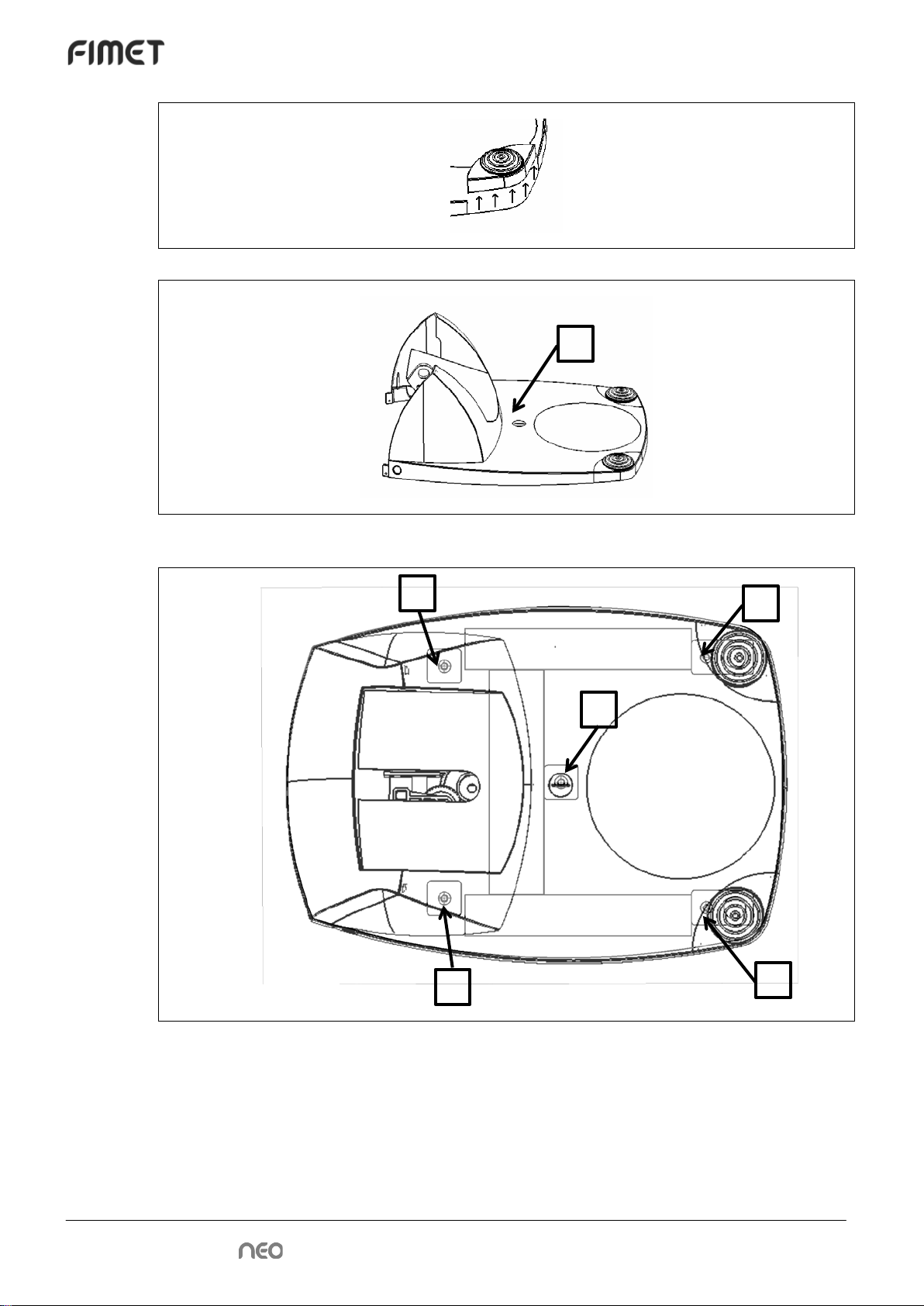

2.4 Attachment to floor

Remove screws A from both sides of the base.

Then detach the back cover. Now two out of five attachment screws are accessible.

Then push joystick inwards to uncover the screw hole. Then unscrew joystick attachment

screw and detach the joystick by lifting it carefully.

A

A

B

C

C

16 • Technical Manual

The C attachment screws are now accessible (4/5 in total).

The last attachment screw (3) is under a cover which can be detached using a suitable tool,

for example a coin.

Figure 1: Attachment bolts

The five attachment screws are located as shown in picture above.

B

3

1

5

2

4

Technical Manual • 17

2.5 Floor materials

The Fimet Neo can be attached to different kinds of floors; for example floors made of con-

crete, wood, or gypsum. Table 2: Examples of attachments lists examples which are ac-

ceptable. The following table (Table 1: Minimum withdrawal strengths) shows the required

pulling strengths the attachment bolts have to withstand (withdrawal strengths).

Table 1: Minimum withdrawal strengths

Number of attachment

bolts

Attachment bolt places (see Figure 1:

Attachment bolts)

Minimum withdrawal

strength / bolt

1

[3]

2700 N

3

[1],[3],[5]

800 N

5

[1],[2],[3],[4],[5]

700 N

Table 2: Examples of attachments

Material of floor Number of

attachment

bolts

Attachment type Attachment hole

diameter and

depth

Withdrawal

strength / bolt

Concrete, K25 1 Würth Wümax 8x50 8 mm x 60 mm 3600 N

Concrete, K25 3,5 Würth Wümax Dome

6x40 6 mm x 45 mm 1200 N

Wood, 28 mm

solid wood floor 3,5 Hex Head Wood

Screw 6x40 6 mm x 45 mm 2000 N

Gypsum, 25 mm 5 Toggler Alligator –

anchor + WÜPO

General Screw 6x40

8 mm x 50 mm 775 N

2.6 Attaching unit to the chair

Slide the unit pallet next to the chair. Connect power cords from the unit to the chair tempo-

rarily to position the chair. Connect the connection box to the mains temporarily. Power up

the chair and position the height of the adapter (raise the chair) so that the unit can be

placed on it easily by sliding the pallet closer.

Attach the adapter. See chapter Adapter adjustments.

18 • Technical Manual

2.7 Adapter adjustments

Figure 2: Adapter with bolts

Attach the black hex screws. Adjust the cuspidor horizontally and vertically straight by loos-

ening the corresponding attachment screws. Ensure that at least 8 mm of the threaded part

of the bolt is inside the hole of the patient chair body plate. When the cuspidor is in the cor-

rect position attach and tighten the bright securing hex screws.

The black attachment hex socket (Allen) screws are of type M8 * 40, hardness 12.9, non-

galvanized. 6 pcs.

The bright securing hex socket (Allen) screws are of type M8 * 30, hardness 8.8, galva-

nized. 6 pcs.

2.8 Connecting the cables

Connect the cables

Figure 3: Chair connector PCB (CNA)

Black attachment

hex screw

Bright securing &

adjusting hex

screw

Screw for

grounding wire

Data bus con-

nector

Power connector

Technical Manual • 19

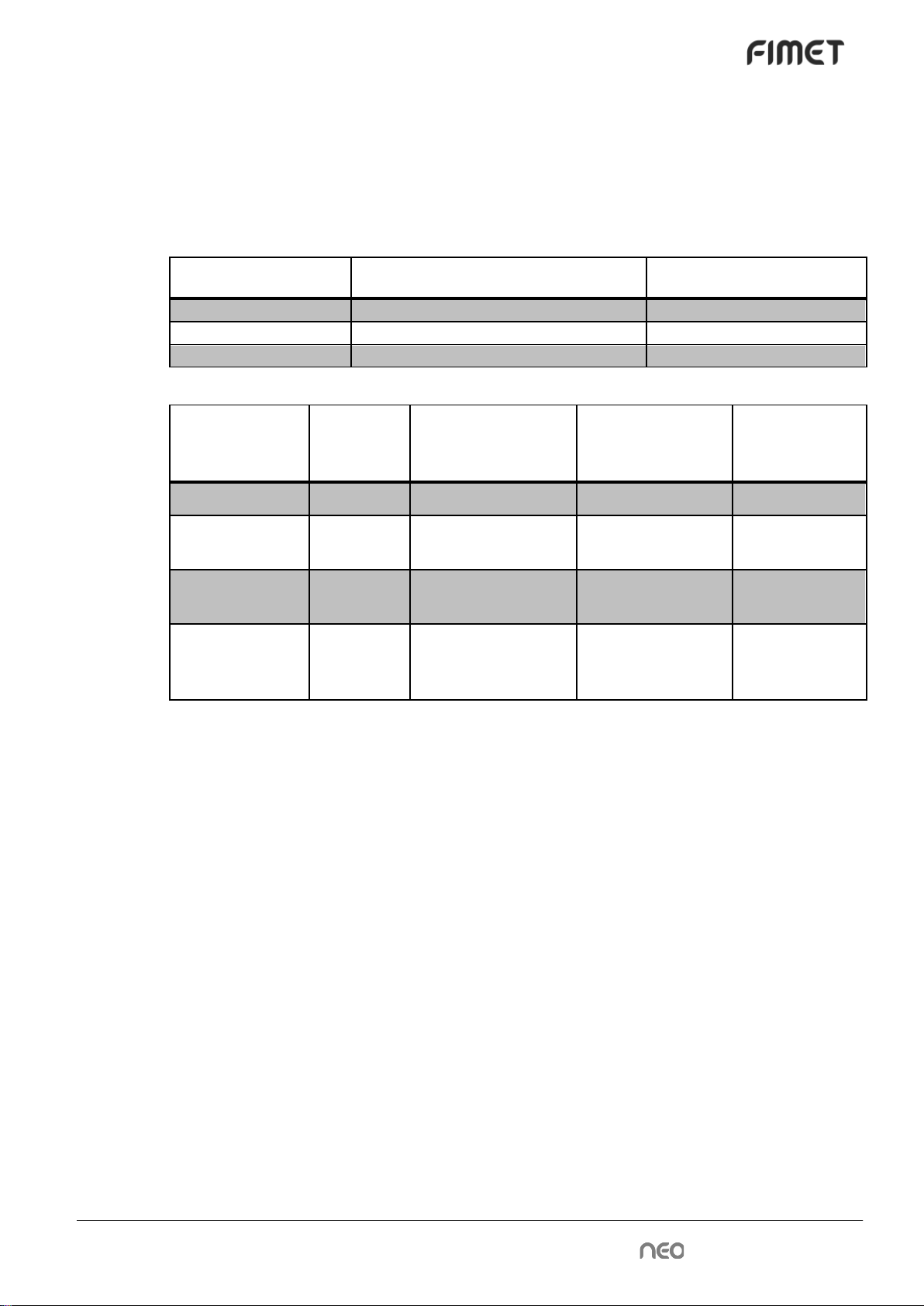

2.9 Removing transport screw

Figure 4: Electronics protection cover

Unscrew the attachment screw and remove electronics protection cover.

Figure 5: Transportation locking screw

Loosen the transportation locking screw. This screw prevents the rotation of the cuspidor

during transportation.

2.10 Adjusting the instrument arm spring

Transportation

locking screw

Electronics

protection

cover screw

Adjustment

opening cover

20 • Technical Manual

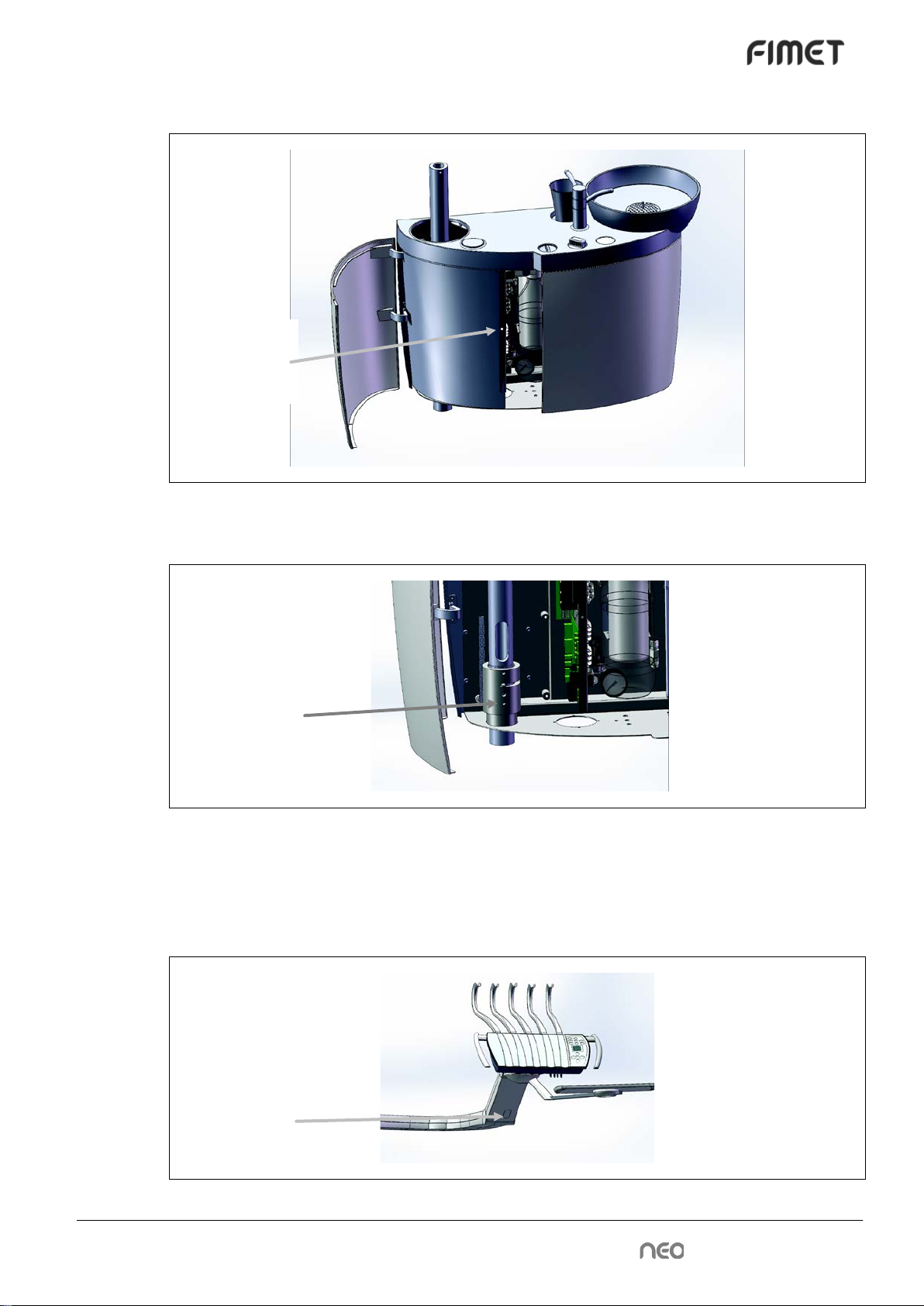

Figure 6: Instrument Arm spring adjustment

Remove the spring adjustment opening cover before adjusting the tension of the spring.

This adjusts the balance and displacement force of the instrument arm.

2.11 Adjusting the stiffness of tray rotation

Tray Arm

The stiffness of the rotation of the tray arm is adjusted with the adjustment screw (shown on

the picture). Use 3 mm hex key for the adjustment. The adjustment screw is locked with the

locking screw to prevent loosening. Use 4 mm hex key for the locking.

2.12 Headrest lock tightness adjustment

The movements of the headrest are double articulated. The headrest can be adjusted

around the two axels when the locking lever is in open position. The tightness of the locking

system is adjusted with a plastic tool delivered with the system.

Figure 7: Headrest lock tightening tool

Remove the plastic plug on the vertical bar carefully with the chisel end of the tool. Then

adjust the tightness of the nut with the key and replace the plug. The plug locks the tighten-

ing nut in its place.

Adjustment

screw

Locking

screw

Other manuals for NEO

1

Table of contents

Other Fimet Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual