Fineart FINE 2000WASH-PERF User manual

http:// www.fineart-light.com

- 1 -

CONTENTS

Contents……………………………………………………………………1

FINE 2000 (FINE 2500) Wash Perf dimension diagram……………..3

Security Information……………………………………………………..4

Delivery……………………………………………………………………..5

Included items..………………………………………………………5

Transportation lock..…………………………………………………6

Single flight case..……………………………………………………6

Double flight case..…………………………………………………..6

Lamp..………………………………………………………………………7

Lamp introduction..…………………………………………………..7

Lamp replacement.…………………………………………………..7

AC power supply………………………………………………………….9

Fuses.…………………………………………………………………9

Power supply adjustment...…………………………………………9

Power connection…...…………………………………………….. 10

Data………………………………………………………………………..10

Connection equipment……………………………………………..11

Data link……………………………………………………………. 11

Rigging …………………………………………………………………...11

Equipment installation to stand...…………………………………11

Control panel…………………………………………………………….12

DMX address and protocol settings.……………………………..12

FINE 2000 (FINE 2500) Wash Perf functional introduction……………...... 13

Color...……………………………………………………………….13

Framing system.……………………………………………………14

Dimmer and Strobe...………………………………………………14

Strobe..………………………………………………………………14

Color temperature correction.……………………………………..14

Auto Zoom... ………………………………………………………..15

P/N 399903650601 VERSION A

http:// www.fineart-light.com

- 2 -

Iris…………………………………………………………………15

Pan/tilt.……………………………………………………………15

Speed control.……………………………………………………15

Controlling channels……………………………………………………16

DMX channels..…………………………………………………19

Menu control..……………………………………………………26

Routine maintenance…………..………………………………………32

Cleaning.…………………………………………………………32

FINE 2000(FINE 2500) Wash Perf channels diagram..……………33

http:// www.fineart-light.com

- 3 -

FINE 2000 (FINE 2500) Wash Perf dimension diagram

http:// www.fineart-light.com

- 4 -

Protection against explosion

Shields lenses and ultraviolet screens must be replaced if they

have become visible damaged to such an extent that their

effectiveness is impaired.

Replace the lamp immediately if it becomes visually deformed,

damaged or in any way defected.

Protection against electrical shock

Must disconnect the power supply when install, or remove of

bulbs, fuses and other components. Meanwhile using the ground-

ing must be closed to the ground.

Make sure that the mains power supply you use is up to local

construction and electronic code regulation, the over-load

protection earthing is essential.

Do not expose the device to rain or moisture.

All the equipment maintenance must be performed by a qualified

person with technical certificate.

Protection against ultraviolet radiation and light bulb explodes

Never operate the fixture with missing or damaged lenses and/or

covers.

Protecting your hands and eyes with

gloves and glasses, make the equipment

cool down at least 15 minutes.

Prolonged exposure to an unshielded

discharged lamp can cause eye and skin

burns.

Need to replace the broken bulb and the

bulb is to be replaced before the useful life.

Protection against burning or fire

Do not attempt to bypass the thermostat switch or fuse, replace

defective fuses with specified ratings only.

Keep flammable materials far away from the fixture (fiber, food,

and paper). Minimum distance from the flammable material is 1

meter.

Figure 1: pan/tilt lock

http:// www.fineart-light.com

- 5 -

Don’t illuminate surfaces within 3 meters of

the fixture. Projecting object in short

distance.

Ensure a minimum clearance of 0.1 meter

around the cooling fans and ventilations.

Do not place any filter or other object onto

the optical lens.

Allow the fixture to cool for at least 15

minutes before transit.

Do not revise the fixture or install any parts

not from Guangzhou CHAI YI LIGHT Co. Ltd.

When the ambient temperature exceeds 40 ℃,prohibit the use of

equipment.

Protection against injury due to falls

Do not lift or carry the fixture alone.

To inspect that the structure and the truss hooks

are in good condition and can bear about 10

times the weight of the fixture.

Ensure the cover and all riggings are securely

fastened, safety wire is necessary to use as a

secondary attachment.

To make the pulley lower than the

working position while installing or

dismantling the fixture.

Delivery

Important! Always open the horizontal and

vertical transport lock before use.

Included items

The FINE 2000 (FINE 2500) Wash

performance is packed with single or double

flight case. Included items show as below:

Figure 4: Open the rear cover

Figure 3: double transportation

Figure 2: single

transportation

http:// www.fineart-light.com

- 6 -

User manual 2 Suspension fasteners

Warranty card 1 Safety wire

1 Signal cable

Fuse configuration

Power

Fuse

200/250V

15A 6×30(main fuse)

6.3A 5×20(PCB board fuse)

3.15A 5×20(PCB board fuse)

10A 5×20(PCB board fuse)

100/120V

20A 6×30(main fuse)

6.3A 5×20(PCB board fuse)

3.15A 5×20(PCB board fuse)

10A 5×20(PCB board fuse)

Transportation lock

The head and arm can be locked during transport, locked location as

Figure 1. Open the lock before operation.

Single flight case

Dismantle the packaging

1. Unlock the flight case

2. Lift up the fixture by two men, each holding a lift handing, then

take it out from the flight case.

3. Open the horizontal and vertical transport lock before operation.

Fixture package

1. Cut off the power and cool down.

2. Lock up the head and arm (shown as figure 2)

3. Pack included items to the bottom of flight

case and then lock up the flight case.

Double flight case

Unpack

1. Open the flight case and pull out the drawer

2. Open the head vertical lock

3. Lift it by two men, each person for one side.

Figure 5: Unlit the lamp

http:// www.fineart-light.com

- 7 -

Package

1. Disconnect power and allow it to cool.

2. Turn the arm horizontally to the bottom so that it locks vertically from

the rear.

3. Pull out the drawer at its full length. Hang the fixture to the drawer

by two men, shown in Figure.3.

4. Lens cap faced the sidewall rather than door( as Figure.3). Then

lock the moving head(do not lock the horizontal lock)

5. Slide the drawer in and do not close the air box with violence.

Lamp

FINE 2000(FINE 2500)Wash Performance

Comes with OSRAM HMI/HTI 1200W/S

(1500W/S) or PHILIPS MSR GOLDTM

1510(1200)SA/DE discharge lamp. This lamp

offers color temperature 6000K, color rendering

index: larger than 90, life expectancy: 750 hours.

Only fixture of FINE 2000(FINE 2500)Wash Perf

incorporated with electronic ballast is capable of

hot re-strike.

The lamp sources features in a dedicate key on

a lamp end, as Figure 6

Warning! Don’t use other types of lamps instead of the intended ones,

otherwise safety hazards or damages to the fixture may arise.

The average life expectancy of the lamp is 750 hours, in order to

reduce the risk of damage to the lamp, should replace the lamp when

lamp life is in the use of more than 125%.

Lamp replacement

Important! Do not touch the quartz bulb of the lamp by bare hand,

always keep the lamp clean and free of oil, clean the lamp by alcohol

with a fry cloth, especially when you accidentally touch the bulb.

Replace bulb

Figure 6: install fixture

http:// www.fineart-light.com

- 8 -

1. Cut off the power and cool down

the fixture completely. Lock the

moving head when it’s horizontal.

2. As figure 4, CCW rotate the

screws on the lamp-access panel

by 90 degree with a flat-head

screw driver. Slide out the panel

and leave it still.

3. As shown in Figure 5, the left side

of the control spring up, pull out one end of the lamp, the other side

is also out of the hole.

4. As shown in Figure 6, put the gas nozzle backwards, and place the

new lamp in right side to the groove. Pull the spring of left side,

and then the place the other end of lamp.

5. Align the lamp with the slots in the reflector until they are on the

same plane. Slide the lamp inside and make sure the lamp will not

collide with the reflector, then screw up lamp-access panel.

6. Attention: When installing and removing the bulb, push the cover

gently along the slide bar and pull it out. Do not let the bulb touch

the reflector and the surrounding hard objects to prevent the bulb

from being damaged. (Figure 7)

Lamp adjustment

1. Turn on the power and wait for reset. Ignite the lamp through a

lighting controller or control panel. Then cast a beam on a plane at

least 3M away.

2. Adjust “UP-DOWN” screw with hex key

(=3MM), until highlight spot appear at

the flash centre.

3. If the illumination of the flash centre is

too bright, counterclockwise adjust

IN-OUT screws till brightness uniform.

If too dim, clockwise adjust “IN-OUT”

screws till brightness uniform(as figure 8)

Figure 8 adjust light

UP-DOWN

IN-OUT

Figure 7

http:// www.fineart-light.com

- 9 -

AC power supply

Warning! In prevention of electrical shock, the fixture must be well

earthed. Fuse applied in AC mains cords, leakage switch and

fault-earth protections are necessary.

Important! Inspect the supply apparatus before powering.

Mains fuses

There are 2 kinds for FINE2000(FINE2500) Wash Perf

Main fuse rating 20A with AC 100-120V

Main fuse rating 15A with AC 200-250V (Install fuse of the correct

rating in proximity to the main switch.)

Power supply adjustment

90-260V 50-60HZ for FINE 2000(FINE 2500) Wash perf

(electronic ballast)

00-250V 50/60HZ for FINE 2000(FINE 2500) Wash perf

( magnetic ballast)

FINE 2000(FINE 2500) Wash perf(electronic ballast)

90-260V 50-60HZ wide operating voltage range, a dedicated

range-setting switch (110V-220V) should be appropriately chose

based on the mains used.

An intelligent power functionality is extremely useful in the cases

when blackout caused by dimmer or superimposition of all CMY

filters over 3 seconds, the lamp power will be 700W. As a result, it

prolongs the lamp life as well as protecting color filters from high

temperature, and reduces the energy consumption.

FINE 2000(FINE 2500) Wash perf(magnetic ballast version)

Transformer and ballast used must conform to local supply

voltage and frequency. Fault installation may cause over-heat

damage or degrade its performance. Equipment intended to be

connected to mains supply has been marked for correct wiring.

Note: 100-120V power supply is not applicable for FINE 2000

Wash perf ( magnetic ballast)

http:// www.fineart-light.com

- 10 -

Power connection

Notice: Connecting the equipment to the power supply, do not

connect to silicon system, or else, it will destroy the equipment. The

fixture is provided with standard 3-pin socket. Please according to

below table connect to power supply, Yellow/Green line must be

earthed. If you still have any question to the installation, please

consultant with the experienced electrician.

When power is supplied, put the base switch to the position “I”.

Color

Wire

Mark

Brown

Live

L

Blue

Neutral

N

Yellow/Green

Earth

Data

Note! Do not connect more than one input and one output

FINE 2000(FINE 2500) Wash Perf has 3-pin and 5-pin plug connectors

for DMX inputs and outputs.All jacks are grounded with 1 pin, 2 pins

with negative polarity and 3 pins with positive polarity.

Connection equipment

Use an insulated twisted-pair shielded cable for the DMX 512

unit; standard loudspeaker cables can not reliably control

long-range data. 24AWG cable is for more than 300 meters. To

use long-distance signal transmission, you must join the DMX

512 signal amplifier.

Do not use two outputs to separate the connection. To isolate

this continuous connection component branch, use the DMX512

distributor.

Do not overload the connection, can be connected up to 32

devices in a continuous connection.

Terminate the connection by installing a terminal plug in the

output jack of the final fixture. The 0.25W 120Ω resistance

welding terminal plug 2, 3 pin, receiving control signal so that it

http:// www.fineart-light.com

- 11 -

does not reflect or cause interference. If you use a distributor,

please terminate each branch of the connection.

Data link

a) Connect the DMX input, from the controller to the 3-pin socket

of FINE2000 (FINE2500) Wash perf.

b) Use the plug that matches the data cable to connect the

output of the nearest device to the next device input.

c) Make the plug which will match the 120Ω terminal plug

inserted into the last device 3 pin socket output.

Rigging

FINE 2000 (FINE 2500) Wash Perf can be placed on the stage or

installed in the bracket of any direction. With fast lock system, four

directions of Figure 9 can be locked on the bracket quickly and easily.

Figure 9 Fixture holder position

Warning!

To secure the unit with 2 clamps, turn 1/4 turn clockwise to lock the

fastener. Adding a safety rope connected to the hole in the base, be

careful not to connect to the transport handle.

Equipment installation to stand

1. To inspect the truss hook/rigging are in good condition and can

bear about 10 times the weight of the light fixture. Be sure the truss or

pipe construction can bear 10 times the weight of all equipment of all

equipment including lights, truss hooks, cables and accessories.

2. Lock bracket by M12 screws and nuts.

http:// www.fineart-light.com

- 12 -

3. Install a clamp point in the base, insert the fasteners into the base

and turn the two levers a full 1/4 buckle clockwise to lock it completely,

and install the second clamp in the same way.

4. If the truss can be lift down, the light fixture can be lifted and

hooked from flight case directly. When the lights equipments need to

lift high, the working area below should have some barrier to ensure

the installation works operated under safety condition. Finally suspend

the fixture onto the truss, let the arrows point in the projection direction,

and fasten clamps totally. (figure 10)

5. Connect a safety rope which can bear 10 times weight of the

fixture, the attachment is designed to fit a clamp.

6. Check the horizontal and vertical locks have been unlocked, be

sure there is no explosive or inflammable materials around the fixture

in 1meter around.

Control panel

LCD controlling panel for address setup and property setup

DMX address and protocol settings

DMX address, also known as the start channel, is an indication

channel used to receive the controller and is controlled individually. If

you want the same action, address sharing can be used for diagnostic

purposes, symmetrical control, especially in combination with

horizontal vertical position inversion.

About personality setup, please refer to the menu control in the user

manual.

Picture 10

http:// www.fineart-light.com

- 13 -

When fitting a color

filter or gobo, the

coated side should

face the lamp

source

FINE 2000(FINE 2500)WA PERF Functional Introduction

Color

The color mixing system consist dichroic cyan, magenta and yellow

(CMY) color filters. It is a subtractive system that removes color

components from the white light.A full superimposition of all CMY

filters results in blackout. For the maximum brightness of the color

mixture can be mixed with two colors.

Color wheel I: Color wheel II:

Color filter 1: green Color filter 1: dark red

Color filter 2: dark blue Color filter 2: orange

Color filter 3: UV Color filter 3: dark green

Color filter 4: pink Color filter 4: blue

Color filter 5: white light Color filter 5: white light

The color system consist two color wheels (gobo wheel 2 can change

to glass gobos), each equipped with 4 interchangeable filters through

which easier and quicker color transferred can be achieved.

Color wheel 2 can change gobos

http:// www.fineart-light.com

- 14 -

Framing system

FINE 2000 (FINE 2500) Wash PERF comes with a framing module,

which can be swiveled by 90°through synchronous belt drive. Four

interleaved framing blades, each driven by stepping motor, are

capable of panning +/-30°. Combination of displacements and pan of

four individual blades bring up unlimited shades, rectangle, diamond,

triangle, etc. Besides, 90°swiveling range of the whole framing

module make it possible to rotate the above shades at any angle, a

perfect means of setting up scenes for theatre.

The iris module is attached to the framing module, thus it can work

independently or swivel in conjunction with the framing module.

Dimmer and strobe system

Two dimmer system——internal machine dimmer/ strobe

system(shutter),one dimmer wheel for option(customed indivudual)

Strobe system

0—100% electromotion dimmer,on/ off instant, convert by random,can

strobe to 10HZ, random and varibalefrequency can control the dimmer

machinturn onm slowly and fade away or off, then turn on slowly.

CTC (color temperature correction)

The CTC system applies a specific color filter by which it can lower CT

(color temperature) from 6500K to 2900K.

Framing system

http:// www.fineart-light.com

- 15 -

Auto zoom

Zoom lens beam range:24°-40°, use standard lens and iris system

Iris

The minimum diameter of the aperture only amounts to 15% of its full

open diameter. Strobe effects can be achieved through setting up

opening/closing speeds. (200-step resolution).

Pan/tilt scan

Pan scan 540°tilt scan 255°, if you need more accurate positioning,

please choose 16bit.

Pan/tilt speed(fast、normal、slow)can set by speed selection in menu.

Speed control

Speeds from actuating to normal working are controllable. Tracking

tracing comes along by setting “pan/tilt speed” channel and “effect

speed” channel. These channels are independent.

Open iris by the ways as follow:

for an instant case of track tracing, fade out previous scene after

aperture completely close, then reset a new scene before the aperture

fully open. If preset interval for this cycle is 10 seconds, an initial value

199(aperture fully close) will reduce to 0(aperture fully open) within the

interval, a controller regulates the aperture closing or opening in

accordance with the value varied.

http:// www.fineart-light.com

- 16 -

Controlling channels

Control channel:45 control channels mode and 28 control channels

45 control channels mode function:

Channel 1:Strobe

Channel 2:Dimmer

Channel 3:Dimmer 16bit

Channel 4:Pan rotation

Channel 5:Pan rotation 16bit

Channel 6:Tilt rotation

Channel 7:Tilt rotation 16bitI

Channel 8:Pan/tilt speed adjustment

Channel 9:Pan/tilt macro function

Channel 10:Pan/tilt macro speed

Channel 11:Blade 1 pan

Channel 12:Blade 1 pan16bit

Channel 13:Blade 1 moves inwards/outwards

Channel 14:Blade 1 moves inwards/outwards 16bit

Channel 15:Blade 2 pan

Channel 16:Blade 2 pan 16bit

Channel 17:Blade 2 moves inwards/outwards

Channel 18:Blade 2 moves inwards/outwards 16bit

Channel 19:Blade 3 pan

Channel 20:Blade 3 pan 16bit

Channel 21:Blade 3 moves inwards/outwards

Channel 22:Blade 3 moves inwards/outwards 16bit

Channel 23:Blade 4 pan

Channel 24:Blade 4 pan 16bit

Channel 25:Blade 4 moves inwards/outwards

Channel 26:Blade 4 moves inwards/outwards 16bit

Channel 27:CMY cyan

Channel 28:CMY cyan 16bit

Channel 29:CMY magenta

http:// www.fineart-light.com

- 17 -

Channel 30:CMY magenta 16bit

Channel 31:CMY yellow

Channel 32:CMY yellow 16bit

Channel 33:CTC color temperature

Channel 34:CTC color temperature16bit

Channel 35:Zoom

Channel 36:Zoom 16bit

Channel 37:Iris

Channel 38:Blade rotation

Channel 39:Color 1

Channel 40:Color 2

Channel 41:Color macro function

Channel 42:Speed effect adjustment

Channel 43:CMY macro function

Channel 44:Lamp half power selection

Channel 45:Fan control

28 control channel function:

Channel 1:Strobe

Channel 2:Diming

Channel 3:Pan rotation

Channel 4:Pan rotation 16bit

Channel 5:Tilt rotation

Channel 6:Tilt rotation 16bit

Channel 7:Pan/tilt speed adjustment

Channel 8:Pan/tilt macro function

Channel 9:Pan/tilt macro speed

Channel 10: Blade 1 pan

Channel 11:Blade 1 moves inwards/outwards

Channel 12:Blade 2 pan

Channel 13:Blade 2 moves inwards/outwards

Channel 14:Blade 3 pan

http:// www.fineart-light.com

- 18 -

Channel 15:Blade 3 moves inwards/outwards

Channel 16:Blade 4 pan

Channel 17:Blade 4 moves inwards/outwards

Channel 18:CMY cyan

Channel 19:CMY magenta

Channel 20:CMY yellow

Channel 21:CTC color temperature

Channel 22:Zoom

Channel 23:Iris

Channel 24:Blade rotation

Channel 25:Color 1

Channel 26:Color 2

Channel 27:Color macro function

Channel 28:Speed effect adjustment

http:// www.fineart-light.com

- 19 -

DMX Channels Opening code =0

28

channel

45

channel

Value

Percentag

e

Function

1

1

0-19

20-49

50-72

73-79

80-99

100-119

120-127

128-147

148-167

168-187

188-190

191-193

194-196

197-199

200-202

203-207

208-217

0-17

8-19

20-28

29-31

31-39

39-47

47-50

50-58

58-65

66-73

74-75

75-76

76-77

77-78

78-79

80-81

82-85

Strobe

Shutter, close

Open

Strobe, fast→slow

Shutter open

Strobe open, fast→slow

Strobe close, fast→slow

Shutter open

Random Strobe, fast

Random Strobe, medium

Random Strobe, slow

Shutter open

Random opening pulse, fast

Random opening pulse, slow

Random closing pulse, fast

Random closing pulse, slow

Shutter, open

Fixture reset

2

2

0-255

0-100

Dimming 0%-100%

-

3

0-255

0-100

Dimming 16bit

3

4

0-255

0-100

Pan rotation

4

5

0-255

0-100

Pan rotation 16bit

5

6

0-255

0-100

Tilt rotation

6

7

0-255

0-100

Tilt rotation 16bit

This manual suits for next models

1

Table of contents

Other Fineart Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Govee

Govee H61E0 user manual

Federal Signal Corporation

Federal Signal Corporation 151XST Series Installation and maintenance manual

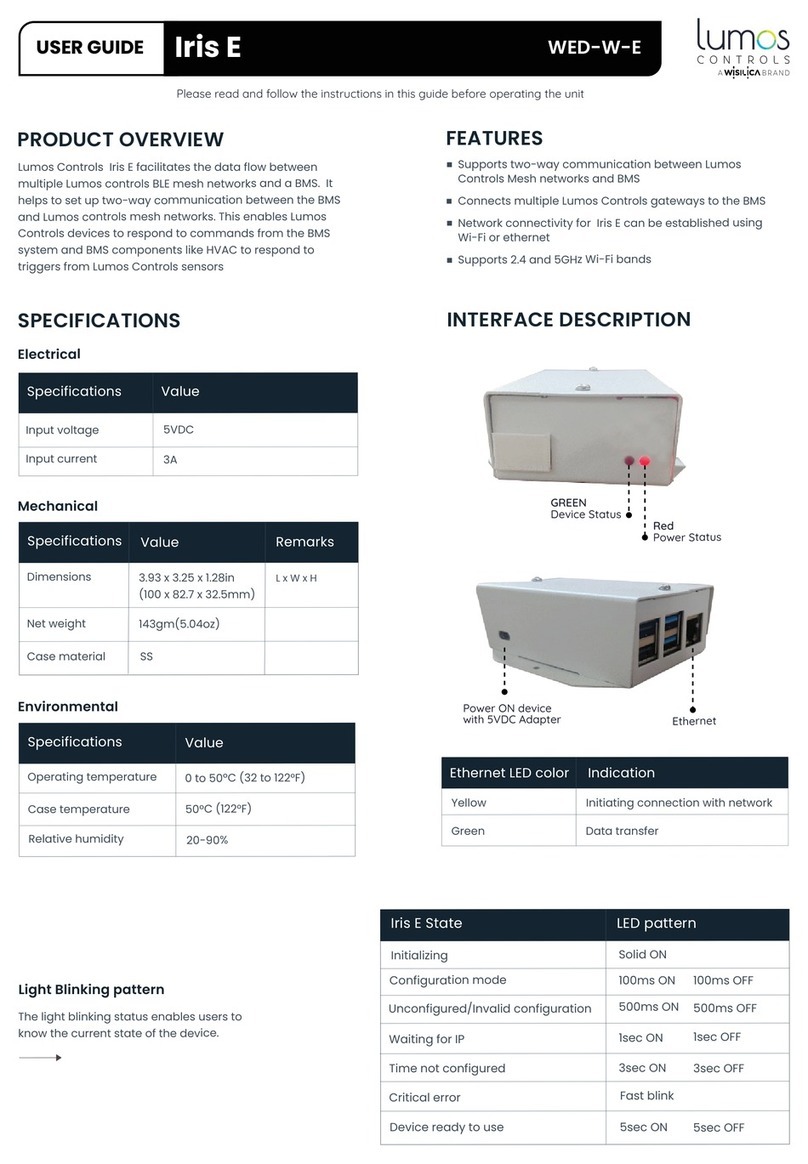

WiSilica

WiSilica Lumos Controls Iris E user guide

LDR

LDR Nota f1200 XL black operating instructions

Velleman

Velleman HQ POWER VDL25ST user manual

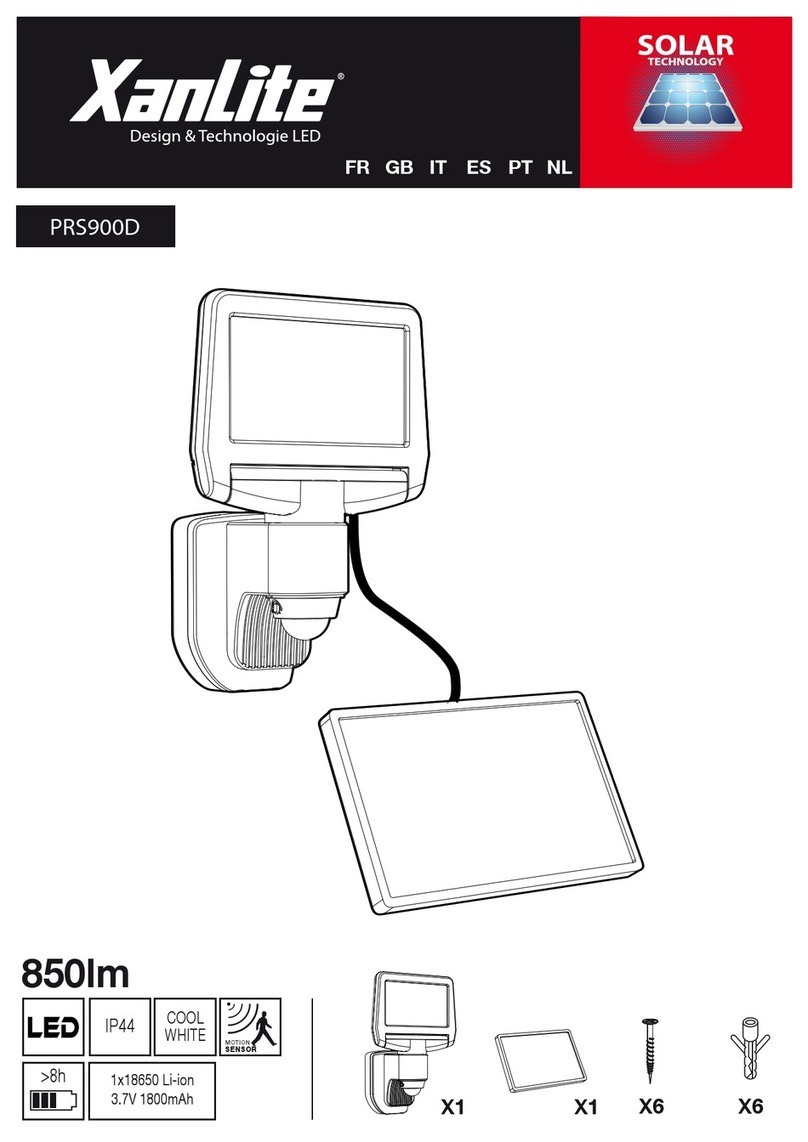

XanLite

XanLite PRS900D user manual