FIORENTINI I115SSDE Specification sheet

ING. O. FIORENTINI S.p.A.

INDUSTRIAL CLEANING MACHINES

COMBINED MODEL

I115SSE/ DE/ GE

INSTRUCTIONS FOR USE

AND MAINTENANCE

CONTENTS

1.

GENERAL INFORMATION

1.1. Symbols used…………………….…….........................……......……..……….

1.2. Notes…….................................................…………...…………..............…...............

1.3. Consulting the manual……......…………………………....….........………….…………

1.4. Warranty..............................................................…………...…………...….…...........

1.5. Declaration of Conformity…….....................................…...........………….…...………

2.

MACHINE FEATURES AND TECHNICAL DATA

2.1. Identification………...................................…........……………………….....…..........

2.2. Descriptions and components……...............................….…………….….……...........

2.3. Technical data sheet……………...……………………………….…….…........

3.

SAFETY

3.1. Recommended machine use……....………....…....……………….......…………........

3.2. Misuse.……………………………………………….…..…………..

3.3. Recommended equipment…………………………………………………………………

3.4. Operator qualifications........………….......……………...…………............................

3.5. Safety and warning devices ……………..................…...…………..............................

3.6. Safety systems...............................................…………..….…....…………......…........

3.7. Residual dangers …………………………………………………………………………

3.8. Safety signs…………………………………………………………….………………...

4.

START-UP AND OPERATION INSTRUCTIONS

4.1. Transport and handling……..............….....................…....……………….….…........

4.2. Storage………..............................................…………….……………..................

4.3. Machine unpacking ..…………………….......................….....

4.4. Unpacked machine handling ........………………………..……..........

4.5. Installation…............................................................………………..…….….............

4.5.1. Battery installation (battery powered version).…...……………….…...…........…....

4.5.2. Battery charger installation…………………………………………………………

4.6. Control and monitoring devices………………………………………….……………..

4.6.1. Control panel…………………………………………………………………………

4.6.2 Control board diagnostics………………………………………………………….

4.7. Operation……………………………………………………………………………..

4.7.1. Machine preparation and start-up…………………………………………………….

4.7.2. Choosing the right detergent……………………………..………………………..

4.7.3. Driving position adjustment…………………………………………………

4.7.4. Pedal controlled functions……………………………………………………………..

4.7.5. Detergent solution preparation……………………………………………………

4.7.6. Squeegee adjustment………………………………………………………………..

4.7.7. Water draining, waste box emptying and maintenance…………………………..

4.7.8. Sweeping brushes replacement and maintenance………………………………

4.7.9. Scrubbing brushes and splash guard replacement……………………………

4.7.10. Squeegee replacement…………………………………..……………………..

4.7.11. Sweeping unit suction filter and filter shaking motor replacement…………

4.7.12. RH/LH rubber blade replacement (centre brush)……………………………….

4.7.13. Oil top-up……………………………………………………………..

Congratulations on your choice!

Thank you for having chosen to purchase a product by FIORENTINI S.p.A., a world-leading

manufacturer and distributor of industrial cleaning machines.

Our long-standing experience and acquired know-how are the best guarantee of the technical

quality of your purchase; all our products are built from top quality materials to ensure

maximum reliability, sturdiness and functionality and to meet the requirements of even the most

demanding customers.

Feel free to contact us with any technical or commercial inquiry; we will be happy to supply any

details and information that you may need.

5.

MAINTENANCE

5.1. Routine maintenance table……………………..................….....…..………………..

5.2. Battery maintenance……………………………………………………………………..

5.2.1. Hydrometrics.………………………………………………………………………..

5.2.2. Water top-up…………………………………………………………………………...

5.2.3. Charge limits…………………………………………………………………………

5.2.4. Standby or inactive batteries …………………………………………………………

5.2.5. Battery charger technical features…………………………………………………..

5.2.6. Battery disposal…………………………………………………………………………

5.3. Engine maintenance (Diesel/Gas versions)………………………………………..

5.3.1 Engine removal…………………………………….………………………………..

5.3.2 Motor maintenance……………………………………………………………………..

5.3.3. Dynamo motor belt replacement …………………………………………………….

5.4 Suction motor and recovery tank float maintenance…..………..

5.5. Wiring system checks………………………………………………………………...

5.6. Inspection summary schedule…………………………………………………………..

5.7. Maintenance log……………………………………………………………………….

6.

TECHNICAL ASSISTANCE

6.1. Technical assistance contact information......…………..........................................

6.2. Claim report ……………………………..…………...………………….…......................

GENERAL INFORMATION

I115SS

Rev. 001

22/12/2014

4/58

1. GENERAL INFORMATION

1.1. SYMBOLS USED

This symbol is used to alert the operator to important procedures or precautions to be

followed in ordertopreventdamages to usersorthe machine

This symbol is used to alert the operator to important general information.

1.2. NOTES

1.3. CONSULTING THE MANUAL

This manual deals exhaustively with all the issues considered necessary for an easy and safe use of the

machine, in compliance with European Directives on product safety.

We therefore suggest to all authorised operators to carefully read this manual throughout and

contact FIORENTINI S.p.A. in case of any doubt. This manual should also be used for reference

whenever there are doubts concerning a procedure or operation to carry out or to train new

operators.

In print, pictures and drawings can look slightly different from actual machine parts, without however being

perceived as confusing.

Special symbols and bold and/or Italic fonts are used to highlight important information, particularly

concerning safety.

The current revision code is indicated in the bottom left corner of every page. The list of revised pages is

shown at the end of the manual.

1.4. WARRANTY

Warranty terms and conditions are stated here below unless otherwise specified in the order confirmation.

SCOPE OF THE WARRANTY

The machine has been designed and built for trouble-free use over several years. However, if any

malfunctioning is observed during the warranty period, FIORENTINI S.p.A. undertakes to repair or replace

free of charge any parts showing breaks or early wear due to faulty materials, working defects or incorrect

assembly. The manufacturer warranty will not cover anyparts whose early breaking or wear-and-tear are caused

by:

This manual is the property of FIORENTINI S. p. A.

The reproduction of all or part of this manual or its transmission to third parties by any

mechanical or electronic system or otherwise is forbidden without a written authorisation

by the manufacturer. This manual is supplied to the customers in a single original copy

unless otherwise specified at the time of ordering.

This manual is supplied as an integral part of the machine and if the machine is transferred to a new owner,

this manual should also be transferred. This manual should be stored at a safe location throughout the

machine working life. The purchaser is responsible for making this manual available to all users. If this manual

is lost, aduplicateshould be obtainedfrom FIORENTINI.

FIORENTINI S.p.a. will not be held responsible for any damages to persons and/or property resulting from

failure to comply with the instructions in this manual.

FIORENTINI reserves the right to introduce any required technical and commercial changes without giving

any notice. Therefore, any data and information contained in this manual may be changed and/or updated.

GENERAL INFORMATION

I115SS

Rev. 001

22/12/2014

5/58

failure to observe the instructions contained in this manual;

tampering or alterations introduced without FIORENTINI’s specific approval;

use of non-original spare parts;

wear parts e.g. brushes, squeegee blades etc.

For installed electrical parts and commercially available parts, FIORENTINI S.r.l. will extend to purchasers

the same warranty terms granted to FIORENTINI itself by the parts' suppliers.

WARRANTY VALIDITY

The Ing.O.Fiorentini S.p.A. general terms conditions also apply to the warranty.

The manufacturer cannot be held responsible in any way for damages resulting from unauthorised

modifications made to the appliance, from the use of unsuitable brushes and accessories and after use of

the device other than that intended.

EXCLUSIONS

The warranty will not cover materials and components exposed to normal wear (brushes, squeegee blades

etc.) and those whose working life cannot be established beforehand.

WARRANTY APPLICATION TERMS

Defective components must be returned to FIORENTINI S.p.a. in order to establish the causes of any

observed defects and determine warranty applicability. Repairing and replacement under the warranty will be

carried out on FIORENTINI’s premises, by subcontractors or on customer's premises. For services under the

warranty to be carried out on customer premises, power supply and any equipment that might be necessary

for repairing purposes will have to be provided by the customer.

PRODUCT RETURNS

In case of parts to be returned for replacement or repairs under the warranty, a written authorisation must be

obtained in advance from FIORENTINI's Technical Assistance Department.

All defective parts must be carefully repacked in order to avoid damages during transport. Products must be

returned on a free-on-board basis, complete with:

the serial number read from the equipment ID plate (see point 2.1);

the item code and installation position of the returned parts, read from the spare part list (see point 7.2);

a detailed description of the observed defect and conditions under which it became apparent;

In case of defective electric or electronic components,

please return the parts separately from other materials,

so that waste

containing dangerous substances can be separated and

Waste Electrical and Electronic Equipment (WEEE) can be

recycled according to the 2002/96/EC Directive.

A missing machine data plate will imply the immediate loss of any warranty rights.

1.5. DECLARATION OF CONFORMITY

The Declaration of Conformity is supplied with the purchased machine and the use and maintenance

manual.

GENERAL INFORMATION

I115SS

Rev. 001

22/12/2014

6/58

MACHINE FEATURES AND TECHNICAL DATA

I115SS

Rev. 001

22/12/2014

7/58

2. MACHINE FEATURES AND TECHNICAL DATA

2.1. MACHINE IDENTIFICATION

An adhesive machine identification label containing indelible “CE” marking details is affixed on the right-hand

guard just below the driver's seat.

The label must never be removed and should always be kept readable. In case of

damage a duplicate should be ordered. The machine may not be sold without this label.

2.2. DESCRIPTION AND COMPONENTS

This combined sweeping-scrubbing-drying machine has been designed for use on flat surfaces according to

a combined cleaning process which includes: surface sweeping, wet scrubbing and subsequent washing

water suction process. The machine is powered off the box-type battery.

The machine consists of the following parts:

an electric motor connected to a variable delivery hydraulic pump and a fixed delivery hydraulic

pump;

a rear drive hydraulic motor, connected via the hydraulic system to the variable delivery pump

actuated by the operator through the control pedal;

two front side brushes;

a centre roller brush;

a fine particle suction system;

a waste collection box;

three scrubbing brushes located centrally behind the roller brush;

a floor-wiping squeegee;

a polyethylene washing solution filling tank;

a polyethylene recovery tank for washing effluents with inlet and outlet suction hose;

a box-type battery;

a hydraulic power steering assembly;

driving seat.

FIGURE N. 2.1

MACHINE FEATURES AND TECHNICAL DATA

I115SS

Rev. 001

22/12/2014

8/58

The machine uses the two side rotating brushes (left side, clockwise rotation - right side, anti-clockwise

rotation) to convey any dirt towards the centre of the machine, where a roller brush rotating in the opposite

direction to the machine's direction of movement will push any collected residues into the the collection tank.

A vacuum system powered by the electric motor installed on top of the waste box is designed to take in by

suction and deliver to the waste box the finer particles that cannot be trapped by the panel filter. During the

sweeping process, the scrubbing brushes can be operated simultaneously to scrub the floor with water and

detergent. During machine forward travelling, the squeegee, in contact with the floor, takes up any water by

suction for its subsequent delivery to the recovery tank.

Important: remember to actuate the fine particle filter shaking motor to clean the particle

filter. This should be done with an open bucket next to the emptying area.

All machine functions can be controlled via controls located on the instrument panel and designed for

immediate actuation.

Through the control panel, all the main machine functions can be activated:

control the side brushes and centre brush of the sweeping unit;

start the sweeping unit suction system;

lift and lower the waste box;

close and open the flap;

control the filter shaking motor;

control the parking brake lever;

lift and lower the scrubbing brush plate;

control the scrubbing brush plate sideways movement;

start the scrubbing brushes;

regulate the water delivery flow;

start the suction motor;

start the squeegee up/down stroke;

select the forward or backward travelling direction;

turn the machine on and off;

turn the flashing light on and off;

turn the headlights on and off.

MACHINE FEATURES AND TECHNICAL DATA

I115SS

Rev. 001

22/12/2014

9/58

The machine load-bearing structure consists in a steel frame, sanded and painted to prevent oxidation which

might affect machine reliability.

In consideration of recent EU concerns regarding product safety, FIORENTINI designed and built this

machine in compliance with the safety and health requirements provided by applicable Directives. The high

quality of the materials used, the applied advanced technology and FIORENTINI’s long-standing experience

are a guarantee of the performance and reliability of this machine. Each machine is submitted to rigorous

testing during construction and to a thorough final test.

MACHINE FEATURES AND TECHNICAL DATA

I115SS

Rev. 001

22/12/2014

10/58

TECHNICAL DATA SHEET

TECHNICAL DATA

I115SSE

I115SSDE

I115SSGE

Power supply

Box-type battery 36V

630 A/h

Diesel engine

Petrol/Gas engine

Drive system

Rear hydraulic system

Scrubbing width

1150 mm

Squeegee width

1350 mm

No. of brushes

3 x Ø 380 mm

Brush pressure

180 Kg

Cleaning capacity/h

6900 sq.m/h

Range

3 h

-

Solution tank

220 litres

Recovery tank

210 litres

Water lift

1795 mm H2O / 17 Kpa

Centre brush

850 mm x Ø 300 mm

Front side brushes

2 x Ø 550 mm

Scrubbing range with side

brushes

1300+60 (side brush clearance) mm

Filtering surface

5.5 sq.m

Waste container working

capacity

112 l

Hydraulic oil tank capacity

26.5

Fuel tank capacity

-

20

Rear wheel

No-track wheel

Front wheels

No-track wheels

Brakes

Hydraulic foot controlled

Forward speed

0 –6 Km/h

0 –7 Km/h

ENGINE & MOTOR SPECIFICATIONS

Drive motor

400cc hydraulic

Kubota D902 Diesel

engine

Kubota DF972 Petrol

engine

Displacement

898 cm3

962 cm3

N. of cylinders

-

3

3

Max power

-

17.5Kw –23.5HP

23.1Kw –31HP

Squeegee suction motor

2 x 36 V 500 W

Scrubbing brush motor

3 x 36 V 800 W

3 hydraulic motors

Waste box suction fan motor

1 x 36 V 350 W 3500 rpm

Centre brush motor

N. 1 32 cc hydraulic motor

Side brush motor

N. 2 100 cc hydraulic motors

MACHINE BODY DIMENSIONS

Length

2100 mm

Width without brush guard

1200 mm

Width with brush guard

1230 mm

Height with roll bar

1850 mm

Height without roll bar

1420 mm

MACHINE FEATURES AND TECHNICAL DATA

I115SS

Rev. 001

22/12/2014

11/58

Drive

Driver operated

Waste container outlet height

1350mm

Max travelling gradient

10 %

Noise

< 75 dB(A)

The above mentioned specifications are not binding on the manufacturer and may therefore

be changed without notice. FIORENTINI can be contacted at any time for further information

(point 7.1.).

UNIT OF MEASURE CONVERSION TABLE

Length

1 inch = 1” = 25.4 mm

Power

1 kW = 1.36 CV = 1.34 BHP

Temperature

T (K) = t (°C) + 273 / t (°F) = 1.8 t (°C) + 32

Pressure

1 bar =100 kPa = 14.5 psi

SAFETY

I115SS

Rev. 001

22/12/2014

12/58

3. SAFETY

3.1. RECOMMENDED USE

This combined floor sweeping-scrubbing-drying machine has been designed and

built for use in industrial environments, to carry out sweeping, wet scrubbing, drying

and effluent collection on flat horizontal surfaces or surfaces with a gradient not

exceeding 10%. The maximum travelling gradient allowing for U-turns at 2 Km/h is

3%.

3.2. MISUSE

machine driving by unauthorised personnel;

scrubbing uneven and/or bumpy surfaces;

scrubbing surfaces inclined along the machine horizontal roll axis;

scrubbing surfaces whose gradient exceeds 10%;

performing U-turns at a speed in excess of 2 km/h with a gradient in excess of

3%;

using the machine in environments containing dangerous substances, and in

particular, in explosive atmospheres or inadequate microclimatic conditions;

cleaning machine surfaces in the presence of flammable substances;

the machine may not be used as a means of transport for people or other

vehicles;

altering or tampering with safety devices;

charging batteries at not sufficiently ventilated locations;

failure to comply with applicable safety standards currently in force;

fitting equipment/devices likely to interfere with machine operation;

introducing changes or alterations not authorised by FIORENTINI;

using acid solutions likely to damage the machine;

failing to comply with use and maintenance manual specifications.

Informative labels provided on the machine should be carefully read and should not

be covered for any reason. FIORENTINI shall not be liable in any case for any of the

above not recommended uses of the machine (instances of misuse).

3.3. SUGGESTED EQUIPMENT

To make the best use of your machine, equipment specially designed and tested by Fiorentini and original

spare parts should be used. The Design Department of FIORENTINI S.p.A. is willing to meet any design

requirements concerning parts and components for personalised applications.

SAFETY

I115SS

Rev. 001

22/12/2014

13/58

3.4. OPERATOR QUALIFICATIONS

The table here below specifies the operator qualifications required for each operation to carry out.

OPERATION

OPERATOR QUALIFICATIONS

Machine driving/control

Skilled operator

Installation/removal

Skilled operator

Mechanical parts maintenance

Skilled operator

Electrical part maintenance

Skilled operator

Cleaning maintenance

Skilled operator

Dismantling and scrapping

Skilled operator

The personnel in charge of operating the machine should be specifically trained, particularly in regard to

safety issues; machine operators must have read and become familiar with this manual.

FIORENTINI declines all responsibility for accidents involving persons or property caused by

not adequately skilled, unauthorised operators.

3.5. SAFETY AND WARNING DEVICES

It is strictly forbidden to tamper with, remove or deactivate safety and warning

devices while the machine is in operation.

The efficiency of safety and warning devices should be regularly checked (see point

5.1.).

Scrubbing brush guards

The machine I115SSE is equipped with three (standard) brushes with nylon

bristles that rotate during normal machine operation. Access to dangerous

areas is limited by fixed guards provided in each area. These safety guards

can only be removed intentionally. Removing a fixing element will cause the

obvious separation of the guard from the machine.

Roller centre brush

guards

The machine is equipped with a roller centre brush that rotates during normal

use. Access to dangerous areas is limited by protective metal skirting plates

provided in each area. These protective plates can only be removed

intentionally. Removing a fixing element will cause the obvious separation of

the guard from the machine.

Warning devices

The machine I115SSE is equipped with several warning devices to alert

anyone who happens to be within the machine working range:

a horn-type acoustic signal to warn any persons who are near the

machine during normal use;

an intermittent acoustic signal (buzzer) to warn any nearby persons

while the machine is reversing;

a visual signal (yellow flashing lights) to indicate that the machine is in

operation;

lights for use in poorly lit areas.

SAFETY

I115SS

Rev. 001

22/12/2014

14/58

3.6 SAFETY SYSTEMS

The machine is equipped with the following safety systems:

Power outlet: the same outlet used for the battery charger. In case of emergency, the machine must

be unplugged pulling on the handle. Before using the machine, the operator should become familiar

with its safety devices, to be able to automatically actuate them in an emergency. The safety devices

should never be reset before having corrected the cause of an observed problem; contact a skilled

technician if necessary.

Insufficient battery charge: the combined machine electronic control board is provided with a

safety system which deactivates all machine functions, with the exclusion of machine drive,

whenever battery charge goes below 20%, in order to prolong your battery life.

Emergency seat switch: The machine is equipped with a presence-sensing device: without an

operator on board, it will not start, and if the driver leaves the machine without having first turned off

the key switch, the machine will stop. To turn it back on, climb into the driver's seat, turn the key

switch to its OFF position, wait a few seconds then return the key switch to its ON position.

Parking brake: the machine is equipped with a brake lever located at the bottom left of the

operator's seat. To engage it, pull the lever towards yourself; to deactivate it, push it down to the end

of its stroke.

Safety rod: the machine is equipped with a red safety rod located below the waste box, which

should be operated whenever maintenance must be carried out under the box.

Always remember to lock the front wheels with the parking brake before getting off the

machine even when it is still on.

SAFETY

I115SS

Rev. 001

22/12/2014

15/58

3.7. RESIDUAL DANGERS

Ever since the design phase, FIORENTINI has analysed all the possible dangers related to machine use in

order to eliminate or at the very least minimise the risk of injuries for machine operators. In order to minimise

the risk associated with residual dangers, danger signs and indications of accident-prevention systems and

procedures have been provided for machine operators.

DANGER OF CRUSHING

Crushing risks are possible:

during side brush adjustment;

during battery charging in case of sudden battery cover falling;

during oil tank filling in case of sudden battery cover falling;

during waste box filter inspection;

during squeegee adjustment;

during centre brush replacement and scrubbing;

during waste box emptying;

During sweeping side brush, centre roller and scrubbing centre brush adjustment, the operator must

ensure that the ignition key is not in its slot in the control panel, to prevent unwanted machine starts.

During battery charging, the operator must keep all body parts out of the battery compartment.

Danger pictograms are provided on the brush guards and collection tank (point 3.8.).

DANGER OF CRUSHING AND SHEARING

Crushing and shearing risks are possible:

during waste box emptying;

when installing or replacing batteries;

During waste box emptying, make sure that no-one is within dangerous areas with any body parts.

Danger pictograms are provided on the steering column safety guard (point 3.8.).

RISK OF OVERTURNING

Machine overturning is possible:

SAFETY

I115SS

Rev. 001

22/12/2014

16/58

during normal machine operation when going over slopes with a higher gradient than the

recommended value and when the machine is used to clean uneven/bumpy surfaces (see

3.2)

Do not use the machine to scrub surfaces with gradients exceeding 10% or

bumpy or uneven surfaces likely to affect the stability of the machine.

FIORENTINI declines all responsibility for accidents involving persons or property caused by

machine use on stability-affecting floors. The buyer must provide suitable signage to inform

the user about the condition of the working surfaces.

DANGER OF OVERHEATING

Machine overheating is possible:

during normal machine use, when oil can become very hot with resulting burning risks; to

prevent these risks, an electric fan is provided to keep internal temperature lower (see 3.2).

Be extra careful when servicing any machine internal parts, especially after machine

use. Regularly check electric fan efficiency.

FIORENTINI declines all responsibility for accidents involving persons or property caused by

machine use with the electric fan off or unsafe machine use.

SAFETY

I115SS

Rev. 001

22/12/2014

17/58

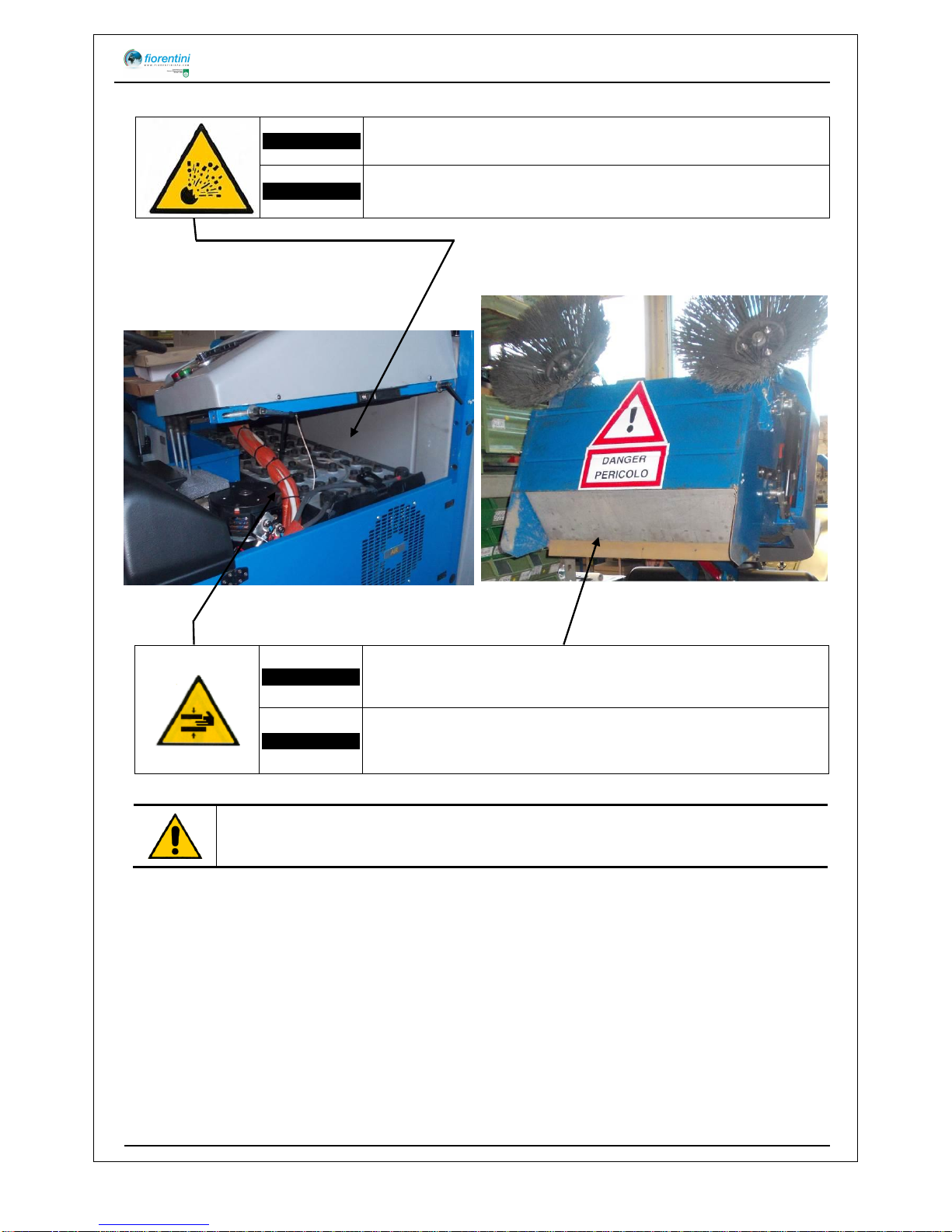

3.8. SAFETY SIGNS

The safety signs include signs indicating:

DANGERS

Danger signs are triangular with black

pictograms on yellow background

PROHIBITIONS

Prohibition signs are round with black

pictograms on white background and a red

stripe

What is it?

this sign indicates a crushing danger caused by moving parts or

machine overturning risks

What to do?

During installation or maintenance make sure that the ignition key is

not in the dashboard.

What is it?

This sign warns that it is forbidden to remove safety guards from

around moving parts.

What to do?

During installation/maintenance, before removing guards always

ensure that the ignition key is not in its slot in the control panel. During

work, keep body parts off the dangerous areas and ensure that guards

are securely fixed.

SAFETY

I115SS

Rev. 001

22/12/2014

18/58

What is it?

this sign indicates a crushing danger caused by moving parts or

machine overturning risks

What to do?

During installation or maintenance make sure that the ignition key is

not in the dashboard.

What is it?

this sign indicates a crushing danger caused by moving parts or

machine overturning risks

What to do?

During installation or maintenance make sure that the ignition key is

not in the dashboard.

What is it?

This sign warns that it is forbidden to remove safety guards from

around moving parts.

What to do?

During installation/maintenance, before removing guards always

ensure that the ignition key is not in its slot in the control panel. During

work, keep body parts off the dangerous areas and ensure that guards

are securely fixed.

SAFETY

I115SS

Rev. 001

22/12/2014

19/58

If any signs become damaged, the purchaser must replace them with identical

signage. It is strictly forbidden to remove or tamper with these signs.

What is it?

Danger of crushing caused by suction tank overturning.

What to do?

During battery charging or tank filling, provide a special support

What is it?

Explosion risk during battery charging due to the released hydrogen.

What to do?

During battery charging, ensure that the machine is under a suction

hood or in a ventilated area and keep it away from heat sources and

corrosive substances.

START-UP AND OPERATION INSTRUCTIONS

I115SS

Rev. 001

22/12/2014

20/58

4. START-UP AND OPERATION INSTRUCTIONS

4.1. TRANSPORT AND HANDLING

The machine is delivered to the purchaser without any packaging and tied with straps. The side brushes and

scrubbing brushes are removed before transport to prevent any damaging.

Upon customer request, the machine can be packaged on a special pallet.

The purchaser should check upon delivery that the machine has not been damaged during

transport and that all the material listed in the transport documentation has been received;

otherwise, the forwarders and manufacturer should be promptly informed.

Unless otherwise agreed, purchased goods will travel at the purchaser's own risk.

Handling must be carried out as follows:

TYPE OF PACKAGING

HANDLING EQUIPMENT

FIG.

Pallet

Fork lift truck

N. 4.1

None

The machine should be handled with a fork lift truck/overhead

crane with a two-strap balance harness.

N. 4.2

The harness straps used must be suitable for the load to lift. Handling operations

should be carried out at very slow speed to prevent load swinging and loss of

stability. Any operation performed incorrectly may damage the machine and expose

operators to dangers.

Refer to point 2.3 for machine dimensions and weight. Machine handling should be

carried out by authorised personnel trained for lifting equipment use only.

LOADING DIAGRAM

FIGURE 4.1

FIGURE 4.2

This manual suits for next models

2

Table of contents

Other FIORENTINI Ultrasonic Jewelry Cleaner manuals