FireFlex VACTEC Installation guide

FM-060M-0-110A

Advanced Integrated Fire Protection System

Owner's Operation

and

Maintenance Manual

DRY-PIPE VACUUM SPRINKLER SYSTEM

ELECTRIC RELEASE

Page ii

Integrated Fire Protection System

OWNER'S OPERATION &MAINTENANCE MANUAL

FM-060M-0-110A

Manufactured by FIREFLEX Systems Inc.

1935 Lionel-Bertrand Blvd

Boisbriand, QC (Canada) J7H 1N8

Tel: (450) 437-3473 Toll free: (866) 347-3353

Fax: (450) 437-1930

Page iii

Integrated Fire Protection System

O

WNER

'

S

O

PERATION

&

M

AINTENANCE

M

ANUAL

FM-060M-0-110A

Table of Contents

Dry-pipe Vacuum Sprinkler System - Electric Release

General Section............................................................................................................................ Section A

1- General description

2- Listings and approvals

3- Applicable standards

4- Environment

5- Features

6- Configuration description

7- System release

Mechanical Section...................................................................................................................... Section B

1- Installation, operation and instruction

1.1 Installation

1.2 Preliminary inspection before placing the system in service

1.3 Placing the system in service

1.4 System operation

1.5 Emergency instructions

1.6- Placing system back in service after operation

1.7 Inspections and tests

1.8 Maintenance

2- Trim Schematics

Trim Options................................................................................................................................. Section C

1- Semi & full flange option

Vacuum Supply Section.............................................................................................................. Section D

1- Vacuum supply

1.1 Operation

1.2 Pressure settings

1.3Maintenance and inspection

Controls Section ...........................................................................................................................Section E

1- Release control panel

2- Vacuum pump control box

Electrical Section .........................................................................................................................Section F

1- Operation

2- Electric release programming

3- FLX-PC®pressure controller

4- Optional modules

Dimensional Data & Cabinet.......................................................................................................Section G

1- Cabinet for FIREFLEX®VACTEC®unit

Limited Warranty ......................................................................................................................... Section H

Page iv

Integrated Fire Protection System

OWNER'S OPERATION &MAINTENANCE MANUAL

FM-060M-0-110A

Copyright ©2017 FIREFLEXSystems Inc.

All Rights Reserved

Reproduction or use, without express written permission from FIREFLEX Systems Inc, of any portion of this manual is prohibited.

While all reasonable efforts have been taken in the preparation of this manual to assure its accuracy, FIREFLEX Systems Inc

assumes no liability resulting from any errors or omissions in this manual, or from the use of the information contained herein.

FIREFLEX®is a registered trademark of FIREFLEX Systems Inc. VACTEC®is a registered trademark of VACTEC Vacuum

Technology.

FIREFLEX Systems Inc. reserves the right to make changes to this manual and the data sheets herewith at any time, without prior

notification.

Page 1 of 2

Integrated Fire Protection System A

General Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-111B

1- General description

Dry-pipe vacuum sprinkler system uses closed vacuum

sprinklers specified for vacuum use with vacuum sprinklers

piping network.

This FIREFLEX®VACTEC® integrated fire protection system

consists of a vacuum system trim totally pre-assembled,

pre-wired and factory tested. All electrical and mechanical

components of the system are contained in one single unit.

The only connections required for installation are the water

supply inlet, water discharge outlet, main drain, as well as

the AC power line(s) and alarm connections. The

discharge outlet is connected to a fixed vacuum sprinklers

piping network. Water is the extinguishing agent.

The FLX-PC® VACUUM / PRESSURE CONTROLLER allows the

release control panel to receive the appropriates alarm

and supervisory signals which supervises the vacuum

pressure and activates discharge condition. It also

controls the vacuum pump operation. For more

information, refer to FLX-PC® VACUUM / PRESSURE

CONTROLLER at section F .

Note: Every FIREFLEX®VACTEC® unit is identified with its

unique serial number. This number is located on an

adhesive label inside the main door panel and is used to

maintain a record in our computerized data base. Have

this serial number handy when calling for information on

your unit (format is VAC # # # # #).

2- Listings and approvals

In addition to being fabricated under tight ISO-9001

manufacturing and quality control procedures, your

FIREFLEX®VACTEC® unit by FIREFLEX Systems Inc. has

also been tested and approved by recognized laboratories.

Here is the list of listings & approvals it meets:

- Pending Factory Mutual Research <FM>:

FIREFLEX®VACTEC® vacuum systems are FM Approved

under the heading: "Automatic Water Control Valves"

when installed with specific components.

Note: Although most FIREFLEX®VACTEC® units are listed

and approved, custom built units are sometimes supplied

on request. Components in these special units maintain

their individual listings/approvals but the units are not listed

as an assembled unit.

Warning ! Any unauthorized modification or addition made

on-site to a factory built listed unit will void this listing.

Such modifications or additions may void the unit's

warranty as well. Consult your nearest FIREFLEX Systems

Inc. authorized distributor before proceeding with such

modifications or additions.

3- Applicable standards

The FIREFLEX®VACTEC® complies with the following

standards:

- NFPA-72 Fire Alarm Systems

Before installation, the contractor installing the unit shall

also be familiar with the following documents and

standards:

- Applicable local & state building codes

- Any additional requirements of the local authority having

jurisdiction

4- Environment

The FIREFLEX®VACTEC® unit shall be installed in a dry and

clean location. Verify that all equipment is properly heated

and protected to prevent freezing and physical damage.

The unit and its components must be kept free of foreign

matter, freezing conditions, corrosive atmospheres,

contaminated water supplies, and any condition that could

impair its operation or damage the components.

The frequency of the inspections and maintenance will

vary depending on these environmental conditions as well

as the condition of the vacuum supply to the system. The

owner is responsible for maintaining the fire protection

system and devices in proper operating condition. Refer to

section B MECHANICAL SECTION for maintenance

instructions.

Page 2 of 2

A

Integrated Fire Protection System

General Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-111B

5- Features

The FIREFLEX®VACTEC® unit is superior to many other

products available on the market now, and has been

proudly manufactured by the company that has introduced

and developed the concept of integrated fire protection

systems in the market.

Main features are:

Trouble free design for safe and easy application

Available in 4 sizes from 3" to 8" diameter

Uses the Viking deluge valve

Unit comes standard with its owned integrated releasing

control panel

Uses the FLX-PC® VACUUM / PRESSURE CONTROLLER

Compact, aesthetic and easy to move

User-friendly standardized owner's manual with every

unit

Unique serial number on every unit

Trim is fully assembled and tested at the factory

All trims are galvanized steel, listed and approved for

175 PSI (1207 kPa) service maximum

Quick connections to water supply and drain on both

sides, and vacuum sprinklers riser on top of unit, all

available with grooved end or optional flanged fittings

Shut-off valve at the outlet of the vacuum sprinklers riser

for easier maintenance

No open drain cup inside unit

Sturdy 14 gauge steel cabinet, painted fire red with oven

baked polyester powder on phosphate base

Textured rust proof finish

Neoprene gasket on all doors to eliminate vibrations

Removable doors for ease of access

Separate unlocked access hatch to emergency manual

release

Key-alike locks on all cabinet doors

Manufactured under ISO-9001 quality control procedures

6- Configuration description

The FIREFLEX®VACTEC® system is built around the Viking

deluge valve Model F-1.

Each system is rated up to a maximum of 175 PSI WWP

(1207 kPa) max. and are available in the following

diameters:

3" (75 mm) 6" (150 mm)

4" (100 mm) 8" (200 mm)

The FIREFLEX®VACTEC® unit is supplied with groove/

groove deluge valve. Unit with flange/flange deluge valve

is also available upon request.

6.1 Dry-pipe Vacuum Sprinkler System

Note: Numbers indicated between brackets refer to items

on the TRIM SCHEMATICS from section B MECHANICAL and

section D VACUUM SUPPLY.

The vacuum sprinklers piping network is under vacuum

pressure. This dry-pipe vacuum sprinkler system utilizes a

Viking deluge valve (A1) which opens by the operation of

the solenoid valve (F1) or the manual emergency release

valve (B10).

The vacuum level inside the piping network is supervised

by the FLX-PC® VACUUM / PRESSURE CONTROLLER for low,

high and alarm vacuum levels. One objective of this

device is to perform the opening of the deluge valve in less

than 5 seconds following the opening of a vacuum

sprinkler, thereby permitting a more rapid fire attack.

The electric release system operates by the alarm

pressure of the FLX-PC® VACUUM / PRESSURE CONTROLLER.

If a vacuum sprinkler is fused, or damage to a vacuum

sprinkler or to piping network occurs, the FLX-PC® will

operate and the deluge valve (A1) will open, flowing water.

The electric release system also operates when a manual

pull station is triggered, opening the deluge valve (A1).

Water will be contained in the piping network until the

opening of a vacuum sprinkler.

In the event of no operation of the electric release system

or if the release control panel is no more powered from AC

power and batteries, the dry-pipe vacuum sprinkler system

can be manually trip by triggering the manual emergency

release valve (B10), causing the deluge valve (A1) to

open. Water will be contained in the piping network until

the opening of a vacuum sprinkler.

7- System release

7.1 Electric release

Electric release trim for dry-pipe vacuum sprinkler system

utilizes an electric solenoid valve (F1) controlled by the

approved release control panel provided with this system

(see section E CONTROLS and VFR-400 manual for

details).

In fire condition, when a vacuum sprinkler is fused, or

damage to a vacuum sprinkler or to piping network occurs,

an alarm pressure signal from the FLX-PC® VACUUM /

PRESSURE CONTROLLER to the release control panel

energizes the solenoid valve (F1), causing the deluge

valve (A1) to open. Water will flow from the previous

opening.

When a manual pull station is triggered, the release control

panel energizes the solenoid valve (F1), causing the

deluge valve (A1) to open. Water will be contained in the

piping network until the opening of a vacuum sprinkler.

Page 1 of 10

Integrated Fire Protection System

B

Mechanical Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-112B

1- Installation, operations & instructions

Note: Numbers indicated between brackets refer to

figures 1 and 2 SIMPLIFIED and DETAILED SYSTEM TRIM

SCHEMATICS from this section and section D VACUUM

SUPPLY.

1.1 Installation

1. Conform to local municipal or other codes regarding

installations of fire protection systems. Refer to

FIREFLEX®Design Manual for vacuum sprinklers piping

installation.

2. Install the FIREFLEX®VACTEC®unit and connect the

system according to instruction manual and technical

data supplied.

Note: The drain collector shall be connected to an open

drain. Do not restrict or reduce drain piping.

3. Install the vacuum sprinklers piping network and

vacuum sprinklers in accordance with applicable

standards.

4. Connect alarm audible devices, where applicable,

according to electrical schematics (see field wiring

diagram in section F ELECTRICAL).

5. Connect the AC power to the release control panel and

the vacuum pump on two separate breakers in the

electric distribution panel (see field wiring diagram in

section F ELECTRICAL).

Notes:

AC power connections must be made by a qualified

installer according to national standards.

Do not apply AC power to the release control panel and

the vacuum pump yet.

6. Perform preliminary inspection as outlined in

paragraph 1.2 of the current section prior to putting

system in service.

7. Place the system in service as outlined in paragraph 1.3

of the current section.

8. Perform the annual inspection sequence and test alarm

unit.

9. If the system does not operate as it should, make the

necessary corrections according to manuals issued or

consult your distributor or FIREFLEX Systems Inc.

10. Make sure that building owner or a delegated

representative has received instructions regarding the

operation of the system.

WARNING ! FIREFLEX®VACTEC®unit must be installed in an

area not subject to freezing temperatures or physical

damage.

1.2 Preliminary inspection before placing the system in

service

1. Open door to mechanical section.

a) Main water supply valve (D1) must be CLOSED.

b) Priming valve (B1) must be CLOSED.

c) Flow test valve (B6), main drain valve (D3) and

system drain valve (G10)must be CLOSED.

d) Alarm test valve (B5) and alarm line drain valve (B7)

must be CLOSED.

e) Manual emergency release valve (B10)must be

CLOSED.

f) Vacuum supply must be CLOSED (see section D

VACUUM SUPPLY).

g) Gauges (B11 and B12) should show 0 PSI (0 kPA).

h) The shut-off valve (D4)must be OPEN.

2. Using the built-in contractor's hydrostatic test ports (see

figure 2 DETAILED SYSTEM TRIM SCHEMATIC of the current

section for location), fill vacuum sprinklers piping

network with water and maintain pressure as per

NFPA-13 requirements.

WARNING ! Do not subject the pressure gauges and

pressure transducer to hydrostatic pressure above 250 PSI

(1724 kPA). Close gauge valves before proceeding with

hydrostatic test.

3. Correct leaks if any before completing test.

4. Verify that main water supply valve (D1) is CLOSED.

OPEN main drain valve (D3), alarm drain valve (B7) and

system drain valve (G10)to completely drain the

vacuum sprinklers piping.

5. Apply AC power to the release control panel and the

vacuum pump (see section F ELECTRICAL).

6. Install and connect the batteries. Observe battery size

and polarity.

For battery capacity calculations, see the VIKING VFR-400

INSTALLATION, OPERATION AND INSTRUCTION MANUAL

provided with the FIREFLEX®VACTEC®unit. Don't forget to

add the current consumption of the FLX-PC®(G18).

7. Reset the release control panel and silence the alarm.

Note: Batteries shall be installed with the control panel at

hanged position. Battery compartment should always stay

closed while rotating the control panel.

8. The FLX-PC® (G18) VACUUM / PRESSURE CONTROLLER

should show 0 mBAR (0 kPA).

Page 2 of 10

B

Integrated Fire Protection System

Mechanical Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-112B

1.3 Placing the system in service

1. Verify that all vacuum sprinklers are set and that

inspector's test valve and/or piping auxiliary drain valves

are CLOSED.

2. Verify that the system has been properly drained (see

warning note below). CLOSE main drain valve (D3),

system drain valve (G10) and alarm line drain

valve (B7). Verify that the manual emergency

release (B10) is CLOSED.

Warning ! It is very important to properly drain the piping

network in order to reduce the effect of corrosion.

3. Turn on the vacuum pump switch (G16) (see

section D VACUUM SUPPLY).

The sign [] will be displayed on the FLX-PC®(G18)

when the pump is running and excess water in deluge

valve (A1) will be drained by vacuum pump (G1).

4. When vacuum pump (G1) stops, solenoid valve (G2)

should close. FLX-PC®(G18)should display vacuum

level.

5. OPEN priming valve (B1).

6. Reset the release control panel. Solenoid valve (F1)

should close. Water pressure rises slowly on

gauge (B11). Silence the alarm.

7. OPEN flow test valve (B6). PARTIALLY OPEN main water

supply valve (D1).

Note: Do not open main water supply valve (D1)until

gauge (B11) shows stabilized pressure.

8. When full flow develops from the flow test valve (B6),

CLOSE the flow test valve.

9. FULLY OPEN the main water supply valve (D1). Reset

the release control panel.

10. Verify that the alarm test valve (B5) is CLOSED and that

all other valves are in their "normal" operating position

(refer to paragraph 2.2 NORMAL CONDITION of the current

section for details).

11. Check and repair all leaks.

12. On new installation, system that has been placed out of

service, or where new equipment has been installed, trip

test the system to verify that all equipment functions

properly. Refer to paragraph 1.7.2 INSPECTIONS & TESTS

of the current section for instructions.

WARNING ! Performing a trip test will result in operation of

the deluge valve (A1). Water will flow into the piping

network. Take necessary precautions to prevent damage.

13. After completing the trip test, perform paragraph 1.8

MAINTENANCE – SEMI-ANNUALLYof the current section.

14. Notify the AUTHORITY HAVING JURISDICTION, remote

station alarm monitors, and those in the affected area

that the system is in service.

Warning ! Do not open main drain valve (D3) or alarm line

drain valve (B7) or the manual release valve (B10) while

system is in service. This will cause the system to trip.

Pressures settings

For complete pressures settings, see section D VACUUM

SUPPLY.

Page 3 of 10

Integrated Fire Protection System

B

Mechanical Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-112B

1.4 System Operation

1.4.1 In the SET condition

System water supply pressure enters the priming chamber

of the deluge valve (A1) through the priming line which

includes a normally open priming valve (B1), strainer (B2),

restricted orifice (B3) and spring loaded check valve (B4).

Water supply pressure is trapped in the priming chamber

of the deluge valve (A1) by spring loaded check

valve (B4), normally closed solenoid valve (F1), manual

emergency release valve (B10) and PORV (B9)

(pressure operated relied valve). The pressure in the

priming chamber holds the deluge valve clapper closed,

keeping the outlet chamber and vacuum sprinklers piping

dry.

1.4.2 In a fire condition

When the FLX-PC®alarm condition is satisfied, the

release control panel activates an alarm and energizes the

normally closed solenoid valve (F1) to open.

Pressure from the priming chamber of the deluge

valve (A1) is released to the open drain manifold faster

than it is supplied through the restricted orifice (B3). The

deluge valve clapper opens to allow water to flow into the

piping network and alarm devices, causing water flow

alarms connected to the alarm pressure switch (C1) and

the optional water motor alarm (C2) to activate. When a

vacuum sprinkler head opens, water will flow from the

vacuum sprinklers piping network.

When the deluge valve (A1) operates, the sensing end of

the PORV (B9) (pressure operated relief valve) is

pressurized, causing it to open, draining the priming

chamber, preventing the deluge valve from resetting, even

if the open releasing devices close. The vacuum pump will

be automatically disabled. The deluge valve can only be

reset after the system is taken out of service, and the

outlet chamber of the deluge valve and associated trim

piping is depressurized and drained.

1.4.3 Manual operation

Anytime the handle of the manual emergency release

valve (B10) is triggered, pressure is released from the

priming chamber of the deluge valve (A1) causing deluge

valve to open. Alarm devices (C1 and C2) will operate.

When a vacuum sprinkler opens, water will flow through

the piping network.

1.4.4 Vacuum loss condition

If a vacuum sprinkler opens or any time vacuum is lost in

piping network, the FLX-PC® (G18) will display LOW

PRESSURE followed by ALARM PRESSURE, and the release

control panel will receive supervisory and alarm signals.

Pressure is then released from the priming chamber of the

deluge valve (A1) causing deluge valve to open. Alarm

devices (C1 and C2) will operate.When a vacuum

sprinkler opens, water will flow through the piping network.

1.5 Emergency instructions

To take system out of service

WARNING ! Placing a control valve or detection system out

of service may eliminate the fire protection capabilities of

the system. Prior to proceeding, notify all local

AUTHORITIES HAVING JURISDICTION. Consideration should

be given to employ a fire patrol in the affected areas.

After a fire, verify that the fire is OUT and that placing the

system out of service has been authorized by the

appropriate local AUTHORITY HAVING JURISDICTION.

Vacuum sprinklers piping that have been subjected to a

fire must be returned to service as soon as possible. The

entire system must be inspected for damage, and repaired

or replaced as necessary.

1. CLOSE main water supply valve (D1).

2. Silence alarms (refer to section E CONTROLS for

additional details).

Note: Electric alarms controlled by a pressure switch

installed at the ¾"-NPT (20mm) connection (C2) for a non-

interruptible alarm signal cannot be shut-off until the

deluge valve (A1) is reset or taken out of service.

3. OPEN main drain valve (D3), system drain valve (G10)

and alarm line drain valve (B7).

4. CLOSE priming valve (B1).

5. Replace any vacuum sprinkler that have opened, been

damaged or exposed to fire conditions.

6. Perform all maintenance procedures recommended in

paragraph 1.8 MAINTENANCE in the current section,

describing individual components of the system that has

operated.

7. Return the system to service as soon as possible as

outlined in paragraph 1.6 PLACING THE SYSTEM BACK IN

SERVICE AFTER OPERATION of the current section.

Note: When a system has been removed from service and

is subject to freezing or will be out of service for an

extended period of time, all water must be removed from

the priming chamber, trim piping, water supply piping and

any other trapped areas.

Page 4 of 10

B

Integrated Fire Protection System

Mechanical Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-112B

1.6 Placing the system back in service after operation

1. Verify that all vacuum sprinklers are set and/or piping

auxiliary drain valves are CLOSED.

2. Verify that the system has been properly drained (see

warning note below). CLOSE main drain valve (D3),

system drain valve (G10) and alarm line drain

valve (B7). Verify that the manual emergency

release (B10) is CLOSED.

Warning ! It is very important to properly drain the piping

network in order to reduce the effect of corrosion.

3. Verify that the shut-off valve (D4)is OPEN.

4. The sign [] will be displayed on the FLX-PC®(G18).

Press and hold the push-button of the FLX-PC®for

5 seconds until the sign [] disappears to start the

vacuum pump (G1).

Note: The history display appears after 3 seconds; do not

release the push-button before the end of 5 seconds.

Solenoid valve (G2) should open. Excess water in

deluge valve (A1)will be drained by vacuum

pump (G1).

Note: The vacuum pump (G1) may not need to start after

following the sequence of the paragraph 1.7.4 OPERATION

OF THE SHUT-OFF VALVE.

5. When vacuum pump (G1) stops, solenoid valve (G2)

should close. The FLX-PC®(G18)should display the

vacuum level.

6. OPEN priming valve (B1).

7. Reset the release control panel. Solenoid valve (F1)

should close. Water pressure rises slowly on

gauge (B11). Silence the alarm.

8. OPEN flow test valve (B6). PARTIALLY OPEN main water

supply valve (D1).

Note: Do not open main water supply valve (D1)until

gauge (B11) shows stabilized pressure.

9. When full flow develops from the flow test valve (B6),

CLOSE the flow test valve.

10. FULLY OPEN the main water supply valve (D1).Reset

the release control panel.

11. Verify that the alarm test valve (B5) is CLOSED and that

all other valves are in their "normal" operating position

(refer to paragraph 2.2 NORMAL CONDITION of the current

section for details).

12. Check and repair all leaks.

13. Notify the local AUTHORITY HAVING JURISDICTION, remote

station alarm monitors, and those in the affected area

that the system is back in service.

1.7Inspections and tests

NOTICE:The owner is responsible for maintaining the fire

protection system and devices in proper operating

condition.

It is imperative that the system be inspected and tested on

a regular basis in accordance with NFPA-25.

The frequency of the inspections may vary due to

contaminated or corrosive water supply to the system. For

minimum maintenance and inspection requirements, refer

to NFPA-25. In addition, the AUTHORITY HAVING

JURISDICTION may have additional maintenance, testing,

and inspection requirements that must be followed.

WARNING ! Any system maintenance that involves placing

a control valve out of service may eliminate the fire

protection capabilities of that system. Prior to proceeding,

notify all local AUTHORITIES HAVING JURISDICTION.

Consideration should be given to employment of a fire

patrol in the affected areas.

1.7.1 Vacuum Supervisory/Alarm Test

To test vacuum sprinklers piping network for LOW

PRESSURE supervisory and ALARM PRESSURE

1. Notify the local AUTHORITY HAVING JURISDICTION and

those in the area affected by the test.

2. To prevent operation of the deluge valve (A1) and filling

of the piping network with water during the test, CLOSE

main water supply valve (D1).

3. Verify that the shut-off valve (D4)is OPEN.

4. FULLY OPEN the inspector's test valve on the piping

network or PARTIALLY OPEN main drain valve (D3).

5. Verify that LOW PRESSURE supervisory and ALARM

PRESSURE signals operate within the specified pressure

settings of the FLX-PC®(G18)(refer to paragraph 2.2

NORMAL CONDITION).

6. CLOSE the inspector's test valve or main drain

valve (D3).

7. CLOSE priming valve (B1).

Page 5 of 10

Integrated Fire Protection System

B

Mechanical Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-112B

When testing is complete, return the system to service

1. The sign [] will be displayed on the FLX-PC®(G18).

Press and hold the push-button of the FLX-PC®for

5 seconds until the sign [] disappears to start the

vacuum pump (G1). Solenoid valve (G2) should open.

Excess water in deluge valve (A1) will be drained by

vacuum pump (G1).

Note: The history display appears after 3 seconds; do not

release the push-button before the end of 5 seconds.

2. When vacuum pump (G1) stops, solenoid valve (G2)

should close. The FLX-PC®(G18)should display

vacuum level.

3. OPEN priming valve (B1).

4. Reset the release control panel. Solenoid valve (F1)

should close. Water pressure rises slowly on

gauge (B11).Silence the alarm.

5. Verify that flow test valve (B6) is open. PARTIALLY OPEN

main water supply valve (D1).

Note: Do not open main water supply valve (D1)until

gauge (B11) shows stabilized pressure.

6. When full flow develops from the flow test valve (B6),

CLOSE the flow test valve.

7. FULLY OPEN the main water supply valve (D1). Reset

the release control panel.

8. Notify the local Authority Having Jurisdiction, remote

station alarm monitors, and those in the affected area

that the system is back in service.

1.7.2 Full flow trip test

Note: If it is not required to fill the piping network with water,

refer to paragraph 1.7.4 OPERATION OF THE SHUT-OFF

VALVE.

Performance of a full flow trip test is recommended

annually during warm weather. Consider coordinating this

test with operation testing of the releasing devices.

Caution ! Performance of this test will cause the deluge

valve (A1) to open and the piping network to be filled with

water.

To trip test the electric release system

1. Notify the local AUTHORITY HAVING JURISDICTION and

those in the area affected by the test.

2. Open the door of emergency release valve (B10) and

trigger the handle.

3. The deluge valve (A1) should open. Water flow alarms

should operate. The piping network will be filled with

water.

4. OPEN the piping network inspector's test valve to verify

adequate flow.

When trip testing is complete

1. Perform steps of paragraph 1.5 EMERGENCY

INSTRUCTIONS to take the system out of service.

2. Perform steps of paragraph 1.6 PLACING THE SYSTEM

BACK IN SERVICE AFTER OPERATION.

3. Notify the local AUTHORITY HAVING JURISDICTION and

those in the affected area that testing is complete.

1.7.3 Main drain test

A main drain test shall be conducted to determine whether

there has been a change in the condition of the water

supply piping and control valves.

Test procedure

1. Record the pressure indicated by the water supply

gauge (B12).

2. Close the alarm control valve (if applicable).

3. FULLY OPEN the flow test valve (B6).

4. Record residual pressure.

5. CLOSE the flow test valve (B6) slowly.

6. Record the time taken for supply water pressure to

return to the original pressure.

Note: A main drain test shall be conducted any time the

main water supply valve (D1) is closed and reopened at

the system.

1.7.4 Operation of the shut-off valve

Inspection of the system can be implemented without filling

the piping network with water. The use of shut-off

valve (D4) and sight glass assembly (D5) allows to verify

the operation of the system and prevents water from

reaching the piping network.

1. CLOSE the shut-off valve (D4) to isolate the piping

network; the valve is supervised on the same circuit as

the main water supply valve (D1).

2. SLOWLY OPEN the system main drain valve (D3).The

deluge valve (A1) should open.

3. Silence the alarms (refer to section E CONTROLS for

additional details).

4. Using a flashlight in one of the sight glasses, verify that

water flows through the sight glass assembly (D5).

5. Once tests are completed, CLOSE main water supply

valve (D1).

6. OPEN main drain valve (D3), system drain valve (G10)

and alarm line drain valve (B7).

7. CLOSE priming valve (B1).

8. Reset the system as per paragraph 1.6 PLACING THE

SYSTEM BACK IN SERVICE in section B MECHANICAL.

Page 6 of 10

B

Integrated Fire Protection System

Mechanical Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-112B

1.8 Maintenance

NOTICE:The owner is responsible for maintaining the fire

protection system and devices in proper operating

condition.

The system shall be maintained in full operation condition

at all times.

All troubles or impairments shall be corrected promptly

consistent with the hazard being protected.

Refer to MAINTENANCE INSTRUCTIONS provided in Viking

Technical Data describing individual components of the

system used.

The vacuum pump system shall be maintained in full

operating condition at all times (refer to section D

VACUUM SUPPLY).

Refer to NFPA-25 for a full description of maintenance.

1.8.1 FLX-PC®vacuum pump monitoring

The monitoring of the vacuum pump operation time is

useful because it notified you about a minor leak in the

piping system. If there is a leak in the piping system, the

pump will operate much more than it would normally do.

Moreover, the operating time will change if there is water

in the piping system (the system must be properly

drained).

To access the vacuum pump operation time, press and

hold the push-button of the FLX-PC®(G18)unit for

3 seconds then release the push-button.

***VER: 1.0.0***

1000:45:33 HRS

The second line shows the total operating time of the

vacuum pump.

The display will automatically return to its normal condition

after 10 seconds of inactivity of the push-button.

For more information, refer to FLX-PC®VACUUM /

PRESSURE CONTROLLER at section E ELECTRICAL.

Records

Records of inspections, tests and maintenance of the

system and its components shall be made available to the

AUTHORITY HAVING JURISDICTION upon request. Typical

records include, but are not limited to: valves inspection;

flow, drain, and pump tests, and trip test of the deluge

valves.

Acceptance test records should be retained for the life of

the system or its special components. Subsequent test

records should be retained for a period of one (1) year

after the next test. The comparison determines

deterioration of system performance or condition and the

need for further testing or maintenance.

Monthly

1. Inspection of gauges (water supply and system

pressure) to ensure good condition and normal water

supply pressure.

2. Control valve shall be externally inspected. The valve

inspection shall verify the following:

a) The gauges indicate that normal supply water

pressure is being maintained.

b) The valve is free of physical damage.

c) All valves are in the appropriate open or closed

position.

d) There is no leakage from the alarm drains.

Quarterly

1. Check alarm pressure switch (C1) and optional water

motor gong (C2) by opening the alarm test valve (B5).

Once the valve (B5) is closed, open alarm line drain

valve (B7) to release water pressure (~ 3 seconds) then

close it.

2. Conduct alarm pressure test; refer to paragraph 1.7.1

VACUUM SUPERVISORY / ALARM TEST of the current

section.

Semi-annually

1. Main water supply valve (D1) switch shall be operated

to verify the switch actuation upon movement of the

hand wheel.

2. Check alarm pressure switch (C1) and optional water

motor gong (C2) by opening the alarm test valve (B5).

Once the valve (B5) is closed, open alarm line drain

valve (B7) to release water pressure (~ 3 seconds) then

close it.

3. Perform functional test of all components of the system.

Annually

1. Perform full flow trip test; refer to paragraph 1.7.2 FULL

TRIP TEST.

2. Perform main drain test; refer to paragraph 1.7.3 MAIN

TRIP TEST.

Every 5 years

1. Test on gauge (gauge precision required: less than 3%

of the full scale).

2. Perform test on control valve operation.

3. Deluge valve (A1) and their associated strainers, filters

and restriction orifices shall be inspected internally.

4. Perform main drain test; refer to paragraph 1.7.3 MAIN

TRIP TEST.

Page 7 of 10

Integrated Fire Protection System

B

Mechanical Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-112B

2- Dry-pipe vacuum sprinkler system with

electric release

Note: Numbers indicated between brackets refer to

figures 1 and 2 SIMPLIFIED and DETAILED SYSTEM TRIM

SCHEMATICS from this section and section D VACUUM

SUPPLY.

2.1 Description

The FIREFLEX®VACTEC®system with the dry-pipe vacuum

sprinkler trim utilizes a Viking deluge valve (A1) to control

water flow into piping network equipped with closed

vacuum sprinklers. Under normal operating conditions,

the piping network is supervised with vacuum to ensure

against undetected leaks.

Electric release system requires an electrically operated

solenoid valve (F1) controlled by an approved release

control panel.

If a vacuum sprinkler is fused, or damage to a vacuum

sprinkler or to piping network occurs, a low pressure

supervisory signal from the FLX-PC®(G18) VACUUM /

PRESSURE CONTROLLER will be sent to the release control

panel followed by an alarm pressure signal.

Dry-pipe vacuum sprinkler system is designed so the

deluge valve (A1) will open by the operation of the

solenoid valve (F1) when the FLX-PC®(G18) alarm

pressure signal operates, or when a manual pull station is

triggered. When the deluge valve (A1) opens, water will

flow into the piping network and out of any open vacuum

sprinklers or any opening on the piping network.

Note: The FIREFLEX®VACTEC®trim is provided with a

contractor's hydrostatic test water supply port handily

located on the priming trim. Simply remove the plug of the

connection and connect the test pump between this port

and the system side port located on the riser trim. Refer to

figure 2 DETAILED SYSTEM TRIM SCHEMATIC of this section

for exact location of these connections.

2.2 Normal condition

1. Control panel of the FIREFLEX®VACTEC®system

a) Green lamp identified "AC POWER"lights up.

b) All other lamps are off.

2. Valves

a) Main water supply valve (D1) is OPEN.

b) All upstream water supply valves are OPEN.

c) Priming valve (B1) is OPEN.

d) Flow test valve (B6) is CLOSED.

e) Main drain valve (D3) is CLOSED.

f) Alarm test valve (B5) is CLOSED.

g) Alarm line drain valve (B7) is CLOSED.

h) Manual emergency release valve (B10) is CLOSED

(handle in vertical position).

i) Gauge valves (B11 and B12) are OPEN.

j) System drain valve (G10) is CLOSED and water ring

cut-off valve (G13) is OPEN (see section D VACUUM

SUPPLY).

k) Shut-off valve (D4) is OPEN.

3. Gauges

a) Water supply (B12) at water supply pressure.

b) Priming chamber (B11) should be equal to, or higher

than, water supply pressure (B12).

c) FLX-PC® displays vacuum level between -150mBAR

(-15kPa) and -180 mBAR (-18 kPa).

d) Pre-regulator (G14) should be 50 PSI (344 kPA).

e) Fine-adjust regulator (G15) should be zero; 10 PSI

(69 kPA) when vacuum pump (G1) is running (see

section D VACUUM SUPPLY).

4. Pressure switches & settings (factory set)

a) Alarm pressure switch (C1) should activate when

pressurized higher than 5 PSI (34 kPa).

b) Vacuum pump control pressure switch (G20) should

activate when pressurized lower than 18 PSI

(124 kPa).

c) FLX-PC®(G18)should start vacuum pump (G1) when

vacuum is lower than -150 mBAR (-15 kPa) and stop

vacuum pump (G1) when vacuum reaches

-180 mBAR (-18 kPa).

d) FLX-PC®(G18)should activate a LOW PRESSURE

supervisory when vacuum is lower than -140 mBAR

(-14 kPa).

e) FLX-PC®(G18)should activate a HIGH PRESSURE

supervisory when vacuum is higher than -220 mBAR

(-22 kPa).

f) FLX-PC®(G18)should activate an ALARM PRESSURE

when vacuum is lower than -130 mBAR (-13 kPa).

Page 8 of 10

B

Integrated Fire Protection System

Mechanical Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-112B

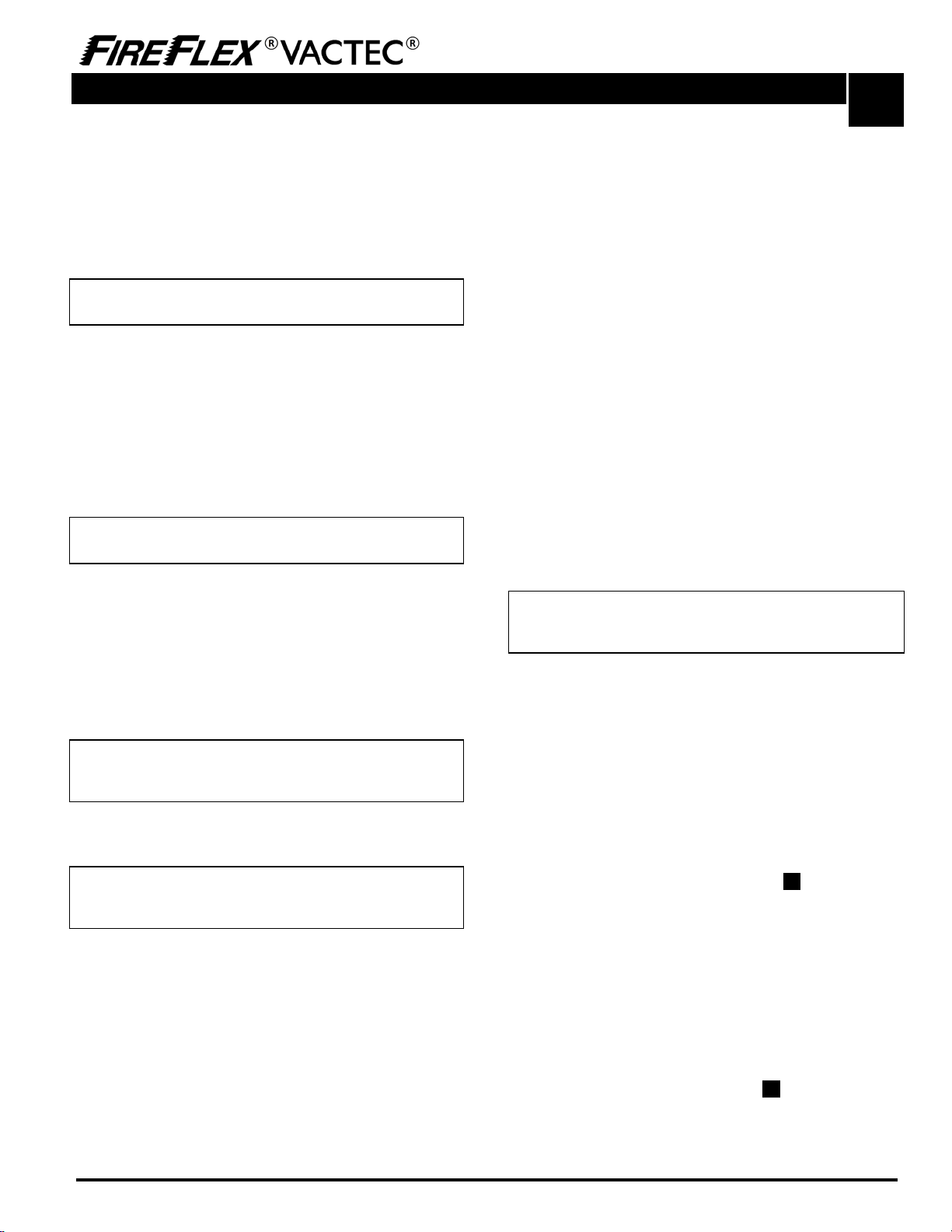

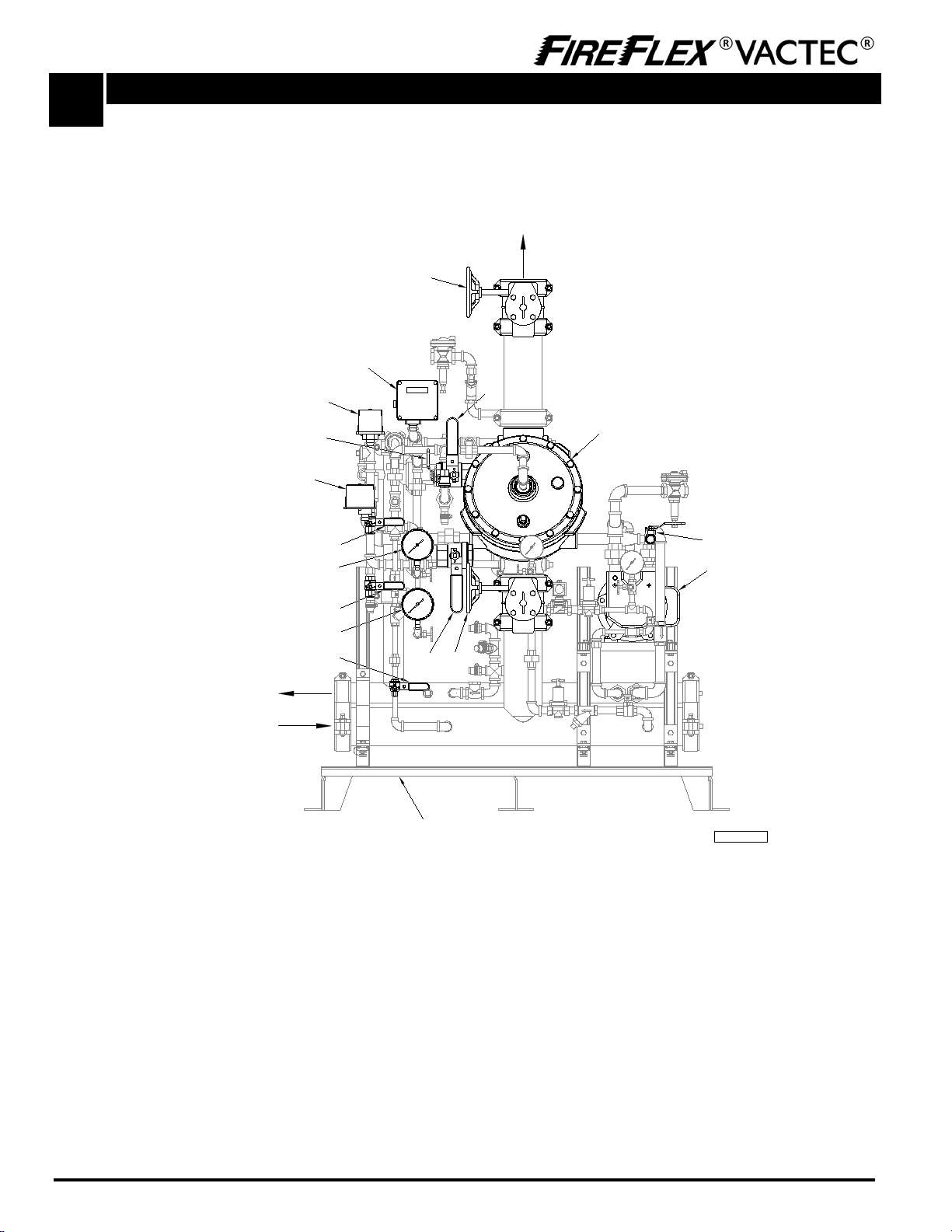

Figure 1 - Simplified system trim schematic

Typical dry-pipe vacuum sprinkler system with electric release (4" system shown)

FM-061H-0-254A

FIELD CONNECTION

TO OPEN DRAIN

(on both sides)

FIELD CONNECTION

TO WATER SUPPLY

(on both sides)

FIELD CONNECTION TO VACUUM

SPRINKLERS PIPING NETWORK

F

IRE

F

LEXd

VACTEC

d

System Base

(shown without enclosure)

D4

G1

A1

D3

G18

C1

G20

G10

B11

B12

B7

B5

B1 B6 D1

B10

Trim components:

A. Valve

A1 Deluge valve

B. Deluge valve trim

B1 Priming valve (N.O.)

B5 Alarm test valve (N.C.)

B6 Flow test valve (N.C.)

B7 Alarm line drain valve (N.C.)

B10 Manual emergency release valve (N.C.)

B11 Priming pressure water gauge & valve (N.O.)

B12 Water supply pressure gauge & valve (N.O.)

C. Water flow alarm trim

C1 Alarm pressure switch

D. Valves

D1 Water supply control valve (N.O.)

D3 Main drain valve (N.C.)

D4 Shut-off valve (N.O.)

G. Vacuum control

G1 Liquid ring vacuum pump

G10 System drain valve (N.C.)

G18 FLX-PC®VACUUM / PRESSURE CONTROLLER

Page 9 of 10

Integrated Fire Protection System B

Mechanical Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-112B

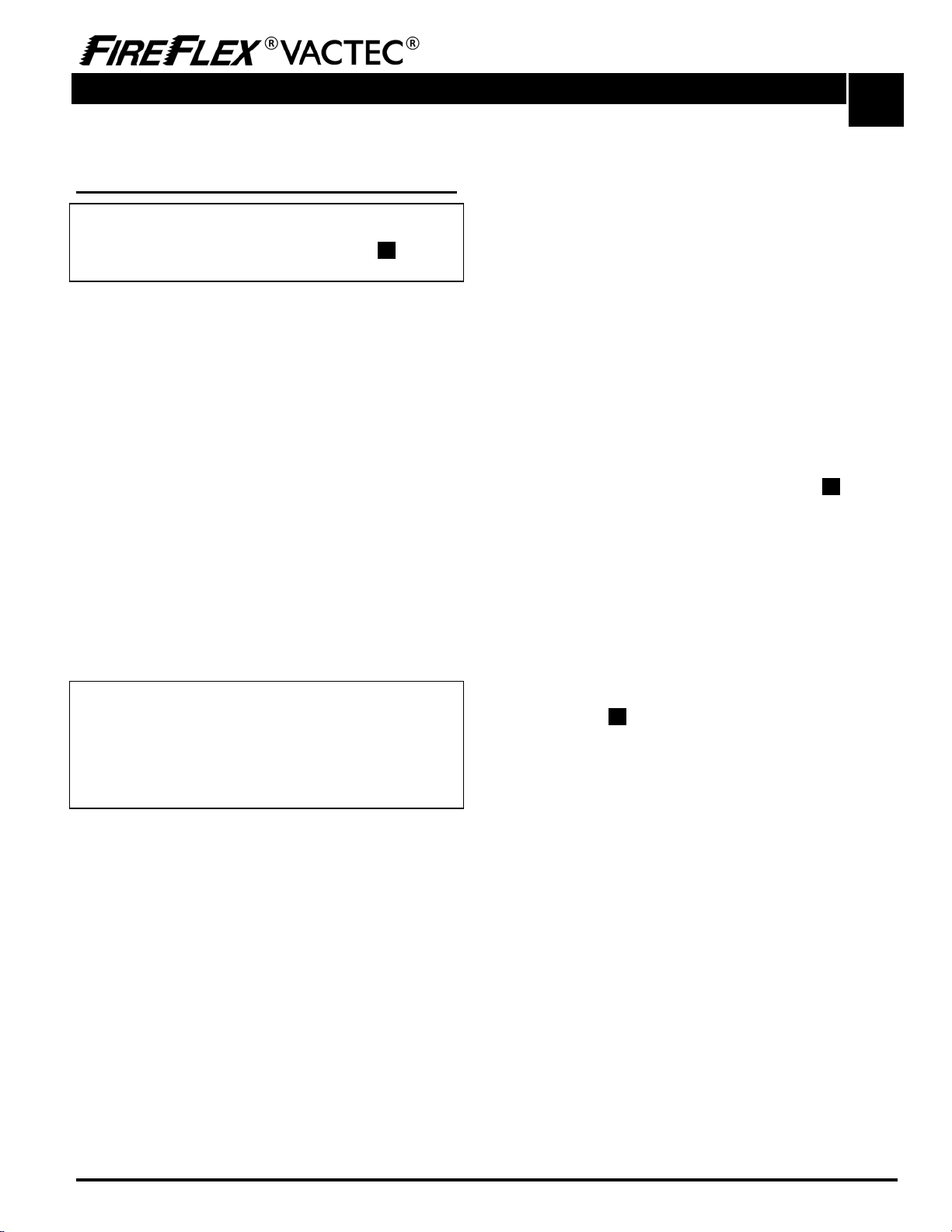

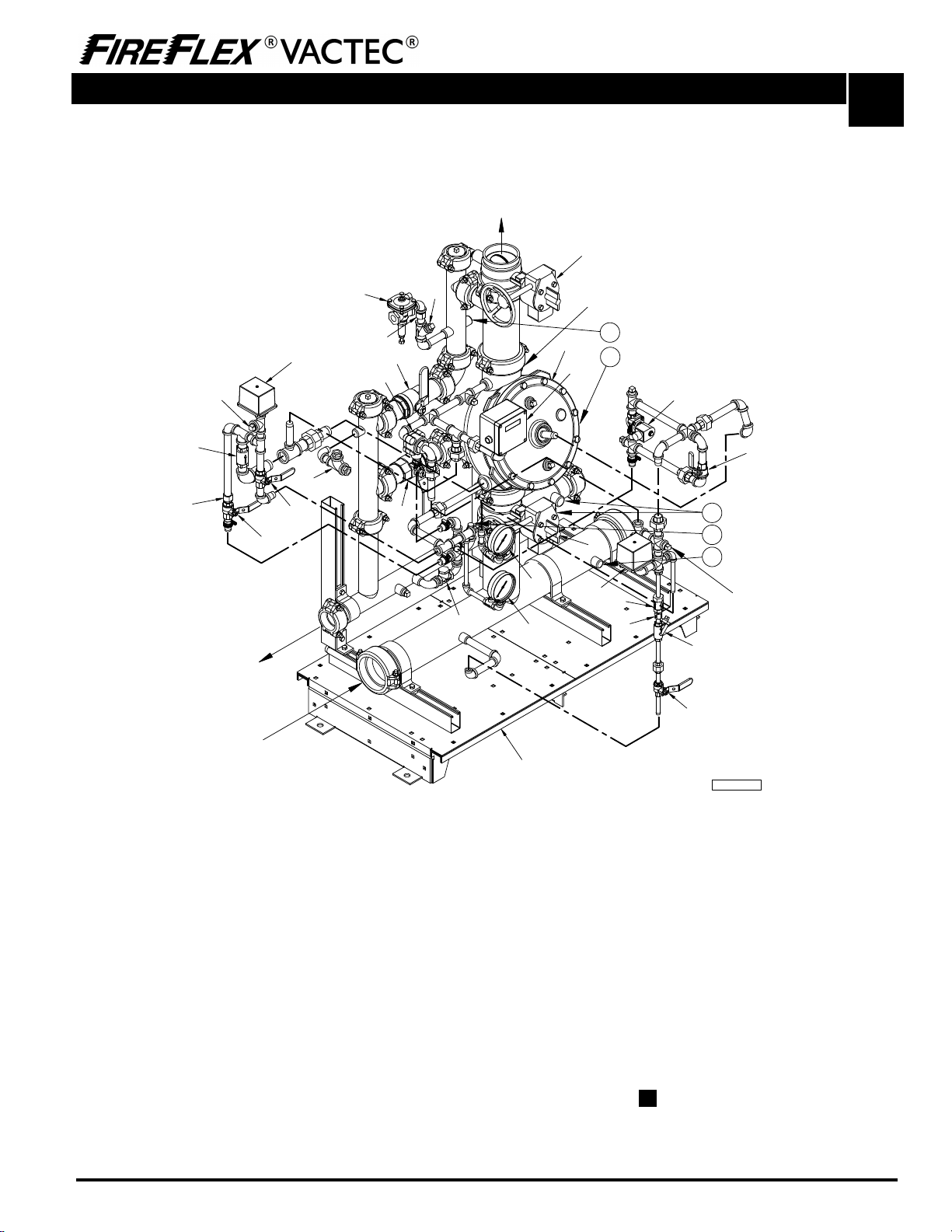

Figure 2 - Detailed system trim schematic

Typical dry-pipe vacuum sprinkler system with electric release (4" system shown)

G18

B7

B8

5

FM-061H-0-247A

FIELD CONNECTION

TO OPEN DRAIN

(on both sides)

FIELD CONNECTION

TO WATER SUPPLY

(on both sides)

D1

C1 D3

B6

B5

B9

B1

B2

B4

B3

B13

A1

B11

B12

B10

CONTRACTOR'S

HYDROSTATIC

TEST PORT

(water supply side)

FIELD CONNECTION TO VACUUM

SPRINKLERS PIPING NETWORK

B4

G20

F1

4

Towards Vacuum Supply

System Trim

3

1

Towards Vacuum Supply System Trim

2

CONTRACTOR'S HYDROSTATIC

TEST PORT (system side)

C2

G12

FIREFLEX VACTECSystem Base

(shown without enclosure)

D5

D4

G6

G8

Trim components:

A. Valve

A1 Deluge valve

B. Deluge valve trim

B1 Priming valve (N.O.)

B2 Strainer

B3 1/16" Restricted orifice

B4 Spring loaded check valve

B5 Alarm test valve (N.C.)

B6 Flow test valve (N.C.)

B7 Alarm line drain valve (N.C.)

B8 1/8" Restricted orifice

B9 PORV (pressure operated relief valve)

B10 Manual emergency release valve (N.C.)

B11 Priming pressure water gauge & valve (N.O.)

B12 Water supply pressure gauge & valve (N.O.)

B13 Clapper check valve

C. Water flow alarm trim

C1 Alarm pressure switch (PS10-1A)

C2 ¾"-NPT (20mm) connection to water motor gong

(strainer supplied by contractor)

D. Valves

D1 Water supply control valve (N.O.)

D3 Main drain valve (N.C.)

D4 Shut-off- valve (N.O.)

D5 Sight glass assembly

F. Release trim

F1 24VDC N.C. solenoid valve

G. Vacuum control

G6 Vacuum pump drain float check

G8 Vacuum pump network strainer

G10 See section D VACUUM SUPPLY

G12 Vacuum breaker valve

G18 FLX-PC® VACUUM / PRESSURE CONTROLLER

G20 Vacuum pump control pressure switch (PS40-1A)

Page 10 of 10

B

Integrated Fire Protection System

Mechanical Section - Dry-pipe Vacuum Sprinkler System - Electric Release

FM-060M-0-112B

This page is left intentionally blank.

Page 1 of 2

Integrated Fire Protection System

C

Trim Options - Vacuum Sprinkler System

FM-060M-0-88A

1. Semi-flange and full-flanged configuration

When required by the user, FIREFLEX®VACTEC®unit can

be provided in either a semi-flanged of full-flanged

configuration.

The semi-flanged option provides flanged fittings only on

the water inlet pipe (side needs to be specified at the time

of order) and on the system riser outlet. The drain

manifold is provided with a threaded end that also needs

to have its side specified (left or right). The rest of the

fittings are the same as usual with the main components

being provided in the standard flanged/grooved

configuration.

The full-flanged option is the same as above but goes a

step further with the main components being also provided

with a flanged/flanged configuration.

When provided, the face of the flanges will always be

located 6 inches (150mm) from the outside face of the

mounting base or cabinet surface.

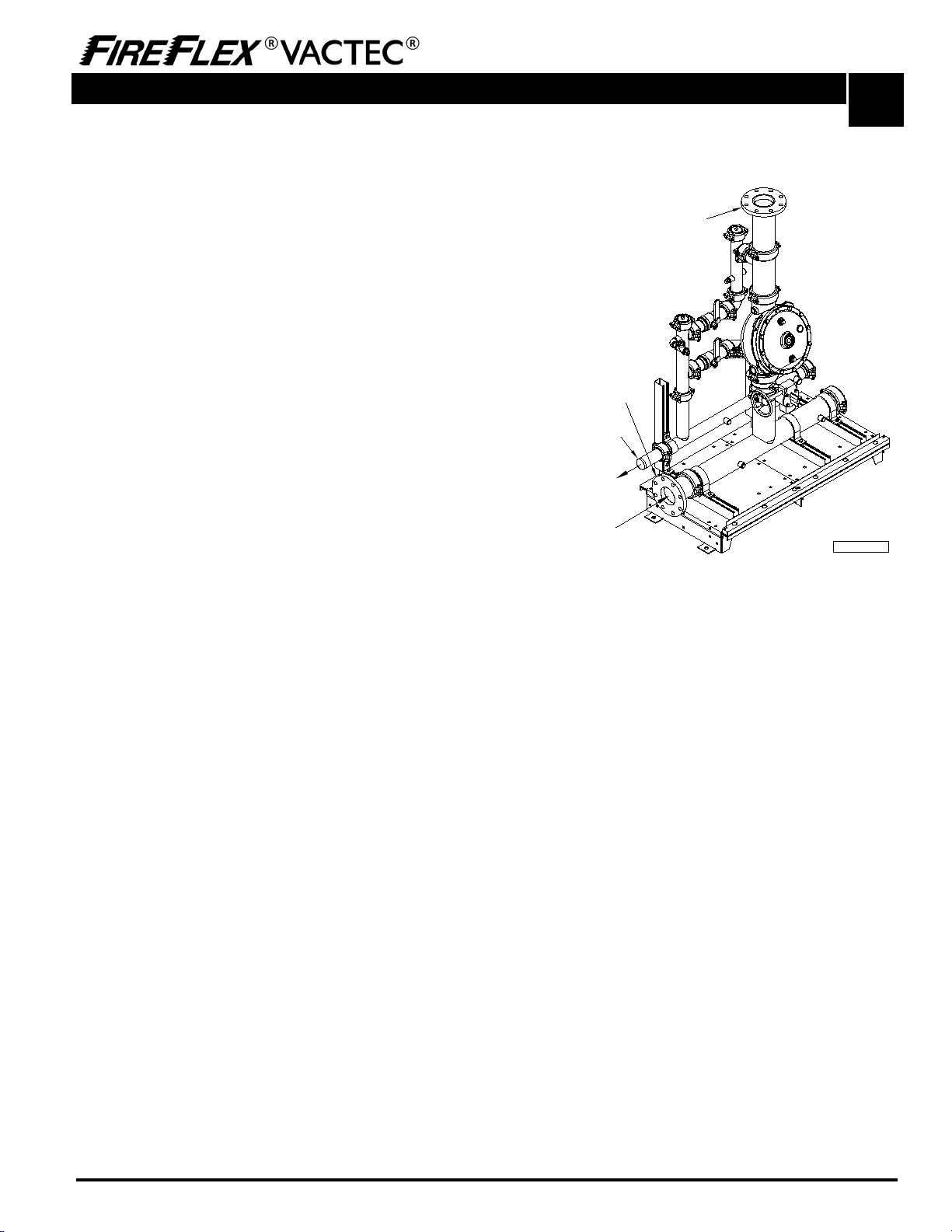

Figure 1 - Semi-flanged configuration for vacuum

sprinkler system (shown without system trim)

Field Connection

to Water Supply

(specify side)

Flanged fitting

outside cabinet

(when provided)

FM-061H-0-225A

Flanged fitting outside cabinet

(when provided)

Threaded end

Field Connection

to Open Drain

(specify side)

Page 2 of 2

C

Integrated Fire Protection System

Trim Options - Vacuum Sprinkler System

FM-060M-0-88A

This page is left intentionally blank.

Page 1 of 2

Integrated Fire Protection System D

Vacuum Supply Section - Vacuum Sprinkler System - Electric Release

FM-060M-0-89C

1- Vacuum supply

Note: Numbers indicated between brackets refer to items

on the TRIM SCHEMATICS from this section and section B

MECHANICAL.

Vacuum sprinkler system uses negative vacuum pressure to

supervise the piping network. The vacuum supply is

provided within the FIREFLEX®VACTEC® unit. The vacuum

supply trim is factory assembled in the system cabinet,

calibrated and pressure tested.

The vacuum supply system trim includes a liquid ring

vacuum pump (G1), all regulating devices to control flow of

water and pump motor shut off electrical components.

The vacuum pump (G1) power requirement is specified at

220/240VAC, 50/60Hz, 1.5HP, 1phase.

The vacuum pump (G1) is able to establish the total required

vacuum pressure in 30 minutes for system capacity up to

4000 gallons.

1.1 Operation

The start and stop adjustments of the vacuum pump (G1)

are factory set and require no further adjustments. The

pump motor is controlled by a contactor (G17) which is

activated on and off by the FLX-PC® (G18) VACUUM /

PRESSURE CONTROLLER.

The liquid ring of the vacuum pump (G1) is generated by a

water line composed by a water ring control valve (G13), a

solenoid valve (G2), a pre-regulator (G3), a fine-adjust

regulator (G4) and a restricted orifice (G5). A float check

valve (G6) and a reversed check valve (G11) prevent flood

through possible water coming from drain collector.

Vacuum is sucked from the piping network through the

2-way check valve (G7). This check valve allows vacuum to

be sucked, but will prevent water to enter the vacuum

pump (G1) when deluge valve (A1) is opened.

When the piping network has been drained after operation,

the remaining water inside the deluge valve (A1) will be

drained out by the operation of the vacuum pump (G1).

To apply vacuum supply:

Switch ON the vacuum pump (G1) On/Off switch (G16).

To close vacuum supply:

Switch OFF the vacuum pump (G1) On/Off switch (G16).

1.2 Pressure settings

All pressure settings are factory set and do not need further

calibration unless malfunction.

a) FLX-PC® (G18) set to -140 mBAR (-14 kPa) for LOW

PRESSURE supervisory condition.

b) FLX-PC® (G18) set to -220 mBAR (-22 kPa) for HIGH

PRESSURE supervisory condition.

c) FLX-PC® (G18) set to -130 mBAR (-13 kPa) for ALARM

PRESSURE condition.

d) FLX-PC® (G18) set to -150 mBAR (-15 kPa) for vacuum

pump (G1) start.

e) FLX-PC® (G18) set to -180 mBAR (-18 kPa) for vacuum

pump (G1) stop.

f) Pre-regulator (G3) set to 50 PSI (344 kPa) via pre-

regulator pressure gauge (G14).

g) Fine-adjust regulator (G4) set to 10 PSI (69 kPa) via

fine-adjust regulator pressure gauge (G15).

h) Vacuum breaker valve (G9) set to -300 mBAR (-30 kPa)

i) Vacuum breaker valve (G12) set to -200 mBAR (-20 kPa)

1.3 Maintenance and inspection

If the vacuum pump (G1) is hard to start, too much water

could be present in the deluge valve (A1) system. To fix this

problem, close vacuum system and open system drain

valve (G10) until all water has been drained out. Close the

system drain valve and apply vacuum supply.

If the vacuum pump (G1) doesn't start at all, contactor (G17)

may have tripped. Open the junction box cover of the

vacuum pump controller and reset the contactor (refer to

section E CONTROLS). Reinstall the junction box cover.

The FLX-PC® (G18) VACUUM / PRESSURE CONTROLLER is

equipped with an hour counter which reveals the operating

time of the vacuum pump (G1). During regular maintenance,

verify the counter to see if the vacuum pump (G1) is

activated often. If so, this could point to an excessive leak in

the piping network.

The vacuum pump (G1) is fitted with "sealed for life" bearing

and should provide maintenance free life.

The vacuum pump (G1) is fitted with single acting

mechanical seals. These seals should be replaced when

worn, scratch or cracked. Replacement is also necessary

when rotating portion of the seal does not firmly grip the

shaft.

If the vacuum pump (G1) is to be out of service for extended

period of time, it should be internally protected from rusting

by using a suitable water soluble rust inhibitor, available from

Busch GVT. This will give protection for up to twelve (12)

months. Rotate the pump by hand to coat the interior of the

pump surfaces with the fluid. The pump should be revolved

periodically to prevent bearing indentation.

For more information, refer to Vacuum Pumps Dolphin

LX 0300-0430 A Installation and Operating Instructions.

Page 2 of 2

D

Integrated Fire Protection System

Vacuum Supply Section - Vacuum Sprinkler System - Electric Release

FM-060M-0-89C

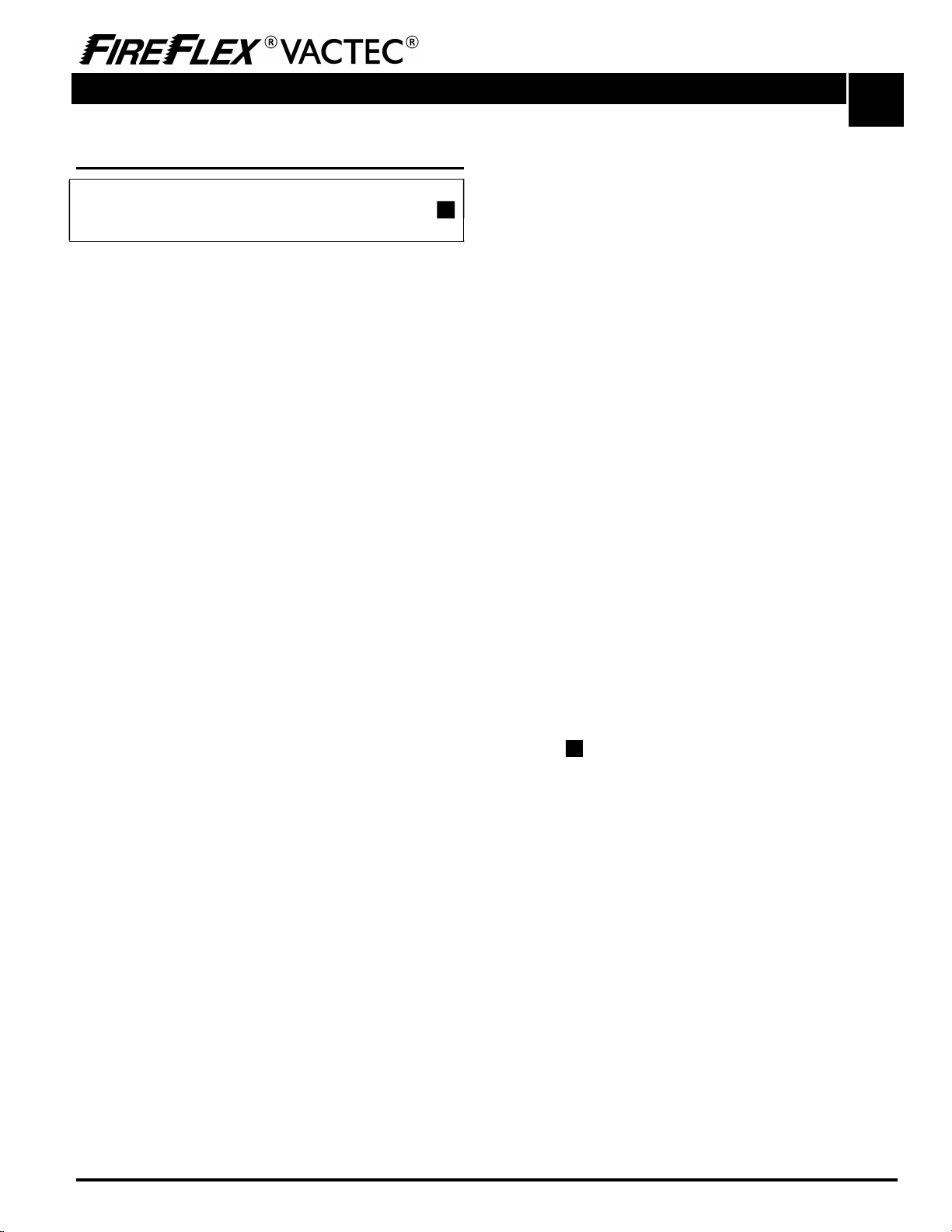

Figure 1 – Detailed vacuum supply trim schematic

5

To System Trim

2

G10

FM-061H-0-218E

G8

G7

1

To Riser Trim

G8

G5

G15

G14

G4

G8

G6

G13

G3

G2

4

To Drain Trim

3

To Water Supply Trim

4

To Drain Trim

G9

G1

G11

Vacuum pump components:

G. Vacuum supply

G1 Liquid ring vacuum pump

G2 240VAC N.C. solenoid valve

G3 Pre-regulator

G4 Fine-adjust regulator

G5 0.125" restricted orifice

G6 Float check valve

G7 2-way check valve

G8 Strainer

G9 Vacuum breaker valve

G10 System drain valve (N.C.)

G11 Reversed check valve

G12 Refer to section B MECHANICAL

G13 Water ring cut-off valve (N.O.)

G14 Pre-regulator gauge & valve

G15 Fine-adjust regulator gauge & valve

G16 On/Off manual switch (see section E CONTROLS)

G17 Electric contactor (see section E CONTROLS)

G18 Refer to section B MECHANICAL

Table of contents