2

1.4. Safety Instructions for Operators

Safety instructions for the proper use of this product must

be followed. This information must be available at all

times to personnel responsible for installation, operation,

maintenance and inspection of this product. Adequate

steps must be taken to prevent the occurrence of hazar-

dous conditions that can be caused by electric energy

and the convertible energy of the process media. Such

conditions can, for example, be the result of improper

electrical or process connections. Detailed information is

available in relevant published norms (DIN EN, UVW in

Germany; and equivalents in other countries), industrial

standards such as DVWG, Ex-, GL-, VDE guidelines, as

well as regulations of the local authorities (e.g., EVUs in

Germany).

1.5. Modifications Forbidden

Modification or other technical alteration of the product is

not permissible. This also applies to the use of unautho-

rized spare parts for repair / maintenance of the product.

Any modifications to this product, if and as necessary,

should be done only by Fischer Mess- und Regeltechnik

GmbH.

1.6. Operational Restrictions

The operational reliability of the product is guaranteed

only when used for intended purposes. The product must

be selected and configured for use specifically with defi-

ned process media. The limiting values of operating pa-

rameters, as given in the product specification sheet,

must never be crossed.

1.7. Safety Considerations during Installation and

Maintenance

The safety instructions given in this manual, existing na-

tional regulations relating to accident prevention and the

internal safety rules and procedures of the user organi-

zation regarding safety during installation, operation and

servicing must all be followed meticulously.

It is the responsibility of the users to ensure that only sui-

tably qualified and experienced technical personnel are

used for installation, operation and servicing of this

equipment.

2. Intended Applications

The DA01 is used for indication and switching differential

pressure of gaseous and liquid media. The product must

be used only for applications and under conditions spe-

cified by the manufacturer.

3. Product Description and Functions

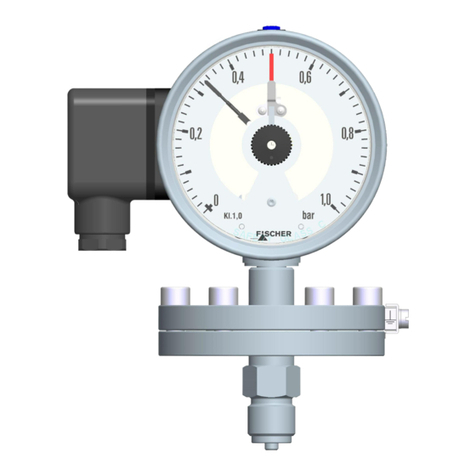

3.1. Schematic Diagram

3.2. Principles of Operation

The pressures to be compared act on flexible stainless

steel diaphragms on either side of the sensing capsule.

The two diaphragms are mechanically linked by a rigid

connecting rod. To compensate high static pressures,

the cavity between the two diaphragms is filled with hy-

draulic fluid. When pressures are equal on both dia-

phragms, they are at zero position. When there is a

difference in pressures acting on the two diaphragms,

they are deflected away from the high pressure side, to-

wards the lower pressure side, causing a displacement

of the connecting rod. A precision mechanism translates

the linear displacement of the diaphragm connecting rod

to angular movement of the gauge's dial pointer. The

pointer's displacement range of 270° corresponds to the

full scale differential pressure.

The connecting rod has intermediate flanges on either si-

de, which protects the diaphragms against excess diffe-

rential pressure. When differential pressure exceeds the

specified limit, the flange towards the lower pressure side

is pressed against the sealing O-ring on the inside of the

sensing capsule. This action isolates the fluid adjacent to

the diaphragm exposed to lower pressure, from the fluid

at higher pressure on the other side. This limits the pres-

sure differential across the lower pressure diaphragm,

and equalizes the pressure across the higher pressure

diaphragm. Thus both diaphragms are protected against

excess deflection and risks of rupturing.

1 Connecting rod

2 O-ring, differential over-

pressure protection

3 Sensing diaphragm

4 Pointer mechanism

5 Lever

6 Link

7 Pressure transfer liquid