2

1.4. Safety Instructions for Operators

Safety instructions for the proper use of this product must

be followed. This information must be available at all

times to by personnel responsible for installation, opera-

tion, maintenance and inspection of this product. Ade-

quate steps must be taken to prevent the occurrence of

hazardous conditions that can be caused by electric en-

ergy and

the convertible energy of the process media. Such con-

ditions can, for example, be the result of improper electri-

cal or process connections. Detailed information is

available in relevant published norms (DIN EN, UVW in

Germany; and equivalents in other countries), industrial

standards such as DVWG, Ex-, GL-, VDE guidelines, as

well as regulations of the local authorities (e.g., EVUs in

Germany).

1.5. Modifications Forbidden

Modification or other technical alteration of the product is

not permissible. This also applies to the use of unautho-

rized spare parts for repair / maintenance of the product.

Any modifications to this product, if and as necessary,

should be done only by Fischer Mess- und Regeltechnik

GmbH.

1.6. Operational Restrictions

The operational reliability of the product is guaranteed

only when used for intended purposes. The product must

be selected and configured for use specifically with defi-

ned process media. The limiting values of operating pa-

rameters, as given in the product specification sheet,

must never be crossed.

1.7. Safety Considerations during Installation and

Maintenance

The safety instructions given in this manual, existing na-

tional regulations relating to accident prevention, and the

internal safety rules and procedures of the user organi-

zation regarding safety during installation, operation and

servicing must all be followed meticulously.

It is the responsibility of the users to ensure that only sui-

tably qualified and experienced technical personnel are

used for installation, operation and servicing of this

equipment.

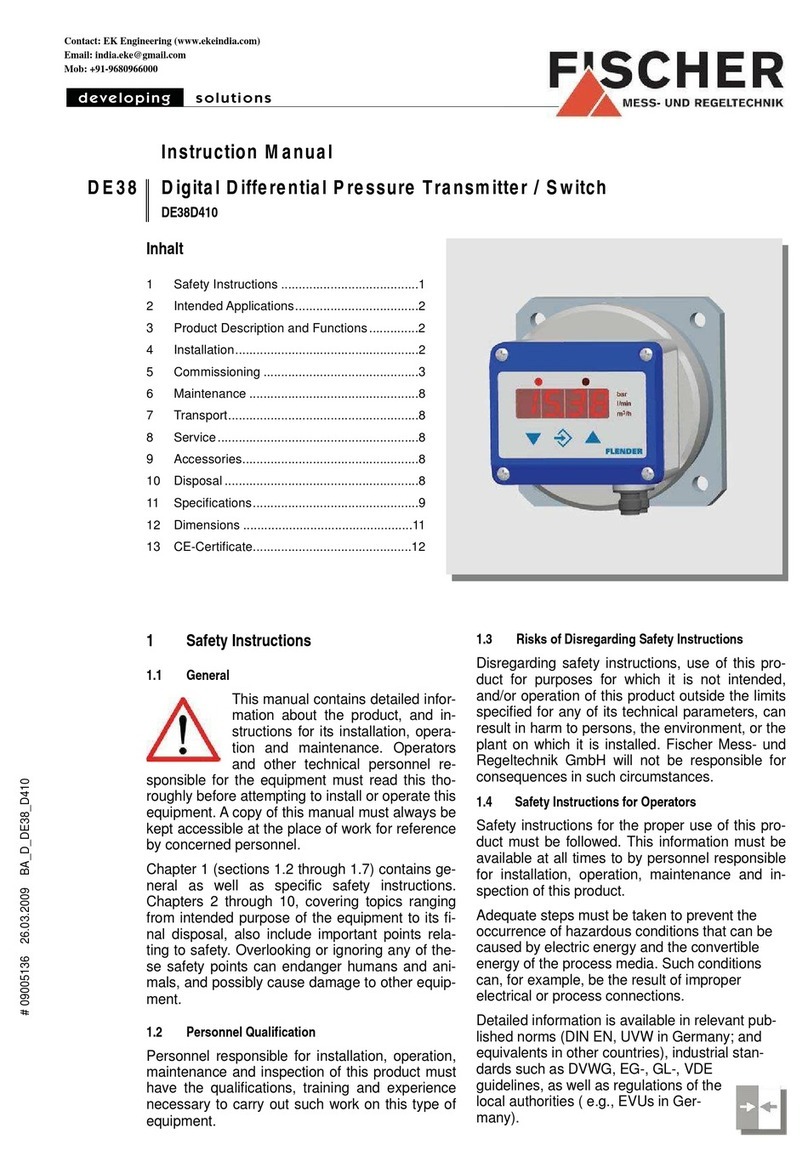

2. Intended Applications

The DE23 is a 2-wire transmitter. It is suitable for accura-

te measurement of low positive / negative gauge pressu-

re or differential pressure of air and gases.

3. Product Descriptions and Functions

3.1. Functional Scheme

3.2. Principles of Operation

The instrument is based on a capacitance sensor ele-

ment and can measure positive gauge, negative gauge

or differential pressure.

The pressure is measured directly by a micromachined

silicon-on-glass differential capacitance sensor element.

Pressure changes cause capacitance changes interpre-

ted by the integrated electronics.

4. Installation

The electronic module is mounted on a flat plate or panel,

for which it has 4 holes at the rear for self-tapping screws

∅3.5 mm. A wall-mounting plate is available as an option

(s. 13. Ordering Code).

The pressure transmitters are calibrated at the factory

while mounted vertically, pressure ports downward.

However, they can be mounted in any orientation.

IP65 protection for the housing is guaranteed only if sui-

table connecting cable is used.

If the instrument is intended for outdoor application, we

highly recommend using an adequate protective housing

(or at least a big enough shelter) as protection against

UV-radiation on the membrane keyboard and against ex-

posure of the instrument to rain or snow.

4.1. Process Connections

• Only technicians who are qualified and authorized for

this type of work should undertake installation.

• Ensure that the process equipment and pressure li-

nes are at atmospheric pressure before making pres-

sure connections to the instrument.

• The instrument should be provided with suitable pro-

tection against pressure surges (e.g., snubber or pul-

sation damper).

• Ensure that the mechanical configuration and materi-

als of construction of the instrument are compatible

with the process media.