2-12 | Page

1.5 Unauthorised Modification

Modifications of or other technical alterations to the

instrument by the customer are not permitted. This

also applies to replacement parts. Any modifica-

tions / alterations required shall be carried out by

Fischer Mess- und Regeltechnik GmbH only.

1.6 Inadmissible Modes of Operation

The operational safety of this instrument can only

be guaranteed if it is used as intended. The instru-

ment model must be suitable for the medium used

in the system. The limit values given in the technical

data may not be exceeded.

1.7 Safe working practices for

maintenance and installation work

The safety instructions given in this operating man-

ual, any nationally applicable regulations on acci-

dent prevention and any of the operating company's

internal work, operating and safety guidelines must

be observed.

The operating company is responsible for ensuring

that all required maintenance, inspection and instal-

lation work is carried out by qualified specialized

personnel.

1.8 Symbol explanation

WARNING!

… indicates a potentially dangerous

situation, non-observance of which

could endanger persons, animals, the

environment or objects.

INFORMATION!

… highlights important information for

efficient and smooth operation.

TIP!

… indicates recommendations that are

not specifically necessary in certain

situations but which could be useful.

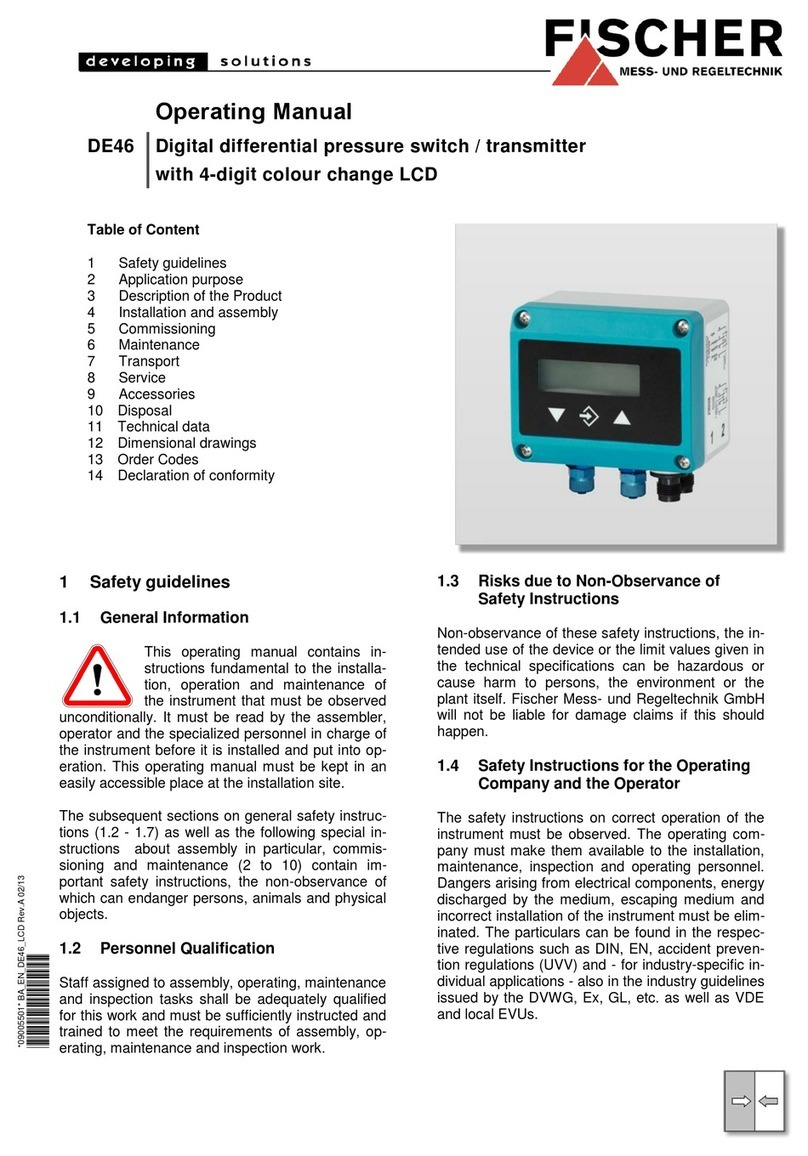

2 Application purpose

Measuring transducer and switching device for

over-pressure, under-pressure and differential

pressure of gaseous media. It may only be used for

the intended use given in the manufacturer's data

sheet. If any soiled or aggressive media is expected

on the system side, the instrument needs to be

modified in terms of those parts that have contact

with the medium. Talk to the manufacturer before

ordering.

3 Description of the product and func-

tional description

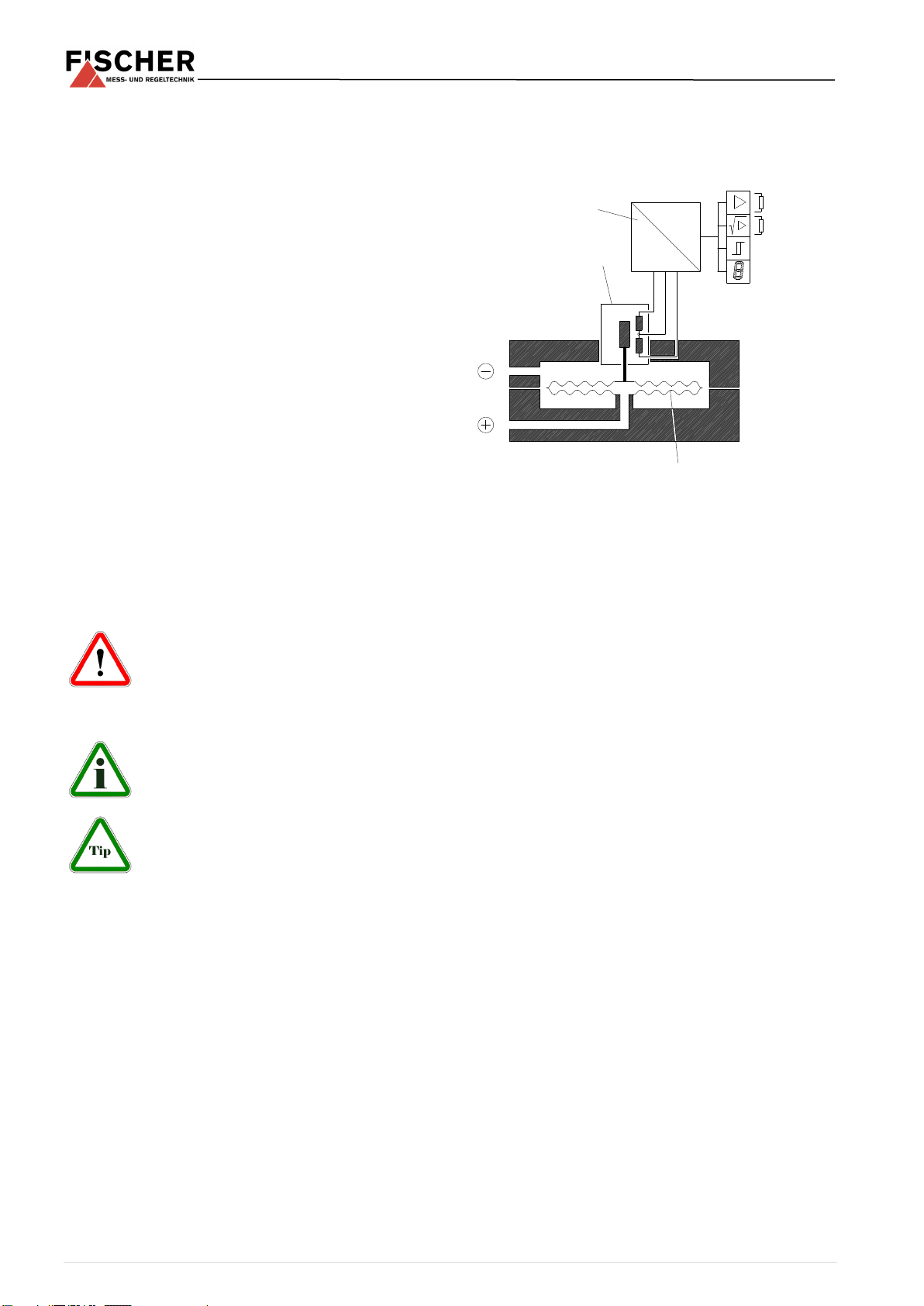

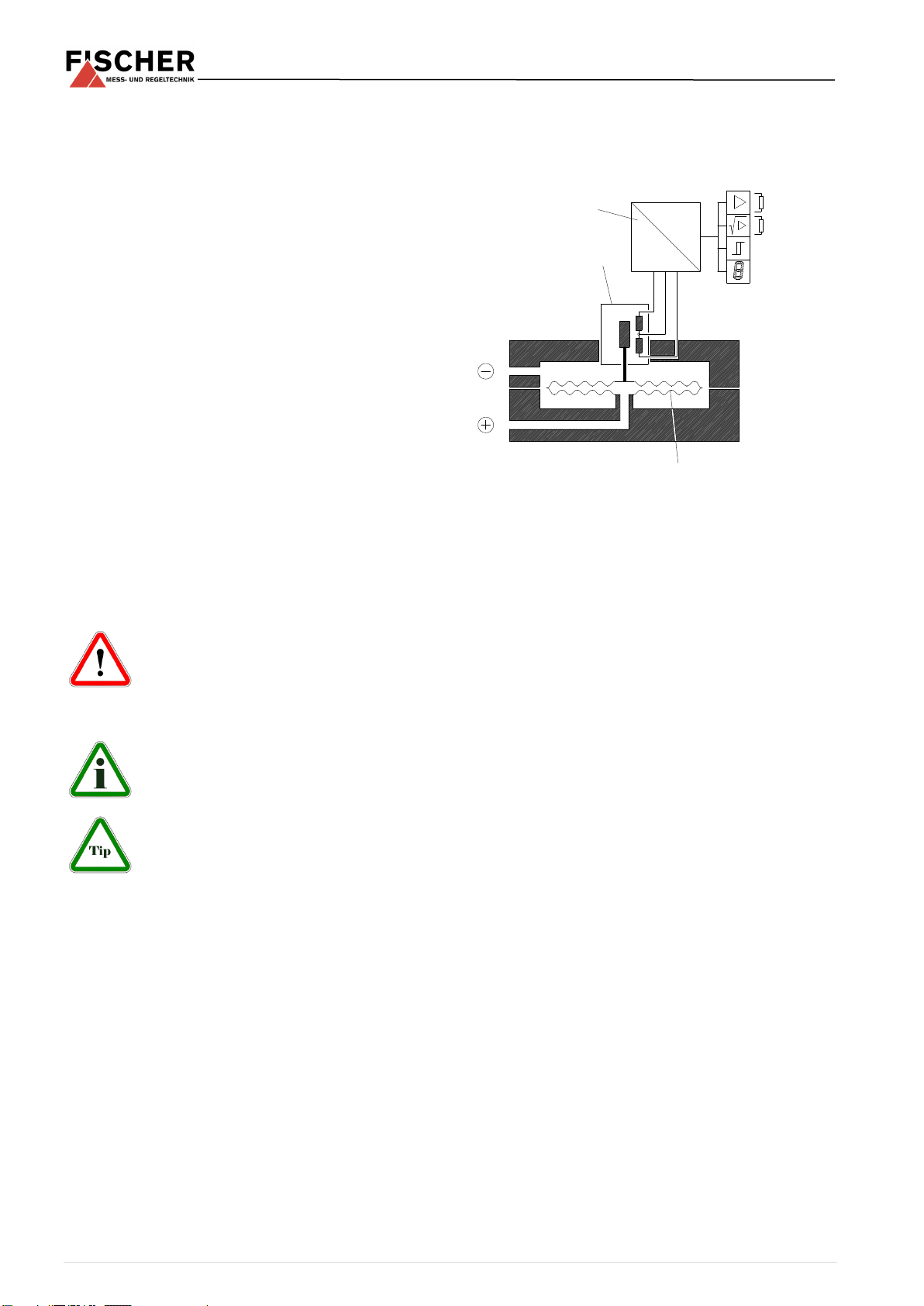

3.1 Functional Schematic

3.2 Design and mode of action

The base of the measuring and switching instru-

ment DE 50 is a diaphragm capsule measuring sys-

tem that is suitable for measuring overpressure,

under-pressure and differential pressure. The pres-

sure or differential pressure that is to be measured

triggers the diaphragm capsule, thereby moving the

core of the inductive displacement transducer. This

is converted to an electrical output signal in the

downstream electronics. The transformer electron-

ics are available in several models.

In addition to the various operating voltages, the

output signal can be designed as a current or volt-

age signal.

Flows in gaseous media are often measured ac-

cording to the effective pressure principle. To

achieve a flow-proportional measured value, the ef-

fective pressure signal needs to be rooted. There

are transformer electronics available to supply the

rooted output signals for these applications.

In addition to the analogue output signal, the in-

strument can be equipped with potential-free con-

tact outputs that can be set to each value within the

measuring range.

The pressure / differential pressure values can be

displayed as linear measured values on site via an

installed LC display (optional).

4 Installation and assembly

The instrument can be installed on even walls, as-

sembly plates or switch cabinet assembly rails. The

four attachment boreholes are accessible after the

lid has been removed from the instrument.

At the factory, the device is calibrated for vertical

installation, but the installation position is arbitrary.

For any installation positions that are not vertical,

Inductive displacement

transducer