2

This information must be available at all times to by per-

sonnel responsible for installation, operation, mainte-

nance and inspection of this product. Adequate steps

must be taken to prevent the occurrence of hazardous

conditions that can be caused by electric energy and the

convertible energy of the process media. Such conditi-

ons can, for example, be the result of improper electrical

or process connections. Detailed information is available

in relevant published norms (DIN EN, UVW in Germany;

and equivalents in other countries), industrial standards

such as DVWG, Ex-, GL-, VDE guidelines, as well as re-

gulations of the local authorities (e.g., EVUs in Germa-

ny).

1.5. Modifications Forbidden

Modification or other technical alteration of the product is

not permissible. This also applies to the use of unautho-

rized spare parts for repair / maintenance of the product.

Any modifications to this product, if and as necessary,

should be done only by Fischer Mess- und Regeltechnik

GmbH.

1.6. Operational Restrictions

The operational reliability of the product is guaranteed

only when used for intended purposes. The product must

be selected and configured for use specifically with defi-

ned process media. The limiting values of operating pa-

rameters, as given in the product specification sheet,

must never be crossed.

1.7. Safety Considerations during Installation and

Maintenance

The safety instructions given in this manual, existing na-

tional regulations relating to accident prevention, and the

internal safety rules and procedures of the user organi-

zation regarding safety during installation, operation and

servicing must all be followed meticulously.

It is the responsibility of the users to ensure that only sui-

tably qualified and experienced technical personnel are

used for installation, operation and servicing of this

equipment.

2. Intended Applications

Measuring Transmitter for overpressure, partial vacuum

and differential pressure of liquid and aerial media. The

product may be used only for applications and under

conditions specified by the manufacturer. Please confer

with Fischer Mess- und Regeltechnik prior to using this

transmitter along with polluted or aggressive media. For

use with this media it needs to be adjusted in every part

with direct contact to the media.

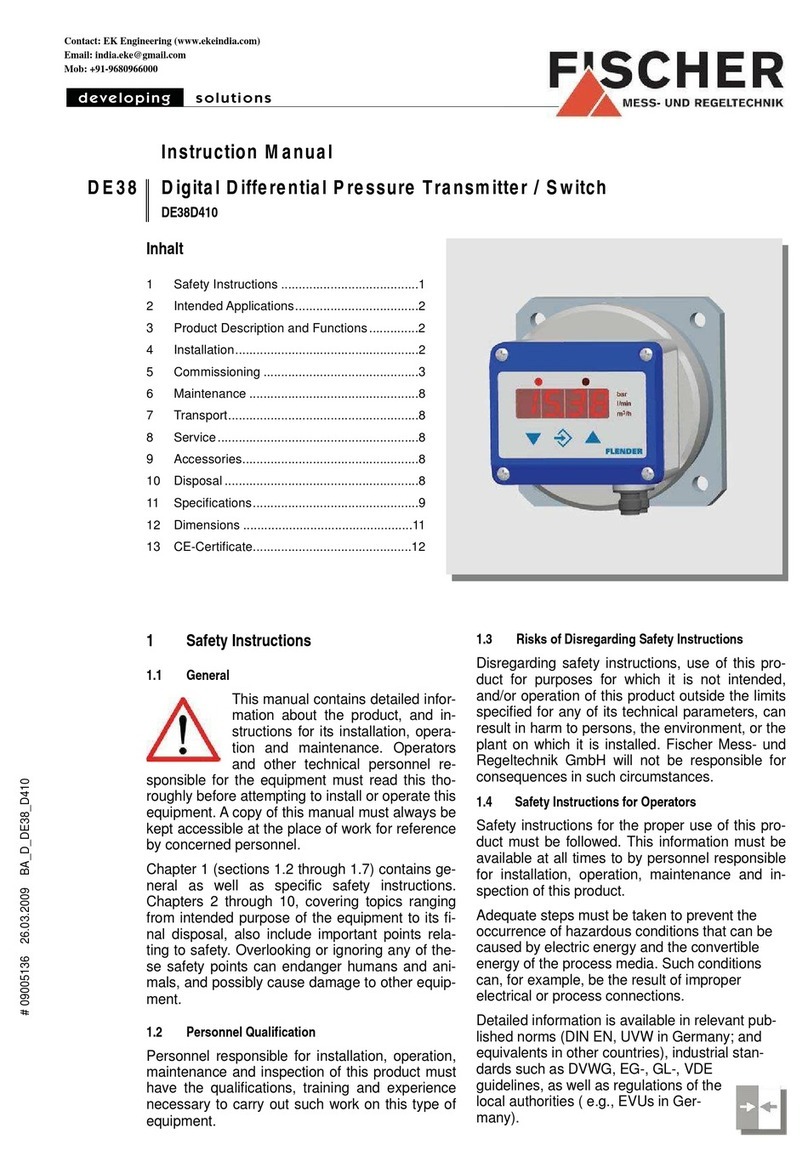

3. Product Description and Functions

3.1. Block Schematic Diagram

3.2. Principles of Operation

This transmitter is based on a rugged and uncomplicated

diaphragm movement. The operating principle of the sy-

stem is identical for all applications of this type. In a state

of equilibrium, the forces of the springs on both sides of

the diaphragm are balanced.

The pressure or differential pressure to be measured

creates an unbalanced force of the springs for the

measuring range until a new equilibrium is reached.

A centre-mounted tappet transfers the motion of the dia-

phragm system to the core of an inductive displacement

transducer. The subsequent converter circuit converts

this motion into an electrical output signal 0(4) - 20 mA li-

near, 3-wire connection.

4. Installation

The electronic module is mounted on a flat plate or panel,

for which it has integral hole flanges. The pressure trans-

mitters are calibrated at the factory while mounted up-

right, pressure ports downward and must be mounted

this way.

4.1. Process Connections

• Only technicians who are qualified and authorized for

this type of work should undertake installation.

• Only for intended mechanic process connection - see

ordering code on type plate on the instrument for mo-

del specification.

• Ensure that the process equipment and pressure li-

nes are at atmospheric pressure before making pres-

sure connections to the instrument.

• The instrument should be provided with suitable pro-

tection against pressure surges.

• Ensure that the mechanical configuration and materi-

als of construction of the instrument are compatible

with the process media.

• Ensure that process pressure is always less than the

specified safe pressure rating.

1 pressure chamber

2 inductive

displacement

transducer

3 measuring springs

4 measuring

diaphragm