Fisher-Rosemount 3660 User manual

D101402X012

Type 3660 and 3661 Positioners

Contents

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of Manual 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioner Mounting 5. . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting on the Type 1250, 1250R, and

3024S Actuators 5. . . . . . . . . . . . . . . . . . . . . . . . .

Mounting on Baumann Actuators 7. . . . . . . . . . . . .

Mounting on the Type 657 and 667 Actuators 8. .

Feedback Lever Assembly and

Range Spring Installation 11. . . . . . . . . . . . . . . . . .

Pressure Connections 14. . . . . . . . . . . . . . . . . . . . . . .

Supply Connection 13. . . . . . . . . . . . . . . . . . . . . . . . .

Output Connection 13. . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Connection 15. . . . . . . . . . . . . . . . . . . . .

Diagnostic Connections 15. . . . . . . . . . . . . . . . . . . .

Vent Connection 15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Connections for

Type 3661 Positioners 15. . . . . . . . . . . . . . . . . . . .

Calibration 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Split Range Operation 18. . . . . . . . . . . . . . . . . . . . . . .

Type 3660 Bypass Operation 18. . . . . . . . . . .

Principle of Operation 19. . . . . . . . . . . . . . . . . . .

Maintenance 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Positioner Action 20. . . . . . . . . . . . . . .

Changing the Range Spring 20. . . . . . . . . . . . . . . . . .

Changing the Input Signal Range on

Type 3660 Positioners 21. . . . . . . . . . . . . . . . . . . .

Removing the Positioner from the Actuator 21. . . . .

Center-Bolt Mounting on the Type 1250,

1250R, 3024S and Baumann Actuators 21. . . .

Clamp Mounting on the Type 1250,

1250R and 3024S Actuators 21. . . . . . . . . . . . . .

Mounting Bracket/U-Bolt Mounting on

Type 657, and 667 Actuators 21. . . . . . . . . . . . .

Changing the Input Module

Diaphragm Assembly 21. . . . . . . . . . . . . . . . . . . . .

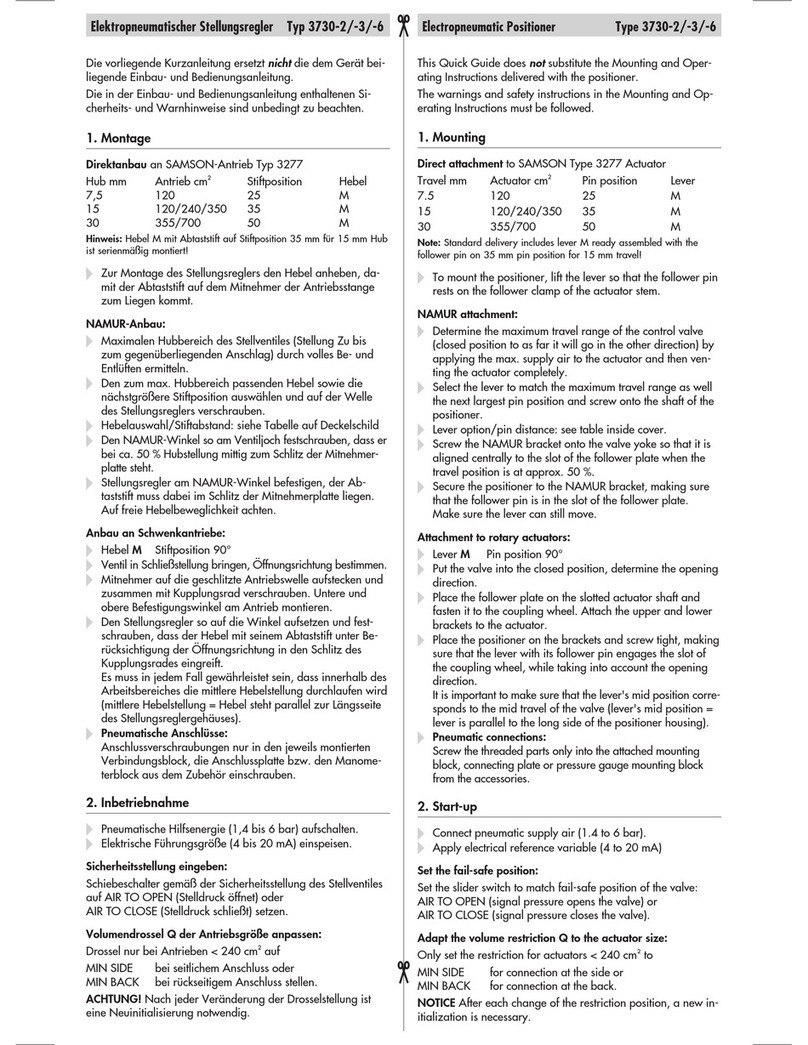

Figure 1. Type 3660 Positioner Mounted on a

Baumann Actuator

W7174 / IL

Disassembling and Assembling Relay

Components 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembling and Assembling the Bypass

Valve 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Type 3661 Converter Module 23. . . .

Parts Ordering 23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Kits 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Kits 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Kits 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioner Common Parts 24. . . . . . . . . . . . . . . . . . . .

Diagnostic Connections 25. . . . . . . . . . . . . . . . . . . . . .

Mounting Parts 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loop Schematics 31. . . . . . . . . . . . . . . . . . . . . . . .

Instruction Manual

Form 5265

December 2000 Type 3660 and 3661

Type 3660 and 3661

2

Table 1. Specifications

Available Configuration

Type 3660: Single-acting pneumatic valve

positioner

Type 3661: Single-acting electro-pneumatic valve

positioner

Input Signal(1)

Type 3660

J0.2 to 1.0 bar (3 to 15 psig),

J0.4 to 2.0 bar (6 to 30 psig), or

Jsplit range (see tables 2 and 3)

Type 3661:

J4 to 20 mA dc constant current with 30 V dc

maximum compliance voltage.

Jsplit range is also available, see tables 2 and 3

Equivalent Circuit (Type 3661)

120 ohms shunted by three 5.6 V zener diodes

Output Signal(1)

Type: Pneumatic pressure as required by the

actuator up to full supply pressure

Action:

JDirect (increasing input signal pressure increases

positioner output),

JReverse (increasing input signal pressure

decreases positioner output)

Supply Pressure(1)

Recommended: 10% above actuator requirements

Maximum: 6.2 bar (90 psig) or pressure rating of

actuator, whichever is lower

Performance(1)

Independent Linearity: ±1% of output span

Hysteresis: 0.5% of output span(4)

Deadband: 0.1% of input span

Electromagnetic Interference (EMI) (Type 3661)

When tested per SAMA Standard PMC 33.1-1978,

change in steady-state deviation is less than ±1% in

an electromagnetic field classified as 3-abc with a

field strength of 30 V/m. Positioner is tested with

cover on and with external wiring in rigid metal

conduit

These instruments have the CE mark in accordance

with the Electromagnetic Compatibility (EMC)

Directive. They meet the requirements of

EN50081-1 (emmissions for light industry) and

EN50082-2 (immunity for industrial environment).

Positioner Adjustments

Span: JAdjustable up to 20 mm (0.75 inch) stem

travel, or JAdjustable from 20 mm (0.75 inch) to

50 mm (2 inch) stem travel

Zero: 0 to 100%

Gain: 0.5 to 6% PB (proportional band)(5)

Output Volume Damping: Loop dynamic response

adjustment

Delivery Capacity(2)

1.4 Bar (20 Psig) Supply: 4.3 normal m3/hour

(150 scfh)

2.4 Bar (35 Psig) Supply: 6.6 normal m3/hour

(230 scfh)

Exhaust Capacity(2)

1.4 Bar (20 Psig) Supply: 4.8 normal m3/hour

(170 scfh)

2.4 Bar (35 Psig) Supply: 7.4 normal m3/hour

(260 scfh)

Steady-State Air Consumption(1)(2)(3)

Type 3660: 0.16 normal m3/hour (6.0 scfh) at 1.4

bar (20 psig) supply pressure. 0.21 normal m3/hour

(7.9 scfh) at 2.4 bar (35 psig) supply pressure

Type 3661: 0.24 normal m3/hour (8.8 scfh) at 1.4

bar (20 psig) supply pressure. 0.33 normal m3/hour

(12.3 scfh) at 2.4 bar (35 psig) supply pressure

Operating Influences(1)

Supply Pressure: 70 mbar (1 psig) change in

supply pressure changes the actuator stem position

less than 0.16%(6) of travel

Operative Temperature Limits(1)

Type 3660 without Pressure Gauges: –40 to

120°C (–40 to 250°F)

Type 3660 with Pressure Gauges: –40 to 60°C

(–40 to 140°F)

Type 3661 without Pressure Gauges: –40 to 80°C

(–40 to 180°F)

Type 3661 with Pressure Gauges: –40 to 60°C

(–40 to 140°F)

Hazardous Area Classification

Refer to Hazardous Area Classification bulletins for

approvals

– Continued –

Type 3660 and 3661

3

Table 1. Specifications (Continued)

Housing Classification (Type 3661)

IP 54 per IEC 60529, NEMA 3 (FM) and Enclosure

3 (CSA): Mounting orientation requires vent location

to be below horizontal.

Mounting

The positioner can be mounted in one of four

different configurations. See figure 2 for mounting.

Pressure Connections

1/4-inch NPT female

Conduit Connection for Type 3661

1/2-inch NPT (M20 or PG13 adaptors, optional)

Maximum Valve Stem Travel

Two ranges:

J50 mm (2 inch) to 20 mm (0.75 inch) minimum;

J20 mm (0.75 inch) adjustable to lesser travel with

standard input signal

Options

Type 3660:

JInstrument and output pressure gauges,

JIntegrally mounted bypass valve

Type 3661: Output pressure gauge

Approximate Weight

Type 3660: 1.2 kg (2.6 pounds)

Type 3661: 1.4 kg (3.0 pounds)

Vent Connection

1/4-inch NPT female

1. This term is defined in ISA Standard S51.1.

2. Normal m3/hr—normal cubic meters per hour (0°C and 1.01325 bar absolute); Scfh—standard cubic feet per hour (60°F and 14.7 psia).

3. Air consumption at a gain setting of 1/2 turn.

4. Hysteresis value at a gain setting of 1/2 turn.

5. Adjusting the gain (PB) adjustment changes the nozzle flapper relationship. This nozzle flapper change affects the actuator/positioner response time.

6. At supply pressure of 2.4 bar (35 psig).

Introduction

Scope of Manual

This instruction manual includes installation, operation,

calibration, maintenance, and parts ordering

information for the Type 3660 and 3661 positioners.

Refer to separate instruction manuals for information

on the actuator and control valve.

Only personnel qualified through training or experience

should install, operate, or maintain the positioner. If

there are any questions concerning the instructions in

this manual, contact your Fisher sales office or sales

representative before proceeding.

Description

The Type 3660 pneumatic and Type 3661

electro-pneumatic, single-acting positioners are used

with Fisher Controls Type 657, 667, 1250, and 1250R

actuators. These positioners can also be mounted on

Gulde 3024S and Baumann actuators. Figure 1 shows

a Type 3660 positioner mounted on a Baumann

actuator.

The positioner mounts on the actuator and provides

the desired plug position for a specific input signal.

The Type 3660 positioner accepts a pneumatic signal

and the Type 3661 accepts a 4 to 20 milliampere dc

input signal.

Specifications

Specifications for the Type 3660 and 3661 positioners

are shown in table 1.

Installation

Normally, a positioner is shipped with the actuator. If

so, the factory mounts and calibrates the positioner

and connects the positioner to actuator tubing. If the

positioner is ordered separately from the actuator,

perform the appropriate mounting procedure. Refer to

the appropriate instruction manuals for actuator and

valve installation procedures.

WARNING

Avoid personal injury and property

damage from sudden release of process

pressure. Before mounting the

positioner on a valve in service:

DDisconnect any operating lines

providing air pressure, electric power, or

a control signal to the actuator. Be sure

the actuator cannot suddenly open or

close the valve.

Type 3660 and 3661

4

Input Signal Positioner Output

Direct

0.2 to 1.0 bar (3 to 15 psig)

0.4 to 2.0 bar (6 to 30 psig)

4 to 20 mA

Reverse

1.0 to 0.2 bar (15 to 3 psig)

2.0 to 0.4 bar (30 to 6 psig)

20 to 4 mA

Up to 6.2 bar (90 psig)

For split range signal refer to tables 2 and 3

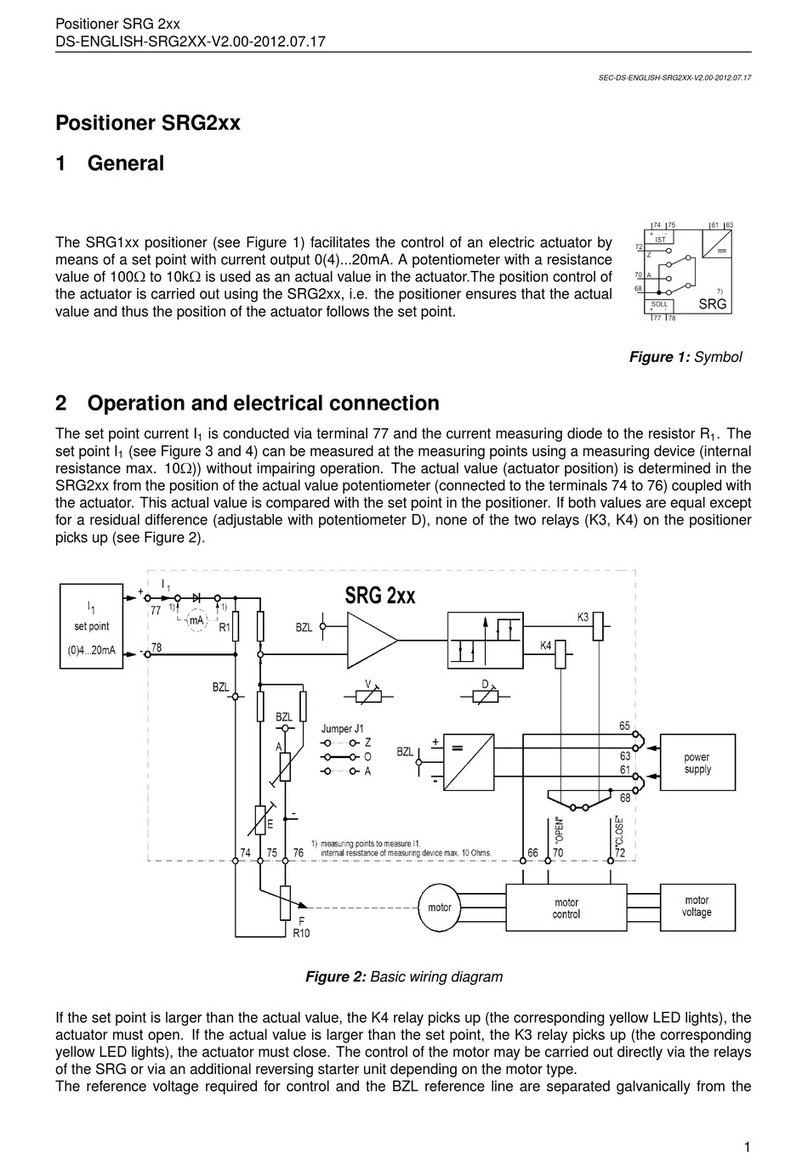

Figure 2. Mounting Configurations

ACTUATOR: AIR-TO-RETRACT

POSITIONER ACTION: DIRECT

(INCREASING INPUT SIGNAL INCREASES

OUTPUT PRESSURE TO ACTUATOR)

INPUT SIGNAL

AIR SUPPLY

OUTPUT

PILOT SHAFT

1

ACTUATOR: AIR-TO-RETRACT

POSITIONER ACTION: REVERSE

(INCREASING INPUT SIGNAL DECREASES

OUTPUT PRESSURE TO ACTUATOR)

INPUT SIGNAL

AIR SUPPLY

OUTPUT

FEEDBACK

PLATE

2

ACTUATOR: AIR-TO-EXTEND

POSITIONER ACTION: REVERSE

(INCREASING INPUT SIGNAL DECREASES

OUTPUT PRESSURE TO ACTUATOR)

INPUT SIGNAL

AIR SUPPLY

OUTPUT

1

ACTUATOR: AIR-TO-EXTEND

POSITIONER ACTION: DIRECT

(INCREASING INPUT SIGNAL INCREASES

OUTPUT PRESSURE TO ACTUATOR)

INPUT SIGNAL

AIR SUPPLY

OUTPUT

2

NOTES:

WHEN MOUNTING ON BAUMANN ACTUATORS, INSTALL FEEDBACK PLATE SO LIP IS UP. INSTALL FEEDBACK LEVER ARM

ASSEMBLY, PRELOADED, SO PILOT SHAFT IS ON TOP OF THE FEEDBACK PLATE.

WHEN MOUNTING ON BAUMANN ACTUATORS, INSTALL FEEDBACK PLATE SO LIP IS DOWN. INSTALL FEEDBACK LEVER ARM

ASSEMBLY, PRELOADED, SO PILOT SHAFT IS UNDERNEATH THE FEEDBACK PLATE.

1

2

17B9106-B

17B9105-B

38B0195-B

A4035-2 / IL

DUse bypass valves or completely

shut off the process to isolate the valve

from process pressure. Relieve process

pressure on both sides of the valve.

Drain the process media from both sides

of the valve.

DVent the power actuator loading

pressure and relieve any actuator spring

precompression.

DUse lock-out procedures to be sure

that the above measures stay in effect

while you work on the equipment.

Type 3660 and 3661

5

DFor 3661 positioners in intrinsically

safe areas, current monitoring during

operation must be with an approved

meter for hazardous areas in order to

avoid personal injury or property

damage caused by an explosion or fire.

Positioner Mounting

Mounting on the Type 1250, 1250R, and

3024S Actuators

During the following mounting procedures, refer to

figures 3, 24, and 25 for key number locations. Figure

3 shows keys 61 through 78 and 101 through 104.

Other key numbers are shown in either figure 24 for

the Type 3660 positioner or figure 25 for the Type

3661 positioner. Two mounting methods are available,

center-bolt mounting and clamp mounting.

1. Determine the positioner mounting configuration

from figure 2. The actuator size, actuator travel, and

positioner action must be known. If center-bolt

mounting is desired, be certain the actuator is

equipped with tapped holes in the posts.

2. Thread the hex head screws with washers (keys 69

and 70) several turns into the stem connector. The

feedback plate (key 68) is reversible and must be

positioned so that the pilot shaft (key 19A) will operate

correctly in the slot of the feedback plate. For actuator

travels between 20 and 30 mm (0.787 and 1.18

inches) (for 3024S actuators, travel ranges between

16 and 32 mm), position the feedback plate so the

long portion of its slot, when bolted to the stem

connector, is closest to the positioner as shown in

figure 4. For travels greater than 30 mm (1.18 inches),

reverse the position of the feedback plate as shown in

figure 4.

a. For size 30 and 34 actuators with all travels and

for size 45 actuators with travel greater than 30 mm

(1.18 inches), position the feedback plate (key 68)

between the stem connector and washers and

tighten the hex head screws (key 69).

b. For size 45 actuators with travel between 20 and

30 mm (0.787 and 1.18 inches) (16 and 32 mm for

3024S actuators), attach the feedback adaptor (key

103) to the feedback plate (key 68) using machine

screws, lockwashers, and wedge nuts (keys 102,

101, and 104). The feedback plate and the wedge

nuts must be assembled as shown in the lower

right portion of figure 3. Use the mounting holes in

the feedback adaptor and position it as indicated in

figure 4. Then, position the feedback plate between

the stem connector and washers and tighten the

hex head screws (key 69).

3. Unscrew the two machine screws (key 24), and

remove the positioner cover (key 21).

Center-Bolt Mounting

a. As shown in figure 5, a thin knockout section is

cast across the mounting hole in the housing.

Check to make certain this knockout section has

been removed. If the knockout section has not

been removed, use a punch to knock it out.

b. Attach the positioner to the actuator using a

sealing washer and hex head screw (keys 71 and

72).

c. Install the feedback lever assembly and range

spring.

Clamp Mounting

a. Install a hex nut (key 66) on one end of each of

two studs (key 65). Turn the nuts all the way to the

end of the threads.

b. Thread the end of each stud (key 65), (the end

with hex nut—key 66), into the back of the

positioner housing (key 1) as far as the studs will

go. Tighten both nuts against the housing.

c. Set the actuator at mid-travel using a manual

loading regulator.

d. With the finger end of the bracket (key 64)

toward the positioner pressure connections as

shown in figure 3, place the bracket and washers

(key 67) over the studs (key 65). Thread the hex

nuts (key 66) several turns onto the studs.

Note

Do not install the range spring in the

following step. Feedback lever assembly

(key 19) installation in the next step is

only temporary to permit verifying

alignment.

e. Install the positioner on the actuator by placing

the bracket (key 64) around the appropriate

actuator leg. Visually center the center line of the

slot in the feedback plate (key 68) with the center

line of the hole in the housing. Then, tighten the

nuts (key 66) only tight enough to prevent the

positioner from moving on the actuator leg. Locate

the feedback lever assembly (key 19) so that it may

be temporarily installed into the positioner housing

(key 1) and the feedback plate (key 68) to verify

alignment. Do not install the range spring at this

time. Place the pilot shaft (key 19A) in the slot of

the feedback plate, and, at the same time, insert

Type 3660 and 3661

6

Figure 3. Positioner Mounting on Type 1250, 1250R, and 3024S Actuators

41B3946-F/DOC

NIPPLE MOUNTED

FILTER REGULATOR

CLAMP MOUNT

SECTION

AĆA

CENTER BOLT

MOUNT

SIZE 45 WITH TRAVEL BETWEEN

20 AND 30 mm (0. 8 AND 1.18 INCHES)

AA

WEDGE NUT

(KEY 104) FEEDBACK

PLATE

(KEY 68)

FEEDBACK

ADAPTOR

(KEY 103)

LOCKWASHER

(K3Y 101)

MACHINE SCREW

(KEY 102)

FEEDBACK

LEVER

ASSEMBLY

FILTER

REGULATOR

Type 3660 and 3661

7

Figure 4. Feedback Plate Orientation with Positioner

Mounted on Type 1250, 1250R, and 3024S Actuators

B2260-1 / IL

FOR SIZE 30 AND 34 ACTUATORS WITH TRAVEL

BETWEEN 20 AND 30 mm (0. 8 AND 1.18 INCHES)

FOR SIZE 30,34 AND 45 ACTUATORS WITH

TRAVEL GREATER THAN 30mm (1.18 INCHES)

FOR SIZE 45 ACTUATORS WITH TRAVEL BETWEEN

20 AND 30 mm (0. 8 AND 1.18 INCHES)

POSITIONER

ACTUATOR LEG STEM CONNECTOR

FEEDBACK

PLATE

PILOT SHAFT FEEDBACK LEVER

ASSEMBLY

POSITIONER

ACTUATOR LEG STEM CONNECTOR

FEEDBACK

PLATE

PILOT SHAFT

FEEDBACK LEVER ASSEMBLY

STEM CONNECTOR

FEEDBACK

PLATE

ACTUATOR STEM

FEEDBACK

ADAPTOR

VALVE STEM

USE THESE HOLES

WHEN MOUNTING

THE FEEDBACK

ADAPTOR TO THE

FEEDBACK PLATE

the feedback shaft in the hole of the positioner

housing. Depress the feedback lever assembly

inward until it stops against the housing. Make

certain the slots in both the feedback lever

assembly and the feedback plate are horizontal

with each other and that the feedback lever

assembly and the feedback plate are parallel with

each other. If necessary, correct alignment by

loosening the hex nuts (key 66) and moving the

positioner on the actuator leg as required.

Figure 5. Actuator Center-Bolt Mounting

A4949-1 / IL

THIN SECTION

f. Tighten the two hex nuts (key 66) to secure the

positioner to the actuator leg.

g. Install the feedback lever assembly and range

spring.

Mounting on Baumann Actuators

During the following mounting procedures, refer to

figures 2, 5, 6, 24, and 25. Key numbers are shown in

either figure 24 for the Type 3660 positioner or figure

25 for the Type 3661 positioner.

1. Determine the positioner mounting configuration

from figure 2. The actuator size, actuator travel, and

positioner action must be known.

2. Attach the feedback plate to the actuator stem

connector by locating the feedback plate between the

actuator stem and valve stem nuts (figure 6) as

follows:

DIf after the positioner is mounted the feedback

lever assembly will be on the left side of the positioner,

install the feedback plate so the lip is up.

DIf after the positioner is mounted the feedback

lever assembly will be on the right side of the

positioner, install the feedback plate so the lip is down.

3. Unscrew the two machine screws (key 24), and

remove the positioner cover (key 21).

4. As shown in figure 5, a thin knockout section is cast

across the mounting hole in the housing. Check to

make certain this knockout section has been removed.

If the knockout section has not been removed, use a

punch to knock it out.

5. For air to extend actuators, the feedback lever

assembly must be installed into the positoner and

Type 3660 and 3661

8

Figure 6. Feedback Plate Installation for Baumann Actuators

ACTUATOR

STEM

VALVE

STEM

FEEDBACK LEVER

ARM ASSEMBLY

FEEDBACK

PLATE

PILOT SHAFT

IF AFTER MOUNTING POSITIONER, THE FEEDBACK LEVER ARM AS-

SEMBLY WILL BE ON THE LEFT SIDE OF THE POSITIONER, INSTALL THE FEED-

BACK PLATE SO THE LIP IS UP. INSTALL THE FEEDBACK LEVER ARM AS-

SEMBLY, PRELOADED, SO THE PILOT SHAFT IS ABOVE THE PLATE.

IF AFTER MOUNTING POSITIONER, THE FEEDBACK LEVER ARM ASSEMBLY

WILL BE ON THE RIGHT SIDE OF THE POSITIONER, INSTALL THE FEEDBACK

PLATE SO THE LIP IS DOWN. INSTALL THE FEEDBACK LEVER ARM ASSEMBLY,

PRELOADED, SO THE PILOT SHAFT IS BELOW THE PLATE.

1

1

A7223 / IL

preloaded before attaching the positioner to the

actuator.

6. Attach the positioner to the actuator using a sealing

washer and hex head screw (keys 71 and 72).

7. Install the feedback lever assembly and range

spring.

Mounting on the Type 657 and 667

Actuators

During the following mounting procedures, refer to

figures 7, 24, and 25 for key number locations. Figure

7 shows keys 61 through 63, 69 and 70, 73 through

78, and 82 through 93. Other key numbers are shown

in either figure 24 for the Type 3660 positioner or

figure 25 for the Type 3661 positioner.

1. Determine the positioner mounting configuration

from figure 2. The actuator size, actuator travel, and

positioner action must be known.

Note

The actuator bench set spring load must

be released before removing the stem

connector cap screws. Refer to the

appropriate actuator instruction manual

for this procedure. After installing the

positioner and mounting hardware, reset

the actuator bench set.

2. Attach the connector bracket (key 87) to the

actuator stem connector using washers and cap

screws (keys 70 and 69), but do not tighten the

screws. Refer to figures 7 and 8 for the proper

orientation of the connector bracket with respect to the

actuator stem connector. The face of the stem

connector should be perpendicular to the legs of the

actuator yoke.

3. Refer to figure 8 for the feedback arm (key 88)

location with respect to the connector bracket (key 87).

Position the feedback arm so that the pilot shaft (key

19A) will operate correctly in the slot of the feedback

arm. For actuator travels between 19 and 30 mm (0.75

and 1.18 inches), position the feedback arm so that

the long portion of the feedback arm slot, when

fastened to the connector bracket, is closest to the

positioner (see figure 8). For travels greater than 30

mm (1.18 inches) reverse the feedback arm so the slot

in the feedback arm is opposite the positioner (see

figure 8).

4. Attach the feedback arm (key 88) to the connector

bracket (key 87) using machine screws, washers and

hex nuts (keys 91, 92 and 93), but do not tighten the

hex nuts.

5. Unscrew the two machine screws (key 24), and

remove the positioner cover (key 21).

6. As shown in figure 5, a thin knockout section is cast

across the mounting hole in the housing. Check to

make certain that this knockout section has been

removed. If the knockout section has not been

removed, use a punch to knock it out.

7. Set the actuator at mid-travel using a manual

loading regulator.

8. Install the stud clamp (key 83) in the mounting

bracket (key 82). Place the mounting bracket against

the outside of the actuator leg. Attach the two U-bolts

(key 84) and the mounting bracket to the actuator leg

using washers and hex nuts (key 85 and 86), but do

not tighten the nuts. Depending on the positioner

action, it may be necessary to straddle the travel

indicator scale located on the inside of the actuator

leg.

Note

Do not install the range spring in the

following step. Feedback lever assembly

(key 19) installation in the next step is

only temporary to permit verifying

alignment.

9. Attach the positioner to the stud clamp (key 83)

using the sealing washer and hex nut (keys 89 and

90), but do not tighten the nut. Visually center the

center line of the slot in the feedback arm (key 88) with

the center line of the hole in the housing. Then, tighten

the nuts (keys 90 and 86) only tight enough to prevent

the positioner and mounting bracket from moving on

the actuator leg. Locate the feedback lever assembly

Type 3660 and 3661

9

Figure 7. Positioner Mounting on Type 657 and 667 Actuators

FILTER

REGULATOR

41B6744-D/DOC

SECTION

AĆA

TO POSITIONER

OUTPUT

TYPE 66

NIPPLE MOUNTED

FILTER REGULATOR

AA

APPLY LUB

Type 3660 and 3661

10

Figure 8. Feedback Arm Orientation with Positioner Mounted on

Type 657 and 667 Actuators

B2256-1 / IL

SIZES 30 THROUGH 40 ACTUATORS WITH

TRAVEL UP TO 30 mm (1.18 INHES)

SIZES 45 THROUGH 60 ACTUATORS WITH

TRAVL UP TO 30 mm (1.18 INCHES)

SIZES 30 THROUGH 40 ACTUATORS WITH

TRAVEL GREATER THAN 30 mm (1.18 INCHES)

SIZES 45 THROUGH 60 ACTUATORS WITH

TRAVEL GREATER THAN 30 mm (1.18 INCHES)

(key 19) so it may be temporarily installed into the

positioner housing (key 1) and the feedback arm (key

88) to verify alignment. Do not install the range spring

at this time. Place the pilot shaft (key 19A) in the slot

of the feedback arm, and, at the same time, insert the

feedback shaft in the hole of the positioner housing.

Depress the feedback lever assembly inward until it

stops against the housing. Make certain the slots in

both the feedback lever assembly and feedback arm

are horizontal and that the feedback lever assembly

and the feedback arm are parallel with each other. If

necessary, correct alignment by loosening the hex

nuts (keys 86 and 90) and either moving the stud

clamp in the mounting bracket or moving the mounting

bracket on the actuator leg.

10. Tighten the nuts that were not tightened in the

previous steps.

a. Tighten the hex nut (key 90) to secure the

positioner to the stud clamp (key 83).

b. Tighten the four hex nuts (key 86) to secure the

mounting bracket (key 82) to the actuator leg.

c. Tighten the machine screws and hex nuts (key

91 and 93) to secure the feedback arm (key 88) to

the connector bracket (key 87).

d. Tighten the hex head screws (key 69) to secure

the connector bracket (key 87) to the actuator stem

connector.

11. Install the feedback lever assembly and range

spring.

Feedback Lever Assembly and Range

Spring Installation

Key numbers are shown in either figure 24 for the

Type 3660 positioner or figure 25 for the Type 3661

positioner. Key numbers for the feedback lever

assembly are shown in figure 26.

CAUTION

The range spring (key 30) and feedback

lever assembly (key 19) must be

installed together. Installing the range

spring after the feedback lever assembly

Type 3660 and 3661

11

Figure 9. Installing the Feedback Lever Assembly

(Key19) on the Positioner

RETAINING SCREW

(KEY 19P)

ANTI-ROTATING

SLOT

W7367 / IL

is installed may result in damage to the

lever assembly (key 17) flexures.

1. Refer to figure 9. Loosen the retaining screw

(key 19P) located in the positioner housing until it is

fully retracted into the housing.

2. On the feedback lever assembly (key 19), loosen

the zero adjustment screw (key 19S) until it is fully

retracted into the clinch nut.

3. On the feedback lever assembly, loosen the hex

nut (key 19D) so the pilot shaft (key 19A) moves freely

in the slot.

CAUTION

In the next step, be sure the feedback

spring (key 19N) hooks on the spring pin

(key 19R) opposite the zero adjustment

screw. If the feedback spring does not

hook on the spring pin correctly, the

feedback spring may be damaged during

feedback lever assembly (key 19)

installation.

4. Refer to figure 10. Verify that the feedback spring in

the feedback lever assembly bushing is hooked on the

end of the spring pin opposite the zero adjustment

screw.

Note

When installing the feedback lever

assembly bushing, be sure the

anti-rotating slot aligns with the

retaining screw (key 19P).

Figure 10. Positioning Feedback Spring

ZERO

ADJUSTMENT

COVER

FEEDBACK

SHAFT

SPRING PIN

FEEDBACK SPRING

FEEDBACK SPRING MUST

HOOK AROUND SPRING PIN

END OPPOSITE THE ZERO

ADJUSTMENT SCREW

27B9999-D

A7224 / IL

5. Position the feedback lever assembly (key 19) so

that the pilot shaft (key 19A) will rest on the feedback

plate or slide into the slot of the feedback arm (key 88)

after installation.

6. Be sure the anti-rotating slot aligns with the

retaining screw (key 19P), then install the feedback

lever assembly bushing partially into the positioner.

Slight tension on the feedback spring (key 19N) may

be required to get the anti-rotating slot to align with the

retaining screw.

Note

The reason for partially sliding the

feedback lever assembly (key 19) into

the housing is to permit installing the

range spring (key 30) without damaging

the lever assembly (key 17) flexures.

Installing the range spring after the

feedback lever assembly is completely

installed may damage the lever

assembly flexures.

7. Tighten the retaining screw (key 19P) until the

screw engages the anti-rotating slot so that the

bushing does not rotate, but leave the screw loose

enough so that the bushing can slide freely into the

housing.

8. Refer to figures 11 and 12. Select the appropriate

range spring (key 30) from tables 2 and 3. Place the

range spring in the positioner so that one end of the

spring is fully in the lever assembly slot. Next, rotate

the feedback lever assembly so that:

Dthe other end of the range spring aligns with the

slot in the feedback shaft, and

Type 3660 and 3661

12

Figure 11. Range Spring Installation

LEVER

ASSEMBLY

FEEDBACK

SHAFT

W7366 / IL

Figure 12. Range Spring Alignment

A5211 / IL

Dthe pilot shaft (key 19A) is either above or below

the actuator feedback plate or engages the slot in the

feedback arm (key 88).

Note

The feedback lever assembly bushing

will no longer slide freely in the housing

after it is placed in the normal operating

position due to the side loading of the

retaining screw (key 19P) on the

anti-rotating slot.

9. Center the range spring (key 30) in the lever

assembly (key 17) and feedback shaft slots; then push

the feedback lever assembly bushing into the housing

far enough so that the spring is retained without

holding it.

Figure 13. Pressing the Feedback Lever Assembly Busning

into the Positioner

W7365 / IL

CAUTION

Installation of the feedback lever

assembly (key 19) prior to installation of

the range spring (key 30) may result in

damage to the lever assembly (key 17)

flexures. The range spring must be in

place before pushing the feedback lever

assembly bushing fully into the

positioner housing.

10. Ensure the range spring (key 30) is properly

aligned as shown in figure 12, then, as shown in

figure 13, place hands on both sides of the positioner

and press firmly until the feedback lever assembly

bushing shoulder is against the positioner housing

(figure 14).

11. While holding the feedback lever assembly

bushing securely against the housing, tighten the

retaining screw (key 19P). The feedback lever

assembly bushing should be tight against the

positioner housing as shown in figure 14.

12. Move the pilot shaft (key 19A) to the approximate

span position shown in table 3

Note

To ensure proper positioner

performance, make certain, after

alignment and all tightening is

completed, that there is clearance

between the face of the pilot shaft and

the feedback arm.

13. Install the feedback lever assembly cover

(key 19T) with cover screw (key 19U).

Type 3660 and 3661

13

Figure 14. Feedback Lever Assembly in Operating Position

BUSHING(AGAINST

POSITIONER

HOUSING)

ZERO ADJUST

(SELF-LOCKING)

W7366 / IL

14. Verify the positioner action. Note the letters D and

R on the flapper (key 10). If the letter D is nearest the

adjustment screw (key 18), the positioner is set for

direct action. To change the positioner action, refer to

the Changing Positioner Action procedure in the

“Maintenance”section. If the action is changed,

complete the “Calibration”section before putting the

unit into operation.

15. Install the positioner cover (key 21) and secure

with the two machine screws (key 24). Make certain

the Fisher logo reads correctly and the vent is pointing

downward. Continue with the “Pressure Connections”

section.

Pressure Connections

Installing a Type 3660 or 3661 positioner requires

tubing and pressure fittings. The fittings, tubing, and

mounting parts required depend on the type number

and optional equipment, such as filter/regulator and

bypass valve. See figure 15 for the location of the

positioner pressure connections.

WARNING

The positioner is capable of providing

full supply pressure to connected

equipment. To avoid personal injury and

equipment damage, make sure the

supply pressure never exceeds the

maximum safe working pressure of any

connected equipment.

Supply Connection

WARNING

Personal injury or property damage may

occur from an uncontrolled process if

the supply medium is not clean, dry,

oil-free, or noncorrosive gas. Industry

instrument air quality standards

describe acceptable dirt, oil, and

moisture content. Due to the variability

in nature of the problems these

influences can have on pneumatic

equipment, Fisher Controls has no

technical basis to recommend the level

of filtration equipment required to

prevent performance degradation of

pneumatic equipment. A filter or filter

regulator capable of removing particles

40 microns in diameter should suffice

for most applications. Use of suitable

filtration equipment and the

establishment of a maintenance cycle to

monitor its operation is recommended.

Connect a clean, dry air source to the supply

connection of the positioner. Use 3/8-inch tubing or

1/4-inch pipe for the supply line. A supply air filter or a

filter regulator capable of removing particles 40

microns in diameter is recommended. The supply

pressure should not exceed the following limits:

1. For the positioner, do not exceed the maximum

pressure rating of 6.2 bar (90 psig).

2. For actuator pressure, refer to the appropriate

actuator instruction manual for maximum allowable

pressures.

3. For the valve body assembly, do not exceed the

maximum allowable thrust of the specific valve.

Output Connection

Connect the OUTPUT connection to the actuator

diaphragm casing connection. Use 3/8-inch, 1/4-inch,

or 6 mm tubing, or 1/4-inch pipe between the actuator

and the positioner.

Type 3660 and 3661

14

ACTUATOR CENTERLINE TO POSITIONER

Type

Size

Dim X

Type Size mm Inch

657/667

30

34

40

45/46

50/60

92.2

95.3

104.9

108.0

128.5

3.63

3.75

4.13

4.25

5.06

1250 30

34

45

86.0

86.0

110.0

3.39

3.39

4.33

3024S 1.21

1.31

1.41

83.5

87.5

87.5

3.29

3.44

3.44

Baumann

16in2

32in2

54in2

70in2

53.8

71.4

71.4

71.4

2.12

2.81

2.81

2.81

Figure 15. Typical Mounting Dimensions and Connections

31B3959-C

C0686-3/IL

ACTUATOR POST

CENTERLINE

34.32

(1.35)

49.2

(1.94)

191.2

(7.53)

93

(3.66) 49

(1.93)

34.32

(1.35)

ACTUATOR POST

CENTERLINE

142.2

(5.60)

49.2

(1.94) 93

(3.66)

ACTUATOR

CENTERLINE

ACTUATOR

CENTERLINE

DIM X

122.3

(4.81)

30

(1.18))

30

(1.18)

21.5

(.85))

1/4–INCH NPT

OUTPUT

CONNECTION

1/4–INCH NPT

INSTRUMENT

CONNECTION

1/4–INCH NPT

SUPPLY

CONNECTION

1/4–INCH NPT

SUPPLY

CONNECTION

1/4–INCH NPT

INSTRUMENT

CONNECTION

1/4–INCH NPT

OUTPUT

CONNECTION

122.3

(4.81)

67.5

(2.66) DIM X

30

(1.18))

30

(1.18)

21.5

(.85))

27.5

(1.08)

1/2–INCH NPT

TYPE 3661 I/P

ONLY

mm

(INCH)

67.5

(2.66)

0.5

(.02)

Type 3660 and 3661

15

Figure 16. FlowScannertValve Diagnostic System Connections

12B8052-A

A6084*/IL

Instrument Connection

Connect the control device output to the positioner

INSTRUMENT connection. Use 3/8-inch tubing to

1/4-inch pipe.

The Type 3661 electro-pneumatic positioner requires a

4 to 20 milliampere dc current input signal from the

control device. For connections to the Type 3661, refer

to the “Electrical Connections for Type 3661

Positioners”section.

Diagnostic Connections

To support diagnostic testing of

valve/actuator/positioner packages, special connectors

and hardware are available. Typical connector

installations are shown in figure 16. The hardware

used includes 1/4-inch NPT pipe nipples and pipe tees

with 1/8-inch NPT pipe bushings for the connectors.

The connectors consist of 1/8-inch NPT bodies and

body protectors. If the diagnostic connectors are

ordered for a positioner with gauges, 1/8-inch stems

are also included.

Install the connectors and hardware between the Type

3660 or Type 3661 positioner and the actuator.

1. Before assembling the pipe nipple, pipe tee, pipe

bushings, actuator piping, and connector body, apply

sealant to all threads. Sealant is provided with the

diagnostic connectors and hardware.

2. Turn the pipe tee to position the connector body

and body protector for easy access when doing the

diagnostic testing.

Vent Connection

The Type 3660 and 3661 positioners are equipped

with a 1/4-inch NPT vent connection in the cover.

WARNING

If a flammable, toxic, corrosive, or

reactive gas is to be used as the supply

pressure medium, personal injury or

property damage could result from fire

or explosion of accumulated gas or from

contact with toxic, corrosive, or reactive

gas. The positioner/actuator assembly

does not form a gas-tight seal, and when

the assembly is enclosed, a remote vent

line, adequate ventilation, and necessary

safety measures should be used. A

remote vent pipe alone cannot be relied

upon to remove all hazardous gas. Vent

line piping should comply with local and

regional codes and should be as short

as possible with adequate inside

diameter and few bends to reduce case

pressure buildup.

Electrical Connections for Type 3661

Positioners

Refer to figures 17 and 18 when making electrical

connections. Use the 1/2-inch NPT (or M20 thread)

conduit connection for installation of field wiring. Run

the input wires through the conduit, and connect the

positive wire from the control device to the positioner +

terminal and the negative wire from the control device

Type 3660 and 3661

16

Figure 17. Equivalent Circuit

21B2335-D

A6012/IL

5.6V 5.6V 5.6V 60 Ohms

60 Ohms

4 - 20 mA +

–

+

–

+

––+

1

CONTROL

DEVICE

POSITIONER

HOUSING

TERMINAL

BLOCK

FIELD WIRING

EARTH

GROUND

NOTE:

FOR TROUBLESHOOTING OR MONITORING OPERATION,

AN INDICATING DEVICE CAN BE A VOLTMETER ACROSS

A 250 OHM RESISTOR OR A CURRENT METER.

1

Figure 18. Typical Field-Wiring Diagram

A3875*/IL

to the positioner –terminal. Do not over tighten the

terminal screws. The maximum torque is

0.45 NSm (4 lbfSin.).

Calibration

The following calibration procedures are for the

adjustment of the pneumatic positioner. For the Type

3661 positioner, there are no adjustments within the

converter portion of the positioner. All adjustments are

accomplished within the pneumatic portion of the

positioner.

WARNING

Avoid personal injury or equipment

damage from sudden release of process

fluid. Before calibration:

DIsolate the valve from the process,

and

DRelease process pressure.

Refer to figure 24 (Type 3660) or figure 25 (Type

3661) for key number locations unless otherwise

indicated. Adjustment locations are shown in figure 19.

1. If mounting a new positioner on an actuator or if the

positioner action has not been changed, do not

perform steps 2 through 7.

2. If the positioner action has been changed or if the

positioner has had maintenance performed on it,

complete steps 3 through 17.

3. If the cover (key 21) has not been removed,

unscrew the two machine screws (key 24), and

remove the cover.

4. Release all pressure from the positioner.

Disconnect the positioner output tubing to the actuator.

If the positioner is equipped with an output gauge, plug

the positioner output connection. If the positioner is not

equipped with an output gauge, provide a gauge to

monitor positioner output and connect it to the

positioner output connection.

5. Set the supply pressure to the required setting. Set

the gain(1) (proportional band) adjustment screw at a

nominal value by turning it clockwise until it stops, and

then turning it counterclockwise 1 turn.

Note

To improve holding of the calibration

tool as used in step 6, the actuator may

be used to create the load (manual

pressure) by winding up the positioner

range spring. The direction of windup,

looking at the spring from outside the

housing, must be clockwise. This

windup will create a torsional force over

the input diaphragm through the lever

assembly. The spring is automatically

wound up in two of the

positioner/actuator mounting positions

when the loading pressure is removed.

These are left-hand mounting on a

spring-to-close actuator and right-hand

mounting on a spring-to-open actuator

(refer to figure 2). In the other two

mounting positions, the actuator must

be pressurized to 100 percent input to

create the spring holding force.

1. Adjusting the gain (PB) adjustment changes the nozzle flapper relationship. This

nozzle flapper change affects the actuator/positioner response time.

Type 3660 and 3661

17

Figure 19. Adjustment Locations (Equivalents of Pressures Shown in This Drawing

are:6 bar = 86 psig, 4 bar = 58 psig, and 1.4 bar = 20 psig)

28B0006-B / DOC

INCREASE

TRAVEL

6. Remove the calibration tool (key 6) from the cover.

Place the calibration tool between the lever assembly

(key 17) and the input diaphragm assembly (key 28).

When making the following adjustment, apply manual

pressure to the lever assembly over the input

diaphragm assembly to hold the calibration tool in

place. Loosen the lock nut (key 57), and turn the

adjusting screw (key 18) until the output is 50% ±10%

of supply pressure. For example, if supply pressure is

2.4 bar, set the output to 1.2 bar ±0.24 bar.

7. Lock the adjusting screw (key 18) with the lock nut

(key 57). After the adjustment is complete, remove the

calibration tool and replace it in the positioner cover.

8. Release all pressure from the positioner. Remove

the plug or the gauge that was installed in step 4, and

reconnect the output tubing to the actuator.

9. Turn on supply pressure. Set the input signal to the

minimum value.

10. Remove the cover (key 19T) from the feedback

lever assembly (key 19).

11. Set the travel (span) adjustment to the desired

actuator travel by loosening the hex nut (key 19D) and

sliding the pilot shaft (key 19A) to the desired setting

on the feedback lever assembly (key 19). The travel

settings are marked in millimeters on the feedback

lever assembly.

12. Set the gain (PB) adjustment and/or the output

volume damping adjustment to a setting that provides

the best actuator/positioner response. Observe the

gain dependency on the air supply pressure as shown

in the graph of figure 19. The gain adjustment

restrictor for air delivery should be fully open for large

size actuators and adjusted to a mid-value for smaller

size actuators with 225 cm2(35 square inches) or less

diaphragm area. Start by setting the gain adjustment

at approximately one turn open, and, if the output

volume damping adjustment is used, turn it clockwise

to decrease the air delivery.

13. Adjust the valve stem position by rotating the zero

adjustment screw (key 19S).

14. Set the input signal to the maximum value.

15. Readjust the travel (span) adjustment to achieve

correct actuator travel.

Note

When a travel (span) adjustment is

made, there will be a zero shift.

16. Repeat steps 11 through 15 as necessary to

achieve correct actuator travel.

Type 3660 and 3661

18

Table 2. Range Spring Selection for Fisher Actuators

TYPE 3660 3660 3661

VALVE STEM TRAVEL

Split

0.2 to 1.0 bar

(3 to 15 psig)

Input Signal

0.4 to 2.0 bar

(6 to 30 psig)

Input Signal 4 to 30 mAdc

Input Signal

VALVE STEM TRAVEL

WHEN USING

TYPES 3660 AND 3661

RANGE SPRING

PART NUMBER

(KEY 30)

Bar Psig Bar Psig

Inp

u

t

Signal

mm Inches

(KEY

30)

One Way 1:1 0.2 to 1.0 3 to 15 0.4 to 2.0 6 to 30 4 to 20 20 to 50 0.787 to 1.969 11B3880 X012

Two Way 2:1 0.2 to 0.6

0.6 to 1.0 3 t0 9

9 to 15 0.4 to 1.2

1.2 to 2.0 6 to 18

18 to 30 4 to 12

12 to 20 20 to 50 0.787 to 1.969 11B3881 X012

Three Way

3:1

0.2 to 0.5

0.5 to 0.8

0.8 to 1.0

3 to 7

7 to 11

11 to 15

0.4 to 1.0

1.0 to 1.5

1.5 to 2.0

6 to 14

14 to 22

22 to 30

4 to 9.33

9.33 to 14.66

14.66 to 20 15 to 33.3 0.591 to 1.311 11B3881 X012

Table 3. Range Spring Selection for Baumann Actuators

TYPE 3660 3661 VALVE STEM TRAVEL

0.2 to 1.0 bar

(3 to 15 Psig)

Input Signal

0.4 to 2.0 bar

(6 to 30 Psig)

Input Signal

4 to 20 mA dc

Input Signal 12.7 to 19.1 mm

(1/2 to 3/4 inch) 19.1 to 50 mm

(3/4 to 2 inch)

Split Range

Bar

(Psig)

Span

Bar

(Psi)

Range

Bar

(Psig)

Span

Bar

(Psi)

Range

mA Span

mA

Range Spring

Part Number

(key 30)

Approximate

Pilot Shaft

Setting(1)

mm (Inch)

Range Spring

Part Number

(key 30)

Approximate

Pilot Shaft

Setting(1)

mm (Inch)

One Way

1:1 0.2 to 1.0

(3 to 15) 0.8

(12) 0.4 to 2.0

(6 to 30) 1.6

(24) 4 to 20 16 17B0662X012 89 (3.50) 17B0662X012 129 (5.09)

Two Way

2:1

0.2 to 0.6

(3 to 9)

0.6 to 1.0

(9 to 15)

0.4

(6)

0.5 to 1.2

(6 to 18)

1.2 to 2.0

(18 to 30)

0.8

(12) 4 to 12

12 to 20 8 11B3880X012 92 (3.63) 11B3881X012 92 (3.63)

Three Way

3:1

0.2 to 0.5

(3 to 7)

0.5 to 0.8

(7 to 11)

0.8 to 1.0

(11 to 15)

0.3

(4)

0.5 to 1.0

(6 to 14)

1.0 to 1.5

(14 to 22)

1.5 to 2.0

(22 to 30)

0.6

(8)

4 to 9.33

9.33 to 14.66

14.66 to 20 5.33 11B3881X012 70 (2.75) 11B3881X012 137 (5.38)

Four Way

4:1

0.2 to 0.4

(3 to 6)

0.4 to 0.5

(6 to 9)

0.5 to 0.8

(9 to 12)

0.8 to 1.0

(12 to 15)

0.2

(3)

0.5 to 0.8

(6 to 12)

0.8 to 1.2

(12 to 18)

1.2 to 1.6

(18 to 24)

1.6 to 2.0

(24 to 30)

0.4

(6)

4 to 8

8 to 12

12 to 16

16 to 20

4 11B3881X012 95 (3.75) ––– – ––

1. Pilot shaft setting is the A dimension in figure 20.

17. Install the cover (key 19T) on the feedback lever

assembly (key 19) with cover screw (key 19U).

18. Install the positioner cover (key 21) and secure

with the machine screws (key 24). Make sure the

Fisher logo reads correctly and the vent is pointing

downward.

Split-Range Operation

Type 3660 and 3661 positioners can be used for

split-range operation with the instrument input signal

from a single controller or another instrument split

between two or three control valves. Tables 2 and 3

show some typical split ranges for the positioners. To

change from a full range to a split range, change the

range spring (key 30, figure 24 or 25) to the

appropriate spring shown in the tables. Complete the

Changing Range Spring portion of the Maintenance

section. Refer to tables 2 and 3 for valve stem travel

available with split range operation.

Type 3660 Bypass Operation

Type 3660 positioners may be supplied with a bypass

assembly.

CAUTION

Do not use bypass operation when the

positioner is reverse acting or is in

split-range operation. In these cases,

bypassing the positioner, sends the

input signal directly to the actuator.

Such a change will affect the desired

operation and possibly upset the

Type 3660 and 3661

19

Figure 20. Pilot Shaft Setting

A

PILOT

SHAFT

(KEY 19A) FEEDBACK LEVER

ASSEMBLY (KEY 19)

FEEDBACK SHAFT

LOCATION

38B0195-B / DOC

system. Use bypass operation only

when the instrument signal range is the

same as the positioner output range

required for normal actuator operation.

Labels on the bypass body assembly (key 41, figure

23), and a pointer on the bypass lever (key 42 in figure

23) indicate if the input signal from the instrument goes

to the positioner or directly to the control valve

actuator.

With the pointer of the bypass lever over the word

POSITIONER, the instrument pressure goes to the

positioner and the output pressure of the positioner

goes to the actuator.

With the pointer of the bypass lever over the word

BYPASS, the instrument pressure goes directly to the

actuator.

Note

A difference between the input signal

pressure and the positioner output

pressure could cause a transient bump

in the controlled system when the

bypass lever is moved to BYPASS.

With a reverse-acting or split-range positioner, the

bypass lever may be secured in the POSITIONER

position so that bypass cannot be used. To lock the

bypass lever in the POSITIONER position, shut off the

instrument and supply pressure to the positioner.

Then, move the bypass lever (key 42 in figure 23) so

the pointer is over the word POSITIONER. Align the

hole in the pointer with the hole in the body assembly

and thread the plastic wire tie (key 79 in figure 23)

through both holes to secure the bypass lever.

Principle of Operation

Refer to figure 21 for the operational schematic.

The instrument pressure acts on the input module,

which controls the flapper-nozzle system of the relay.

Supply pressure is applied to the relay, and the output

pressure of the relay is supplied to the control valve

actuator.

For a direct-acting positioner, increases in instrument

pressure cause the input module to pivot the beam.

The beam pivots the flapper and restricts the nozzle.

The nozzle pressure increases and causes the relay

assembly to increase output pressure to the actuator.

With a direct-acting actuator, this increased pressure

moves the actuator stem downward. Stem movement

is fed back to the beam by means of a feedback lever

and range spring, which causes the flapper to pivot

slightly away from the nozzle to prevent any further

increases in relay output pressure. The positioner is

once again in equilibrium but at a higher instrument

pressure, a slightly different flapper position, and a

new actuator stem position.

A decrease in instrument pressure decreases nozzle

pressure, which allows the relay to bleed off actuator

loading pressure.

Operation of a reverse-acting positioner is similar

except that the position of the flapper is reversed from

that shown in figure 21. The reversed position uses the

alternate flapper pivot point so that increases in

instrument pressure rotate the flapper away from the

nozzle to reduce nozzle pressure.

With a Type 3661 electro-pneumatic positioner, the

electro-pneumatic (I/P) converter provides a 0.2 to 1.0

bar (3 to 15 psig) output pressure proportional to the 4

to 20 milliampere input signal. The 0.2 to 1.0 bar (3 to

15 psig) output pressure becomes the input signal

pressure to the input module.

Maintenance

Positioner parts are subject to normal wear and must

be inspected and replaced as necessary. The

frequency of inspection and replacement depends

upon the severity of service conditions. The following

procedure describes disassembly and reassembly of

the positioner. When inspection or repairs are

required, disassemble only those parts necessary to

accomplish the job. When reassembly is complete,

make adjustments as described in the Calibration

section.

Due to the care Fisher Controls takes in meeting all

manufacturing requirements (heat treating,

dimensional tolerances, etc.), use only replacement

parts manufactured by Fisher.

Type 3660 and 3661

20

Figure 21. Operational Schematic

FLAPPER

DIRECT

ACTING

PIVOT REVERSE

ACTING

PIVOT

NOZZLE

OUTPUT

RANGE

SPRING RELAY

GAIN ADJA

A

FEEDBACK

PLATE

FEEDBACK

LEVER

PILOT

SHAFT

INPUT

MODULE

BEAM

PIVOT

SUPPLY RANGE

SPRING RELAY

GAIN ADJ

SUPPLY

A

A

INPUT SIGNAL

I/P CONVERTER

INPUT

MODULE

BEAM

PIVOT

SECTION AĆA

TYPE 3660

TYPE 3661

31B3960-C

B2152-4 / IL

WARNING

Avoid personal injury or equipment

damage from sudden release of process

fluid. Before disassembly:

DIsolate the valve from the process,

DRelease process pressure, and

DVent the actuator loading pressure.

For intrinsically safe areas, current

monitoring during operation must be

with an approved meter for hazardous

areas in order to avoid personal injury or

property damage caused by an

explosion or fire.

Changing the Positioner Action

This section explains changing the positioner action

from direct to reverse or reverse to direct. With direct

action, the positioner output pressure increases as the

instrument input signal to the positioner increases.

With reverse action, the positioner output pressure

decreases as the input signal to the positioner

increases. To change the action of a positioner that is

already mounted on an actuator, remove the positioner

from the actuator. Refer to the Removing the

Positioner from Actuator section. Refer to figure 24 or

25 for key number locations.

1. Unscrew the two captive cover screws and remove

the cover (key 21). Carefully lift the flapper spring at

the location shown by key 10.

2. Slide out the flapper (key 9) and rotate it so that the

desired letter (D or R for direct and reverse) is nearest

the adjusting screw (key 18). When inserting the

flapper, be sure the end of the flapper engages the

groove in the end of the screw and that the flapper

spring (key 10) sets into the V-notches of the flapper.

3. Mount the positioner to the opposite actuator leg as

explained in the Positioner Mounting section and

shown in figure 2.

4. Refer to the “Calibration”section for the calibration

procedure.

Changing the Range Spring

Refer to figure 24 or 25 for key number locations.

1. Unscrew the two captive cover screws and remove

the cover (key 21). Loosen the retaining screw

This manual suits for next models

1

Table of contents

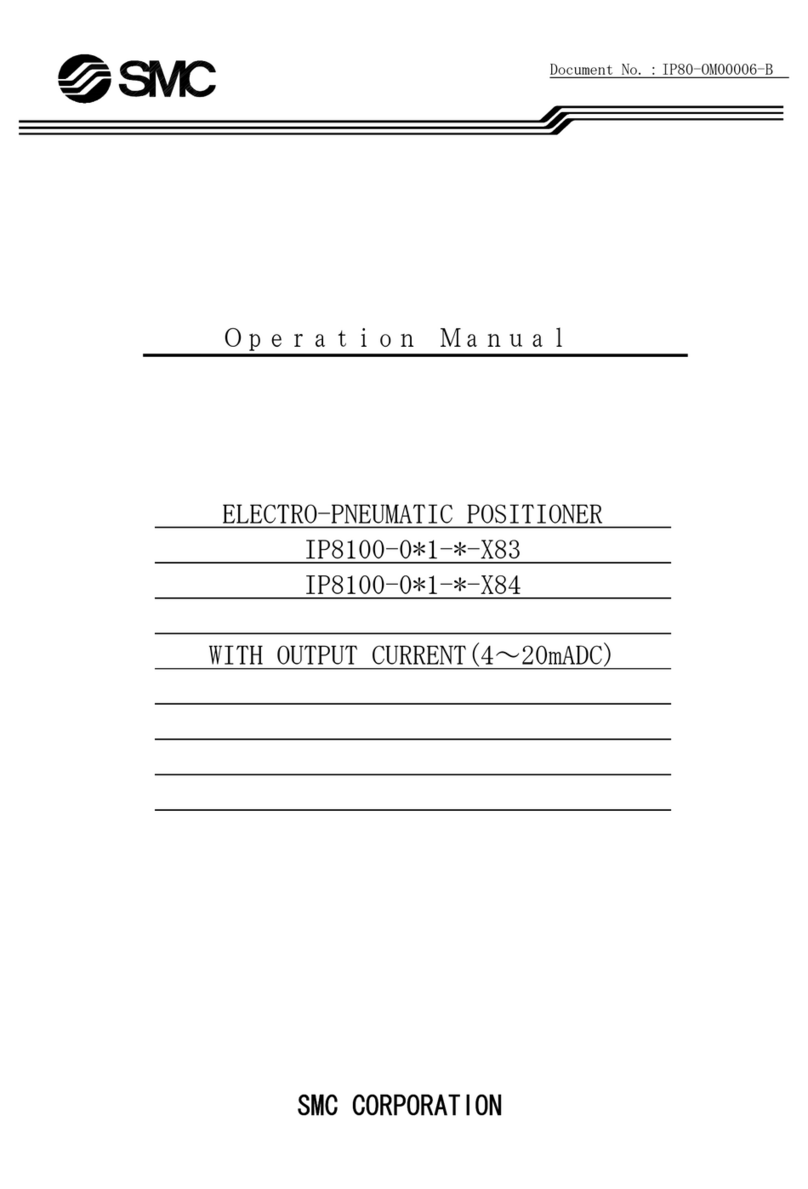

Popular Valve Positioner manuals by other brands

SMC Networks

SMC Networks IP8100-0 1 X83 Series Operation manual

Dresser

Dresser Universal RAI Installation operation & maintenance

Vahle

Vahle APOS installation manual

Spirax Sarco

Spirax Sarco SP7-10 Installation and maintenance instructions

RTK

RTK DAC RE 3581 Series Installation and operating instructions

ESCO Technologies

ESCO Technologies ETS-LINDGREN 2301 user manual

Samson

Samson 3785 series Mounting and operating instructions

Samson

Samson 3730-0 Mounting and operating instructions

SMC Networks

SMC Networks IP8000 manual

Will Burt

Will Burt PositionIt PI-35 Operator's manual

Flowserve

Flowserve Logix 3000MD Series Technical bulletin

M2 Antenna Systems

M2 Antenna Systems FGAE1000-D1-W-COS-A-H manual