1 Design and principle of opera-

tion

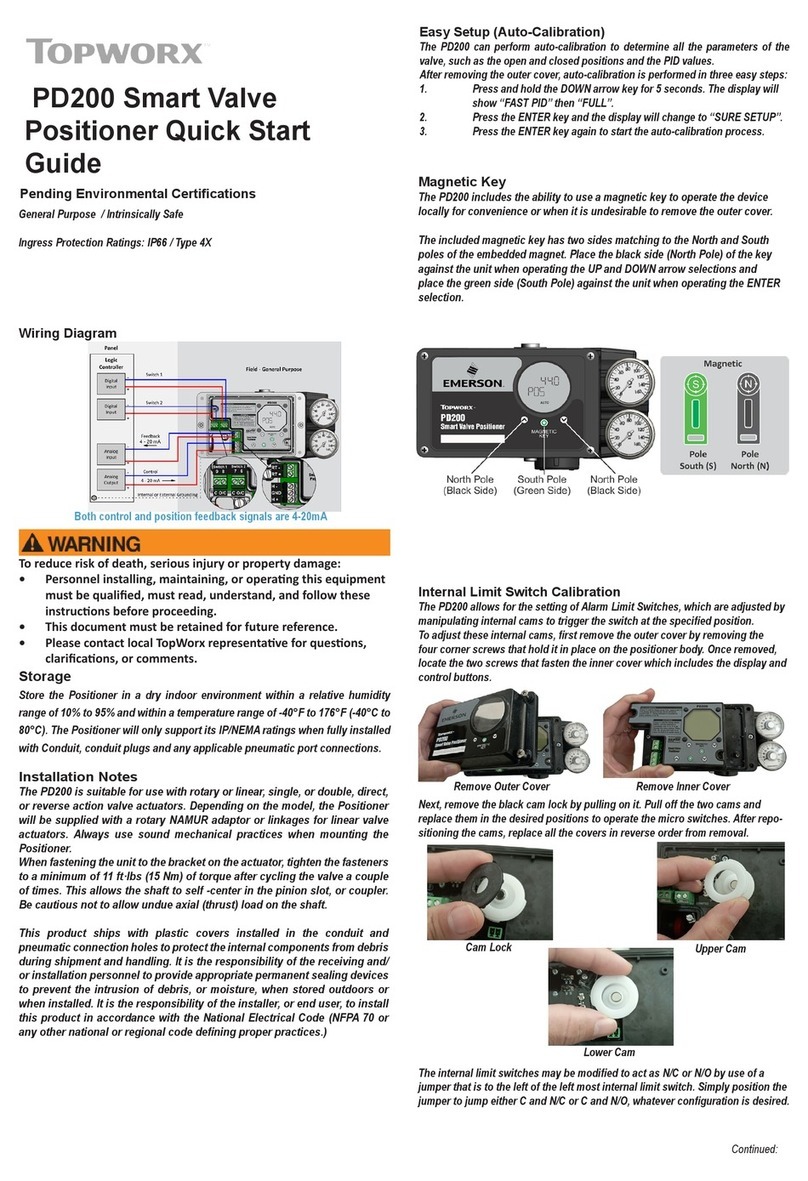

The digital PROFIBUS-PA positioner is de-

signed for attachment to pneumatic control

valves. It is used to assign the valve stem po-

sition (controlled variable) to the control sig-

nal (reference variable). It compares the digi-

tal output signal to the travel of the control

valve and generates a corresponding pres-

sure signal as the output variable. As a re-

sult, the positioner requires auxiliary supply

air with a pressure of 1.4 to 6 bar. The nec-

essary electrical power is supplied by the bus

of the PROFIBUS-PA segment based on

IEC 61158-2 standard transmission technol-

ogy.

The positioner consists of an inductive,

contactless travel pick-off system and an

electrically controlled valve block comprising

two on/off valves and an electronic unit. This

unit contains two microcontrollers for pro-

cessing the control algorithm and managing

PROFIBUS communication.

If a deviation between the actual valve travel

(actual value) and the reference variable (set

point) occurs, the microcontroller produces

binary pulse-pause modulated signals to

control the two on/off valves, each of which

is assigned a downstream amplifier. One of

these valves controls the exhaust air, the

other the supply air.

The supply air valve (3) controls the connec-

tion between the supply air (7, supply air

pressure 1.4 to 6 bar) and the actuator

(pressurizing). The exhaust air valve (4) con-

trols the air exhausted from the actuator to

the atmosphere (venting). The on/off valves

can either have the switching states ("perma-

nently open", "permanently closed" or gen-

erate single pulses of changing widths). The

two valves cause the plug stem to move to a

position corresponding to the reference vari-

able. If there is no system deviation, both the

supply air valve and the exhaust air valve

are closed.

By default, the positioner is equipped with a

binary input for floating contacts, which ad-

ditionally signals the switching state of a

further field device via PROFIBUS.

Activating the write protection switch, which

is located next to the bus address in the

hinged lid, prevents the positioner settings

from being overwritten by PROFIBUS com-

munication.

Positioner with forced venting function:

The positioner is controlled by a 6 to 24 V

signal, causing the signal pressure to be ap-

plied to the actuator. If this voltage signal de-

creases, the signal pressure is shut off and

the actuator is vented. The springs in the ac-

tuator move the valve to its fail-safe position.

The forced venting function is included in all

positioners and can be activated/deactivated

as required over a switch. Refer to sec-

tion 4.3 for details.

1.1 Optional accessories

As a supplement to the standard positioner

version, the positioner can be equipped with

limit switches. Two proximity switches can be

used to indicate the valve's end positions in

safety-related circuits.

1.2 Communication

The positioner is completely controlled by

digital signal transmission according to the

PROFIBUS-PA Profile Class B based on

8EB 8382-1 EN

Design and principle of operation