Instruction Manual

D100324X012

1061 F & G Actuator

June 2017

2

Table 1. Specifications

Available Configuration

Double‐acting pneumatic piston rotary actuator for

J throttling service when used with positioner, or

J on‐off service when used with switching devices

Actuator Sizes

J 30, J 40, J 60, J 68, J 80, J 100, J

and J 130,

Cylinder Operating Pressure

Minimum Recommended:

J 1.4 bar (20 psig) without positioner or

J 0.3 bar (5 psig) above actuator requirement with

positioner

Maximum Allowable(1):

Size 30 and 60: 6.9 bar (100 psig)

Size 40: 10.3 bar (150 psig)

Size 68: 5.9 bar (85 psig)

Size 80: 10.3 bar (150 psig)

Size 100: 10.3 bar (150 psig)

Size 130: 10.3 bar (150 psig)

Valve Shaft Diameters, mm (Inches)

Size 30: J 12.7 (1/2), J 15.9 (5/8), J 19.1 (3/4),

J 22.2 (7/8), J 25.4 (1), and J 31.8 (1‐1/4)

Size 40, 60, and 68: J 19.1 (3/4), J 22.2 (7/8),

J 25.4 (1), J 31.8 (1‐1/4), J 38.1 (1/2), J 44.5

(1‐3/4), and J 50.8 (2)

Size 80 and 100: J 44.5 (1‐3/4), J 50.8 (2), and

J 63.5 (2‐1/2)

Size 130: J 76.2 (3), J 88.9 (3‐1/2)

Maximum Valve Shaft Rotation

J 90 degrees or J 60 degrees (travel stop required

for 60 degree rotation limit)

Material Temperature Capabilities with Standard

Elastomers(1)

-34 to 82_C (-30 to 180_F)

Pressure Connections

J1/4 NPT internal (standard)

J1/2 and 3/4 NPT internal (optional on sizes 68, 80,

and 100)

J3/4 NPT internal for Pipe-Away Vent option

J1 NPT internal for size 130

Travel Indication

Graduated scale and pointer located on actuator

cover at actuator end of valve shaft

Mounting Positions

See figure 2

Approximate Weights

Size 30: 22 kg (49 lb)

Size 40: 29 kg (63 lb)

Size 60: 39 kg (86 lb)

Size 68: 56 kg (123 lb)

Size 80: 122 kg (246 lb)

Size 100: 135 kg (298 lb)

Size 130: 299 kg (660 lb)

1. The pressure/temperature limits in this manual and any applicable standard or code limitation for valves should not be exceeded.

Description

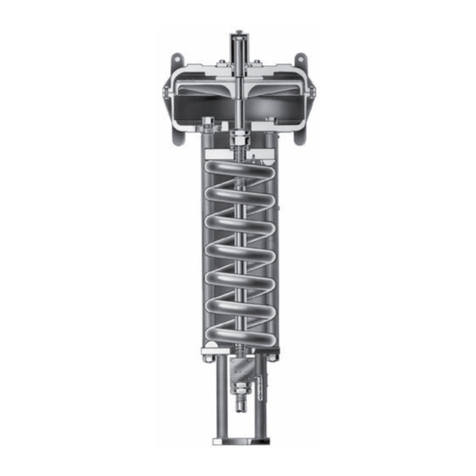

The 1061 actuator is a double‐acting pneumatic piston rotary actuator for use with rotary‐shaft valves having splined

valve shafts. The 1061 actuator can be used for either throttling or on‐off applications.

The style G mounting bracket is for Fisher 9500 valves only. The style F mounting bracket is for all other rotary valves.

Specifications

Specifications are shown in table 1 for 1061 actuators. Specifications are stamped on the nameplate. Refer to the

actuator nameplate for the construction setting and serial number for the actuator when it originally came from the

factory.