2502 Series

10

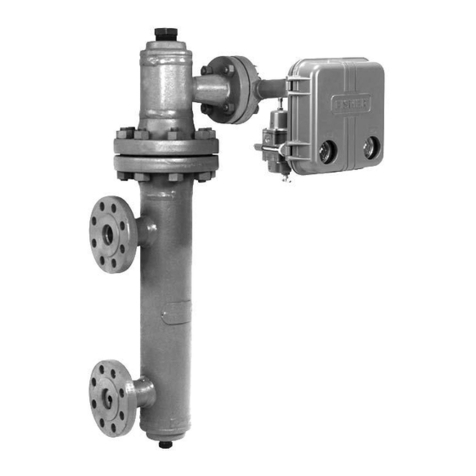

structions in the Calibration section to simulate the

process variable changes required for these checks.

Make sure that the raise level dial on the controller is

mounted with the correct side facing out. The dial is

printed on both sides with the arrow on one side point-

ing to the left and the arrow on the other side pointing

to the right. Figure 11 shows the dial arrow positioned

for a sensor that is mounted to the left of the control-

ler; the arrow points to the left. If the sensor is to the

right of the controller, remove the two mounting

screws, turn the dial over so the arrow points to the

right, then reinstall the mounting screws.

On a controller with optical mechanical indicator as-

sembly, the travel indicator plate is printed on both

sides. If the sensor is to the left of the controller (right-

hand mounting), use the side of the plate that has the

arrow pointing to the left. If displacer is to right of con-

troller (left-hand mounting), use the side of the plate

that has the arrow pointing to the right.

1. Turn on the supply pressure and check that the

controller supply gauge reads 20 psig (1.4 bar) for a 3

to 15 psig (0.2 to 1.0 bar) output pressure range or 35

psig (2.4 bar) for a 6 to 30 psig (0.4 to 2.0 bar) output

pressure range. If the pressure is incorrect, loosen the

locknut of the filter/regulator (figure 3); turn the adjust-

ing screw clockwise to increase or counterclockwise to

decrease pressure. Tighten the locknut after setting

the pressure.

2. Turn the reset control to .05 minutes per repeat.

3. Locate the process variable at its minimum value

(on level applications, for instance, lower the liquid

below the displacer). Zero the proportional band and

raise level controls. Output pressure on direct-acting

controllers should be greater than zero but less than 3

psig (0.2 bar) for the 3 to 15 psig (0.2 to 1.0 bar) range

or 6 psig (0.4 bar) for the 6 to 30 psig (0.4 to 2.0 bar)

range. For reverse-acting controllers, the output pres-

sure should be greater than 15 psig (1.0 bar) and less

than 20 psig (1.4 bar) for the 3 to 15 psig (0.2 to 1.0

bar) range or greater than 30 psig (2.0 bar) and less

than 35 psig (3.4 bar) for the 6 to 30 psig (0.4 to 2.0

bar) range. On a controller with indicator assembly,

the pointer should be over the low point on the indica-

tor plate; slight adjustment might be necessary by

loosening the bottom shaft nut (key 40, figure 16),

shifting the pointer, and retightening the nut.

4. Set the raise level control as desired. Determine

the dial setting by moving the nameplate slide until the

specific gravity on scale B is opposite the displacer

volume on scale A. Choose the percentage of displac-

er length, as measured from the displacer bottom, that

you desire the liquid or interface level to cover. Locate

this percentage on scale D, and read up from this per-

centage to find the raise level dial setting on scale C.

For example, with a liquid level application, a specific

gravity of one (water service), and a 90-cubic-inch (1.5

L) displacer, move the slide so that 1.0 on scale B is

over 90 on scale A. If it is desired to have water level

cover 50 per cent of the displacer length at the control

point, read up from 50 on scale D to find a 4.5 dial set-

ting on scale C.

5. Relocate the process variable to the control point

determined in step 4. If not, see if another setting on

the raise level dial brings the output pressure into

agreement with the process. For example, with water

level at 50 percent of the height of the displacer, the

output of a 3-15 psig (0.2 to 1.0 bar) unit should be

aproximately 50 percent of the way between 3 and 15

psig (0.2 and 1.0 bar) or 9 psig (0.6 bar). If the new

setting is more than one graduation away from the

setting determined in step 4, the unit would appear to

be out of calibration and recalibration may be desir-

able. See Calibribration Procedure on page 12 steps 1

thru 10.

On a controller with level indicator, the pointer should

reflect the magnitude of the process variable; for

instance, with liquid or interface level covering 50 per-

cent of the displacer, the pointer should be in the

middle of the high-low scale. Slight plate adjustment

might be necessary as described at the end of step 3.

6. If all prestartup checks are satisfactory proceed to

the Startup section.

Adjustments

Controller adjustments are provided in this section.

Refer to figure 11 for adjustment locations.

Level Set Adjustment

To perform the level adjustment, open the controller

cover, loosen the knurled adjustment screw (see figure

11), and rotate the adjustment lever around the RAISE

LEVEL dial. To raise the fluid or interface level, or in-

crease density, rotate this knob in the direction of the

arrows. To lower the level or decrease density, rotate

the knob in the opposite direction. This procedure is

the same for both direct and reverse action controllers.

Tighten the knurled screw.

Note

The raise level dial does not reflect actu-

al fluid level in the tank or fluid level

position on the displacer.

Proportional Band Adjustment

Proportional band adjustment is made to change the

amount of displacement force change required to ob-

tain full output pressure change, by determining the