480-12, -15, & -16 Series

Type 481 Combinations

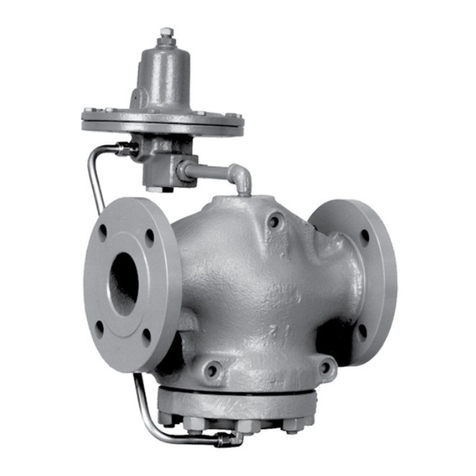

Fisher Type 481 actuator combinations are the basic piston

actuators without integral cylinder loading devices. A

suitable switching device (supplied by the customer)

provides for loading the top or bottom of the cylinder.

Type 489 Combinations

The Type 3579 solenoid manifold acts to alternately load

and exhaust opposite sides of the piston in response to

electrical signals from an outside power source. Since the

solenoid valves are the normally closed type. they lock the

hydraulic fluid in the piston actuator when the circuit is

opened. Thus the actuator can be positioned at any point in

the stroke by opening an external switch at the appropriate

time.

When an external switch is moved to the “DOWN”

position. solenoid valves #I and #4 open as shown in the

figure 3 schematic. Hydraulic fluid flows through solenoid

#4 to load the top of the cylinder while fluid below the

piston flows back to the oil sump through solenoid #I.

Operation continues in this manner until the circuit is

broken. When switched to the “UP” position. solenoid

valve #5 opens to load the bottom of the cylinder and

solenoid valve #2 opens to exhaust the top of the cylinder.

Bypass Piping

If the valve or louver operated by the piston actuator can

also be operated manually, the optional bypass assembly

(figure 7) may be required. Opening the hand valve (key

121, figure 7) allows the operating fluid to flow freely

between the top and bottom of the cylinder. Closing the

hand valve will allow pneumatic or hydraulic operation to

continue.

Adjustments

All adjustments on the Type 480 actuator combinations are

on the Type 3570 or 3570C positioner. For further

information on the positioner, such as Adjustment,

Maintenance. Reversing, and Relay Operation, refer to the

Type 3570 Instruction Manual.

The Type 481 and 489 combinations require no

adjustments. If direct current operation is desired, consult

the Fisher representative in your area.

Actuator Maintenance

It is necessary for efficient and proper operation of the

actuator that all parts be free from dirt, abrasives, and

foreign materials. Upon assembly at the factory, all

synthetic rubber O-rings have been coated with Lubriplate

130.AA, a special lubricant manufactured and distributed

by Fiske Brothers Refining Company of Newark, New

Jersey and Toledo, Ohio. It is recommended that this

lubricant or an equivalent be used on all O-rings, especially

those on moving parts or in contact with moving parts,

whenever the actuator is dismantled. Also apply Pipe Lead

Seal No. 2* or equivalent to the top of the piston rod

where it is tapered and seals with the piston.

To disassemble a Fisher piston actuator, proceed as follows:

(References to “positioner” can be ignored on types not

utilizing positioners.) Key numbers noted refer to figures 5

and 6 unless specifically identified.

I. Bypass the valve body or shut off the pressure in the

pipeline.

The adjustable linkage between the actuator

and the main valve should not be disconnected

when the valve is open with fluid flowing or

under pressure. (Dampers or louvers should be

in safe, stable positions prior to disconnection.)

2. Shut off all pressure lines to the positioner or solenoid

manifold, and lock out the electrical power to the hydraulic

pump and solenoid manifold if appropriate.

3. Remove all tubing lines [cylinder (key 15). instrument,

supply and exhaurtlfrom the actuator.

4. Remove positioner cover after loosening the four cover

screws on the underside of the positioner base.

5. Disengage range spring by unscrewing the spring

retainer from the piston rod extension (key 51.

6. Remove the cap screws (shown in figure 6 as key 79 on

Type 481 combinations) that hold the positioner base.

solenoid manifold, or cylinder cover (key 31, figure 61 to

the cylinder or positioner extension. Do not lose the small

O-ring (shown in figure 6 as key 78 on Type 481

combinations) used to seal the supply air passage at the top

of the cylinder.

7. Next remove the clevis bolt (key 32. figure 5 if -12

construction) from the adjustable linkage. Remove the

bottom snap ring (key 26, figure 5 if -15 construction) and

unscrew the clevis and boot locknut (key 181 from the

actuator piston rod (key 4).

8. Remove cap screw that hold cylinder flange (key 1) to

mounting bracket and lift off actuator assembly.

vvfa”“fact”red b” John Crane co.

4