Instruction Manual

D100325X012

1061 H & J Actuator

January 2016

5

Align the appropriate keyway with the keyway in the operated equipment shaft. If using a Fisher butterfly valve,

align the appropriate keyway on the coupling with the valve shaft keyway indicated in table 5. Then, install the

woodruff key (key 98) in the shaft keyseat, and slide the coupling onto the shaft. It is helpful to apply a light coat of

grease to the inside of the coupling before sliding it onto the shaft.

4. For an actuator with a J mounting adaptation, secure the mounting yoke (key 23) to the valve with the cap screws

(key 87, not shown). For 31.8 and 38.1 mm (1‐1/4 and 1‐1/2 inch) valve shafts, place two spacers (key 99, not

shown) between the mounting yoke and valve or other equipment during this step.

5. For an actuator with an H mounting adaptation and a 22.2 through 38.1 mm (7/8 through 1‐1/2 inch) output shaft,

slide the actuator (with the user‐provided mounting bracket attached) into the user‐provided coupling on the

operated shaft. Then, secure the actuator to the operated equipment in the desired mounting position with

appropriate fasteners, such as mounting cap screws. See figure 2 for output shaft dimensions.

6. For an actuator with an H mounting adaptation and a 50.8 mm (2‐inch) output shaft (key 94, figure 7), note that

the valve shaft coupling (key 97, figure 7) is furnished with two keyways lettered A and B as shown in figure 5

(letters C and D on the coupling are not used and can be disregarded). Align the appropriate keyway with the

keyway in the operated equipment shaft. Then, install the woodruff key (key 98, not shown in figure 7) in the shaft

keyseat, and slide the coupling onto the shaft using the appropriate coupling keyway (see table 5 and figure 5). It is

helpful to apply a light coat of grease to the inside of the coupling before sliding it onto the shaft. Secure the

actuator (user‐provided mounting bracket) to the operated equipment in the desired mounting position with

appropriate fasteners, such as mounting cap screws.

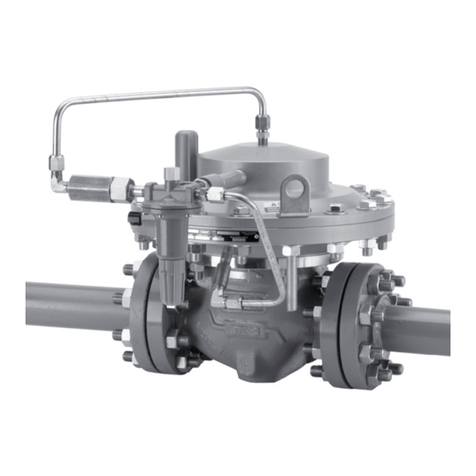

7. If the 1061 actuator is equipped with an auxiliary handwheel actuator, make certain that a cylinder bypass valve

(key 68, figure 8) is used to equalize cylinder pressure during handwheel operation. Operating the handwheel

actuator by itself against the force of differential cylinder pressures is difficult or even impossible. An installation of

a bypass valve is shown in figure 8.

CAUTION

Attempting to pneumatically operate the 1061 actuator while an auxiliary manual actuator is engaged could damage the

actuator shaft. Be certain the manual actuator is disengaged before pneumatically operating the 1061 actuator.

8. Follow the instructions given in the Adjustment section before proceeding to the loading connection portion of this

section.

Table 5. Keyway Alignment Information(1)

DESIRED

ACTUATOR

ACTION

DESIRED

SHAFT

ROTATION,

DEGREES

ACTUATOR

MOUNTING

POSITION

COUPLING

KEYWAY

TO USE(3)

VALVE SHAFT KEYWAY TO USE FOR FISHTAIL™ DISK VALVES(2) (SEE FIGURE 6)

Clockwise to Close Valve Action(4) Counterclockwise to Close Valve Action(4)

Flow Left to Right(4) Flow Right to Left(4) Flow Left to Right(4) Flow Right to Left(4)

Push Down

to Open

(PDTO)

60 or 90

1 B Nose Tail Tail Nose

2 A Tail Nose Nose Tail

3 B Tail Nose Nose Tail

4 A Nose Tail Tail Nose

Push Down

to Close

(PDTC)

60(5) or 90

1 A Tail Nose Tail Nose

2 B Tail Nose Tail Nose

3 A Nose Tail Nose Tail

4 B Nose Tail Nose Tail

1. For actuators with H mounting and 50.8 mm (2‐inch) output shafts, and for actuators with J mounting.

2. For conventional disk valves, use either valve shaft keyway.

3. See figure 6 for reference coupling orientation to use with this table.

4. When viewed from actuator side of valve.

5. For 60‐degree rotation with PDTC action, the coupling and actuator output shaft assembly will be offset 30 degrees clockwise (for actuator housing construction style B) or counterclockwise

(for actuator housing construction Style A) in the lever when viewed from the splined end of the actuator shaft. 30 degrees is one spline tooth for 19.1 through 38.1 mm (3/8 through 1‐1/2

inch) valve shafts.