Automatic Drain Conversion Kits (continued)

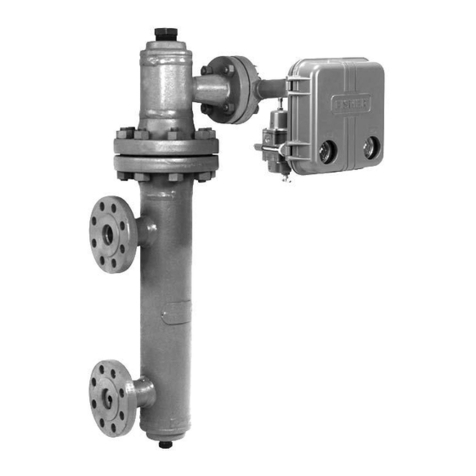

Types 67DF, 67DFR, 67DFS and 67DFSR (continued)

Types 67DFS and 67DFSR

Nitrile (NBR) R67ADNX0022

Fluorocarbon (FKM) R67ADFX0022

1 Body

Type 67D or 67DR, Aluminum GE31800TGY2

Type 67DS or 67DSR, CF8M Stainless steel GE31802TGY2

Type 67DF or 67DFR, Aluminum GE31786TGY2

Type 67DFS or 67DFSR, CF8M Stainless steel GE31788X012

Type 67DFR with Smart Bleed™, Aluminum GE33158X012

Type 67DFSR with Smart Bleed,

Stainless steel GE33159X012

2 Drain Valve

Type 67DF or 67DFR

Brass 1K418918992

316 Stainless Steel AH3946X0052

Type 67DFS or 67DFSR

316 Stainless steel AH3946X0052

Type 67DF, 67DFR, 67DFS or 67DFSR

Auto-drain, Nitrile (NBR) GG00554X012

Auto-drain, Fluorocarbon (FKM) GG00554X022

3 Flange Screw

For Type 67D, 67DR, 67DF or 67DFR

Standard spring case and spring case

with 1/4 NPT vent (6 or 10 required) T13526T0012

Standard spring case for low

temperature service (6 required) T13526T0042

For wire seal

Flange Screw (5 or 6 required) T13526T0012

Flange Screw (1 required) 14B3987X012

For Type 67DS, 67DSR, 67DFS or

67DFSR (10 required) T13526T0042

4* O-ring (Dripwell)

For Type 67DF, 67DFR, 67DFS or 67DFSR

Nitrile (NBR) T14057T0042

Fluorocarbon (FKM) T14057T0022

Silicone (VMQ) T14057T0032

5 Dripwell

For Type 67DF or 67DFR, Aluminum

Manual GE34605X012

Auto-drain GE34606X012

For Type 67DFS or 67DFSR, Stainless steel

Manual GE34607X012

Auto-drain GE31792X012

6* Filter Element

For Types 67DF, 67DFR, 67DFS and 67DFSR

Polyethylene (5 microns) (standard) GE31794X012

Glass fiber (5 microns) GE31795X012

Polyvinylidene fluoride (PVDF) (40 microns) GE31794X022

Stainless steel (40 microns) GE31809X012

7 Spring Case

For Type 67D, 67DR, 67DF or 67DFR, Aluminum

Drilled hole vent (standard) T14070T0012

1/4 NPT vent T14070T0022

For Type 67DS, 67DSR, 67DFS or 67DFSR,

Stainless steel 20C1727X012

9 Filter Retainer, 316 Stainless steel

For Type 67DF, 67DFR, 67DFS or 67DFSR GE31796X012

11* Valve Stem

For Types 67D, 67DR, 67DF and 67DFR

Brass GE35519X012

Aluminum GE35519X022

For All

Stainless steel GE35519X032

12* Valve Spring

Stainless steel GE31783X012

Inconel®(NACE) GG00430X012

14* O-ring (Spring Retainer)

For Type 67D, 67DR, 67DS or 67DSR

Nitrile (NBR) 10A3803X092

Fluorocarbon (FKM) 10A3803X112

Silicone (VMQ) 10A3803X102

15* Soft Seat

Nitrile (NBR) T14055T0012

Fluorocarbon (FKM) T14055T0022

16* Diaphragm Assembly

For Type 67D or 67DF (without relief)

Nitrile (NBR) T14119T0022

Fluorocarbon (FKM) T14119T0042

For Type 67DR or 67DFR (with relief)

Nitrile (NBR) T14119T0012

Fluorocarbon (FKM) T14119T0032

Silicone (VMQ) T14119T0052

For Type 67DS or 67DFS (without relief)

Nitrile (NBR) T14119T0062

Fluorocarbon (FKM) T14119T0072

For Type 67DSR or 67DFSR (with relief)

Nitrile (NBR) T14119T0082

Fluorocarbon (FKM) T14119T0092

Silicone (VMQ) T14119T0102

17 Spring

For Type 67D, 67DR, 67DF or 67DFR,

Music wire (standard)

0 to 20 psig / 0 to 1.4 bar, Green stripe GE07809T012

0 to 35 psig / 0 to 2.4 bar, Unpainted T14059T0012

0 to 60 psig / 0 to 4.1 bar, Blue stripe T14058T0012

0 to 125 psig / 0 to 8.6 bar, Red stripe T14060T0012

For Type 67DR, 67DF or 67DFR

(NACE), Inconel®(NACE)

0 to 35 psig / 0 to 2.4 bar, Silver stripe T14113T0012

0 to 60 psig / 0 to 4.1 bar, Blue T14114T0012

0 to 125 psig / 0 to 8.6 bar, Red T14115T0012

For Type 67DS, 67DSR, 67DFS or

67DFSR, Inconel®(NACE)

0 to 20 psig / 0 to 1.4 bar, Green 10C1729X012

0 to 35 psig / 0 to 2.4 bar, Silver stripe T14113T0012

0 to 60 psig / 0 to 4.1 bar, Blue T14114T0012

0 to 125 psig / 0 to 8.6 bar, Red T14115T0012

0 to 150 psig / 0 to 10.3 bar, Black 10C1730X012

18 Adjusting Screw

For Type 67D, 67DR, 67DF or 67DFR

For standard spring case, Zinc-plated steel

Square head (standard) T14061T0012

Handwheel T14102T0012

Wire seal (not shown) T14104T0012

For Type 67D, 67DR, 67DF or 67DFR (continued)

For spring case with 1/4 NPT vent

Square head for closing cap

Stainless steel T14101T0012

Handwheel

Zinc-plated steel T14103T0012

Wire seal (not shown)

Steel T14198T0012

For Type 67DS, 67DSR, 67DFS or 67DFSR

Square head with or without closing cap

Handwheel

Stainless steel T14101T0022

Zinc-plated steel T14103T0012

19 Hex nut

For Type 67D, 67DR, 67DF or 67DFR

Zinc-plated steel 1A946324122

For All

Stainless steel 1A9463X0042

20 Upper Spring Seat

For Type 67D, 67DR, 67DF or 67DFR

Zinc-plated steel T14051T0012

For Type 67DS, 67DSR, 67DFS or 67DFSR

Stainless steel 10C1725X012

*Recommended spare parts

Inconel®is a mark owned by Special Metals Corporation.

Key Description Part Number Key Description Part Number

8

67D Series