www.Fisher.com

Fisher™easy-Drive™200L

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Specifications 1...............................

Educational Services 3.........................

Installation 3..................................

Special Instructions for “Safe Use” and Installations

in Hazardous Locations 4.....................

Actuator Mounting 4..........................

Startup Overview 6............................

Configuration 11..............................

Control Method Configuration 11............

Modbus Setup 11.............................

Connecting using the Fisher easy-Drive

configuration software 12................

Initial Setup 13............................

Calibration Instructions 13..................

Operational Verification 15..................

Troubleshooting 17.............................

Maintenance 18................................

Disassembly 18................................

Parts Ordering 21...............................

Parts Kits 21...................................

Parts List 21...................................

Appendix A - Modbus 23.........................

Appendix B - Certificate of Conformance 29.........

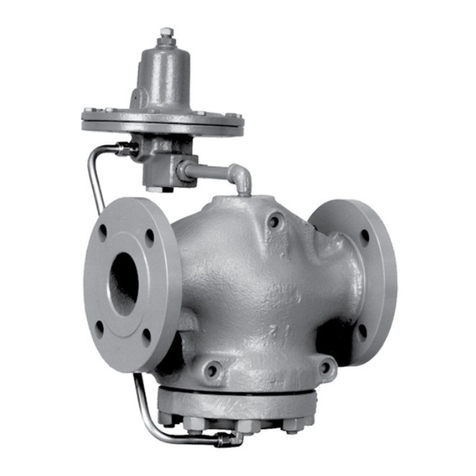

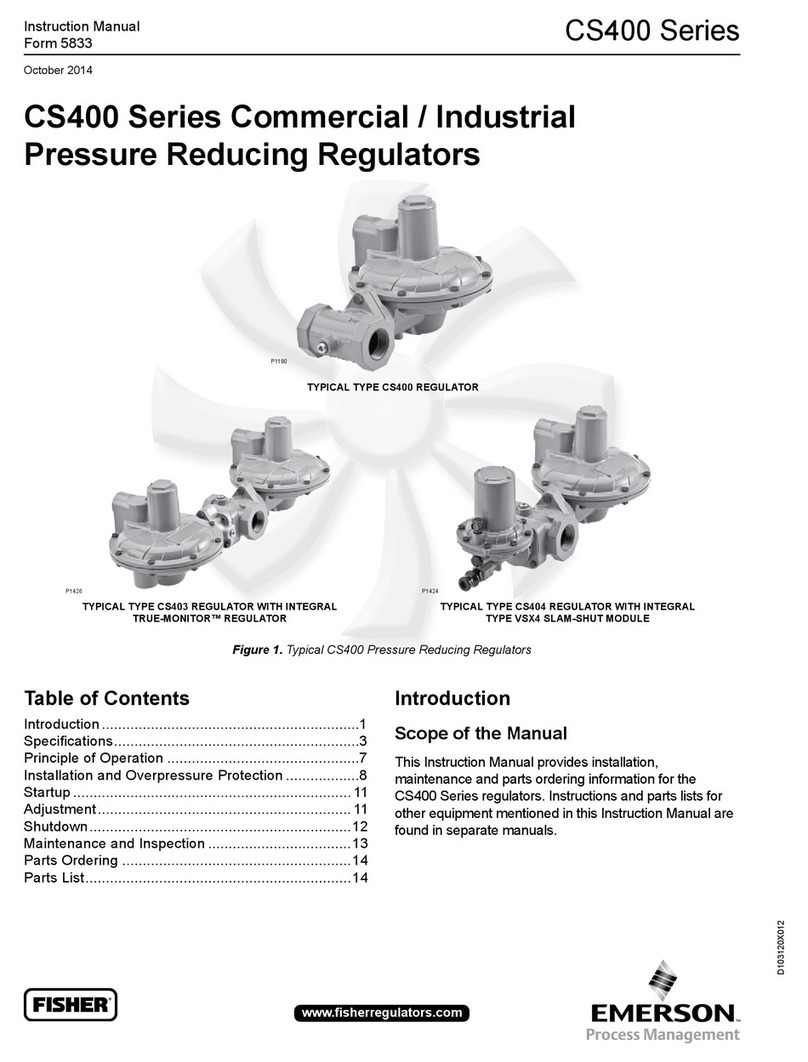

Figure 1. Fisher easy-Drive 200L

X1520-1

Introduction

Scope of Manual

This instruction manual provides installation, maintenance, and parts information for the easy-Drive 200L. Do not

install, operate, or maintain an easy-Drive 200L without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson sales office before proceeding.

Description

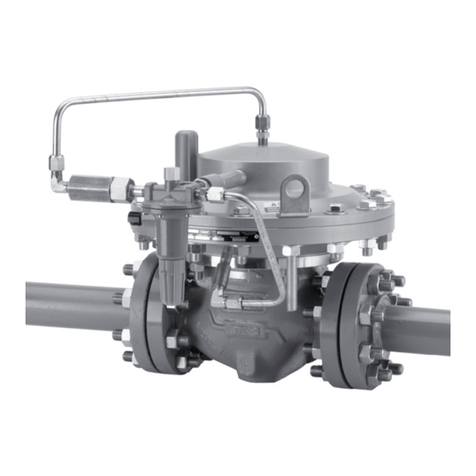

The easy-Drive 200L is a compact, rugged electric actuator designed primarily for high‐pressure throttling

applications. This actuator is ideal for use on pressure and flow control applications.

Specifications

Table 1 lists specifications for the easy-Drive 200L. Some of the specifications for a given actuator as it originally comes

from the factory are stamped on a nameplate located on the lower actuator enclosure.

Instruction Manual

D104331X012

easy-Drive 200L

December 2018