Lit. No. 94432, Rev. 05 6 March 1, 2009

30. Place the spreader on the base plates.

NOTE: If the spreader obstructs the view of the

license plate check for any local regulations that

may apply.

31. Slide the top and bottom connector channel

assemblies up the hinge pins and align the holes

in the spreader angle frame with the holes in the

channel assemblies. Secure the spreader to the

channel assemblies with four 3/8" x 1" cap screws

and 3/8" locknuts per mount arm assembly.

32. Torque all eight cap screws to the proper value.

Refer to Torque Chart.

33. Verify all other fasteners are torqued to the proper

specifications.

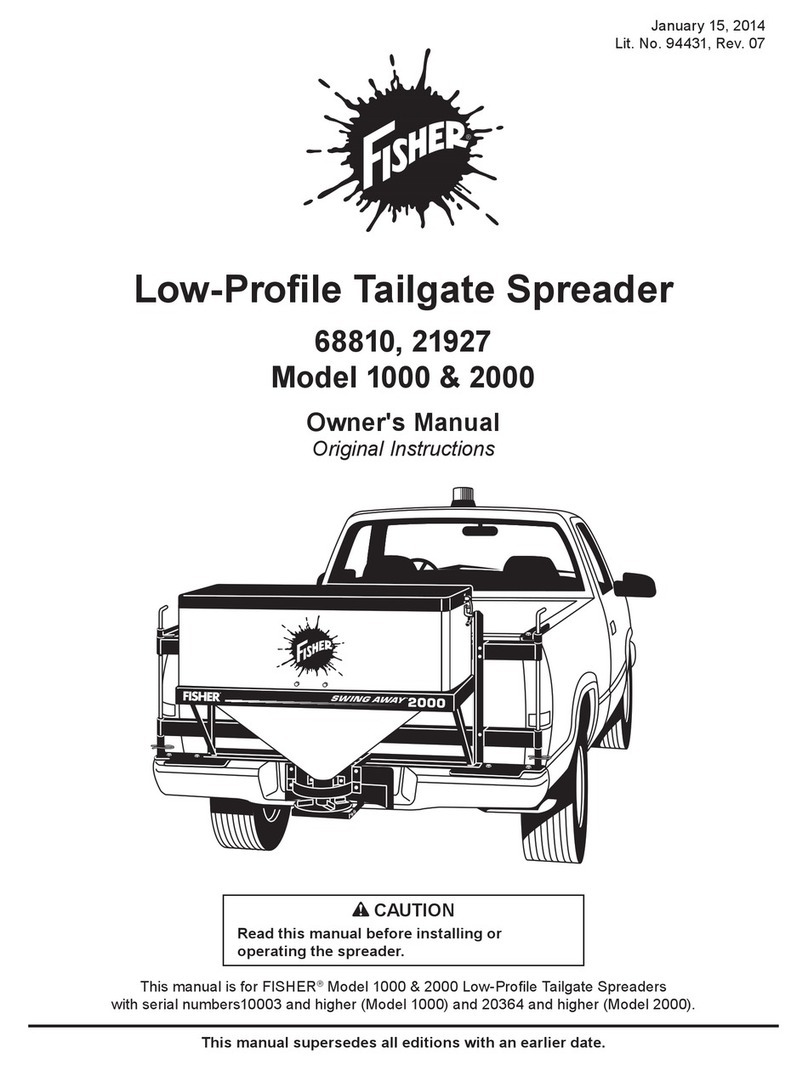

34. Remove one hinge pin and swing the spreader

assembly. When returning the spreader to the

bumper, it may be necessary to lift the spreader

onto the base plate.

35. Choose which way the spreader will swing and fix

the hinge side by installing one 1/4" x 1-3/4" cap

screw and 1/4" locknut through the hole in the

base plate boss and hinge pin.

36. Install the hitch pin clip through the latch side base

plate boss and the removable hinge pin.

SWING AWAY® MOUNT INSTALLATION INSTRUCTIONS

26. Loosely install the base plates to the bumper with

three 3/8" x 1-3/4" cap screws, 3/8" flat washers

and 3/8" locknuts. Shim the top brackets and base

plates as required to prevent the hinge pin from

binding.

CAUTION

Do not operate the spreader or the vehicle

without securing the hinge pin into the base

plate.

NOTE: Place a piece of wood behind the drilling

area to protect the tailgate from the drill as it

breaks through.

20. Install one 3/8" x 1" cap screw and 3/8" locknut in

the end of each end channel to temporarily hold

the arm assemblies together.

21. Adjust the base plates to be aligned with the

bumper and verify that the hinge pins are vertical

and parallel with each other.

22. Use the pre-punched holes in the base plates

to locate and mark three holes on the top of the

bumper for each base plate. The holes should be

chosen in a triangular pattern with two holes in one

of the rows and one hole in another row. Check

under the bumper for any obstructions before

choosing holes.

23. Outline the position of the base plates on the

bumper with a pencil.

24. Remove the clamps, hinge pins and swivel mount

arm assemblies from the truck.

25. Center punch and drill three 13/32" diameter holes

in each side of the bumper as previously marked.

27. Reinstall the channel assemblies and hinge pins

on the truck. Verify that the caution labels located

on the end channels are right side up and located

on the top assembly.

28. Recheck all alignments of the channel assemblies

and hinge pins and torque the base plate

hardware to the proper value. Refer to the Torque

Chart.

29. Remove the 3/8" x 1" cap screws placed in the

connector channel assemblies.

19. Use the pre-punched holes in the connector

channel as a guide to drill two 13/32" diameter

holes through the end channels for a total of eight

holes.

3/8" Flat Washer

3/8" x 1-3/4"

Cap Screw

3/8" Locknut