Instruction Manual

D103606X012

CVX Valve

June 2017

7

valve and replace the gaskets (key 43). If the packing box leaks, tighten hex nuts (key 68). If leakage continues,

replace the packing (key 64). Be sure to properly isolate the CVX valve prior to disassembly of valve or packing.

Maintenance

It is recommended that diagnostic tests be performed on the valve 3-6 months prior to scheduled maintenance

shutdowns. Complete valve disassembly is recommended if tests performed on the valve indicate leakage, sticking or

substandard operation. If diagnostics indicate normal valve operation, complete disassembly and inspection of the

CVX is recommended during every other regularly scheduled outage or after 24-36 months, whichever comes first.

Table 2 identifies the recommended inspection tips and diagnostics that can be performed with corresponding repair

and replacement information.

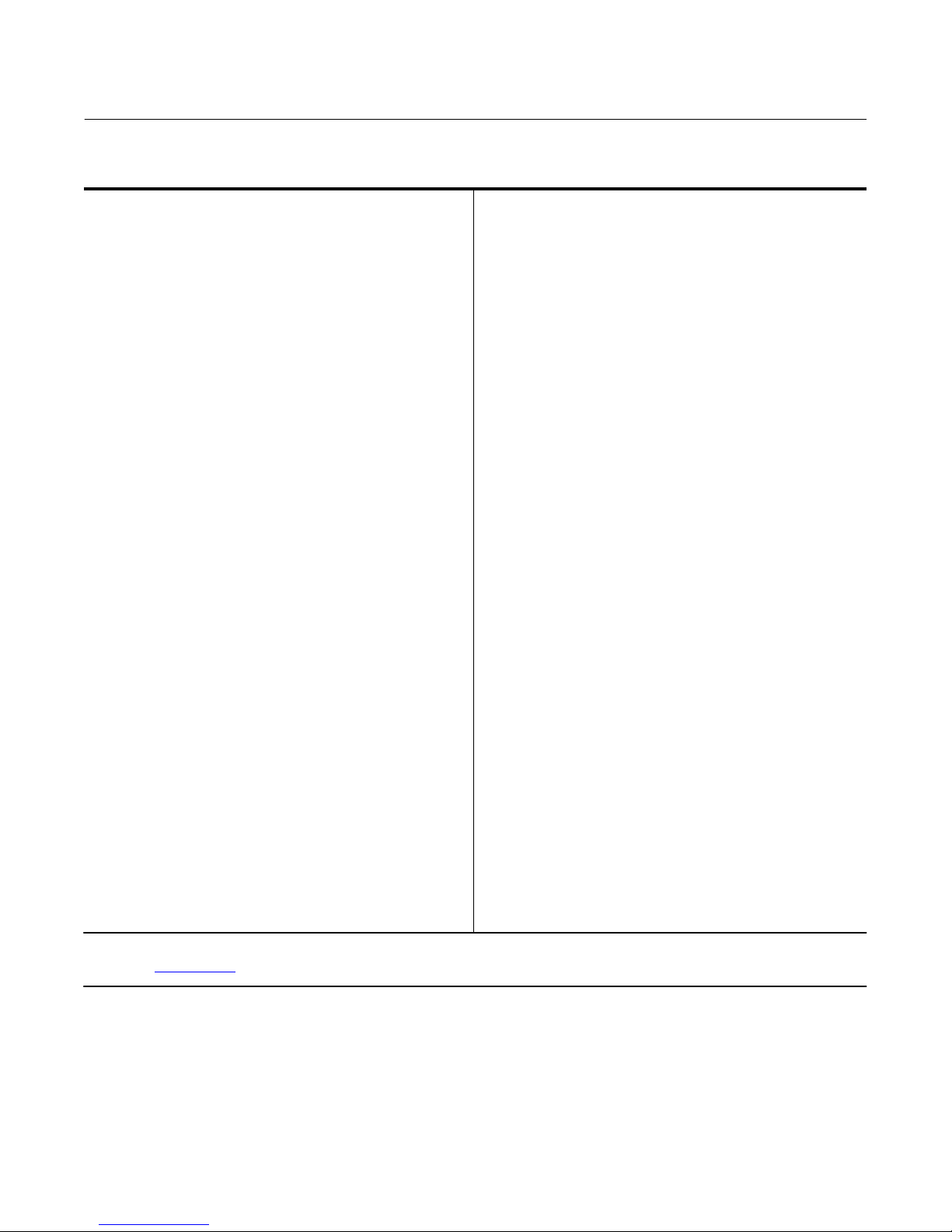

Table 2. Inspection Summary

Key Part Description Inspection Tips and Diagnostics Repair Replacement

1Valve Body Inspect for erosion, thermal fatigue, and other

damage.

Consult your local Emerson Service Center for a recommendation on

necessary weld repair or replacement if damage exists.

6 Bonnet

Inspect gasket surfaces for damage that could indicate

gasket leakage. Inspect packing box to ensure no

galling, scoring, or particulate is present.

If damage exists consult your local Emerson Service Center for a

recommendation on necessary weld repair or replacement.

20 Nozzle Body Flange Inspect gasket surfaces for damage that could indicate

gasket leakage when spray nozzles are replaced. Replacement Only As needed

21 Cage

Inspect cage bore for excessive wear, galling damage,

particulate damage, and flow passage damage or

clogging.

Consult your local Emerson Service

Center for a recommendation on

necessary repair or replacement if

damage exists.

As needed for optimal

performance

22 Plug

Inspect for seat erosion, excessive wear, galling

damage, and particulate damage, paying close

attention to the seating and guiding surfaces.

Re-cutting/machining of seating

surfaces can be performed by your

local Emerson Service Center.

As needed for optimal

performance

23, 53 Stem and Stem Pin Inspect stem for dings, scoring, and galling. Inspect

valve stem connection for tightness.

Valve stem connection can be

repaired by your local Emerson

Service Center.

As needed

24 Seat Inspect for seat erosion, particulate damage, galling,

and proper bolt torque (if applicable, refer to table 5).

Re-cutting/machining of seating

surfaces can be performed by your

local Emerson Service Center.

As needed to maintain proper

shutoff

25 Plug Retainer Inspect for excessive wear, galling, and other damage. Repair can be performed by your

local Emerson Service Center. As needed

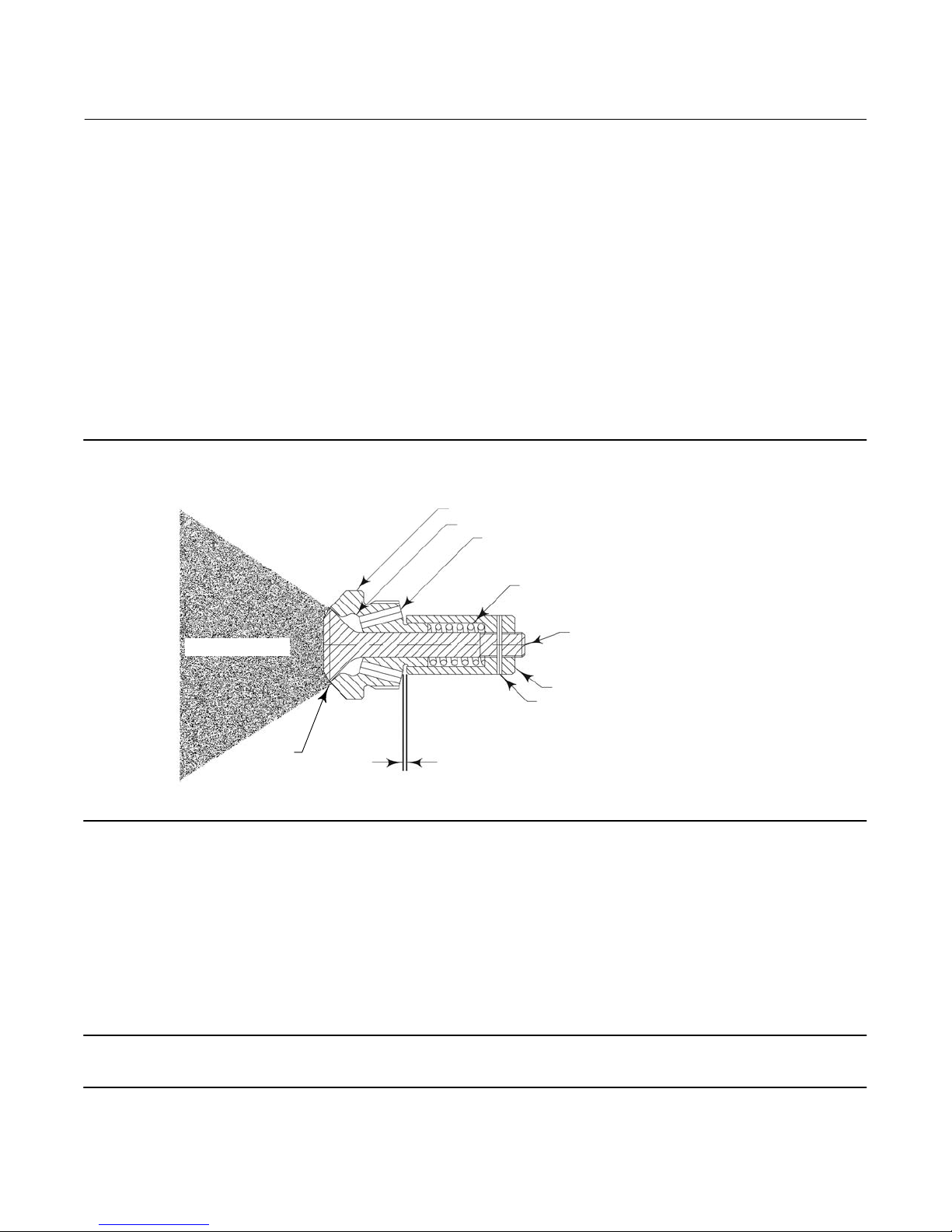

30 Spray Nozzle Refer to Nozzle Maintenance Section. Replacement every 24-36 months

for optimal performance

37 Nozzle Sleeve Inspect for particulate or magnetite buildup when

spray nozzles are replaced. Clean if necessary As needed

43, 47, 48,

75 All Gaskets Every valve disassembly requires replacement of

gaskets. Replacement Only Every valve disassembly

45 Piston Ring

Inspect for particulate buildup, scoring, and excessive

wear. Ensure piston ring is free to expand and contract

in the groove.

Replacement Only As needed

46 Bore Seal Ring Inspect for excessive wear, galling, signs of leakage,

and other damage. Replacement Only Every 36 months for optimal

performance

63 Packing Box Ring Inspect for scoring, galling, and other damage. Replacement Only As needed

64 Packing Set Every valve disassembly requires replacement of the

packing set. Replacement Only Every valve disassembly

65 Packing Follower Inspect for scoring, galling, and other damage. Replacement Only As needed

66 Packing Flange Inspect for scoring, galling, and other damage. Replacement Only As needed

77 Bolted Diffuser Inspect for thermal fatigue, erosion, particulate

damage, and flow passage damage or clogging. Clean if necessary As needed

N/A Welded Diffuser Inspect for thermal fatigue, erosion, particulate

damage, and flow passage damage or clogging. Clean if necessary Consult your local Emerson Service

Center if replacement is necessary.