FKG Rooter X3000 User manual

User Manual

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

Table of Contents

1. Product introducon.................................................................................................... 1

1.1 Descripon of the device............................................................................................................................. 1

1.2 Components and accessories ...................................................................................................................... 2

1.3 Technical specicaons............................................................................................................................... 3

1.4 Warnings ..................................................................................................................................................... 3

1.5 Important precauons ................................................................................................................................ 4

1.6 Device safety classicaon.......................................................................................................................... 4

1.7 Environmental parameters.......................................................................................................................... 4

1.8 User qualicaon ........................................................................................................................................ 4

1.9 Intended use................................................................................................................................................ 4

2. Device setup instrucons ............................................................................................. 4

2.1 Contra-angle setup...................................................................................................................................... 4

2.2 File setup ..................................................................................................................................................... 5

2.3 Apex locator setup ...................................................................................................................................... 6

3. Device Operaon modes and display interface .......................................................... 8

3.1 Motor modes............................................................................................................................................. 8

3.2 Apex locator Operaon mode................................................................................................................... 9

3.3 Combined Motor and Apex locator Operaon mode ............................................................................... 9

3.4 Display interface........................................................................................................................................ 10

4. Device operang instrucons..................................................................................... 11

4.1 Seng interface and bun descripon .................................................................................................. 11

4.2 Power ON and power OFF the device ....................................................................................................... 11

4.3 Select User Programs ................................................................................................................................ 11

4.4 Set User Program parameters ................................................................................................................... 12

4.5 Select FKG FileSystems ............................................................................................................................. 14

4.6 Set device parameters............................................................................................................................... 16

4.7 Torque overload protecon ...................................................................................................................... 16

4.8 Apex locator limitaons ............................................................................................................................ 16

5. Troubleshoong......................................................................................................... 18

6. Cleaning, Disinfecon and Sterilizaon ...................................................................... 18

6.1 Foreword ................................................................................................................................................... 18

6.2 General recommendaons........................................................................................................................ 18

6.3 Step-by-Step Procedure ............................................................................................................................ 19

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

7. Maintenance.............................................................................................................. 20

7.1 Calibraon ................................................................................................................................................. 20

7.2 Lubricaon of the contra-angle............................................................................................................... 20

7.3 Charging of the bry ............................................................................................................................. 20

7.4 Replacement of the baery ...................................................................................................................... 20

8. Storage ...................................................................................................................... 21

9. Transportaon ........................................................................................................... 21

10.Environmental protecon .......................................................................................... 21

11.Aer sales service ...................................................................................................... 21

12.Symbol instrucon ..................................................................................................... 21

13.Statement .................................................................................................................. 22

14.EMC-Declaraon of conformity.................................................................................. 23

14.1 Technical Descripon Concerning Electromagnec Emission................................................................... 23

14.2 Technical Descripon Concerning Electromagnec Immunity.................................................................. 23

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

1. Product introducn

1.1 Descripon of thedevice

The Rooter®X3000 device is a cordless endo motor with an integrated root canal apex locator. It

can be used as an endo motor for preparaon of tooth root canals, or as an apex locator device

to help to determine the root canal working length. It can also be used to prepare the canals

while monitoring the relave poson of the endodonc instrument inside the canal

(combined Motor and Apex locator mode).

1 2345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

Contra angle

OLED screen

Charging base

Charging LED indicator

1.2 Components and accessories

# Designaon Reference FKG

1 Motor handpiece 08.971.00.001.FK

2 Charging base 08.971.00.002.FK

3 Contra-angle [4.7/1]

08.971.00.003.FK

4 Spray noozle 08.971.00.004.FK

5 Measuring wire

08.971.00.005.FK

6 File clip 08.971.00.006.FK

7 Lip hook 08.971.00.007.FK

8 Touch probe 08.971.00.008.FK

9 Protecve silicone cover

08.971.00.009.FK

10 "O"-ring 08.971.00.010.FK

11 Universal AC-Adapter 08.971.00.011.FK

08.971.00.013.FK

08.971.00.014.FK

12

13 Measuring Wire - USB - C

- User manual -

- Package content list -

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

1.Motor handpiece

2.Motor handpiece

3.Contra-angle

4.Spray noozle 6.File clip

10.O-ring

11.AC-Adapter

7.Lip hook

8.Touch probe

5.Measuring wire

1.3 Technical specicaons

a) Motor handpiece lithium baery speccaon

3.7V / 2000mAh

b) Power adapter specicaon

Input: ~100V-240V50Hz/60Hz 400mA

Output: DC5V/1A

c) Motor handpiece mechanical specicon

Torque range: 0.4Ncm-4.0Ncm

Speed range: 100rpm-3’300rpm

d) Wireless charging specicaon

Frequency range: 112-205KHz

Maximum RF output power of the product: 9.46dBuA/m@3m

1.4 Warnings

Please carefully read this Instrucon Manual before rst operon.

a) Do not use this device for anything else than its intended use (refer to Chapter 1.9).

a) Use original components and accessories only.

b) Always set torque and speed following the recommendaons of the e manufacturer.

c) Make sure the contra-angle is well connected before to start the motor handpiece (refer

to Chapter 2.1).

d) Make sure the instrument is well connected and locked before to start the motor

handpiece (refer to Chapter 2.2).

e) Do not connect or disconnect the contra-angle while the motor is running.

f) Do not disconnect the instrument while the motor is running.

g) Be sure to be able to power OFF the device at any me.

h) Operate and store the device in reliable environment (refer to Chapter 1.7 and Chapter

8).

i) Do not use the device in the vicinity of orescent lamps, radio transm devices,

remote control devices, handheld, and mobile high-frequency communicon devices.

j) The motor handpiece, power adapter and charging base are not autoclavable (refer to

Chapter 6).

k) Replace the lithium baery according to the instrucons (refer to Chapter 7.4).

l) Do not make any changes or modicons to the device. Any change, mocaon or any

other alteraon of the device may violate safety regulaons, causing harm to the paent.

m) In case of motor handpiece frequent overheat, contact a local distributor.

n) Do not directly or indirectly place the device near heat sources.

o) Do not cover the device.

p) Remove the baery of the device in case of long period storage.

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

1.5 Important precauons

These precaons are critical to insure safe operon and use.

a) Do not use this device on paents who have implanted pacemakers, debrillators, or any

other implantable devices.

b) Do not use this device on paents sering from Hemophilia.

c) Use with con on paents with heart disease, pregnant women, and young children.

1.6 Device safety classicaon

a) Type of Operon mode: Couous oper electromedical device

b) Type of protecon against electric shock: Class II equipment with internal power supply

c) Degree of protecon against electric shock: B type applied part

d) Degree of protecon against harmful ingress of water: Ordinary equipment (IPX0)

e) Degree of safety applicaon in the presence of a mmable anesthec mixture with air,

oxygen, or nitrous oxide: Equipment cannot be used in the presence of a mmable

anesthec mixture with air, oxygen, or nitrous oxide.

f) Applied part: contra-angle , lip hook, e clip, touch probe.

The contact duron of applied part: 1 to 10 minutes.

Maximum temperature of applied part: 46.6°C.

1.7 Environmental parameters

a) Opera ambient temperature: +5°C ~ +40°C

b) Opera reve humidity: 30% ~ 75%

c) Opera atmospheric pressure: 70kPa ~ 106kPa

1.8 Userqualicaon

a) The device must be operated in hospital or clinic by legally quaed dests.

b) It is assumed that the operator is familiar with root canal apex locator.

1.9 Intended use

a) The Rooter®X3000 is an endo motor, an electro-medical device intended to drive

mechanical instruments intended for dental root canal treatment (endodoc es).

b) In on, it is intended to help to determine the working length (apex locator

funconality).

2. Device setup instrucns

2.1 Contra-angle setup

2.1.1 Before the rst use and er each treatment

a) Clean and disinfect the contra-angle (refer to Chapter 6).

b) Lubricate the contra-angle (refer to Chapter 7.2).

c) Sterilize the contra-angle (refer to Chapter 6).

2.1.2 Warnings

a) Use original contra-angle only.

b) Make sure the contra-angle is well connected before to start the motor handpiece.

c) Do not connect or disconnect the contra-angle while the motor is running.

2.1.3 Connec the contra-angle

1. Align the three pins of the contra-angle with the posoning slots of the motor handpiece.

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

2. Push the contra-angle horizontally. A “click” sound indicates that the instaon is in

place.

3. The contra-angle must rotate 360° freely.

2.1.4 Disconnecng the contra-angle

Pull out the contra-angle horizontally.

2.2 File setup

2.2.1 Warnings

a) Make sure the instruments are compliant to ISO1797 standard (Shanks for rotary and

osc instruments).

b) Connec and disconnec es without holding down the Push buon may damage

the chuck of the contra-angle.

c) Be careful when manipula es to avoid injury to ers.

d) Make sure the e is well connected and locked before to start the motor handpiece.

e) Do not disconnect the le while the motor is running.

2.2.2 Connec a

Plug the e into the hole of contra-angle head.

1. Hold down the Push buon on the contra-angle and push the e.

2. While pushing, rotate the e clockwise and counterclockwise its shank is aligned

with the contra-angle latch groove.

3. When the shank is aligned and slips into place, release the Push on to lock the e

into the contra-angle.

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

2.2.3 Disconnecng a

Hold down the Push buon and pull out the e.

2.3 Apex locator setup

2.3.1 Warnings

a) In Apex locator mode, the e clip must properly hold the le.

b) In case of bad or wrong connecon signal, replace the measuring wire.

c) In apex locator mode it is suggested to install the motor handpiece in the charging base

to get beer visual angle.

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

d) The Apex locator detects the canal apical foramen, not the tooth anatomical apex. This

could explain some erences between the apex locator signal and an X-ray image.

e) Not all condons are ideal for working length determinaon. To be informed about the

Apex locator limitaons, refer to Chapter 4.8.

2.3.2 Connec apex locator wires

1. Connect the measuring wire to the motor handpiece (USB socket at the back).

2. Connect the lip hook to the white socket of the measuring wire.

3. Connect the e clip plug to the black socket of the measuring wire (this is not required in

combined Motor and Apex locator mode).

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

2.3.3 Connecon tes

It is strongly recommended to check the connecon quality before every use.

1. In Apex locator mode, clip the holder on lip hook and check that all the indicator bars light

up, as shown below:

2. In combined Motor and Apex locator mode, touch the lip hook with the e and check

that all the indicator bars light up, as shown below:

3. Device Operaon modes and display interface

3.1 Motor modes

3.1.1 CW Operaon Mode (Clockwise conous rotaon mode)

In this mode, the motor handpiece rotates in clockwise direcon only (forward direcon).

3.1.2 CCW Operaon Mode (Counterclockwise conuous rotaon mode)

In this mode, the motor handpiece rotates in counterclockwise direcon only (reverse direcon).

In this mode, a double beepsounds coously.

3.1.3 REC Operaon Mode (Reciproca moon mode)

In this mode, the motor handpiece generates reciproca moon only (F: Forward angle, R:

Reverse angle).

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

3.1.4 ATR Operaon Mode (Ave Torque Reverse mode)

In this mode, the motor handpiece rotates in clockwise direcon and generates reciprocag

moon when the torque load on the e is higher than the set torque limit.

3.2 Apex locator Operaon mode

3.2.1 EAL Operaon Mode (Electronic Apex Locator)

This mode is intended for working length determon only.

In this mode, the motor handpiece does not run.

3.3 Combined Motor and Apex locator Operaon mode

When a e is inside the canal and the lip hook is in contact with ent’s lip, the device enters

automacally in the combined Motor and Apex locator mode.

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

3.4 Display interface

Stand-by interfaces

While the motor is not running, the display shows the actual sengs of the

motor.

a. User Program (M0-M9)

or

Manufacturer preset program (refer to Chapter 4.5)

b. ry level

c. Set speed (rpm)

d. Set torque limit (Ncm)

e. Motor Operaon mode

f. Set forward angle (°deg)

g. Set reverse angle (°deg)

Motor Operaon interface

While the motor is running, the display shows the torque load on the e.

a. Set speed (rpm)

b. Set torque limit (Ncm)

c. Real me torque (Ncm)

d. Torque display scale (Ncm)

Combined Motor and Apex locator Operaon interface

a. Fileprogression indicaon bar

b. File progression indicaon number

The numbers 1.0, 2.0, 3.0 (a) and numbers “00”-“16” (b) do not represent

an absolute length. It simply indicates the relae le posion towards the

apical foramen. These numbers are used to help the determinaon of the

working length.

c. Apical foramen (AP)

The digital number “00” (b) indicate that the e has reached the apical

foramen. The digital numbers “-1” and “-2” (b) indicate that the e has

passed the apical foramen.

Apex locator Operaon interface (EAL mode)

a. User Program (M0-M9)

b. ry level

c. File posion indicaon bar

d. Apical reference point

e. Motor Operaon mode

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

XP-endo T.

Shaper

f

g

4. Device operang instrucons

4.1 Seng interface and bon descripon

4.2 Power ON and power OFF thedevice

1. To power ON the device, press the Main on. The device enters in stand-by state.

The display shows the stand-by interface of the last program used. For example:

or or …

2. To start the motor from the stand-by state, press the Main on.

The display shows the working interface according to the program used. For example:

3. To stop the motor, press the Main on again. The device goes back in stand-by state.

4. To power OFF the device, hold down the Seng on “P”, and press the Main on.

In stand-by state, the device will automacally shut down er 5 minutes.

4.3 Select User Programs

The device contains 10 memorized User Programs (M0-M9) and 7 preset FKG File Systems

available directly from the stand-by state.

1. To select a program from the stand-by state, press the Adjuson “+”/”-“.

… …

…

2. To select a specc FKG File System, refer to Chapter4.5.

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

XP-endo T.

Shaper 1000rpm

1.0Ncm

XP-endo T.

Shaper 1000rpm

1.0Ncm

XP-endo T.

Finisher 1000rpm

1.0Ncm

RACE EVO

All files 1000rpm

1.5Ncm

XP-endo R.

DR1 1000rpm

1.5Ncm

XP-endo R.

Finisher R 1000rpm

1.0Ncm

XP-endo R.

Shaper 2500rpm

1.0Ncm

R-Motion

All files F: auto

REC R: auto

R-Motion

All files F: auto

REC R: auto

250rpmM9

CW 2.0Ncm

4.4 Set User Program parameters

4.4.1 Warnings

a) Make sure the Operaon Mode is adequate before to start the motor.

b) All the parameters must be set according to the e manufacturer recommendaons.

c) Make sure all the parameters are vered before to start the motor handpiece.

d) M0-M9 User Programs parameters moed by the user are memorized.

e) FKG File Systems parameters cannot be modied by the user (refer to Chapter 4.5).

4.4.2 Parameter se

To modify User Program parameters from the stand-by state:

1. To select the desired parameter, press the Seng on “P”.

2. To modify the parameter se press the Adjus on “+”/“-”.

3. Press the Main on or wait 5 seconds to conrm.

4.4.3 User Program parameters list

Set Operaon Mode

Operaon modes list: CW, CCW, REC, ATR, EAL

(refer to Chapter 3 for modes descripon)

Set Working Speed

In connuous rotaon modes (CW and CCW), the working speed can be adjusted from

100rpm to 3’300rpm (50rpm increments).

In REC mode, the working speed can be adjusted for 100rpm to 500rpm (50rpm

increments).

In ATR mode, the working speed can be adjusted for 100rpm to 500rpm (50rpm

increments).

In REC and ATR modes, the working speed represents the mean speed of one single

angle movement (speed set for both Forward and Reverse angles).

Set Torque Limit

In CW connuous rotaon mode, the torque limit can be adjusted from 0.4Ncm to

4.0Ncm depending on the set speed:

•100-200rpm Max torque limit : 4.0Ncm

•250-400rpm Max torque limit : 3.5Ncm

•450-650rpm Max torque limit : 3.0Ncm

•700-950rpm Max torque limit : 2.5Ncm

•1’000-1’450rpm Max torque limit : 2.0Ncm

•1’500-1’950rpm Max torque limit : 1.5Ncm

•2’000-3’300rpm Max torque limit : 1.0Ncm

In REC mode, the torque limit can be adjusted from 2.0Ncm to 4.0Ncm depending on

the set speed:

•100-250rpm Max torque limit : 4.0Ncm

•300-400rpm Max torque limit : 3.5Ncm

•450-500rpm Max torque limit : 3.0Ncm

In ATR mode, the Trigger Torque can be adjusted from 0.4Ncm to 3.0Ncm.

In CCW connuous rotaon mode, the torque limit cannot be set.

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

Operation Mode

CW

Speed

250rpm

Torque Limit

1.0Ncm

Set Apical Acon

The Apical acon applies when the e reaches the set apical reference point (refer

to Flash Bar Posion)

OFF: Disable Apical Acon

STOP: The motor stops automacally when the e reaches the reference point. The

motor restarts automacally when the e is pulled away from the reference point.

REVERSE: The motor automacally reverses the rotaon direcon when the e

reaches the reference point. The motor goes back automacally to inial rotaon

direcon when the e is pulled away from the reference point.

Set Auto Start

OFF: Disable Auto Start (the Main buon is needed to start the motor handpiece).

ON: The motor starts automacally when the e is inserted into the canal (from when

the le progression indicator shows 2 bars).

Set Auto Stop

OFF: Disable Auto Stop (the Main buon is needed to stop the motor handpiece).

ON: The motor stops automacally when the e is taken out the canal.

Set Flash Bar Posion (Apical reference point)

The apical reference point (ash bar) can be set from 2 to AP (Apical foramen).

(0.5 indicates that the e p is located very near the physiological apical foramen)

Apical Acon and Apical Slow Down are triggered by the apical reference point.

Set Apical Slow Down

When the Apical Slow Down is acvated, the motor slows down to a set nal speed

as the e ps approaches the apical reference point. The motor speed decreases

starng from the posion “3.0” of the file progression indicaon bar .

OFF: Disable Apical Slow Down

In CW connuous rotaon mode, the nal speed can be adjusted from 100rpm to the

current set speed (50rpm increments).

The Apical Slow Down funcon is available for CW & CCW connuous rotaon mode

only.

The nal speed must be lower than the nominal speed.

Forward Angle

In REC mode, the Forward Angle can be adjusted from 20° to 400° (10° increments)

In ATR mode, the Forward Angle can be adjusted from 60° to 400° (10° increments).

Reverse Angle

In REC mode, the Reverse Angle can be adjusted from 20° to 400° (10° increments)

In ATR mode, the Reverse Angle can be adjusted from 20°to the Forward Angle (10°

increments).

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

Apical Slow Down

200rpm

4.4.4 User Programs parameters availability table

Parameter

User Program

Operaon Mode

Set

Working

Speed

Set

Torque

Limit

Set

Apical

Acon

Set Auto

Start

Set Auto

Stop

Set Flash

Bar

Posion

Set

Apical

Slow

Down

Set

Forward

Angle

Set

Reverse

Angle

CW

YES

YES

YES

YES

YES

YES

YES

n/a

n/a

CCW

YES

NO

NO

NO

NO

YES

YES

n/a

n/a

REC

YES

YES

YES

YES

YES

YES

NO

YES

YES

ATR

YES

YES

YES

YES

YES

YES

NO

YES

YES

EAL

n/a

n/a

n/a

n/a

n/a

YES

n/a

n/a

n/a

4.5 Select FKG File Systems

To help the user set the e parameters according to FKG recommendaon, the most popular

FKG File Systems are already preset in the device.

1. To select a preset FKG File System from the stand-by state, long press the Se buon

“P”.

2. To select the desired FKG File System, press the Adjus on “+”/“-” and press the

Se on “P” to corm.

3. To select a le, press the Adjus bon “+”/“-” and press the Main on to corm.

4.5.1 FKG File Systems list

RACE®EVO

File systems selecon

File selecon

Stand-by interface

Operaon interface

XP-endo®Treatment

File systems selecon

File selecon

Stand-by interface

Operaon interface

XP-endo®Retreatment

File systems selecon

File selecon

Stand-by interface

Operaon interface

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

XP-endo T.

Shaper 1000rpm

1.0Ncm

XP-endo T.

Shaper 1000rpm

1.0Ncm

XP-endo R.

DR1 1000rpm

1.5Ncm

XP-endo R.

Shaper 2500rpm

1.0Ncm

XP-endo R.

Finisher R 1000rpm

1.0Ncm

RACE EVO

All files 1000rpm

1.5Ncm

2500rpm 1000rpm 1000rpm

DR1

Shaper

Finisher R

CW

1000rpm

1.0Ncm

Finisher R

DR1

Shaper

Finisher R

CW

2500rpm

1.0Ncm

Shaper

DR1

Shaper

Finisher R

CW

1000rpm

1.5Ncm

DR1

Shaper

Shaper

CW

1000rpm

1.0Ncm

Finisher

Shaper

Finisher

CW

1000rpm

1.0Ncm

Shaper

CW

1000rpm

1.5Ncm

All files

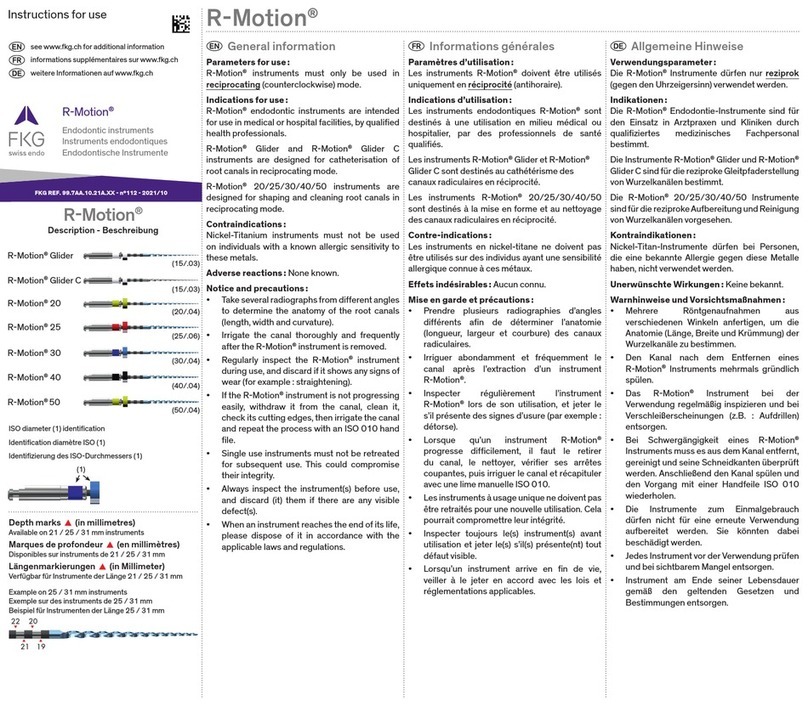

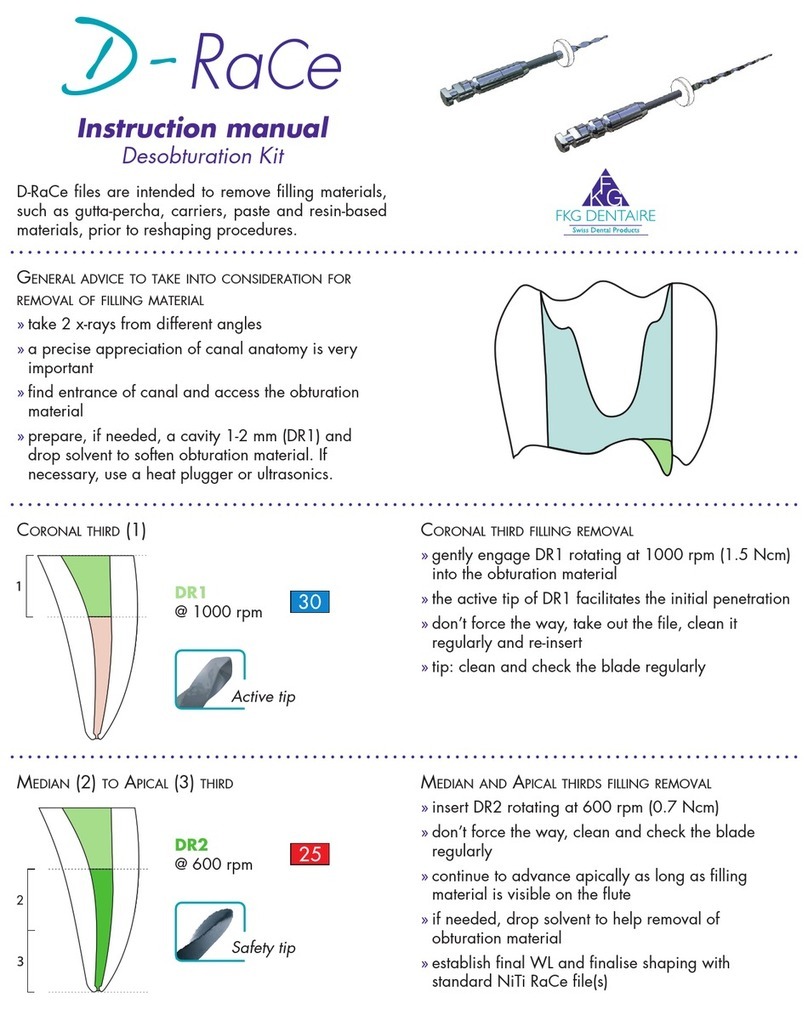

R-Moon®

File systems selecon

File selecon

Stand-by interface

Operaon interface

4.5.2 FKG File Systems parameters availability table

Parameter

FKG File System

Set

Working

Speed

Set

Torque

Limit

Set

Apical

Acon

Set Auto

Start

Set Auto

Stop

Set Flash

Bar

Posion

Set

Apical

Slow

Down

Set

Forward

Angle

Set

Reverse

Angle

RACE EVO

All Files

YES YES YES YES YES n/a n/a

XP-endo Treatment

Shaper

YES YES YES YES YES n/a n/a

XP-endo Treatment

Finisher

YES YES YES YES YES n/a n/a

XP-endo Retreatment

DR1

YES YES YES YES YES n/a n/a

XP-endo Retreatment

Shaper

YES YES YES YES YES n/a n/a

XP-endo Retreatment

Finisher R

YES YES YES YES YES n/a n/a

R-Moon

All Files

YES YES YES YES NO

4.6 Set device parameters

To set the device parameters:

1. To access the device parameters from the power OFF state, hold down the Se on

“P” and press Main buon.

2. To select the desired parameter, press Se on “P”

3. To set the parameter, press the Adjus on “+”/“-” and the Main on to conrm.

4.6.1 Device parameters list

Auto Power OFF

In stand-by state, the device automacally turns OFF r the set mer.

The mer can be adjusted from 3 minutes to 30 minutes (1 minute increments)

Auto Standby Scr

The display switches automacally back to the stand-by interface r the set mer.

The mer can be adjusted from 3 seconds to 30 seconds (1 second increments)

Dominant Hand

The device can be adjusted for l-handed or right-handed user (180° rotaon of the

display).

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

Software Version

V1.0.0

R-Motion

All files F: auto

REC R: auto

--rpm

REC

auto

auto

All files

Calibraon

Make sure the original contra-angle is installed before to launch the motor

calibraon.

OFF: No acon.

ON: Start motor calibraon

The motor must be calibrated before the rstuse and aer lubricaon.

Beeper volume

The device sound volume can be adjusted from Vol. 0 to Vol. 4.

Vol.0: Mute.

Restore Defaults

OFF: No acon.

ON: Device parameters returns to original seng.

4.7 Torque overload protecon

During operon, if the measured torque load exceeds the torque limit, the motor will

automacally reverse the direcon of roon. The motor returns to Operaon mode (CW)

when the torque load goes back below the torque limit.

4.7.1 Warnings

a) In reciprocaon moon mode (REC), when the load value is higher than the torque limit:

i. if the Forward angle is greater than the Reverse angle, the motor automacally

switches to counterclockwise rotaon (reverse direcon).

ii. if the Reverse angle is greater than the Forward angle, the motor automcally

switches to clockwise rotaon (forward direcon).

b) The auto-reverse protecon is not available for CCW and ATR modes.

c) The auto-reverse protecon might not work properly in case of low baery level.

d) Under connuous load, the motor may stop automacally due to overheat. In that case,

the device must be powered OFF enough me to naturally cool down.

4.8 Apex locator limitaons

Not all condons are ideal for root canal length evaluaon. Accurate signal cannot be obtained

if the root canal shows the condions listed below.

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

Rootcanal with a large apical foramen

Root canal with exceponally large apical foramen due

to a lesion or incomplete development might disturb the

electrical signal.

Rootcanal with liquid overowing from the opening

Root canal with blood or any other liquid overowing

from the opening and in contact with the gingival ssue

might disturb the electrical signal.

Broken crown

If the crown is broken and a secon of the gingival ssue

intrudes into the cavity surrounding the canal opening,

the contact between the gingival ssue and the le might

disturb the electrical signal.

Fractured tooth

Fractured tooth might disturb the electrical signal.

Re-treated root canal led with gua-percha

Debris of gua-percha might disturb the electrical signal.

Crown or metal prosthesis touching gingival ssue

The contact between the prosthesis and the le might

disturb the electrical signal.

12345678910 11 12 13 14 15 16 17 18

19 20 21 22 23 24 25 26

Other manuals for Rooter X3000

1

Table of contents

Other FKG Dental Equipment manuals