FKG Rooter Universal User manual

Ver 1.0

Revision Date:20200515

www.g.ch

The Black Church, St. Mary's Place, Dublin 7, D07 P4AX, Ireland

Wellkang Ltd

The trademarks menoned in this manual are the property of their legally

registered companies.

The file manufacturers, file system names and the file names referred to in this

manual are for idenficaon purposes only and are the property of their

respecve manufacturer or brands.

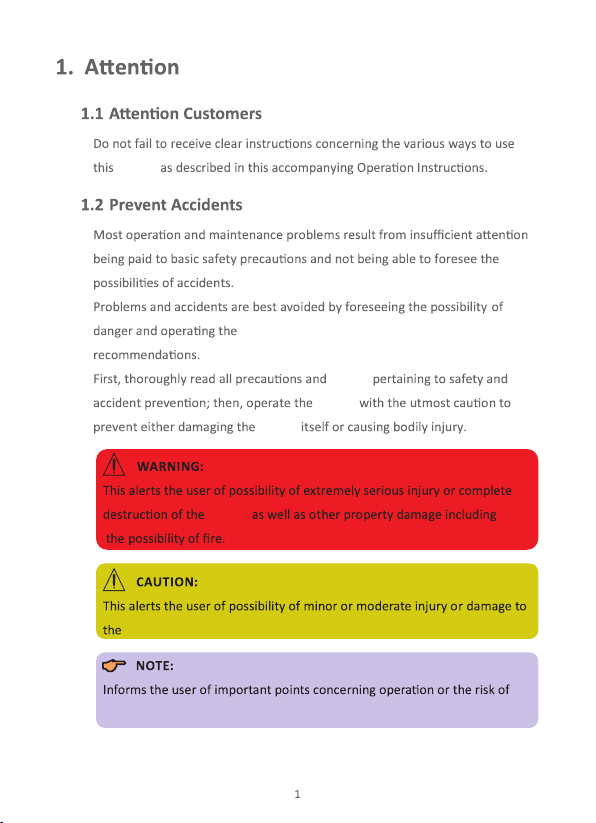

Introducon

Noce

device.

device and pay close aenon to warnings and notes.

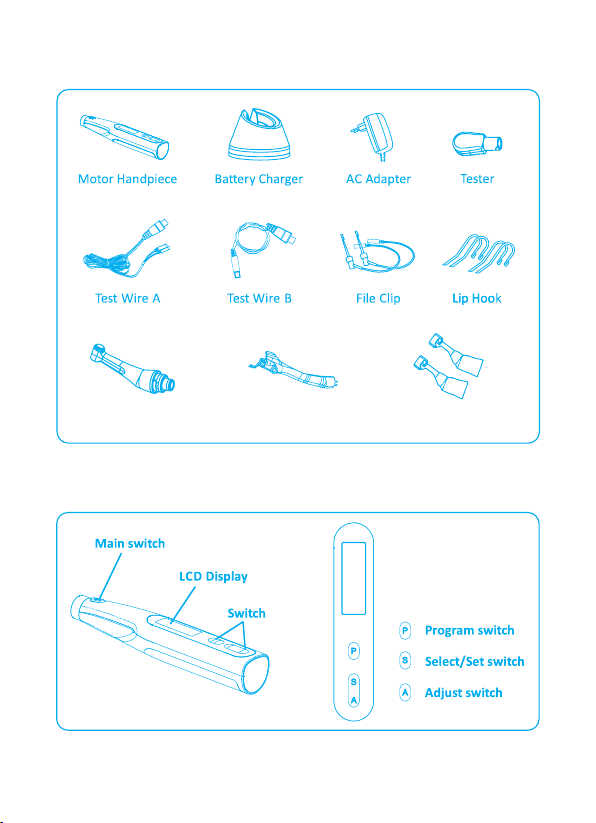

Components and Accessories

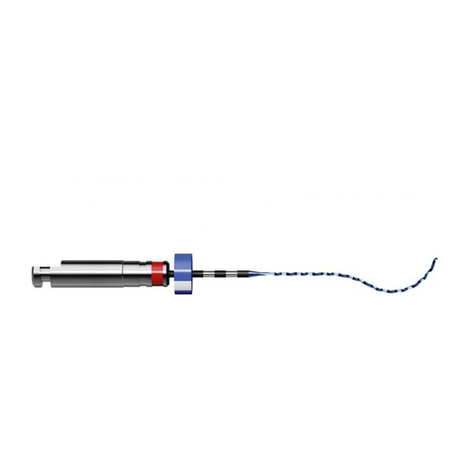

Handpiece and Switch

Fig. A

Fig. B

Lighng Device

16:1 Contra-angle

(CX265-28) (CX265-67)

(CX265-63) (CX265-64) (CX265-52) (CX265-17)

(C4-2M) (CX265-23F)

44

Protecve Sleeve

(CX265-65)

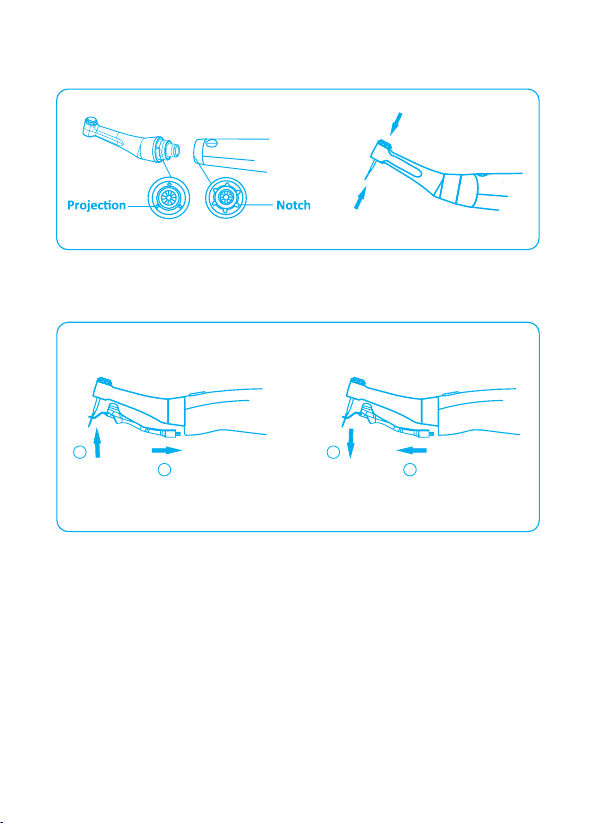

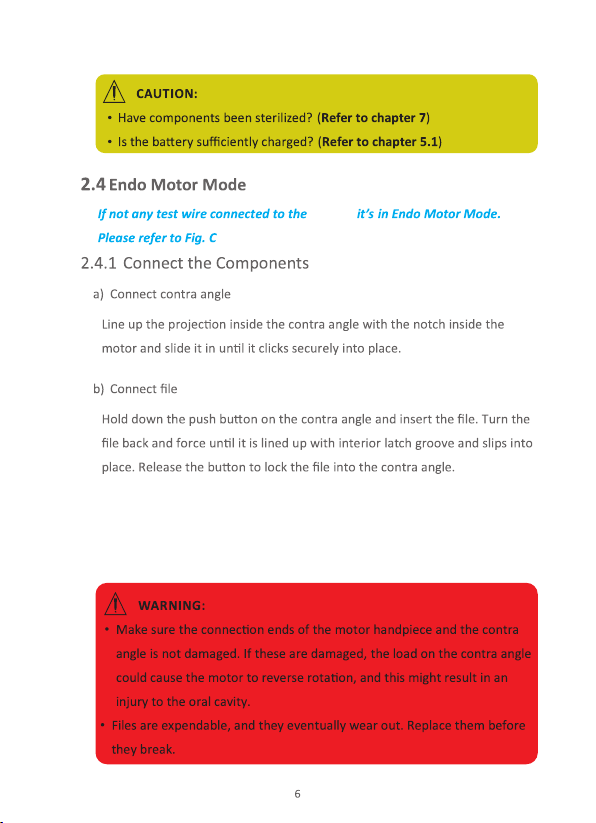

Contra Angle & File connecon

Fig. C

Accessory Connecon

Fig. D

1

2

Install

2

1

Remove

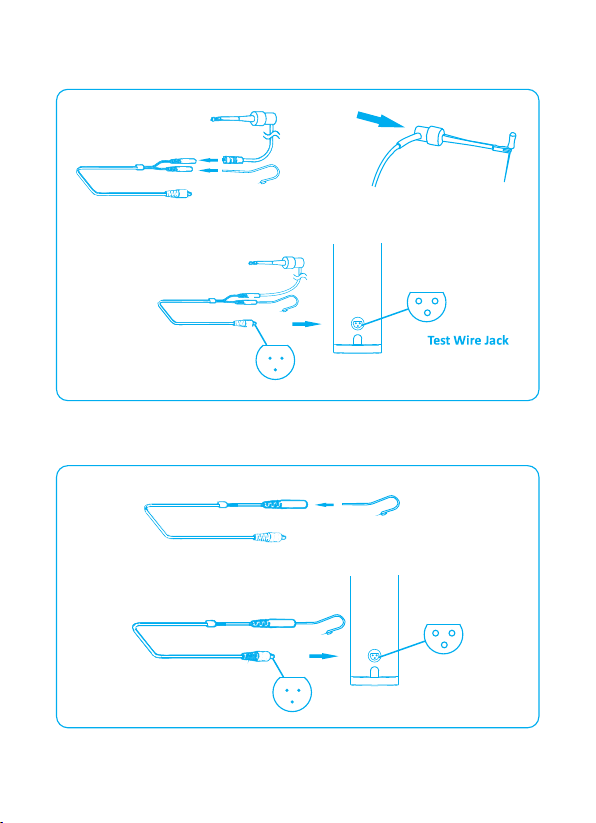

Apex Locator Mode

Fig. E

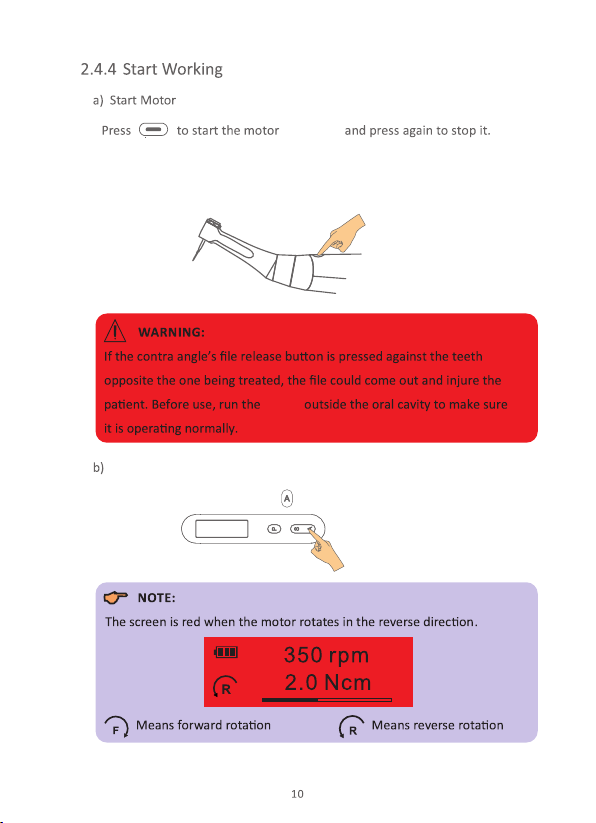

Mul-funcon Mode

Fig. F

Charging

Fig. G

Replace the baery

Fig. H

instrument can

be

the instrument. This may result in incorrect operaon of the instrument.

This instrument has been thoroughly tested and inspected to assure proper perform-

ance and operaon!

This instrument should not be used adjacent to or stacked with other instrument and

this instrument should be observed to

40

device

device in accordance with the manufacturer ’s

device

device

device

device

device.

device damage.

Thermo-Disinfector Autoclave

DC current (connuous

current)

Authorized representa-

ve in the European

community

device

device allowed.

device

device for treatment.

This device might be adversely affected by the electromagnec

radiaon produced by electrical scalpels, illuminaon devices etc.

that are being used nearby.

150 to 1000rpm

min.0.6 Ncm, max.3.5 Ncm

instrument

device damage, or

the device.

device

device

instrument

The Rooter® Universal is an electro-medical device intended to drive

mechanical instruments intended for dental root canal treatment (files).

In addion, it is intended to help to determine the working length (apex

locator funconality).

Keep the accessories in a dry, dust-free environment aer sterilizaon.

7.10 7.10 Storage

Store the sterilizing equipment in a dry, clean and dust-free environment at a

suitable temperature of 5 ° C to 40 ° C.

device has 3 modes:

Do not expose the device to direct sunlight for an extended period

of me.

If the device has not been used for some me, make sure it works

properly before using it again.

Refer to the contra-angle operaon manual for all operaons

regarding the contra-angle.

7.6 Drying

Manual drying: Removing any liquid residue with a lint-free coon cloth, and

then blow dry with compressed air (1-2 Bar).

Automac drying: Refer to chapter 7.5 (f)

7.7 Inspecon and Maintenance

Aer cleaning and disinfecon, visually inspect the Lip Hook, File Clip and Contra

Angle Holder. If no visible contaminants are found, it means that the Lip Hook,

File Clip and Contra Angle Holder have been cleaned.

If damage is found by visual inspecon, stop using it and purchase damaged

parts from the manufacturer or dealer.

7.8 Package

Immediately aer drying, put the Lip Hook, File Clip, Contra Angle Holder/

Lighng device and Contra Angle into the steam sterilizaon bag for sealed

packaging.

Steam sterilizaon bag should comply with ISO 11607-1 and must be sealed

with a sealing machine.

7.9 Sterilizaon

Use a high pressure steam sterilizer in accordance with ISO 17665-1 for

sterilizaon.

a) Sterilizaon parts: The Lip Hook, File Clip, Contra Angle Holder/Lighng device

and Contra Angle

b) Sterilizaon method: Autoclave

c) Sterilizaon condions: 134 °C for not less than 5 minutes

, D

c) Connect lighng device

Insert the lighng device into the motor handpiece and clip the electrode on

device,

the file.

7.5 Automac Cleaning and Disinfecon

It is recommended to use a washer-disinfector to clean and disinfect

the Lip Hook, File Clip and Contra Angle Holder.

Put the Lip Hook, File Clip and Contra Angle Holder on the tray of the washer-

disinfector, select the "surgical instrument", and start the automac cleaning

Cleaning and disinfecon procedure:

a) Pre-cleaning: Pre-clean with tap water less than 40 ° C for 4 minutes

b) Cleaning: Immerse and wash with a mul-enzyme cleaner for 6 minutes

at 55 °C

c) Rinse stage I: Flush with tap water less than 40 ° C for 1 minute

d) Rinse stage II: Flush with tap water less than 40 ° C for 1 minute

e) Disinfecon: The temperature is 80 °C and the acon me is 10 min

f) Drying: The temperature is 100 °C and the acon me is 15 min

The user must follow the special instrucons of the manufacturer of the

fully automac washing machine. In order to ensure the cleaning and

disinfecon effect, the cleaning and disinfecon me should not be less

than the me recommended by the manufacturer.

We recommend the use of proven LIRCON® mul-enzyme cleaning soluon

or mul-enzyme cleaning soluon that complies with local regulaons (e.g.

CE, FDA approval).

Please use a washer-disinfector that meets the requirements of ISO 15883.

Considering that some countries have different requirements for A0 values,

please refer to ISO 15883 for temperature and me of disinfecon.

• When installing/removing the lighng device, do not shake them at will

to avoid damaging the plug.

7.4 Manual Disinfecon

b) Aer cleaning, remove any liquid residue with a lint-free coon cloth and

then dry with compressed air (1-2 Bar).

Do not put the Lip Hook, File Clip, and Contra Angle Holder into the

disinfectant container for immersion and disinfecon. If the internal liquid is

not cleaned and the drying is not complete, the internal parts will be

corroded.

Place the lint-free coon cloth in a container filled with LIRCON® medical

device cleaning soluon (metal type), wring it out and wipe the Test Wire,

Lip Hoop, File Clip, Contra Angle Holder/Lighng device and Contra Angle at

least 3 mes.

It is recommended to use the medical device cleaning soluon (metal type) of

LIRCON®, which with an effecve chlorine content of 1.0%-1.2% (W/V).

Do not put the Test Wire, Lip Hoop, File Clip, Contra Angle Holder/Lighng

device and Contra Angle into the disinfectant container for immersion and

disinfecon. If the internal liquid is not cleaned and the drying is not

complete, the internal parts will be corroded.

If you want to use other disinfectant, use a disinfectant that complies with

local naonal regulaons (such as CE cerficaon, FDA cerficaon), and

follow the instrucons provided by the disinfectant manufacturer.

7.3 Manual Cleaning

a) Rinsing the Lip Hook, File Clip and Contra Angle Holder in flowing tap water

(<40 ° C)

FKG

XP-endo Treatment

Shaper

Finisher

1000 rpm

1.0 Ncm

1000 rpm

1.0 Ncm

Cleaning, disinfecon, and sterilizaon have limited impact on the reusable

part of the motor handpiece. Therefore, the number of mes the procedure

is repeated is determined by the degree of wear of the part. If visual

inspecon reveals damaged parts, stop using them and purchase new parts

from the manufacturer or dealer.

7.1 Preparaon aer Using

Immediately aer use, the reusable parts should be immersed in tap water

<40 ° C (The quality of drinking water, the 'water' menoned in this chapter, is

required to meet this standard.) to remove dirt. Do not use a fixed detergent

or warm water (>40 °C), as this will cause the residue to be fixed and affect the

post-treatment effect.

Transportaon: Transport to the post-processing area for safe storage to avoid

any damage and environmental polluon.

7.2 Preparaon before Cleaning

a) Disassemble the Lip Hook, File Clip and Contra Angle Holder and place them

in a stainless steel box.

b) Decontaminaon preparaon (Pre-cleaning)

Flush the Lip Hook, File Clip and Contra Angle Holder with running tap water

<40 ° C unl all visible residue is removed.

Refer to the contra-angle operaon manual for all operaons

regarding the contra-angle. Some preset files have automac parameters.

If such a file has been selected, the speed and torque value will display

“auto”.

auto

FK G preset

User

FKG

XP-endo Treatment

Shaper

Finisher

FKG

XP-endo Treatment

Shaper

Finisher

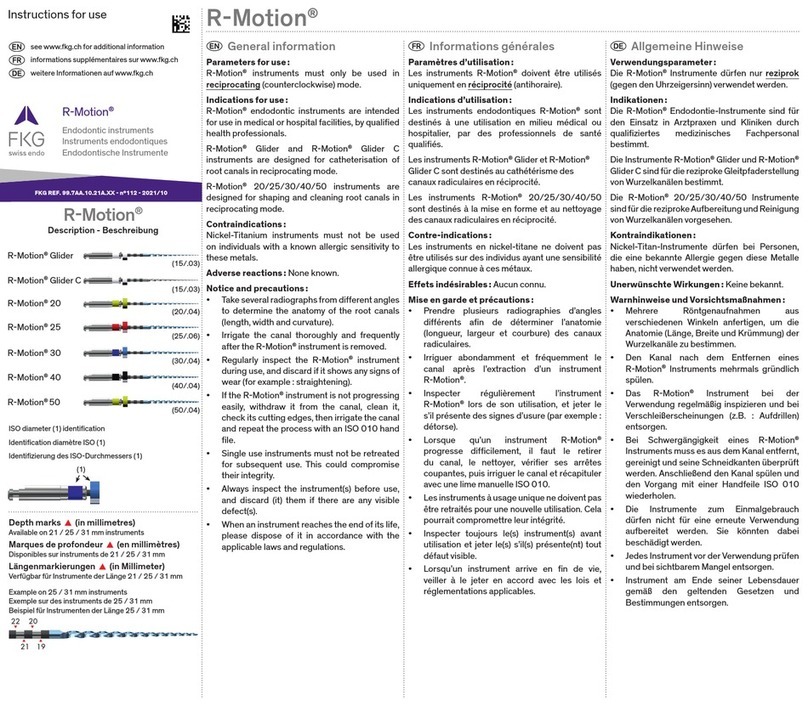

File systems libraries

The device contains libraries of file systems with preset parameters.

file systems library

The lighng device will connue to illuminate while the motor handpiece

Only in User file systems, press to change the motor direcon of rotaon.

handpiece

is running.

device

Change Motor direcon of rotaon

device

that the device is not operang properly. Please

handpiece,

reduced, the motor handpiece returns to normal forward rotaon automacally.

torque limit value torque limit value

Load beyond the

the motor is automacally

When the load is reduced,

restored

Rooter Universal

Software version XX X.X

again to enter seng interface.

to enter seng mode

c)

In User Recipro file system, torque cannot be changed.

In all FKG file systems, rotaon direcon, speed, torque and rotaon

angle cannot be changed. (fixed sengs)

1000 rpm

1.5 Ncm

1000 rpm

1.5 Ncm

Fig. H

motor handpiece.

Other manuals for Rooter Universal

1

Table of contents

Other FKG Dental Equipment manuals

Popular Dental Equipment manuals by other brands

Tecno-gaz

Tecno-gaz Kyri Instructions for use

KaVo

KaVo SMARTmatic PROPHY S31 Instructions for use

Ivoclar Vivadent

Ivoclar Vivadent Bluephase Style Instructions for use

B.A. International

B.A. International Optima BA60E Instructions for use

CEFLA

CEFLA VENUS PLUS Operator's manual

NSK

NSK Ti-Max nano65LS Operation manual