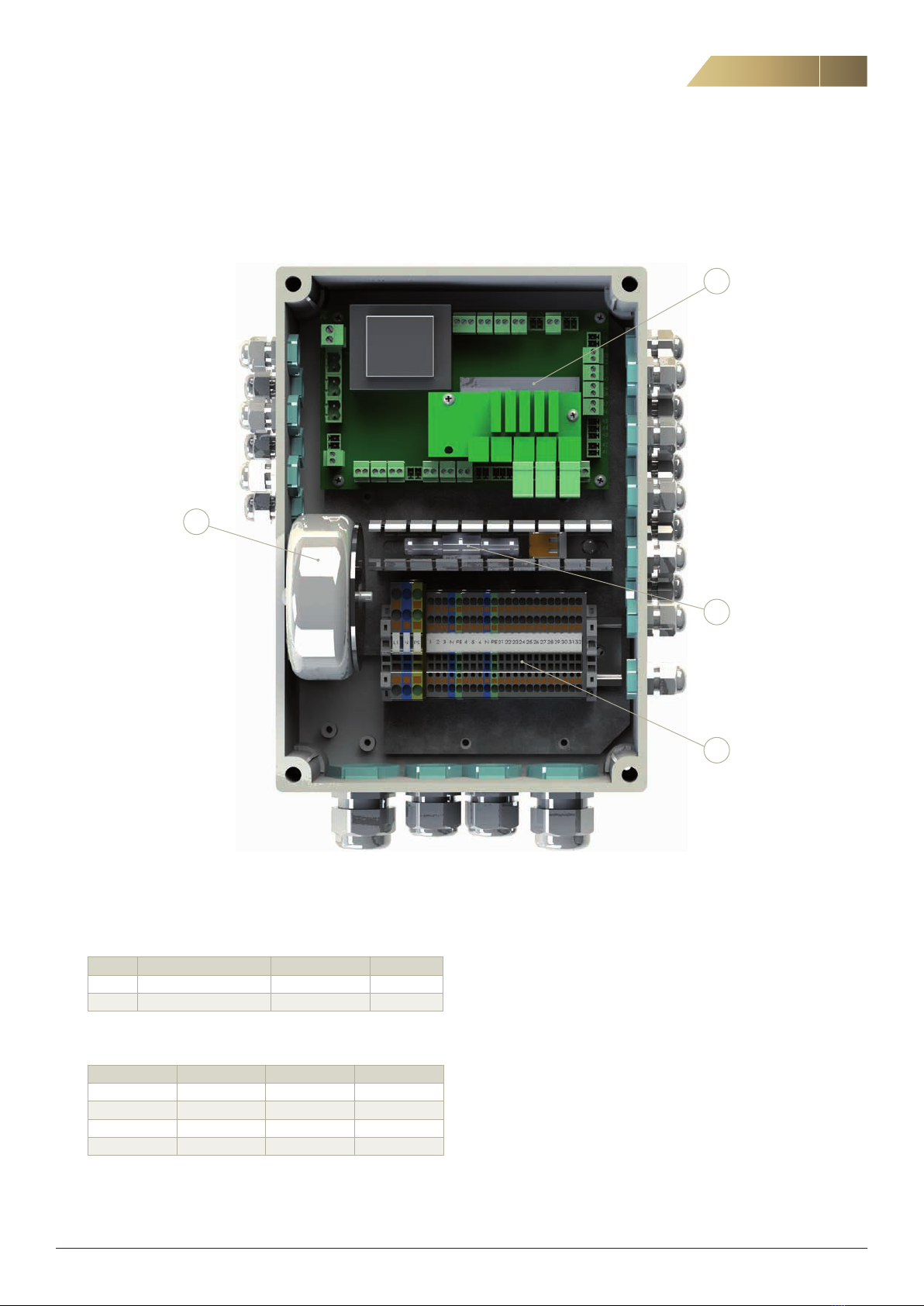

Supply air unit VEKC - Integrated Control Equipment Curo

5

FläktGroup DC_9965GB_20190124_R3 Specifications are subject to alteration without notice

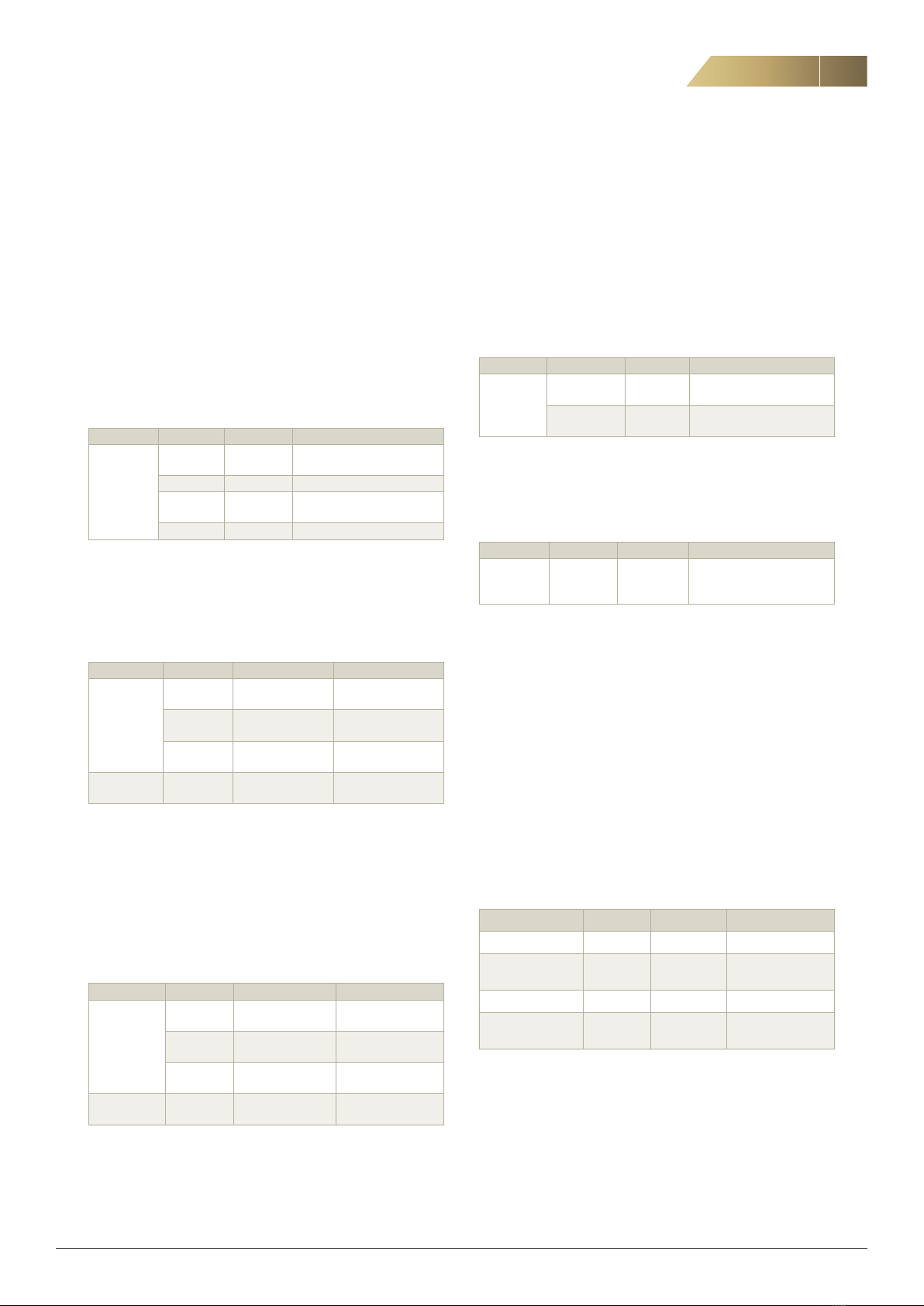

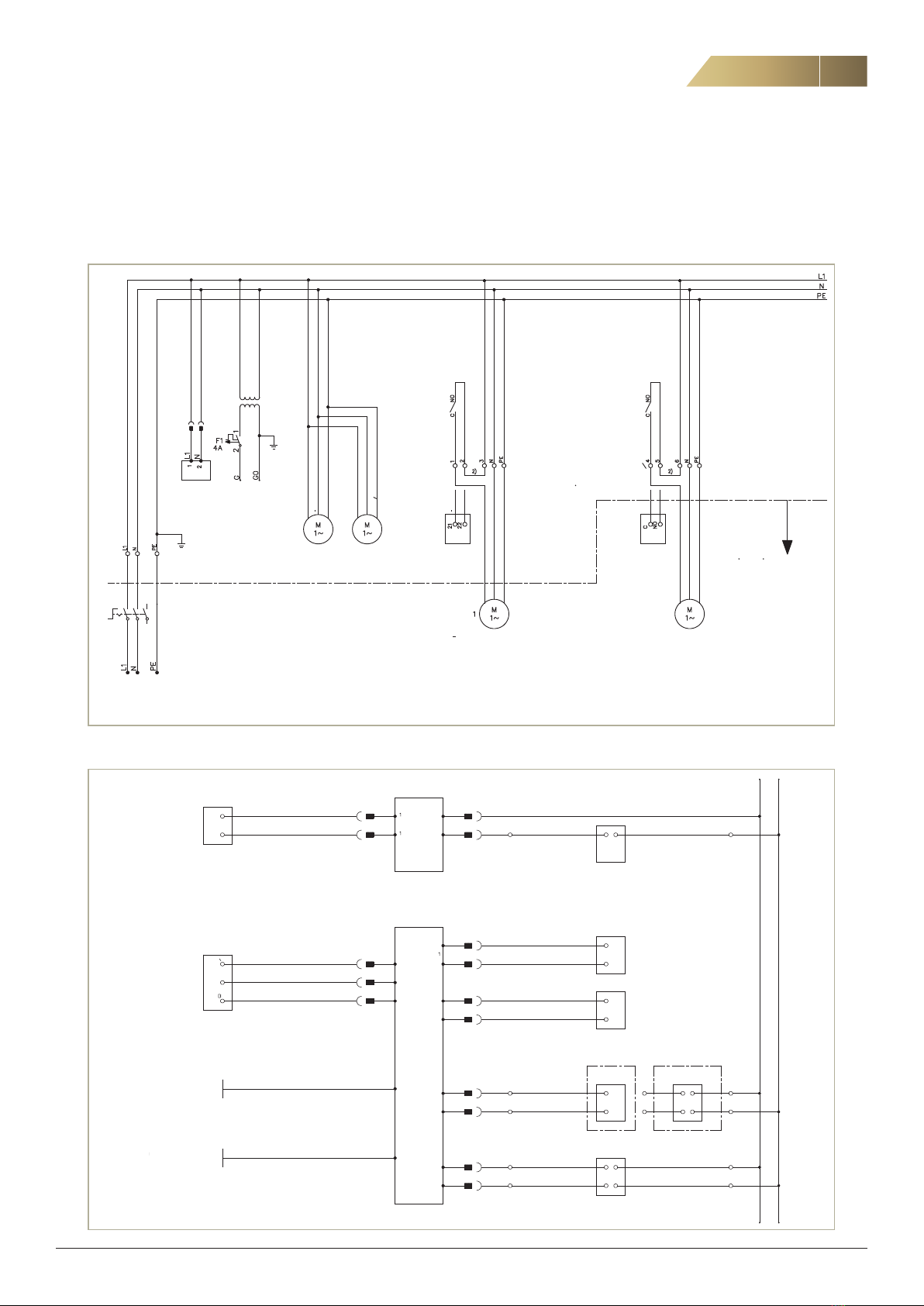

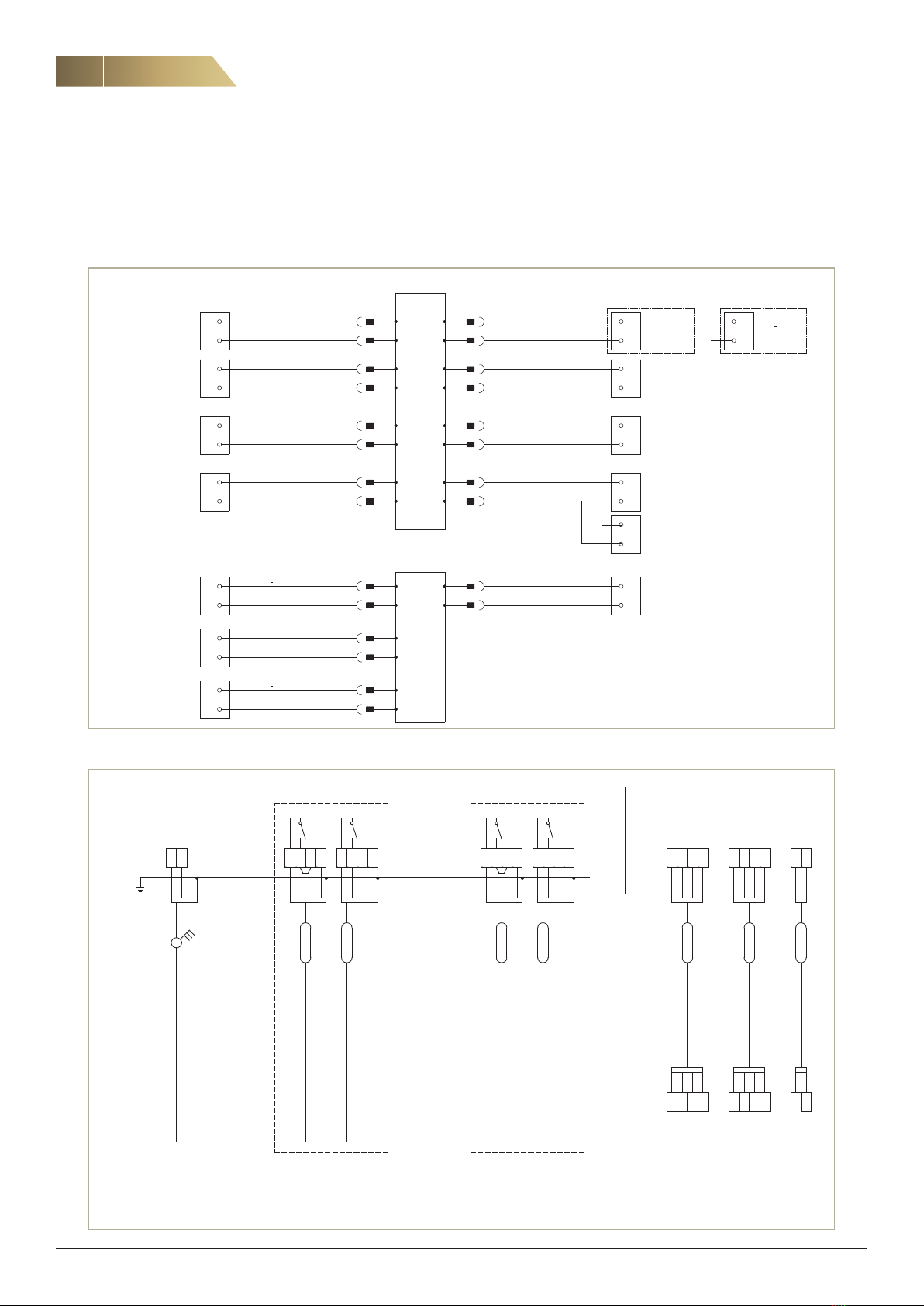

2.1 ELECTRICAL POST HEATER

Duct mounted. Separate supply 3 x 400V.

Connect alarm, start and control signal to the control box. The unit

is preconfigured for electrical post heater.

Component Designation Connection Remark

Electrical

heater

CP1/SK1

Heating

1 - 2

C - NO Start signal

ALM CP1 25 - 261) Alarm, overheating (NC)

SV1 CTRL 21 - 22

Y - M Control signal 0-10 V

Supply 3 x 400 V Not from the unit

1) Connects directly to the control board.

2.2 POST HEATER, HOT WATER

Circulation pump (CP1) and valve actuator (SV1) connects

according to table below.

Component Designation Connection Remark

Circulation

pump CP1

CP1/SK1

Heating 1 - N - PE Pump supply

(230 V max 2A2))

CP1/SK1

Heating

2 - 3

NO - L1

Loop only with cir-

culation pump

ALM CP1 25 - 261) Voltfree alarm input

(NO, configurable)

Valve

actuator SV1 SV1 CTRL 21 - 22 - 23 - 24

Y - M - G - GO

1)

Connects directly to the control board.

2)

The current consumption for CP1 and CP2 is limited to 2 A.

A separate safety switch for the pump is needed if it is a long

distance between the pump and the AHU.

2.3 COOLING COIL, WATER

Circulation pump (CP2) and valve actuator (SV2) connects

according to table below.

Component Designation Connection Remark

Circulation

pump CP2

CP2/DX

Cooling 4 - N - PE Pump supply

(230 V max 2A2))

CP2/DX

Cooling

5 - 6

NO - L1

Loop only with

circulation pump

ALM

CP2/DX 39 - 401) Voltfree alarm input

(NO, configurable)

Valve

actuator SV2 SV2 CTRL 25 - 26 - 27 - 28

Y - M - G - GO

1)

Connects directly to the control board.

2)

The current consumption for CP1 and CP2 is limited to 2 A.

A separate safety switch for the pump is needed if it is a long

distance between the pump and the AHU.

2. CONNECTION OF EXTERNAL COMPONENTS

2.4 COOLING COIL, DX

The unit can manage cooling DX, 1-step. Note that the coil is not

included in the delivery of the unit. For configuration see control

functions.

Component Designation Connection Remark

DX-cooling,

1-step

CP2/DX

Cooling

4 - 5

C - NO

Start: 10 %

Stop: 0 %

ALM CP2/DX 39 - 40 1) Voltfree alarm input (NO,

configurable)

1) Connects directly to the control board.

2.5 SPJÄLL

On/off actuator with spring return, 15 Nm, 24 VAC.

Component Designation Connection Remark

Damper ST1 29 - 30

G - GO

Exhaust air damper if used

is connected in parallel

(Maximum 2 dampers)

2.6 TEMPERATURE SENSORS

The unit is provided with:

Supply air sensor GT1, delivered separately. Duct mounting. Cable

not included.

Room temperature sensor GT2 (accessory) is supplied when the

unit is configured for room temperature control. The room sensor

is intended for wall mounting and needs to have good air circula-

tion and not direct sun light. Cable not included.

Outdoor air sensor GT3 (accessory) is supplied when the unit is

configured for outdoor air compensation. Duct mounting. Cable

not included.

Frost protection sensor GT5 is supplied when hot water coil is

used. Immersion sensor.

Component Designation Connection Remark

Supply air sensor GT1 46 - 471) Duct mounting

Room temperature

sensor GT2 50 - 511) Wall mounting

Outdoor air sensor GT3 48 - 491) Duct mounting

Frost protection

sensor GT5 52 - 531) Immersion sensor

1) Connects directly to the control board.

Use the control box on the outside of the unit to connect all exter-

nal accessories. For information about how to connect available

accessories see below.