flamco logoEco A2RXE Manual

GB

Technical information for installation and operation

LogoEco Heat Interface Unit (HIU) A2RXE

Instantaneous Hot Water & Space Heating

32

1. Operation 4

1.1 Space heating (SH) 4

1.2 Domestic hot water (DHW) 4

1.3 Priority switching 4

2. General Plumbing Requirements 5

2.1 British and Irish standards 5

сѵс $//$)")(*$ޔ/$*). ф

2.3 District heating 6

2.4 Space heating 6

2.5 Domestic water 7

2.6 Servicing 7

3. General Wiring Requirements 8

3.1 Danger of short circuit 8

4. Application 9

4.1 Status indicator LED 9

фѵ + $ޔ/$*) рп

5.1 Facts And Figures 11

6. Installation 12

7. Service 15

7.1 Filling the space heating system 15

7.2 Air venting the HIU 15

7.3 Room thermostat 17

7.4 Power supply 18

7.5 Commissioning 19

7.6 Removing and securing the case 20

7.7 Grundfos Pump 21

7.8 Performance viewview 21

7.9 Hot Water Circulation 22

цѵрп $Ȃ - )/+0(+(* . ст

7.11 Heat Meter 24

7.12 Troubleshoot (technician) 25

8. Appendix A 27

Appendix B 31

Appendix C 32

Contents Symbols and abbreviations

Symbols

Abbreviations

CAUTION, general safety remark

CAUTION, risk of shock

CAUTION, hot surfaces, risk of burns

CAUTION, hot water, risk of burns

Important note

Requirement of 230 Volt Alternating Current

Dispose component

Recycle component if possible

Wrench, manual tool

Drill, power tool

Manual operation, no tools needed

Philips Screwdriver

).0'/ ޕ/# .- 2-$1 -

DH District heating

SH Space Heating

DHW Domestic Hot Water

DCW Domestic Cold Water

VAC Volts Alternating Current

VDC Volts Direct Current

A Current in Ampere

N 230VAC Neutral

L 230VAC Live (phase)

PE Protective Earth

ºC Temperature in degrees

Celsius

kPa Pressure KiloPascal

kg Weight in Kilograms

mm Distance in millimetres

PN Pressure class in Bar

“ Thread size in inch (ISO

228/1)

HIU Heat Interface Unit

ABV Automatic Bypass Valve

230 V

insulated

54

1. Operation

1.1 Space heating (SH)

The heat exchanger physically separates the district heating network from the space heating circuit. The application

minimizes the risk of contamination of district heating water as well as the risk and consequences of leakage in the space

heating circuit. The electronic regulator in the unit, together with electronic control valves and temperature sensors

regulates the temperature of the space heating.

CAUTION!

Components, pipes and radiators in, and connected to, the unit may be hot. The heat interface unit is

designed for use with space heating systems up to 90ºC. The pipes and components in the unit as well as the

pipes and radiators in the space heating installation can reach these temperatures. Contact may lead to burns.

1.2 Domestic hot water (DHW)

The HIU is equipped with single wall plate heat exchangers. The heat exchanger transfers the heat from the heat

distribution system to the domestic hot water. The electronic controller in the unit, together with electronic control valves,

/ (+ -/0- . ).*-.)ޕ*2. ).*-- "0'/ ./# / (+ -/0- *!/# #*/2/ -/*$/.. /+*$)/җ !0'/фф٠Ҙѵ

The unit has two DHW keep hot modes – Eco or Comfort mode. The default setting is Eco mode and in this mode the heat

3#)" -$.& +/0+/*/ (+ -/0- !*-р#*0-ȅ -/# './#*/2/ --2*Ȃѵȅ -р#*0-*!$)/$1$/4/# / (+ -/0- $.

allowed to drop to minimize energy consumption. The comfort mode setting is optional and can be selected at the point

of commissioning. In this mode the heat exchanger is continuously kept warm for quicker hot water delivery. To prevent

' "$*) ''!-*("-*2$)"Ѷ/# # / 3#)" -$.# / /*фф٠ 1 -4су#*0-.!*-/' ./тп($)0/ .ѵ# )/# 0)$/$.ޔ//

with the optional DHW circulation pump, the unit must be set to comfort mode.

CAUTION! Hot water

The hot water temperature is regulated to 55ºC (default value). If there is a power outage during tapping

conditions the unit will stop regulating the domestic hot water temperature. This may lead to a domestic hot

water temperature that is higher or lower than its set point. Hot water can cause burns.

1.3 Priority switching

# $.ޔ// 2$/#+-$*-$/4.2$/#$)"ѵ# )#*/2/ -$.-2)*ȂѶ/# $1 -/.''/# ޕ*2/*# /0+/# *( ./$

water. If there is a power outage during tapping conditions or during a situation where there is no request for heat from the

(connected) thermostat, the space heating valve will stay in closed position. This may lead to a decrease in temperature of

the space heating installation/circuit.

# )$)./''$)"*(+' / '4) 2.4./ ($)) 20$'+-*+ -/4*-ޔ-.//$( $)./''/$*)$)) 3$./$)"+-*+ -/4Ѷ/# )

the heating system must conform to current building regulations Part L1a.

The appliance must be installed in accordance with, and comply to, the current: IEE Regulations, Building Regulations,

Building Standards (Scotland) (Consolidation), Building Regulations (Northern Ireland), local water by-laws, Health & Safety

Document 635 (The Electricity at Work Regulations 1989) and any other local requirements.

2.1 British and Irish standards

# - )*.+ $ޔ$)./-0/$*)$."$1 )Ѷ- ! - ) .#*0' ( /*/# - ' 1)/-$/$.#)ҝ*--$.#/)-* .*!

Practice.

BS7074:1 Code of practice for domestic and hot water supply

EN12828 Space heating for domestic premises

BS7593 Treatment of water in domestic hot water space heating systems

ECTI National rules for electrical installations

Keep following conditions in mind during installation:

• The HIU can only be used with closed heating systems up to a temperature of 90ºC.

• The HIU must be stored and installed in a frost free area.

• The HIU must not be exposed to direct sunlight.

• Ambient temperature must be between +5ºC and +40ºC.

• Humidity must be between 20% and 80%.

• Temperatures of components in the HIU and connected to the HIU can reach high temperatures. Contact may lead

to burns.

сѵс$//$)")(*$ޔ/$*).

Fitting the appliance and any controls to the appliance may only be carried out by a competent engineer. Any misuse or

0)0/#*-$. (*$ޔ/$*)./*/# ++'$) *-..*$/ *(+*) )/.).4./ (.*0'$)1'$/ /# "0-)/ )

may lead to serious injury or even death. The manufacturer accepts no liability arising from any such actions, excluding

statutory rights.

2. General Plumbing Requirements

76

2.3 District heating

CAUTION!

Components, pipes and radiators in, and connected to, the unit may be hot. The heat interface unit is designed

for use with centralized heating systems up to 90ºC. The pipes and components in the HIU as well as the pipes

and radiators in the space heating installation can reach these temperatures. Contact may lead to burns.

Keep following conditions in mind during installation:

• Maximum pressure supplied by the district heating network is 16 bar.

• 3$(0($Ȃ - )/$'+- ..0- .0++'$ 4/# $./-$/# /$)") /2*-&$.сфп&ѵ

җуфп&2# )$Ȃ - )/$'- ..0- *)/-*''1 җҘ$.ޔ// Ҙ

• Maximum supplied temperature by the district heating network is 90ºC.

• Minimal supply temperature is set-point DHW + 5ºC.

2.4 Space heating (SH)

!*- /# $.*(($..$*) Ѷ/# $-0$/(0./ ޔ// 2$/#)0/*(/$4Ҋ+..1'1 /*($)/$)($)$('ޕ*2

-/ *1 -/# ѵ# 1'1 (0./ $)./'' /2 )/# .0++'4)- /0-)Ѷ)*/$)"/# $- /$*)*!ޕ*2ѵ

*-*+/$(' ) -"4 Ȃ$$ )4)*(!*-/Ѷ$/$.*!/# 0/(*./$(+*-/)//*#4-0'$''4') /# $-0$/*-- /'4ѵ

For the same purpose it is advised to design the SH circuit in such a way, that the SH return temperatures are as low as

possible.

Keep following condition in mind during installation:

• -/$ޔ$''4.*ȅ ) 2/ -(0./)*/ 0. /*ޔ''/# .+ # /$)".4./ (

2. General Plumbing Requirements

ABV

Space heating

2.5 Domestic water (DHW)

The DHW circulation pump is an available option within the HIU. The circulation system, connected to the HIU, must not

*)/$))4'*.' 1'1 .*-*./-0/$*)./* ).0- /#/*)/$)0*0.ޕ*22$'''24. +*..$' ѵ++'4$)"1'1 ./*/#

.4./ ()0. +0(+!$'0- 0 /*$).0Ȃ$$ )/ޕ*2ѵ

Keep following condition in mind during installation:

• Maximum pressure supplied by the domestic water circuit is 10 bar.

• ''. '.Ѷ%*$)/.)*(+*0).җ$)'0$)"ޕ03).*' -Ҙ)*(+*) )/.0. .+-/*!/# . *)-4*( ./$

water system must be approved by WRAS.

2.6 Servicing

The end user should be advised to have the system serviced annually by a competent engineer. Contact your supplier for

a list of approved engineers. Approved spares must be used to help maintain the economy, safety and reliability of the

++'$) ѵ# . -1$ )"$) -(0./*(+' / /# -1$ *-ȅ - #. -1$ ѵ

2. General Plumbing Requirements

DHW circulation circuit

98

These instructions apply in the UK and Ireland only and must be followed except for any statutory obligations. Component

.+ $ޔ ' /-$'$)!*-(/$*)(4'.* .0++'$ $).0++*-/*!/# . $)./-0/$*).ѵ

FAILURE TO INSTALL APPLIANCES CORRECTLY COULD LEAD TO PROSECUTION.

CAUTION!

Isolate the mains supply before starting any work and observe all relevant safety precautions. The HIU uses

electrical components (230VAC and 24VDC). These components must stay dry at all times. Touching these

components can result in an electrical shock, burn, or electrocution.

When the HIU is permanently connected to the 230VAC installation, a switch or circuit-breaker must be

included in the installation as the means for disconnection. The switch of circuit-breaker must be suitably

located next to the appliance and easily reached. The switch of circuit-breaker must be marked as the

disconnecting device for the equipment.

CAUTION!

The HIU mains supply must always be connected to a residual current circuit breaker with overcurrent

protection (RCBO) that combines the functionality of a RCD and MCB, breaking the circuit on either incorrect

current or overcurrent. The circuit breaker must have a contact separation of at least 3mm in all poles and

should isolate the appliance and all associated controls. The HIU must, at all times, be connected to the

protective earth of the installation.

3.1 Danger of short circuit

When connecting the cables ensure that no cable pieces fall inside the control panel. Unless otherwise stated, all HIU’s

should be connected to a mains 230V 50Hz Supply fused at 3 Amps. All electrical connections with the HIU control panel are

clearly marked as follows:

L = Live 230V

N = Neutral

E = Earth

PE = Protective Earth

Any additional mains cable should comply fully with the current I.E.E. wiring regulations. It must have a minimum section of

1.5mm2and be capable of withstanding a minimum of 90ºC.

3. General Wiring Requirements

The HIU A2RXE is used to provide domestic hot water and space heating in residences connected to a district heating

system.

4.1 Status indicator LED

Green blinking slow (1x per second): Stand-by condition (no SH heat demand)

Green blinking fast (2x per second): Heating condition (CH heat demand)

Blue blinking: Tapping condition

Red blinking: Error mode

White continuous: Service mode (installer only)

*ѷ *+*2 -ҝ.2$/# *Ȃ

4. Application

Status indicator LED

11рп

фѵ+ $ޔ/$*)

24

23

H

∑

1

11

20

2

3

4

5

6

7

8

9

10

12

13 14 15

16

17

18

19 21

22

25 26

27

28

29

30

A

B

E

D

C

F

G

1 Strainer

2 Flow temperature Sensor (primary)

3 Flow temperature Sensor (heat meter)

у ./+*$)/җ+-$(-4Ѷޕ*2Ҙ

5 Test point (primary, return)

х +**'+$ җ*-.#0/*Ȃ1'1 Ҙ

7 Heat meter

8 Control valve (DHW)

9 Control valve (SH)

10 Plate heat exchanger (DHW)

11 Return Temperature Sensor (primary,

DHW)

12 Plate heat exchanger (SH)

13 Return Temperature Sensor (primary, SH)

14 Over pressure relief valve (3 bar)

рф (+ -/0- ҝ- ..0- "0" җޔ-./ޔ3-$'Ҙ

16 Automatic bleed point

17 Expansion vessel

18 Bleed point

19 Water hammer arrestor

20 Temperature sensor (DHW)

21 Flow sensor

22 Non return valve

23 Non return valve (hot water return,

optional)

24 Circulation pump (DHW, optional)

25 Circulation pump (SH)

26 Temperature/Pressure sensor

27 Drain point

28 Strainer

29 Controller

30 Power supply (mains connection)

-$(-4ޕ*2

B Primary return

C Cold water mains

D Domestic hot water (DHW)

*)-4ޕ*2җҘ

F Secondary return (SH)

G Over pressure relief pipe

H Hot water return (optional)

18 1 2316 30 29

12

10

25

14

28

27

21

11

13

8

9

7

17

6

AB

C

D

EF

G

5.1 Facts And Figures

фѵ+ $ޔ/$*).

Δp3

Δp2

Δp1

t31

t32

t12

t11 t22

t21

q1

q3

q2

DH

DHW

SH

∆p

q

t

P

= District Heating

= Domestic Hot Water

= Space Heating

= Differential Pressure (kPa)

= Flow Rate (l/s)

= Temperature (ºC)

= Power (kW)

Secondary (SH)

Secondary (DHW)

Primary (DH)

P3

P2

P1

Description Type District heating station for indirect heating and instantaneous domestic hot water

Mounting Wall mounted

Dimensions 490 x 275 x 640 mm (WxDxH, height of the case)

Heating System с+$+ ޕ*2

Construction Pipework *++ -+$+ 2$/#-..ޔ//$)".

Heat exchangers Stainless steel, copper brazed

Casing Foam Arpro 50g / White painted metal sheet banding

Primary Fluid Low pressure hot water

Secondary Fluid - Heating Low pressure hot water

Secondary Fluid - Domestic Hot Water Potable hot water service

Primary Duty

$)ѵҝ3ѵޕ*2/ (+ -/0- җ/ррҘ 65ºC / 90ºC

*($)'ޕ*2/ (+ -/0- җ/ррҘ 75ºC

'*2-/ җ,рѶ/)*($)'ޕ*2/ (+ -/0- Ҙ 0.267 l/s (960 l/h) at max. output

Pressure rating PN 16

$)ѵ$Ȃ - )/$'+- ..0- җɂ+рҘ фп&җпѵф-ҘѶ/)*($)'+-$(-4ޕ*2/ (+ -/0-

3ѵ$Ȃ - )/$'+- ..0- җɂ+рҘ 250 kPa (2.5 bar), or 450 kPa (4.5 bar) with additional DPCV

Cold Water Mains $)ѵҗ(3ѵҘ+- ..0- җɂ+тҘ 1 bar (PN 10)

Secondary Duty

Domestic Hot Water Nominal Heat Transfer Capacity (P3) 63 kW

3ѵޕ*2-/ җ,тҘ 20 l/min (0.333 l/s)

Fluid Temperature in (t31) 10ºC

Fluid Temperature out (t32) 55ºC

Duty (secondary) Heating Heat Transfer Capacity (P2) рч&ҽтпɂҗрп&ҽспɂҘѶ/)*($)'+-$(-4ޕ*2/ (+ -/0-

'0$ (+ -/0- ޕ*2җ/ссҘ ' /' ѷуп٠ѵѵѵцп٠җ/)*($)'+-$(-4ޕ*2/ (+ -/0- Ҙ

Fluid Temperature return (t21) Depending on radiators and setup

Maximum secondary pressure PN10 (restricted to 3 bar by over pressure relief valve)

Connections All external connections ¾”

Primary & Secondary Fittings Primary control valves Control valve with electronic stepper motor

Strainer )+-$(-4ޕ*2). *)-4- /0-)

Heat Meter - ޔ// Ҋ*..2 $) - /*)$Ѷ// -4+*2 - ѶҊ0.$)/ -!

Circulation Pump Grundfos UPM3 AUTO 15-70 130

Expansion Vessel ч'$/- ޔ// $). *)-4$-0$/

Overpressure relief valve 3 bar, in secondary heating circuit

#0/*Ȃ1'1 җ*+/$*)'Ҙ #0/*Ȃ1'1 !*-+- Ҋ+4( )/.4./ (.җстпۡѶфп5Ҙ

DPCV (optional) $Ȃ - )/$'+- ..0- *)/-*'1'1 җуфп&(3ѵ+Ҙ

Hot water return (optional) Hot water circulation (incl. pump, non return valve and ball valve)

1312

6. Installation

Connections

Additional items required

Additional Items (optional) Flushing By-Pass

500 mm

3/4”

10 bar max. 110ºC

16 bar, max. 100ºC

-$(-4ޕ*2

B Primary return

C Cold water mains

D Domestic hot water (DHW)

*)-4ޕ*2җ+ # /$)"Ҙ

F Secondary return (Space heating)

G Over pressure relief pipe*

* 15mm copper pipe

First Fix Rail6x

2x

465

435

20 20

13

230

248

Positioning

Preparation - First Fix Rail (FFR)

Mounting to the wall

The wall needs to be strong enough to

support the HIU. If the wall is of drywall

construction make sure that there is a board

installed (e.g. plywood, min. 18mm) to

support the structure, which is strong enough

to hold the HIU. Use a 4mm drill bit (at least

40mm depth for the wall plugs).

If the wall is of concrete or brick construction

use a 10mm drill bit (at least 60mm depth for

the wall plugs).

# - ,0$- .сޔ3$)".- 2.Ѷ/#

- ,0$- .уޔ3$)".- 2.ѵ

Flushing the system

Before mounting the HIU and connecting it to

the FFR all pipework that is to be connected

(0./ /#*-*0"#'4' ) )ޕ0.#

*0/ѵ)4 -$.*-ޕ03/#/*0'*'' /$)

the narrow channels of the heat exchangers

2$'' $Ȃ$0'//*- (*1 *) /# 4-

$)./'' ѵ)4- ($)$)" -$.)ޕ03(4

cause serious corrosion problems, as well as

- ./-$/$)"ޕ*2)- 0$)"/# Ȃ$$ )4*!

/# ѵ. /# ޕ0.#$)"4Ҋ+..җ*+/$*)'

accessory) and connect it to the FFR (A-B).

6. Installation

55 80 60 60 120 60 45

490 275

819

640

55

45

601206060404055

ABEF

ABEFDC

DC

1514

6x

465

4

35

2

0

20

1

3

230

2

4

8

Ø

8

Ø

8

(*1 /# ޕ0.#$)"4Ҋ+..

before installing the HIU.

Over pressure relief pipe (G)

Over pressure relief pipe is a 15mm

*++ -+$+ ѵ' . 0. .0$/' ޔ//$)".

/ systems to make the connection with

the drain pipe.

6. Installation

Installation

Pressure Gauge

7.1 Filling the SH

7. Service

# ) ޔ'' 4*)) /$)") 3/ -)'.0++'4

/#-*0"#/# ޔ''ҝ-$)1'1 $)/# 0)$/ѵ

CAUTION!

Please use caution when handling the HIU.

Parts and components may be hot or energized.

Contact may lead to shock, burn or electrocution.

1. Disconnect the HIU from the mains power.

2. Open all space heating circuits in the property. Turn

the room thermostat and all radiator thermostats to

their maximum setting. (or switch on all underfoor

heating circuits).

3. Remove the case from the unit as described in

chapter 7.6

4. *)) //# ޔ''$)"#*. ҝ'**+/*/# 1'1 ..#*2)ѵ

5. - !0''4*+ )/# 1'1 )./-/ޔ''$)"/# .4./ (ѵ

Observe for leaks during the process.

6. #0//# 1'1 *) /# .4./ ($.ޔ'' ѵ

7. Bleed the air from the system (HIU and radiators).

Please refer to chapter 7.2.

8. Repeat 6. and 7. until all air is removed and the

.4./ ($.+- ..0-$. *-$)"/*/# .+ $ޔ/$*).ѵ

1716

All air has to be removed from the system to ensure full functionality of the SH. Bleeding the air can be either manually (1)

or automatically (2). Also all SH circuits have to be bled to make sure all air is removed.

CAUTION!

Please use caution when handling the

HIU. Parts and components may be hot or

energized. Contact may lead to shock, burn

or electrocution.

1. Disconnect the HIU from the mains

power.

2. Make sure the isolating valves (E, F) are

fully opened.

3. Start bleeding the SH circuits at the

/*+ޕ**-)2*-&/# 24*2)ѵ

4. Set the pump to maximum speed. The

pump should run quietly without any

air noise.

5. # )ޔ)$.# - Ҋ%0.//# +0(+/*

its operating mode/setting.

0$&ޔ''$)"*+/$*)ѷ

# )ޔ''$)"/# .4./ (/0-)/# - #)' *!

the automatic air vent anti-clockwise. Turn on

the circulation pump and let it run until all air

$.- (*1 ѵ.*'/ /# ޔ''$)"'**+Ѷ- Ҋ%0./

the pump setting and close the automatic air

vent by turning it clockwise.

7.2 Bleeding the air

7. Service

7.3 Call for Space Heating (SH)

The unit can be connected to a room thermostat or a timer/heating

controller.

The output of either of the devices needs to be a voltage-free contact

(open/close). Please refer to the manual of the manufacturer of the

appliance to avoid damage of the HIU’s electronics.

Connecting a room thermostat or controller/timer:

1. Remove the terminal block (1)

2. Connect the two wires to the voltage-free output of the

thermostat/timer/controller.

7. Service

12

1

1918

The HIU is equipped with an electric connection box that converts the 230VAC

power supply to 24 VDC and powers the equipped SH pump and optional

DHW pump. It also houses the fuse of the unit.

CAUTION!

The HIU uses electrical component (230VAC and 24VDC). Touching these

components can result in an electrical shock, burn, or electrocution. The

casing shall only be opened by authorised personnel when the power supply

$.0/*Ȃѵ

1. 230VAC fuse (3A)

2. 230VAC connection to circuit breaker or power switch

3. 230VAC DHW circulation pump connection

4. 230VAC SH pump connection

5. 24VDC connection to electronic regulator PCB

6. LED status indicator pump relay (ON = SH pump active)

7. LED status indicator 24V (ON = 24V directed to regulator PCB)

8. WAGO connector, connecting all protective earth cables

7.4 Power supply

7. Service

1

2

3

4

5

67

8

insulated

230 V

230 V

Cable colours

The electronics housing is separated into a 230VAC area

and a 24VDC area. By default the following cable colours

are used:

CAUTION!

230VAC area

- Live 230VAC Brown

- Neutral Blue

- Protective earth Green/Yellow

24VDC area

- 24VDC Black

- Ground Brown

- Signal wire Grey

7.5 Commissioning

Follow the steps shown below to commission the HIU. If leakage or other faults should occur, go to chapter “Troubleshoot”.

7. Service

CAUTION!

Parts and components may be hot or energized.

Contact may lead to shock, burn or electrocution.

1. Close all valves

2. Check all nuts for leakage. (nuts may become loose

during transport)

3. Make sure the electronics are securely mounted to

the frame and avoid cables from blocking the casing.

4. Make sure that the power supply is switched

*Ȃѵ*)) //# 0)$/ҁ.+*2 -' .җрҘ/*/#

power switch. +/# +*2 -.2$/#*ȂѶ0)/$'

further notice below. The power switch must be

permanently connected, suitably located and easily

reached. Also see chapter “Installation requirements”

Blue cable: N (neutral)

Brown cable: L (Live 230VAC)

Green/yellow: PE (protective earth)

5. Open the domestic potable water valves (D&C) to

pressurise the unit and check for leakage.

6. Switch on the power to the unit. The LED should

show a green blinking light (2).

7. Open the DH valve (A) and check for leakage.

8. Open the DH return valve (B) and check for leakage.

9. Open the valve (E).

10. Open the SH return valve (F).

11. /-/' $)"/# $-0$/.//# /*+ޕ**-)

work the way down. (see also chapter “Bleeding the

air”)

12. Check to see if the heating warms up.

13. It is possible to set the pump setting to optimise the

SH system. See chapter “Pump settings”.

14. Completely open a DHW outlet (tap or shower).

Check to see if the unit’s LED shows a blue blinking

light (2).

Leave it running for approximately 5 minutes.

Check if the DHW temperature has reached its set

point (default 55ºC) between 3 and 5 minutes.

15. Close all DHW outlets. The LED will now show a

green blinking light (2).

1

2

Status Indicator LED

ABE

F

DC

21сп

The case of the HIU is secured by the mounting bracket of the heat meter display and a screw through the top of the HIU.

1. Mount the display of the heat meter (if needed) to the bracket.

2. Position the bracket as shown (1) and make sure all cables are routed through the case and are tidy.

3. & .0- /#/-& /). - $)'$) /*ޔ//# . 0-$)".- 2җсҘѵ

7.6 Removing and securing the case

7. Service

1

2

7.7 Grundfos pump

The Grundfos pump has 3 control modes (proportional pressure, constant pressure and constant curve). Each control

mode has 4 settings to choose from. The user interface has one push button, one red/green LED and four yellow LEDs.

7.8 Performance view

#$' /# +0(+$.-0))$)"Ѷ/# ޔ-./2$''.#*2"- )'$"#/ѵ# !*''*2$)"!*0-ҁ.2$''$)$/ /# +*2 -

consumption as shown in the table below.

Settings

You can choose between the performance view and settings

view. If you press the push button for 2 to 10 seconds, the

user interface switches to “select selection” if the user

interface is unlocked. You can change the settings as they

appear. The settings appear in a particular order in a closed

loop. When you release the button, the user interface

switches back to the performance view and the last setting

is stored.

7. Service

Stand-by (only externally controlled) 0%

Low performance 0 - 25%

Medium performance 25 - 50%

Medium High performance 50 - 70%

High performance 70 - 100%

PROP.PRESS.:CURVE 1

PROP.PRESS.:CURVE 2

PROP.PRESS.:CURVE 3

PROP.PRESS.:AUTO ADAPT

CONST.PRESS.:CURVE 1

CONST.PRESS.:CURVE 2

CONST.PRESS.:CURVE 3

CONST.PRESS.:AUTO ADAPT

CONST.CURVE.:CURVE 1

CONST.CURVE.:CURVE 2

CONST.CURVE.:CURVE 3

CONST.CURVE.:CURVE 4

SETTING OPTIONS

2322

7.9 Hot Water Circulation

The domestic hot water circulation pump is an available option within the unit. The

pump is added to minimize delay in the delivery of domestic hot water at the draw

*Ȃ+*$)/$)'*. $-0'/$*)$-0$/ѵ/$." ) -''40. $).4./ (.2# - /#

*( ./$#*/2/ -) ./*/-1 '"- / -$./) ./*$/.-2*Ȃ+*$)/ѵ

Adjustments to the pump settings should be done by authorised personnel only.

Please use caution when adjusting the unit. Parts can be hot or energized. Contact

may lead to shock, burn or electrocution.

Status indicator LED

LED on (continuously): Normal operation (pump is running)

LED blinking short, long: Error due to low voltage

LED blinking short (4x), long:Error due to pump speed feedback

LED blinking short (3x), long:Error due to high temperature

LED blinking short (5x), long:Pump rotor is blocked

)спп(. ѵѶȂспп $-1 )/$)"

msec., On 200 msec.

)фп(. ѵѶȂфп /)Ҋ4

msec., On 50 msec.

Operation errors

Air bleeding the pump

The pump has an air venting function that can be activated by turning the dial to position 7

!*-ф. *).ѵȅ -2-./# .$- +*.$/$*)) #*. )ѵ# +-* 0- 2$''/& *0/

10 minutes. The procedure can be cancelled by switching to position 3 and then back to

+*.$/$*)цѵ0$' ޕ*2)*$. .$)$/ /#//# - $../$''$-$)/# +0(+ѵ#*0'/#$. /#

case the air bleeding procedure needs to be repeated.

Problem Cause Solution

Pump not running - Not connected or connected correctly - Connect correctly

- Pump too hot, dry operation- or overheating protection active - Allow pump to cool down, pump restarts automatically

- Pump blocked - Contact your supplier

Pump is noisy - Air in the system - Bleed the air

- Debris in pump - Contact your supplier

- Worn bearing - Replace pump

Pump settings

# $-0'/$*)+0(+#.ц. //$)"./*#**. !-*(/**((*/ $Ȃ - )/.$/0/$*).Ѷ

position 1 being the lowest and 7 the highest setting.

7. Service

LED indicator

max.

min.

цѵрп$Ȃ - )/$'- ..0- *)/-*''1

*-.4./ (.2$/#$Ȃ - )/$'+- ..0- 3 $)"сфп&җ2$/#(3$(0(*!

уфп&ҘѶ/# *+/$*)*!!/*-4ޔ// %0./' $Ȃ - )/$'+- ..0- *)/-*'1'1 $.

1$'' ѵ# $Ȃ - )/$'+- ..0- *)/-*'1'1 #.*)/-*'-)" *!сп/*хп&

)#.сп*- ѵ*-*+/$('!0)/$*)$)"*!/# Ѷ/# %0./' $Ȃ - )/$'

pressure control valve is set at its maximum of 60 kPa (default setting).

Adjustments to the valve settings should be done by authorised personnel only.

Please use caution when adjusting the unit. Parts can be hot or energized. Contact

may lead to shock, burn or electrocution.

The valve is easily set by means of a 4 mm allen key. The maximum setting of 60 kPa is reached by turning the hexagonal

key clockwise. The number of turns needed to adjust the valve to its maximum setting depends on what the current setting

is. The maximum number of turns is 20, running from its minimum to maximum setting.

7. Service

Higher

dierential

pressure

Lower

dierential

pressure

HEX 4 mm

2524

7.11 Heat Meter

# Ҁ.!/*-4ޔ// # /( / -$.)'..сҗ -/$ޔ ҘѶ// -4+*2 - 0'/-.*)$# /( / -2$/#Ҋ0.

functionality. You can scroll through the menu by shortly pressing the black button next to the display. The serial number (8

digit number) can be found as shown in the picture.

7. Service

6 RAM40 1234 5678

Heat Meter

Quick Mode

Type 775

0102

LCD Loop3: Installation

Class 2

E2 / M2

IP 54

The Table shows the list of error codes which might be

shown on the display. “E-7“ is the general error that is

.#*2)2# )/# #.)*/ )ޔ'' җ$-$)ޕ*2. ).*-Ҙѵ

*-!0-/# -$)!*-(/$*)+' . - ! -/*/# ' ޕ /*!/# # /( / -җ)./''/$*)0$ Ҙ.0++'$ 2$/#/# *-- ! -/*/#

comprehensive manual for the heat meter.

Error code Description

C -1 .$+-( / - --*-$)ޕ.#*-

E1 Temperature range exceeded [-19.9 °C ... 199.9 °C] e.g. sensor

cable short circuit

E 3 ** Flow and return sensors inverted/confused

E4 Hardware fault in ultrasonic unit, e.g. transducer or trigger

faulty or short circuit

E5 Reading interval too short. No communication possible.

E 6 ** -*)"ޕ*2$- /$*)җޕ*2. ).*-Ҙ

E7 ) / -($) ޕ*2. ).*-- $)"җ$-Ѷ -$.Ҙ

E8 No (mains) power supply, running on the backup battery

E9 Battery discharged

E A* Leakage, broken pipe

Eb * Leakage, heat meter

EC * Leakage, pulse input 1

Ed * Leakage, pulse input 2

* optional, ** application dependent

7.12 Troubleshoot (technician)

7. Service

Complaint LED indication light Cause Solution

Leakage

'*. ''1'1 .*)/# ޔ3-$')'*. /# ($)2/ -.0++'41'1 ѵ

Coupling nut shows leakage Coupling nut is loose Fasten coupling nut

Gasket is missing Replace gasket

Temperature sensor shows leakage O ring is missing Fit original

O ring is damaged Replace original

# $Ȃ - )/$'+- ..0- +$+ !-*(/#

$Ȃ - )/$'+- ..0- - "0'/*-$.' &$)"

Coupling is loose ./ )/# ޔ//$)"

$Ȃ - )/$'+- ..0- +$+ $.(" +' $Ȃ - )/$'+- ..0- +$+

Space heating does not warm up

Radiator does not warm up LED does not light up No power at power source Check power source

Unit is not connected to power source Connect the unit to the power supply

Power cables not properly connected to

electronic regulator

Connect the power cables to the electronic

regulator

Fuse is broken Check for any short-circuit problems and

replace fuse (3A)

Failure in the electronics Contact your supplier

'0 ޕ.#$)" Tap is opened, unit is in tapping operation Close Tap

ޕ.#$)" Sensor(s) are not connected or bad contact Check wire tree connections and connect the

sensors properly, then restart electronics

Sensor(s) defect Replace broken sensor and restart electronics

Possibly faulty electronic cables or electronics Contact your supplier

#$/ ޕ.#$)" Unit is in service mode Remove USB cable

Reset the unit by removing and then

reconnecting the power supply

No heating demand from the room thermostat Set the room thermostat to a higher

temperature than the actual room temperature

Radiator valves are closed Open radiator valves

'1 .$)ޔ-./ޔ3-$'- '*. + )1'1 .*)ޔ-./ޔ3-$'

Thermostat cable not properly connected to

room thermostat

Make sure the room thermostat is connected

properly

Short circuit connector of the room thermostat

is not connected or missing (when HIU is not

connected to room thermostat)

Connect the wire ends of the room thermostat

connection cable with a short circuit connector

Air in the SH system Air vent the HIU and the SH system

Pressure in SH circuit is too low Set SH pressure to 2 bar. This might indicate a

leakage in the SH system or a broken expansion

vessel. Check SH system for any leakages and

expansion vessel

Pressure or temperature of the DH system are

)*/$)*-) 2$/#.+ $ޔ/$*).

Check temperature and pressure of the DH

system

The SH pump is not active (LED on pump does

not light up)

Check if the pump cable is properly connected

to the electronics

The SH pump is jammed or broken Contact your supplier

Optional anti-fraud valve is closed Anti-fraud valve is not electrically connected or

powered

Anti-fraud valve is jammed or broken. Replace

this component

+/$*)'$Ȃ - )/$'+- ..0- 1'1 $.+**-'4

adjusted

%0.//# $Ȃ - )/$'+- ..0- 1'1 *-- /'4

Filters are blocked # &)' )ޔ'/ -.

SH heat exchanger is blocked Replace SH heat exchanger

Cables of the control valves are mixed up Connect cables properly. Orange/red connector

must be connected to the SH control valve

Possible defect in control valve Replace control valve

2726

7.12 Troubleshoot (technician)

7. Service

Complaint LED indication light Cause Solution

No DHW

No DHW No water pressure Check/open main water supply valve

# &ޕ*2- ./-$/*-!*-*-- /)+-*+ -

placement

Flow restrictor is clogged or jammed. Replace

ޕ*2- ./-$/*-

'*2. ).*-$.'*"" ѵ +' ޕ*2. ).*-

DHW heat exchanger is clogged. Replace DHW

heat exchanger

Check valve is jammed. Replace check valve

housing including the check valve

DHW not at the right temperature

DHW does not warm up LED does not light up HIU is not connected to power source Connect the HIU to the power supply

No power at power source Check power source

Power cables not properly connected to

electronic regulator

Connect the power cables to the electronic

regulator

Fuse is broken Check for any short-circuit problems and

replace fuse (3A)

Failure in electronics Contact your supplier

- )ޕ.#$)" Tapping threshold is to low, minimal 1 L/min.

has not been reached

Increase tapping to at least 2 L/min. by opening

the tap further

Flow sensor is not installed correctly # &ޕ*2. ).*-Ѷ- +' ' *-- +'

ޕ*2. ).*-

ޕ.#$)" Sensor(s) are not connected or lose contact Check loom connections and connect the

sensors properly, then restart electronics

Sensor(s) defect Replace broken sensor and restart electronics

Possible defect electronic cables or electronics Contact your supplier

Supply and return valves are closed Open supply and return valves

Pressure or temperature of the DH system are

)*/$)*-) 2$/#.+ $ޔ/$*).

Check temperature and pressure of the DH

system

Filter is clogged # &)' )ޔ'/ -

DHW heat exchanger is clogged Replace DHW heat exchanger

Cables of the control valves are mixed up Connect cables properly. Green connector must

be connected to the DHW control valve

Possible defect in control valve Replace control valve

Option: DHW circulation circuit does not

warm up

LED does not light up Fuse is broken Check for any short-circuit problems and

replace fuse (3A)

Power supply cable of the optional DHW

circulation pump unit is not connected

Connect the power supply cable of the optional

DHW circulation pump unit

Optional DHW circulation pump unit is broken

or jammed

Replace DHW circulation pump unit

Failure in electronics Contact your supplier

Casing will not close properly

Casing does not close properly Cables are caught in between unit and casing Keep cables free of any obstructions

Metal bracket holding the heat meter is not

ޔ// *-- /'4

%0./ҝޔ/-& /)/-4"$)

Heat meter is obstructing the casings path Connect the heat meter properly

Electronics are not properly placed Check mounting of electronics

Other defects

It is normal for the HIU to generate a light noise during tapping or heating operation. The regulator valves can also make a light humming sound

Rattling sound *-"- )ޕ.#$)" Flow sensor not installed correctly )./''ޕ*2. ).*-+-*+ -'4

Other defects Contact your supplier

Guidelines for System Conditioning of Heating and Cooling Networks for Flamco Limited - LogoEco Heat Interface

Units (HIU)

Flamco Limited prides itself on bringing to the UK market a proven range of Heating and Cooling Interface Units. To ensure

/#/*0-+-*0/. '$1 -$)- . '*)" 1$/4)+ -!*-() Ѷ/# . "0$ '$) .- .+ $ޔ''42-$// )/*$) ).0-

both the primary and secondary side of the heat network are designed, installed and commissioned to realise the desired

heating comfort levels. # . "0$ '$) .- )*/*Ȃ - !*-0. *)+*/' Ѷ*( ./$Ѷ)2/ --2*Ȃ.$ *!

/# .4./ (ѵ*' '4!*-/# # /$)")**'$)"$-0$/.ѵ*-!0-/# -"0$) *)2/ -/- /( )/)2/ -

)'4.$.+' . - ! -/*сшҝспрсѶфпҝспрт)чффсѵ#$'./)*/ 3#0./$1 Ѷ2 *Ȃ -/# . "0$ '$) .

from experience and a practical standpoint, in addition, as a check list to support design review. These guidelines are not

$)/ ) .()/*-4*-ޔ3 $)/# $-++-*#Ѹ(*- *1 -/# 4- $)/ ) ..0++*-/$)"*0( )//$*)/*#$"#'$"#/

good practise and methodology ensuring operation and maintenance activities are kept to a minimum post handover. We

are not specialists in the design, installation and or cleaning and subsequent treatment of water systems but, nevertheless,

contained in the sections below are importance aspects to consider.

8.1 System Design Considerations

• A review of the system should be undertaken post the design stage. The review should focus on the installation,

'*/$*))+$/4*!./-$) -.*/#ޔ3 )/ (+*--4Ѷ$-)".- (*1' 1$ .Ѷ -$./-+.Ѷ$.*'/$*)

valves to ensure that removal of debris from the system which was not removed in the commissioning activity is

managed and that sub sections can be economically isolated to permit maintenance.

• It should be considered at the design stage to include into the design a means ferrite removal. Poorly commissioned

and maintained systems exhibit corrosion. As the majority of systems contain products manufactured from iron, it is

the iron in the form of steel ferrite which creates the tell tale black sludge or blacked water which indicates corrosion

is taking place of components of the system. This corrosion if remaining unchecked, fouls water ways and controls,

erodes system components, reduces system performance and leads to the production of hydrogen in the system

known as “Gassing”. This is also a tell tale sign of system corrosion.

• .*1 -шпڿ*! -$.$).4./ (.$.! --*0.2 - *(( )/# $)./''/$*)*!-- -/#Ѷ(") /$ޔ'/ -/**/#

remove the ferrite but act as a means of identifying corrosion is taking place and a prompt for remedial action.

• # - (*1' 1$ $ ''4Ѷ.#*0'#1 ޔ-./+..-/ *!цфڿ -$.- (*1'*-"- / -Ѷ#1 $)*-+*-/ $)/*

$/.//$($3$)"!0)/$*)/**+ )/# .4./ (ޕ0$/*+ -($/-+$- (*1'*!/# -$.Ѷ(*0)/ $)/# *((*)

- /0-)Ѷ($)- /0-)+$+ 2*-&ѵ# ޔ'/ -.#'' *! ,0/ .$5 )+$/4/*''*2.0Ȃ$$ )/ޕ*2-/ )

-$.+/0- !*-/# .4./ (.$5 җ'$) .$5 $.- *(( ) Ҙѵ)4.0#ޔ'/ -.#*0'#1 /# !*''*2$)"(") /$

ޔ './- )"/#+$/4.($)$(0(/* ).0- (3$(0(! --$/ - (*1'ѵ

8. Appendix A

# ޔ'/ -.#*0' /*/# - ,0$- ( )/.*!/#

“Operating and Maintenance” instructions handed over with

/# .4./ (ѵ!)1$.*-4./$& -$.+-*1$ 2$/#/# ޔ'/ -$/

should be attached at a suitable location as to indicate the

+- . ) 2$/#$)/# .4./ (*!/# ޔ'/ -/* ).0- + -$*$

checking & servicing by any attending Service Engineer.

2*0''.*- *(( )/#//# . ޔ'/ -.$)*-+*-/

sight glass, particularly on the larger sizes to provide a visual

means of assessing corrosion without the need to disrupt

the operation of the system for checking.

Line Size Magnetic Field Strength

DN15 7500 gauss

DN20 9000 gauss

DN25 10500 gauss

DN35 21000 gauss

DN40 21000 gauss

DN50 52500 gauss

DN80 73500 gauss

DN100 73500 gauss

DN150 94500 gauss

2928

чѵс$)/*-.Ȃ /$)"*--*.$*))4./ (+ -!*-()

• “PH” or relative Acidity/ Alkalinity are of key importance in managing the production of system corrosion. It is

recommended that PH Level of the system water be between 7 and 8.5 (ideally 7.4/7.5). A Lower PH level than

recommended would be classed as acidic and corrode all metals. Alternatively, too high a PH level would be alkaline

and will corrode aluminium components within the wetted part of the system.

• When considering a chemical treatment product to add to the system, we recommend products which incorporate a

($3!*-0Ȃ -$)"Ѷ$)*- -/**)/-*'/# ' 1 '(*- Ȃ /$1 '4ѵ

• Oxygen Ingress should be minimised by the use of closed systems and barrier pipe within the system design.

• ""- ..$1 $*).җ.0#.ޕ03- .$0 .Ҙ+-*(*/ *--*.$*))Ѷ*)/$)0 /**.*0)' ..) 0/-'$. *-ޕ0.# *0/

completely. We would recommend a jointing approach that removes the need to use such compounds and adopt

the use of heat free systems.

• !/-$/$*)'.*' -ޔ//$)".- 0. /# )2 2*0'- *(( )/# 0. *!- *")$. # ($'/- /( )//*ޕ0.#

out and neutralise the system (see section 3.1 below). In addition, it is strongly advised to contact the manufacturer

of the chemical treatment to gain early involvement prior to treatment as to the correct application and chemical to

use.

• The accumulation of sludge & debris can cause deposit corrosion which leads to pitting. We recommend the use

*!- *")$. # ($'/- /( )//*ޕ0.#*0/)) 0/-'$. /# .4./ ()$/$*)Ѷ$/$../-*)"'41$. /*

contact the manufacturer of the chemical treatment to gain early involvement prior to treatment as to the correct

application and chemical to use.

8.3 Refurbishment and Improvement to existing systems

• It is vitally important that before commencing works on existing systems that a complete scan of the water quality

of the system be taken. If it is found that the system contains products of corrosion and/or PH levels in excess

of the required norms, it is recommended that the existing water is conditioned and treated PRIOR to the work

commencing.

8.4 System commissioning (water quality) Water Treatment Chemicals

• *)*/- *(( )/# 0. *!-22/ -!*-#4-0'$/ ./$)"0 /*/# -$.&*!*--*.$*)*!/# 2/ - $)"' ȅ$)

the system and potentially, the internals of the system being exposed to the air due to partial draining.

• # ($''4*. 2/ -.#*0' $)''ޔ''$)"/$1$/$ .$)*-) 2$/#/# # ($'()0!/0- -.ҁ

recommendations and in accordance with BSRIA BG29 2012.

• ȅ -.0$/' ޔ''$)")ޕ0.#$)"- "$( $.0. Ѷ- ' 1)//*/# .4./ ((/ -$'Ѷ''# ($'.0. /* .0$/'

for HIU must comply with EU norms DIN EN 12828 and current guidelines for heating systems. In addition, they

should also be non hazardous, non toxic and biodegradable.

• The use of correct cleaners and inhibitors is of primary, environmental concern. All chemicals used to treat the

system should not contain phosphates, sulphuric acid, nitrites. See BS7593:2006 Code of Practice for treatment of

water in domestic hot water space heating systems.

• Inhibitors should meet Buildcert as a minimum and preferably be recommended by the Energy Savings Trust (ESR).

• Acid based cleaners are unsuitable for older systems as there is a risk of “pinholing” on radiators. They will also

require some form of neutralisation process before being discharged or require being taken away for disposal.

8. Appendix A

8.5 Recommendations for system conditioning - (Basic process)

• # .4./ ((0./ ޕ0.# )$)#$$/ $)*-) 2$/#цфшт)/# *( ./$0$'$)" -1$ .

Compliance Guide.

• The chemicals used should contain the following aspects of their composition:

–Surfactants to reduce surface tension allowing chelating agents to attach to the residues.

–Chelating agents will then entrap the calcium carbonate within the solution.

–Dispersant’s are used to hold residues in suspension.

–The inhibitor then prevents corrosive attacks on metals during cleaning.

–0Ȃ -./*($)/$)) 0/-'ѵ

–Chemicals shall be of a type suitable for disposal through a conventional sewer or foul drain (i.e. no requirement

for tankering or specialist disposal).

–Neutralisation.

–For cooling applications, specialist chemicals and advise should be sought.

8.6 Site installation conditions – Installation of the system

It is recommended that:

–/ -.*'0' ޕ03.#*0' 0. җ)*#'*-$ ҌҘ/# - !*- ҂# /!- ҃.4./ (.- - *(( ) ѵ

–The area of installation should be free from gypsum dust, brick dust, screed or other possible contaminants.

чѵц *(( ) ȅ -- җҘ /2*-&-$(-4.$

• Any relevant details of the installed units and system conditioning to be documented in the O&M manual.

• # - .#*0' ' -)*/$ޔ/$*)*!)4# ($'+-*0/. Ѷ/ . /+' *)/# ѵ

• If there is a requirement for a partial drain down, the inhibitor should be topped up to the required level with full

details.

• #$"#'4- *(( )/#/''. -1$$)"ҝ$).+ /$*) /.+ -()0!/0- -ҁ.$)./-0/$*).җѶޔ'/ -Ѷ# ($'. /Ҙ$.

fully adhered to.

• Any checklist sticker placed within the casing by the manufacturer must be completed.

8. Appendix A

31тп

чѵч *(( ) ȅ -- җ /2*-&Ҙ

It is recommended that a regime of periodic inspection of the system be undertaken. The inspection shall take the form of:

$.0'$).+ /$*)

System visual inspection, exterior corrosion, water stains on the pipe work and equipment, suggesting a slow leak and

make up water entering the system thereby diluting the inhibitor concentrations.

Water Samples

/ -.(+' ..#'' -2)!-*(.0$/' -2*Ȃ+*$)//*. -/$)/# *)$/$*)*!/# ) /2*-&Ѷ*)/# +-$(-4.$

water.

# )'4.$.*!/# 2/ -.#*0'$)'0 ѷ

• Visual assessment – Note any discolouration away from clear as an indicator of possible corrosion

• Chemical assessment – PH value, hardness, precipitate composition and concentration of chemical treatment and type of

treatment contained within the water (A UKAS registered lab is recommended to be used in the system water analysis).

8. Appendix A 8. Appendix B

L2L1 N1 N2

R1 R2 R3

NO C NO C

NO NC C

L N PE

N

L

PE

230V ~

Actuator Head of

pre-payment valve

inside HIU

Fuse

(non switched, 5A)

brown

blue

85 ... 265 V~, 50/60 Hz, 2.5 W, NC

Heat Meter

M-Bus

Pulse

Pulse Inputs

Pulse Output

Pulse Module

M-Bus Module

24 25

2 core cable

230V ~ Module

L

N

PE

01

24 25

2 core cable

01

Example wiring of a pre-payment system (GURU Systems)

3332

8. Appendix C

Spare parts Spare parts

Key Description Detail

1 & 28 Y Strainer G3/4” BT x G3/4” BT L=82 PN20

2 & 20 Temperature sensor NTC 10K3 1/8”BSP ø4.7x17

4 & 5 Pressure test point

6 Spool piece 110mm G 3/4” x G 3/4”

8 & 9 Control valve VDE/ML SIN.ø9.5 24V 50Hz

10 & 12 Plate Heat Exchanger E8LASHx40/1P-SC-S 4xG 3/4”BT

11 & 13 Temperature sensor NTC 10K3 1/8”BSP ø5-6 x 90

14 Over pressure relief valve PRESCOR Rp 1/2” 3 BAR

15 Pressure gauge 0-4BAR / 0-120°C

16 Automatic bleed point MS G3/8” BT

17 Expansion vessel G 3/8” BT 8 LTR

18 Bleed point G 1/8” BT

19 Water hammer arrester G 3/4” WM x G 3/4” BT l=84,5

21 Flow sensor SIKA

22 Non return valve

24 circulation pump, DHW Lowara

25 circulation pump, space heating Grundfos UPM3 AUTO 15-70 130

26 Temperature/pressure sensor RPD 0-6 BAR

27 Drain point

29 & 30 Controller & Power supply

90 $Ȃ - )/$'+- ..0- *)/-*'1'1 2xG3/4”BN 20-60 kPa DN20 PN25

91 #0/*Ȃ1'1 ۔/0/*- R2015-S1 + TRF230NC

92 Seal SENTINEL ø24 x ø16,2 x 3

93 Seal SENTINEL ø29 x ø20 x 2

94 Wall mounting kit (wall plugs, screws,

Washers)

95 & 96 & 97 Heat meter mounting kit

96 & 97 Mounting screw & anti-tampering cap

96 Securing screw ø6

98 EPP case EPP TYPE 9335

99 Steel sleeve White coated

1

94

12

22

164

20

8

29

17

14

18

93

92

25

99

98

95 96 97

19

24

6

91

90

26 21

2

10

30

11

5

9

13 28 27

3534

ContactNotes

United Kingdom

Flamco Limited

Washway Lane

St Helens

Merseyside

WA10 6PB

United Kingdom

+44 1744 744 744

$)!*ҽޕ(*ѵ*ѵ0&

222ѵޕ(*ѵ*ѵ0&

Flamco Limited

Washway Lane

WA10 6PB St. Helens

Merseyside

United Kingdom

T+44 17 447 447 44

F+44 17 447 447 00

E $)!*ҽޕ(*ѵ*ѵ0&

222ѵޕ(*"-*0+ѵ*(

пстфс*"**сҊо)0' -.$*)пфҝршҊ0% //*(*$ޔ/$*).

Table of contents

Other flamco Heating System manuals

Popular Heating System manuals by other brands

Energotech

Energotech EnergoStrip EE-3 Series Mounting and installation

REVENTON

REVENTON INSPIRO Technical documentation

OSTBERG

OSTBERG HERU K Series Assembly and installation instructions

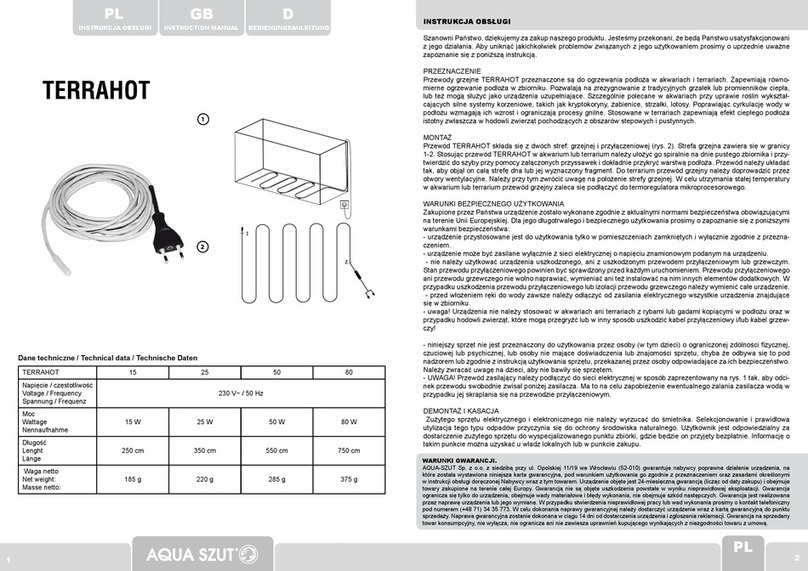

AQUA SZUT

AQUA SZUT TERRAHOT instruction manual

Aqua-Hot

Aqua-Hot 200 Series Use and care guide

International Thermal Research

International Thermal Research CO32D Operator's manual

Airflow

Airflow Uno hab Installation and operating instructions

Danfoss

Danfoss SET2E Installation & user's instructions

Amana

Amana APG14 M Series manual

BLAUBERG Ventilatoren

BLAUBERG Ventilatoren KOMFORT Roto EC S6K 200 user manual

Salda

Salda RIS 700PE EKO 3.0 Technical manual

UTEK

UTEK FLAT GUIDE FOR INSTALLATION, USE AND MAINTENANCE