Contents

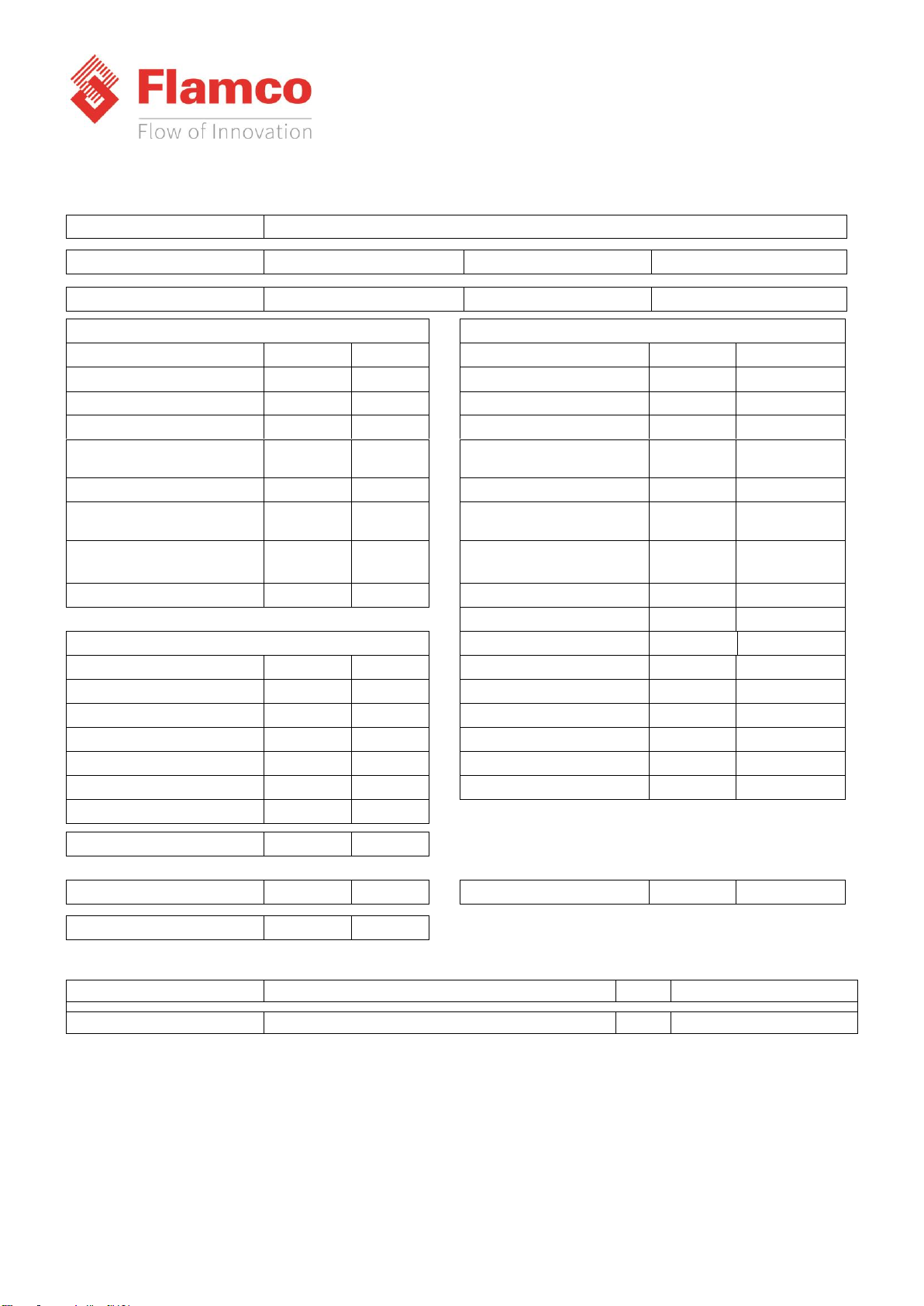

Customer Details ....................................................................................................................................................... 4

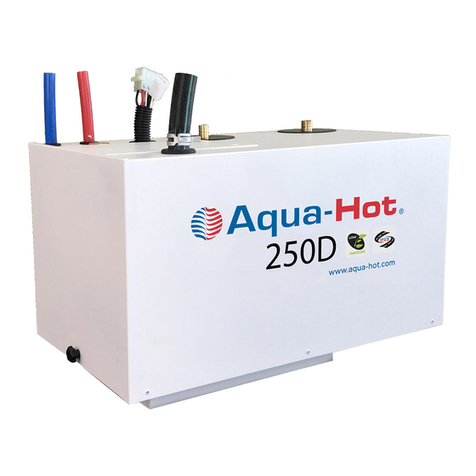

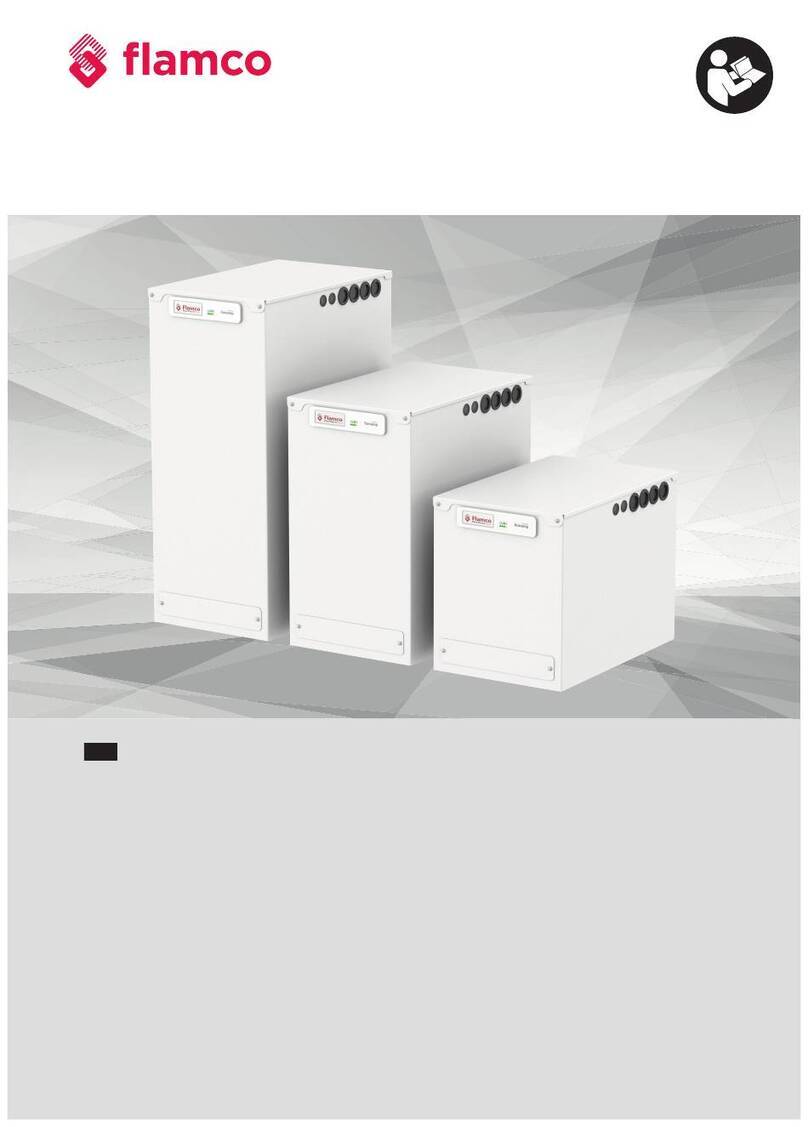

Equipment Details ..................................................................................................................................................... 4

Commissioning Record ..............................................................................................................................................5

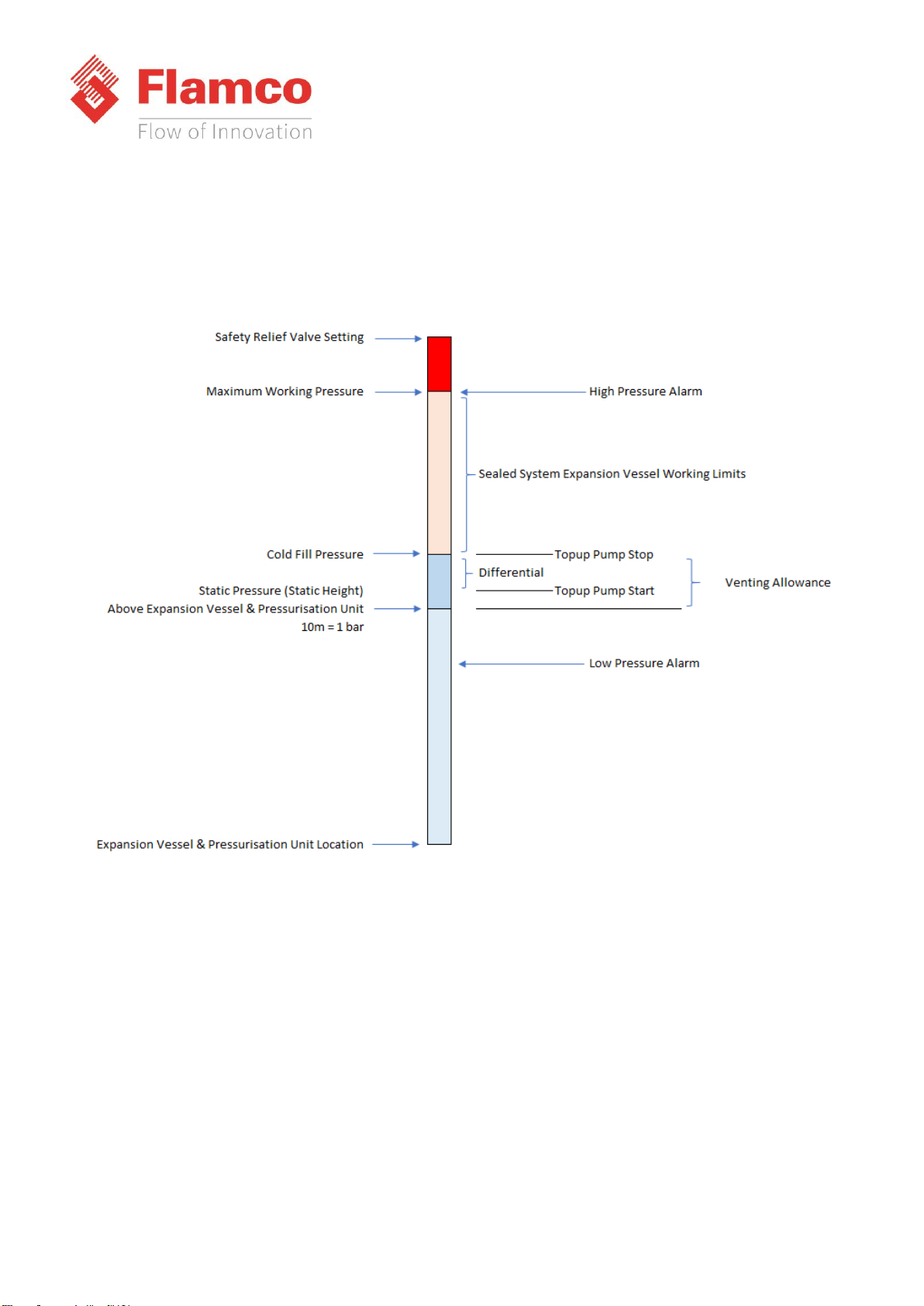

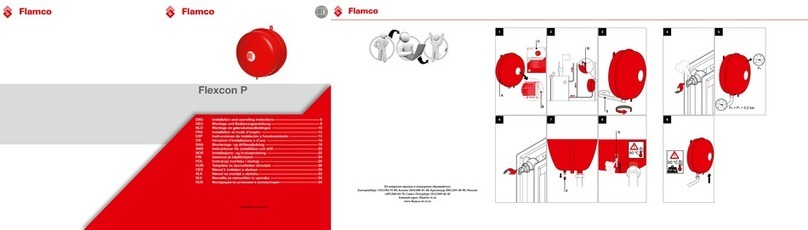

Pressures In A Sealed System.................................................................................................................................... 6

About this Manual..................................................................................................................................................... 7

Conventions used in this Manual .......................................................................................................................... 7

Typography............................................................................................................................................................ 7

Where to find more Information........................................................................................................................... 7

Equipment Overview................................................................................................................................................. 8

Installation................................................................................................................................................................. 9

Pipe Connections................................................................................................................................................... 9

Typical Installation Diagram ..................................................................................................................................9

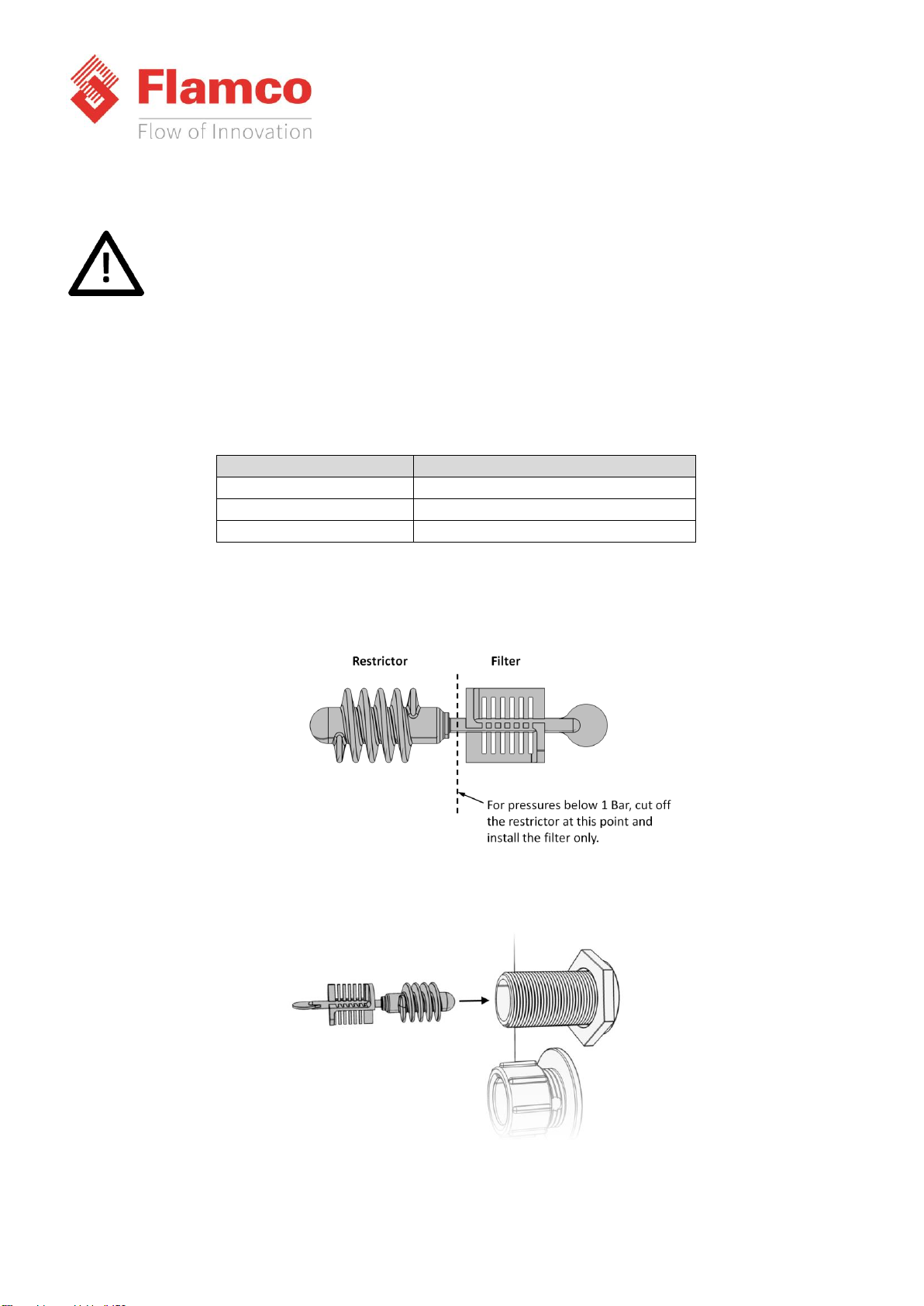

Flow Restrictors (Pro PUm & Pro PDm Only) ......................................................................................................10

Pro PU Clearance and Connection Requirements...............................................................................................11

Pro PUm & Pro PDm Clearance and Connection Requirements .........................................................................12

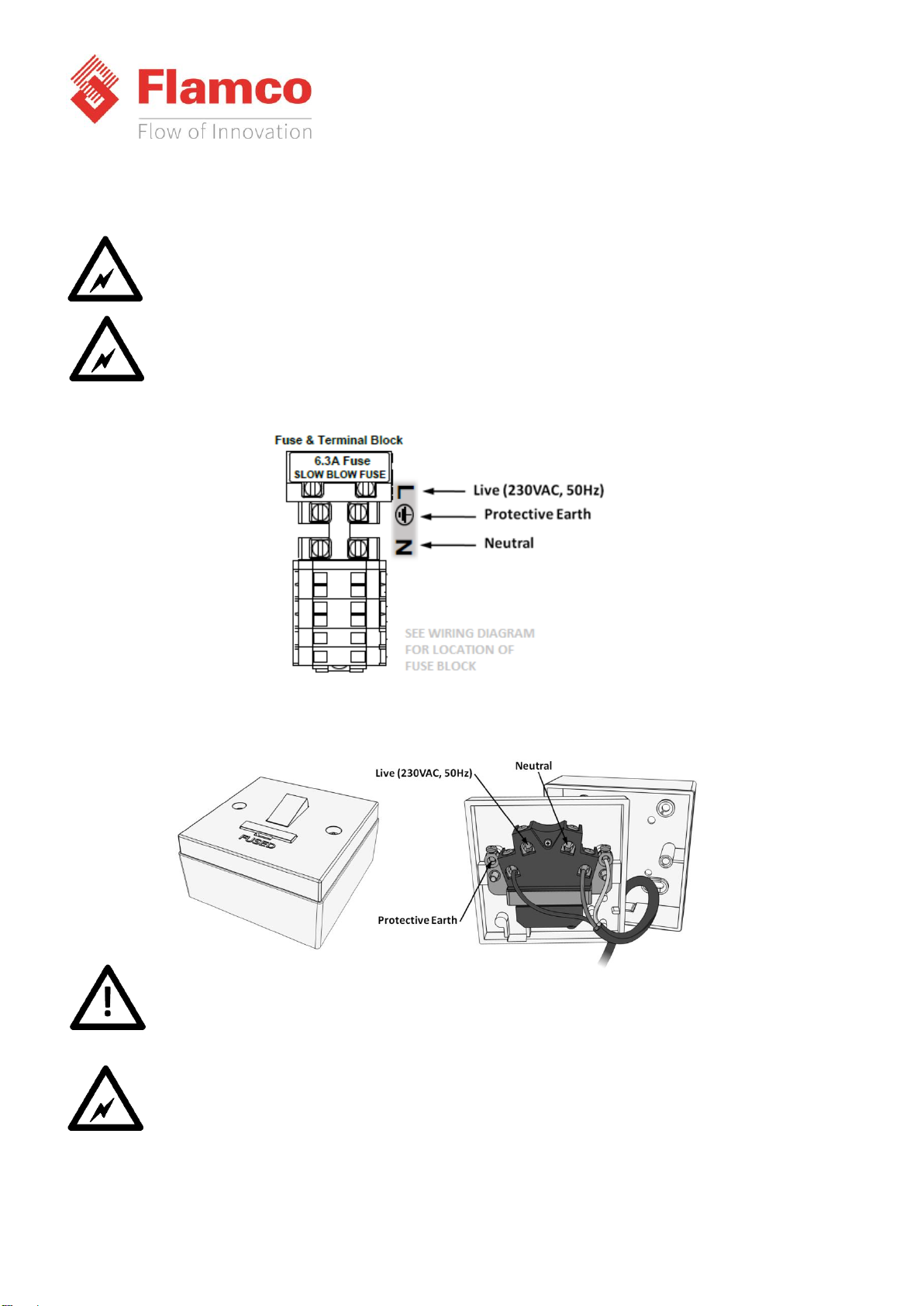

Electrical Power Supply ...........................................................................................................................................13

Micro Controller ......................................................................................................................................................14

Fault contacts ......................................................................................................................................................14

Commissioning ........................................................................................................................................................15

Pre-Commissioning Checklist ..............................................................................................................................15

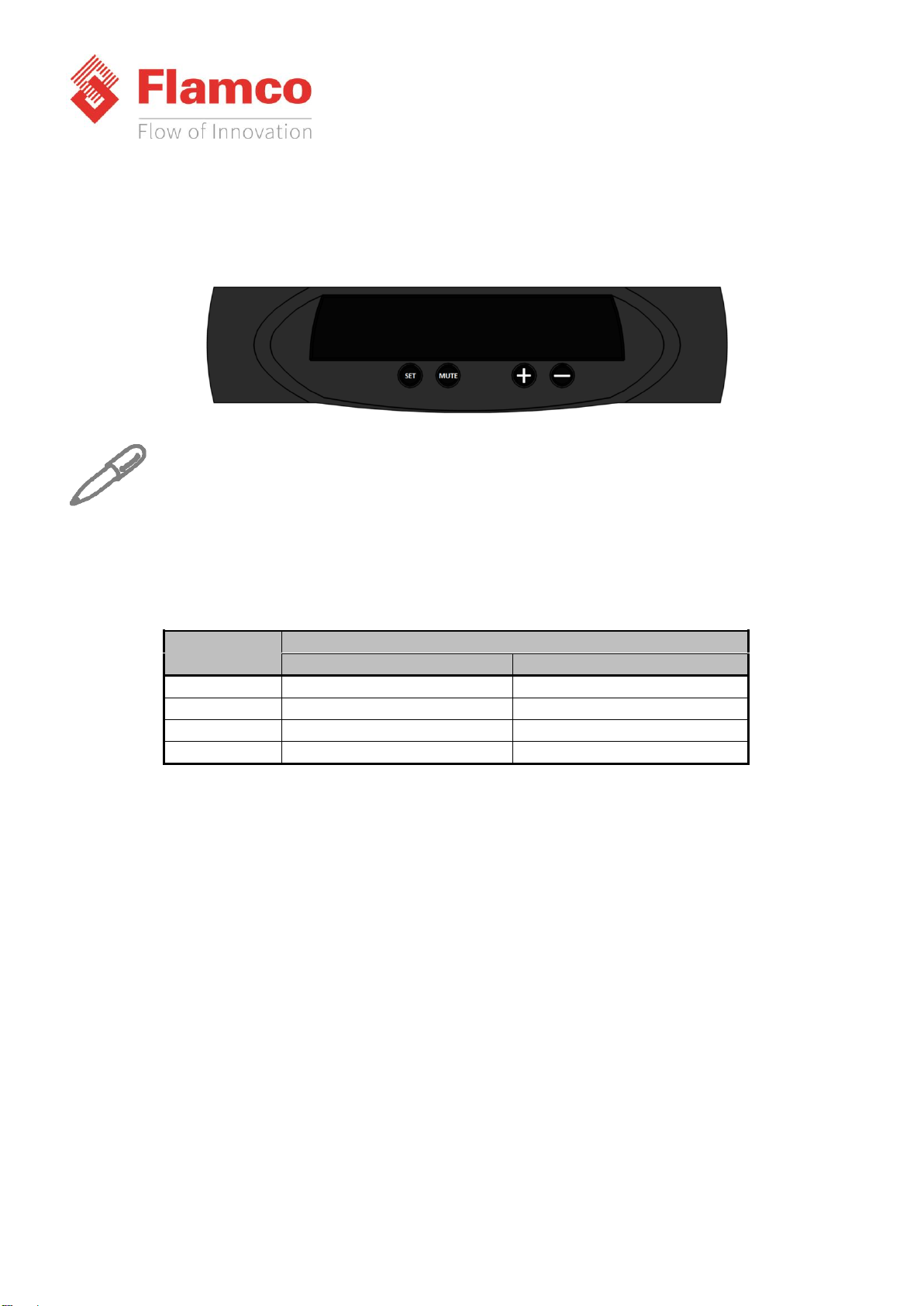

Controller Overview ................................................................................................................................................16

Controller Programming...................................................................................................................................... 17

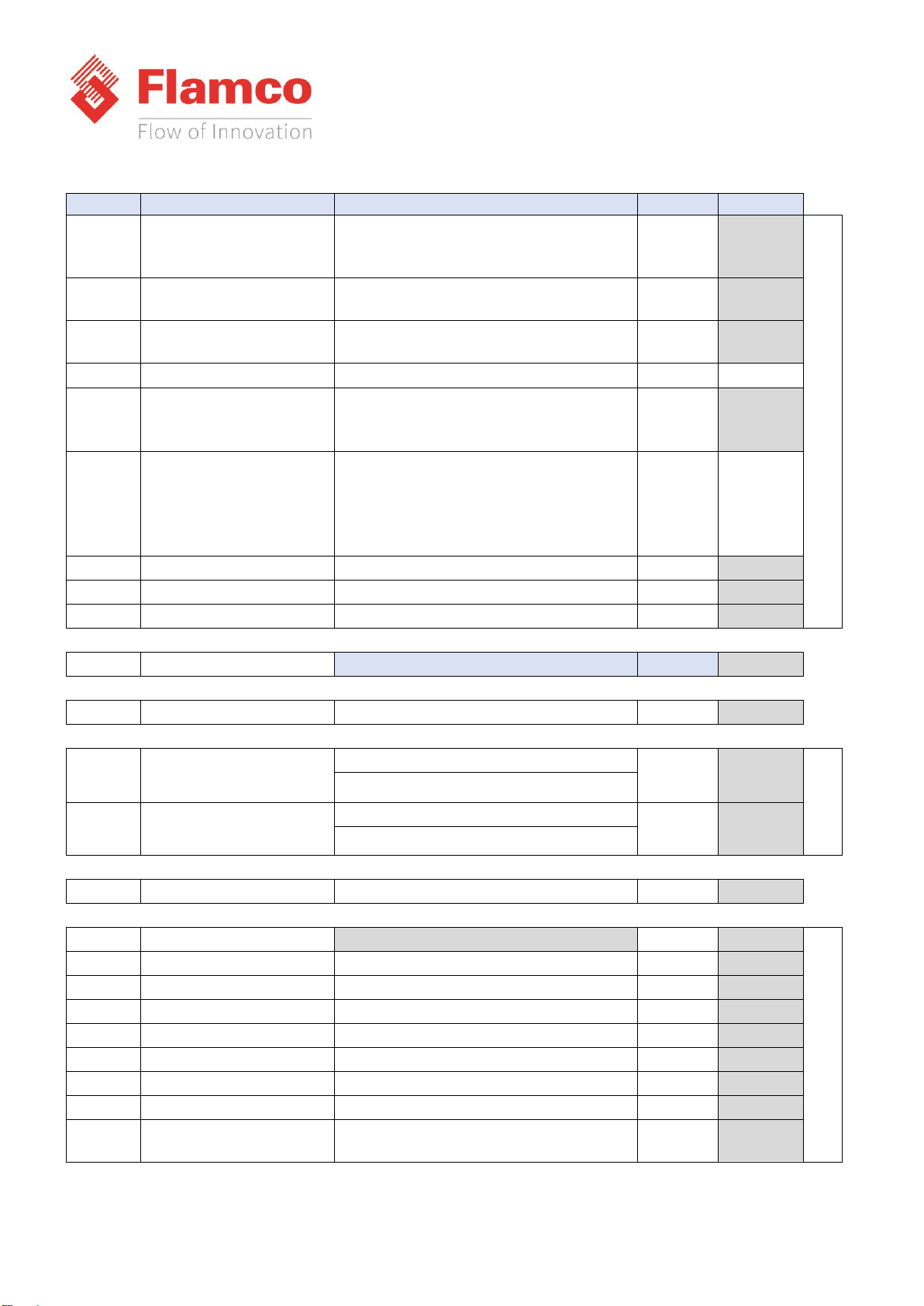

Program Parameter List...........................................................................................................................................18

Hydraulic Commissioning ........................................................................................................................................21

1. Float Valve Setting........................................................................................................................................... 21

2. Bleeding Pumps ...............................................................................................................................................21

3. Forcing Pumps to Run...................................................................................................................................... 23

4. Initial Start-up..................................................................................................................................................24

5. Testing .............................................................................................................................................................25

Quick equipment suitability guide in relation to system expansion vessel ............................................................ 25

Operation................................................................................................................................................................. 26