flamco Logotherm LogoComfort 500 User guide

ENG Installation and servicing instructions

www.flamcogroup.com/manuals

Logotherm

LogoComfort 500, 600 und 600+

as well as LogoComfort thermal heat exchangers BE 500, 600 and optional components

Manual for LogoComfort stations 24002.800

2

Abbreviations

LC LogoComfort

BE Thermal heat exchanger

CW Domestic water, cold

DHW / HW Domestic hot water

DWC/C Domestic water circulation

DW Domestic water

FL Heating flow line

RL Heating return line

UC/RH Unmixed heating circuit, static heating circuit for e.g. radiators

MC Mixed heating circuit

UFH/UFM Underfloor heating circuit / manifold

HC Heating circuit

PHE/HE Plate heat exchanger

CU Copper-soldered

ES Stainless steel-soldered

FT Female thread

MT Male thread

primary Primary heating circuit (heat supply)

sec. Secondary heating circuit (heat consumer)

HFM Energy meter

SM/FM Surface-mounted / flush-mounted

SMC/FMC Surface-mounted / flush-mounted cover

HE High-eiciency pump

BV Ball valve

WxHxD Width, height, depth

We reserve the right to change the designs and technical data of our products.

3

Table of Contents

Abbreviations .................................................................................................................... 2

1. Safety instructions...................................................................................................... 5

1.1 Intended use .............................................................................................................. 6

1.2 Device designations...............................................................................................................7

1.3 Hazard notes .........................................................................................................................7

1.4 What to do in the event of a breakdown or leaks....................................................................8

1.5 Spare and wear parts.............................................................................................................8

1.6 Requirements on trained engineers.......................................................................................9

1.7 Liability and copyrights.........................................................................................................9

1.8 Earth bonding or protective earthing in accordance with VDE................................................9

2. Functional description .............................................................................................. 10

3. LogoComfort stations................................................................................................ 11

3.1 LogoComfort 500/ 600 and 600+ as base stations.................................................................11

3.2 LogoComfort 500/600 and 600+ as prefabricated stations....................................................22

3.3 LogoComfort complete stations (CS)....................................................................................26

3.4 LogoComfort thermal heat exchanger (BE) 500/600 mm wide..............................................28

4. Installation............................................................................................................... 31

4.1 Installationnotesusingtheexampleoftheush-mountedcoverforLC500/600and600+ ..32

4.2 Mountingrailsandassemblyaidsforsurfaceandushmounting(optionalaccessories) ....33

4.3 DN20straight-wayballvalves(add-onelements) ................................................................35

4.4 Topconnections(add-onelement) ......................................................................................36

4.5 Installation of optional components (depending on variant) ...............................................36

5. Description of individual components and setting options .....................................................39

5.1 Hot water throttle (where included in the delivery range)....................................................39

5.2 Dirttrapwith/withoutllanddrainballvalve(dependingonvariant).................................40

5.3 Zone valve for heating circuit...............................................................................................41

5.4 Dierentialpressureregulator(dependingonvariant) ........................................................43

5.5 Thermostatic circulation bridge (depending on variant)......................................................44

5.6 Returntemperaturelimiter(add-onelement)......................................................................45

5.7 Thermostatichotwatermixingvalve(add-onelement........................................................45

5.8 Domesticwatercirculationsystem(LC600/600+add-onelement) ......................................47

5.10 Additional connection for static heating circuit

(LC600+,add-onelementMM28).................................................................................................63

5.11 Claddings / covers for LC stations (as optional accessories) .................................................64

5.12Congurationexamples ......................................................................................................69

6. Commissioning......................................................................................................... 71

6.1 Flushingandlling..............................................................................................................71

6.2 Initialstart-up .....................................................................................................................71

6.3 Seized Grundfos pumps, type UPM3 ....................................................................................72

Manual for LogoComfort stations 24002.800

4

7. Maintenance and service ........................................................................................... 74

7.1 Information regarding domestic water hardness .................................................................74

7.2 Maintenance checklist .........................................................................................................75

8. Troubleshooting and remedying possible faults........................................................... 77

9. Layout diagrams....................................................................................................... 77

10. Decommissioning, dismantling, disposal, environmental protection and disposal of

electrical andelectronic equipment .................................................................................. 79

We reserve the right to change the designs and technical data of our products.

5

1. Safety instructions

Please follow these safety instructions carefully to prevent

hazards and injury to persons and property.

These operating instructions are primarily designed for the safe use and installation of the device

and make no claims to completeness.

These operating instructions describe the functionality of the device and are intended to provide

information about the required safety instructions and to draw attention to possible hazards. Further

technical information can be found in the other applicable documents.

These operating instructions are valid only for the described device and are not subject to the

manufacturer’s revision service. The sketches and drawings they contain are not suitable to scale.

• Keep the operating instructions within easy reach of all employees instructed to carry out work

onthe device so that they can refer to them as required.

• Keep the operating instructions in a clean, complete and legible condition throughout the entire

period of use.

• Read the operating instructions before working on the device for the first time and consult them

whenever uncertainties or doubts arise as to how the device should be handled.

• Should you come across any discrepancies when reading these operating instructions or should

anything remain unclear, please contact the manufacturer.

Target group

These instructions are intended exclusively for authorised trained experts.

Only trained experts/installers authorised by the respective competence authority are permitted

towork on heating systems, domestic water, gas and electrical circuits.

Regulations

When carrying out work, you must comply with:

- The legal regulations concerning accident prevention and legal regulations regarding

environmental protection.

- The German Employer's Liability Insurance Association regulations,

- The pertinent safety requirements of DIN, EN, DVGW, TRGI, TRF and VDE,

- ÖNORM, EN, ÖVGW-TR Gas, ÖVGW-TRF and ÖVE,

- SEV, SUVA, SVGW, SVTI, SWKI and VKF

- and all current region- or country-specific regulations and standards

Instructions for working on the system

- Disconnect the system from the mains and monitor it to ensure that no voltage is being supplied

(e.g. at the separate cut-out or a main switch).

- Secure the system from restarting / switching to auxiliary power supply.

- WARNING! Risk of scalding at media temperatures: >60°C

Note: In the case of anticipated high primary temperatures of >60°C, thermostatic scalding

protection must be ensured at the domestic hot water draw-o point in order to restrict the outlet

temperature (in the event of a power failure).

Manual for LogoComfort stations 24002.800

6

Permissible mains supply and operating parameters

Heating side/primary side: Permissible pressure rating:

Max. permissible operating temperature:

Max. permissible dierential pressure:

- With actuator for zone valve:

PN10

110°C

2.0 bar

1.0 bar

Sanitation side: Permissible pressure rating:

Max. permissible operating temperature:

- In the case of an existing sanitary circulation

system:

(for short periods max. 70°C < 2 h)

Min. cold water pressure:

Recommended cold water operating pressure:

PN10

110°C

65°C

1.5 bar

2 bar

Max. permissible ambient

temperature: 40°C

• The devices must be installed in enclosed, frost-free spaces

• Any noise emissions or radiant heat from the station must be taken into account in the choice of

installation site

• Observe the safety areas in accordance with EN 60529 when designing and installing the system

(equipment protection code in accordance with EN 60520 IP42)

• Any domestic hot water (DHW) installation must be made safe in compliance with DIN 1988 or

DIN EN 806, for example, i.e. with the use of a safety valve and, where applicable, an expansion vessel.

1.1 Intended use

1.1.1 Proper use

Interface stations are used to transfer heat between the supply network and the heat consumer.

Interface stations may only be used for this purpose in compliance with the maintenance and

operating instructions and all relevant standards and regulations.

All instructions in the operating instructions must be followed and the maintenance schedule

adhered to.

Any deviation from the intended use may cause unintended hazards and is fundamentally

not permitted.

The LogoComfort heat interface station provides a residential unit with space heating and

domestichot water according to the continuous flow principle. Any additional or alternative use

isnot permitted and regarded as an unintended use.

Appropriate use in heating and domestic water systems must be in accordance with the applicable

DIN and local standards. Installing and operating the assembly incorrectly will invalidate any

warranty claims. The shut-o valves may only be closed by an approved specialist when servicing,

otherwise the safety valves will not work.

The LogoComfort heat interface station is not suitable for installation in adjacent recreation rooms

or bedrooms.

Care must be taken to avoid sound transmission to adjacent walls or rooms!

Caution:

Do not make any changes to the electrical components, the design of the equipment

or the hydraulic components! This would adversely impact on the safe function of

theequipment.

We reserve the right to change the designs and technical data of our products.

7

Instructions concerning the place of use:

Before using our products, they must be checked regarding their suitability for the respective

application.

In particular for heating systems, please take into account the properties of the heating water

inaccordance with VDI 2035 to protect the heating system and, for domestic water applications,

thewater quality at the place of use.

In the case of critical water qualities, please take action where necessary (e.g. water treatment)

toprevent functional impairment and/or damage, e.g. corrosion damage.

In particular, please check the permissible limit values, e.g. electrical conductivity, the pH value,

thewater hardness level and the ammonium concentration.

Furthermore, in Germany all applicable norms, regulations and guidelines specific to the federal

states must be taken into consideration, alongside the instructions in the applicable installation

andoperating manuals.

Further information can be found in the download section of www.flamcogroup.com.

1.1.2 Improper use

Using the device in any way that does not correspond to the intended use may be hazardous

andistherefore prohibited.

In particular, the following is not allowed:

• The use of liquids other than water with the described properties

• Use of the device without prior knowledge of the operating instructions

• Use of the device without legible warning and information signs

• Use of the device in a faulty condition

1.2 Device designations

Designation: Logotherm interface stations

Function: Transfer of thermal energy to the heating supply and hot water preparation

Type: LogoComfort

Manufacturer: Meibes System-Technik GmbH

1.3 Hazard notes

The safety and warning information draws attention to residual hazards that cannot

be avoided due to the design and construction of the device. Please always observe

the measures shown for avoiding these hazards

Never alter or modify the station yourself. Such work may only be carried out by qualied,

specialist personnel. This also applies to the electrical installation.

When the system is in operation, water-regulating components will be hot. Touching these system

components can lead to scalding. The interface station and its heat-carrying components must

be operated with permanent insulation. This insulation not only prevents unnecessary thermal

dissipation, but also protects against accidental contact and burns. The insulation must therefore only

be removed for maintenance or repair purposes and replaced correctly on completion of such work.

The system is operated using hot, high-pressure water, which can cause scalding on contact.

You should therefore open the bleed or drain valves carefully and not work on pressurised parts.

The control components (controller, servomotors, pumps, etc.) are powered by mains voltage.

Manual for LogoComfort stations 24002.800

8

Therefore, always ensure the station is disconnected from the mains electrical supply when

carrying out any maintenance or repair work. Secure the system against unauthorised operation.

Life-threatening electric shocks can be caused by spraying or splashing water. Escaping water may

also disable the safety devices.

Any changes made to the station that have not been authorised by the manufacturer will invalidate

any warranty claims.

Residual hazards:

The product has been built in accordance with the most relevant and recognised safety regulations.

The following residual hazards may arise during installation, commissioning, maintenance and

disassembly:

Warning: Risk of scalding from high media temperature

- Work with particular caution.

- Use personal protective equipment PPE (e.g. heat-resistant protective gloves).

- If necessary, the surface temperature must be measured before commencing any work.

- Use only designated and appropriate tools.

Hazard: Risk of injury from electrical voltage

- Only trained and qualified electricians may undertake work on electrical equipment.

- Electrical installation spaces must always be kept locked.

Warning: Risk of cuts and scratches due to the possibility of sharp edges

- Work with particular caution.

- Use personal protective equipment PPE (e.g. protective gloves).

Warning: there is a risk of impact/crushing if the station falls over

- Wear personal protective equipment PPE (such as protective work shoes).

1.4 What to do in the event of a breakdown or leaks

• Close any media lines using the appropriate valve.

• Contact a suitably trained expert or the customer service department of the manufacturer.

The device will only be cleared for operation again when the trained engineer has remedied

the fault and restored the device to its intended condition.

1.5 Spare and wear parts

All spare parts to be used, must correspond to the technical requirements defined by Meibes

System-Technik GmbH. This is guaranteed only by using genuine spare parts. The manufacturer

isnot liable for damage caused by the use of unapproved spare parts or ancillary materials.

Appropriate spare parts can be found in our documentation.

We reserve the right to change the designs and technical data of our products.

9

1.6 Requirements on trained engineers

A qualified professional must have undergone advanced technical training and have suicient

experience to independently perform complicated tasks or work associated with residual hazards.

Each experience refers to a certain speciality, e.g. Maintenance, Electrical and/or HVAC Technician

In preparation for impending work, a qualified professional must be able to correctly estimate the

feasibility, risks and hazards of the work as well as the equipment required. A qualified professional

is expected to understand complex plans and descriptions of minimum preparation, and to obtain

missing and required detailed information by suitable means.

The qualified professional must be able to restore and verify the intended/original state of the

system. A worker can be a trained expert in several fields. For the performance of electrical works,

only trained electricians according to DGUV regulation 3 may be used.

1.7 Liability and copyrights

We reserve all copyrights to this document. Any misuse, in particular reproduction or disclosure

tothird parties, is prohibited.

This original operating manual may not be reproduced or distributed, either in part or in its entirety,

without the express permission of the manufacturer. This also applies to translations of this document

and storage on other media. This document must not be used outside its intended purpose.

These installation and operating instructions must be given to the customer. The technician carrying

out and/or authorising the work (e.g. installer) must explain the function and operation of the system

to the customer in a comprehensible way.

1.8 Earth bonding or protective earthing in accordance with VDE

A terminal for earth bonding is provided

on all heat interface stations. An

appropriately labelled earth stud can be

found on the base plate for this purpose

The cable's connection cross-section must

bedesigned according to the applicable standards

andregulations.

Manual for LogoComfort stations 24002.800

10

2. Functional description

The LogoComfort (LC) interface stations provide a residential unit with domestic hot water and

heating. The domestic water is heated according to the continuous flow principle by a plate heat

exchanger and a pressure-controlled proportional flow controller (PF controller with 3- way function)

with anti-scale coating and DVGW

(German Association for Gas and Water)

approval.

Operation:

The PF controller with 3- way function

only opens the domestic water and

heating water media flows via the plate

heat exchanger when the hot water is

being drawn o. Once the water has

been drawn o, the valve closes and

thus prevents the continued heating

of the heat exchanger. The dwelling

heating circuit is shut o while the

hot water is being drawn o (priority

switching).

The entire thermal energy is thus

available for the hot water preparation.

Notes:

If a constant heating supply

temperature is ensured, the same

hot water temperature is always

achieved by means of proportional

flow regulation when small or large

quantities are drawn o.

The use of a thermal mixing valve*

ensures scalding protection with very high or erratic heating medium temperatures and anticipated

hot water temperatures of > 60°C.

We recommend using a thermostatic circulation bridge* at the end of the supply line or in the last

station in order to guarantee the thermal stability and/or avoid waiting times until the desired hot

water temperature is achieved.

If the connecting pipework between the supply line and the station is very long, it is worth installing

a thermostatic circulation bridge* in every station. The dierential pressure regulator* upstream

of the station provides a stable pressure dierential for the hot water preparation. Alternatively, it

is possible to install the dierential pressure regulator or another suitable fitting in the supply line

(heating).

A zone valve permits hydraulic balancing of the dwelling heating circuit.

Installing a living space or reference room controller* allows independent operation of the dwelling

heating circuit.

Any adapters* (L =110 mm, 2 x ¾" MT) for optional water meters and heat meters allow retrofitting in

the stations

* Corresponding station components may be available or present as optional accessories or as add-on

elements.

We reserve the right to change the designs and technical data of our products.

11

3. LogoComfort stations

The following sections describe the station variations as well as possible optional models

withexample illustrations.

3.1 LogoComfort 500/ 600 and 600+ as base stations

LogoComfort base station as a local interface station:

- for customisation

- incl. PF controller with priority switching, incl. adapters for optional heat meter

- Connection pipework made of insulated stainless steel corrugated tube, fully mounted on base

plate and tested

The following base stations can be equipped with various add-on elements (see module

summary, Section 3.1.4). These are installed in the factory and delivered as a prefabricated

station. Corresponding surface-mounted / flush-mounted covers, as well as room controllers

andaccessories, are also available.

3.1.1 Technical data

LogoComfort base station variations with art. No.

Output** LC 500 base LC 600 base LC 600+ base

35 kW S-Line M11401 M11301 M11304

46 kW M-Line M11303 M11306

Dimensions of WxHxD in mm

(where depths depend on the optional accessories)

LC 500 base: 480 x 635 x 175

LC 600 base: 576 x 635 x 175

LC 600+ base: 480 x 657 x 175

Heating capacity 10 kW (at 20 K)

Hot water output** 35 kW (at 40 K), 12 l/min

46 kW (at 40 K), 17 l/min

** Where FL=65°C and DW heating by 40 K

Manual for LogoComfort stations 24002.800

12

LogoComfort 500/ 600 base

3.1.2 Design and components

Components and connections Hydraulic diagrams

Fig.: Example representations

Shown with possible add-on elements

Fig.: Example representations

Shown with possible add-on elements

LogoComfort 600+ base

We reserve the right to change the designs and technical data of our products.

13

Key for LogoComfort base stations

No. Components Comment

1Stainless steel plate heat exchanger

2a Adapter for cold water meter (L = 110 mm, 2 x ¾" MT) Option

2b Adapter for heat meter (L = 110 mm, 2 x ¾" MT)

3Stainless steel corrugated tube pipework, insulated

4a Dirt trap with flushing, filling and drain ball valve Option

5Dierential pressure regulator, control range 10-40kPa Option

6PF controller with 3- way function with priority switching, anti-calcification

coating and DVGW approval

72nd CW connection Option

8Thermostatic circulation bridge 35 ... 65°C Option

9Zone valve (optional: living space controller),

for 1st HC included delivery range

Control valve for heating water (dwelling)/

zone valve

13 Hot water throttle 12 or 17 l/min

14 Automatic air vent Bleed valve on the heating side

15 Thermostatic hot water mixer (scald protection) Option

17 Return line temperature limiter 45… 65°C Option

18 ½" coupler for heat meter immersion sleeve Option, if Item 20 present

19.1 Domestic water circulation group, only for 600/600+ Option

19.2 Circulation bridge 35 ... 65°C, only for 600/600+ Option, if Item 19.1 present

20 DN20 shut-o valve, union nut x ¾" FT domestic water

ball valve DVGW approved, FL ball valve with HFM sensor

Option

21 Corresponding mixing circuit with HE pump Depending on the variant

Connections

ACold water outlet for dwelling, (second CW connection) - Option G ¾" MT

(without ball

valves)

BDomestic hot water outlet for dwelling (HW)

CCold water inlet building connection (CW)

DHeating – flow line building connection (FL heating)

EHeating – return line building connection (RL heating)

FHeating – flow line dwelling heating circuit 1 (unmixed or mixed HC) -

depending on the variant

GHeating – return line dwelling heating circuit 1 (unmixed or mixed HC) -

depending on the variant

HHeating – flow line dwelling heating circuit 2 (unmixed HC) - option

IHeating – return line dwelling heating circuit 2 (unmixed HC) - option

JDomestic water circulation - option

Note: for optional components, see Section 3.1.4

Manual for LogoComfort stations 24002.800

14

3.1.3 Dimensions of connections and base plate with keyholes

Note: Dimensions relate to stations without housing or covers!

Dimensions in [mm]

a=480 (576)

b=620

c=110

d=65

e=24.5 (72.5)

f=50

g=462 (558)

h=450

i=68

Warning!

For 600 series stations,

dimensions are given

in brackets (xxx)

Fig.: Example representations

Dimensions in [mm]

a=576

b=620

c=110

d=65

e=58.8

f=50

g=558

h=450

i=68

LogoComfort 500/600 baseLogoComfort 600+ base

We reserve the right to change the designs and technical data of our products.

15

3.1.4 Add-on elements LogoComfort 500/600 and 600+ as base stations

The following add-on elements (modules) may be present. These are installed at the factory.

Thepossible combination options are also included in the current price list.

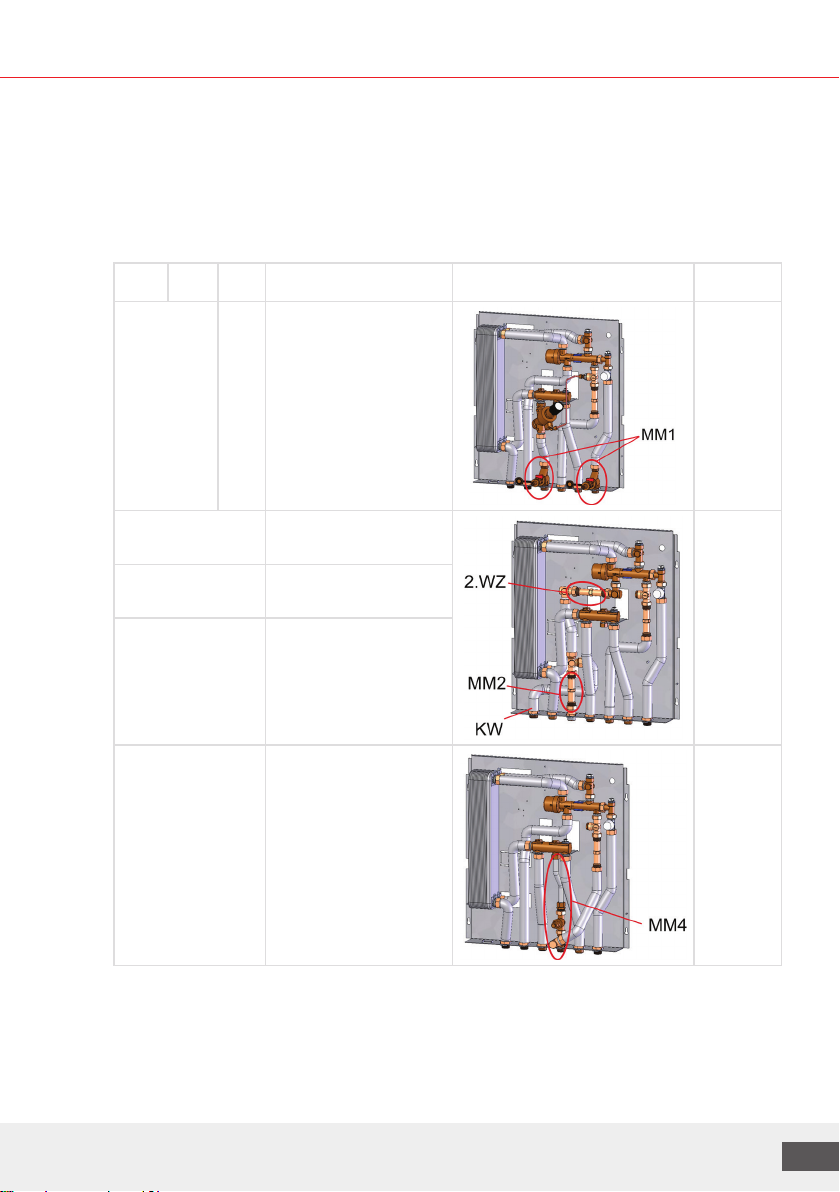

3.1.4.1 Summary of add-on elements and LC equipment options

Module for LC base stations

500 600 600+ Components Fig. Modules

(example representations)

See section

MM1 - 2x dirt traps with drainage

Note:

For LC 600 base variants

with side connection sets

as a mixing circuit or for

the LC 600+, only 1 x dirt

trap ispossible in each case

(seeMM26 module)

5.2

MM2 Cold water connection (CW)

with CW meter connection

piece

4.5.2

Art. No.: M10253.8 2nd water meter adapter

(2nd WM) for stations with

MM2 module

Art. No.: M10253.7 2nd water meter adapter

(2nd WM) for stations without

MM2 module

MM4 Adjustable circulation bridge

35-65°C

5.5

Manual for LogoComfort stations 24002.800

16

MM5 Dierential pressure regulator

with control range 10-40kPa

5.4

MM6 Scalding protection:

thermostatic hot water mixer

valve, adjustable: 35-60°C

5.7

Module for LC base stations

500 600 600+ Components Fig. Modules

(example representations)

See

section

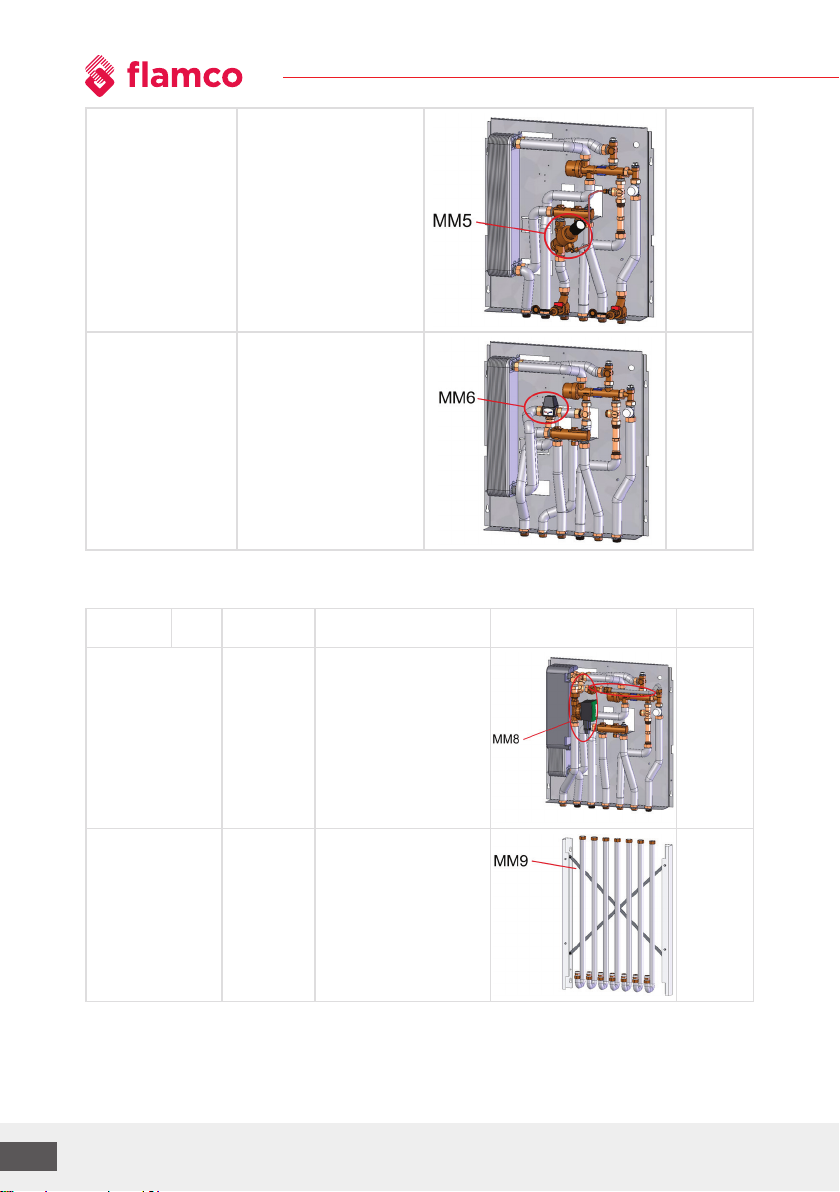

- MM8

(Art No.:

M10252.12)

Domestic water circulation

with:

- Pump incl. automatic

timer

- Backflow preventer

- Adjustable circulation

bridge 35-65°C

5.8

MM9 - Top connection with:

7 x connection lines,

frame depth 50 mm

4.4

We reserve the right to change the designs and technical data of our products.

17

MM11 Return line temperature

limiter 35-65°C

5.6

MM23

(Art No.:

M10252.32)

- Straight-way ball valve

set with:

7x DN20 BV, flow line

ball valve for HFM sensor

mounting

Note:

Domestic water ball valve

DVGW-approved

4.3

MM19

(Art No.:

M10252.34)

Straight-way ball valve set

with:

5x DN20 BV, flow line

ball valve for HFM sensor

mounting

Note:

Domestic water ball valve

DVGW-approved

- MM26 1x dirt trap with drainage

Note:

for LC 600 base variants

with side connection set

as a mixing circuit or for

LC 600+

5.2

Manual for LogoComfort stations 24002.800

18

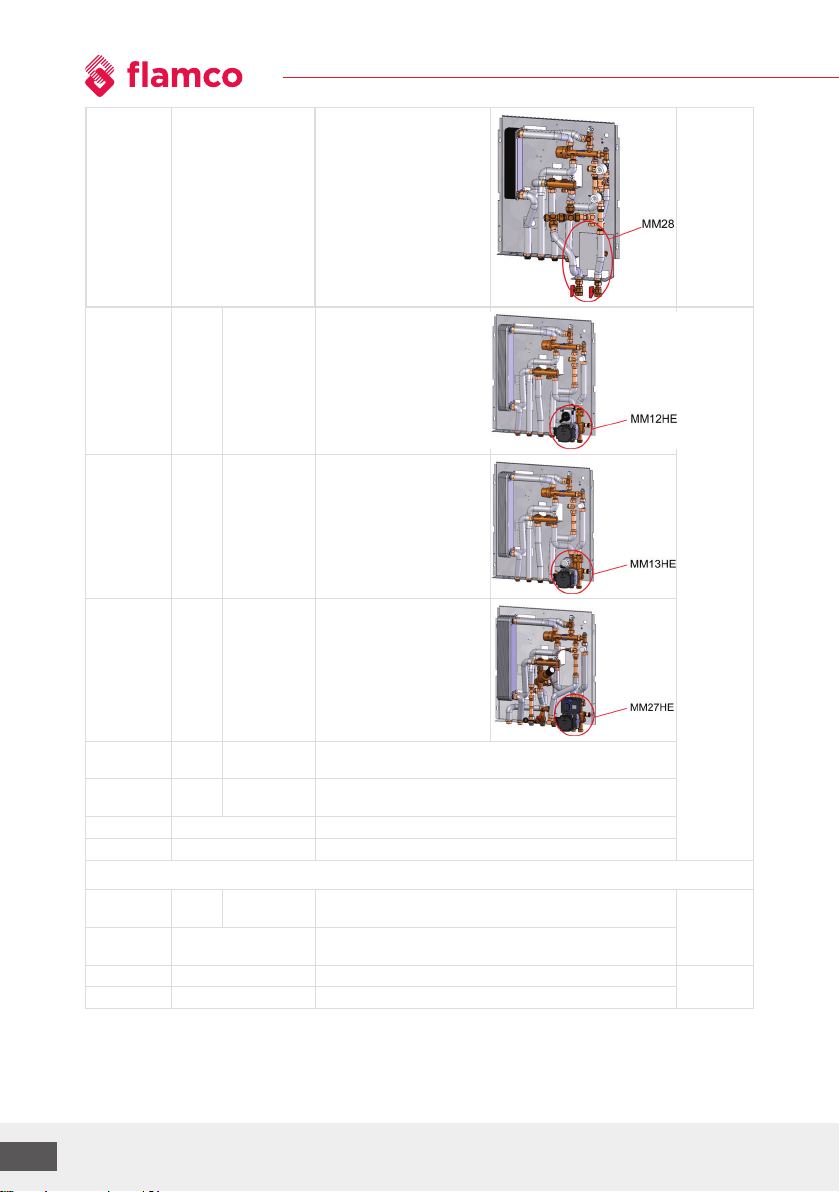

MM28 Additional connection

forstatic heating circuit

Note:

only up to manifolds for

5HC, from the 6th HC

onlyin combination with

600 base

5.9.4.2.

- - MM12HE Compact mixing circuit

group with servomotor

andHE pump for UFH

manifold 3-8 HC (type B).

5.9

- - MM13HE Compact mixing circuit

group with thermostatically

controlled mixing circuit

and HE pump for UFH

manifold 3-8 HC (type B)

- - MM27HE Compact mixing circuit

group with controlled

servomotor, flow line

temperature sensor and

HE pump for UFH manifold

3-8 HC (type B)

- √ - Corresponding side connection sets as a mixing circuit with

HE pump for optional manifold 3-12 HC (type E)

- Type E Type B Underfloor heating circuit manifold, type B: 3-8 or type E:

3-12 HC

MB-10560.09 Pre-wiring concept for use with up to 8 zones*

MB-10560.10 Pre-wiring concept for use with up to 10 zones*

* Up to 18 actuators can be connected and therefore multiples in each zone

MM10230.5SC - MM10230.5SC Heat exchanger for domestic water with high conductivity

for 12 l/min

- MM10232.58ES Heat exchanger for domestic water with high conductivity

for 17 l/min

- M10230.51 Insulated HE for 12 l/min

- M10232.592 Insulated HE for 17 l/min

We reserve the right to change the designs and technical data of our products.

19

M4325.1227.50 Meiflex SST flushing hose

¾" FT x FT, 500 mm long

4.2.2

M43.66124D Flushing connections

10x DN16 double nipples

(¾" flat-sealing)

3.1.4.2 Combination options of the add-on elements for LC 500/600 and 600+

LC 500 base stations

Combination options of the individual add-on elements (modules)

Dirt trap with drainage MM1 o o o o o o o

Cold water connection MM2 o o o o o o

Circulation bridge MM4 o o o o o

Dierential pressure regulator MM5 o o o o

Scalding protection MM6 o o o

Connector set top MM9 o o

Return line temperature limiter MM11 o

Key: o = possible

MM2 Cold water connection

MM4 Circulation bridge

MM5 Dierential pressure regulator

MM6 Scalding protection

MM9 Top connector set

MM11 Return line temperature limiter

MM23 Straight-way ball valve set DN20

Manual for LogoComfort stations 24002.800

20

LC 600 base stations

Combination options of the individual add-on

elements (modules)

Dirt trap with drainage MM1 o o o o o o o o o

Cold water connection MM2 o o o o o o o o

Circulation bridge MM4 o o x o o o o

Dierential pressure regulator MM5 o o o o o o

Scalding protection MM6 o o o o o

Domestic water circ. with pump MM8 x o o o

Connector set top MM9 o x o

Return line temperature limiter MM11 o o

Heating circuit manifold o

Key: o = possible, x = not possible

Note on the LC 600 base:

Manifold installed on base plate for possible connection sets with heating circuit pump: see Section 5.9.2

MM2 Cold water connection

MM4 Circulation bridge

MM5 Dierential pressure regulator

MM6 Scalding protection

MM9 Top connector set

Heating circuit manifold

MM8 domestic water circulation

with pump

MM11 Return line temperature limiter

MM23 Straight-way ball valve set DN20

This manual suits for next models

1

Table of contents

Other flamco Industrial Equipment manuals