Flexball Series 3500 Specification sheet

Flexball Italiana S.r.l. 1

O

Op

pe

er

ra

at

ti

in

ng

g

m

ma

an

nu

ua

al

l

&

&

m

mo

ou

un

nt

ti

in

ng

g

i

in

ns

st

tr

ru

uc

ct

ti

io

on

ns

s

Flexball Italiana S.r.l. 2

Index

1. Introduction.................................................................................................................................................................... 4

2. General installation features .......................................................................................................................................... 4

2.1. Description of the system and its parts............................................................................................................ 4

2.2. Maximum extension of the system .................................................................................................................. 4

2.3. System performance ....................................................................................................................................... 4

3. Pilot instructions............................................................................................................................................................. 5

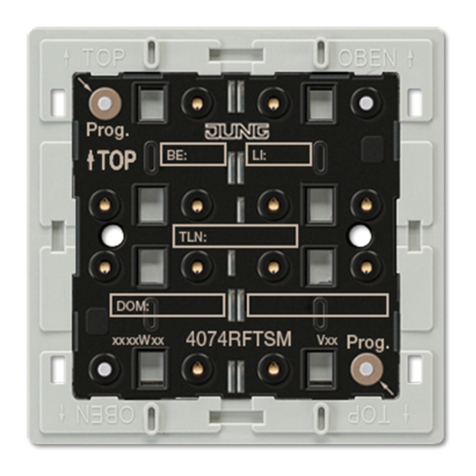

3.1. Control keypad ................................................................................................................................................ 6

3.2. Acquisition of the command ............................................................................................................................ 7

3.3. Engine Warm-up ............................................................................................................................................. 7

3.4. Synchro mode ................................................................................................................................................. 8

3.5. Fast Start-up Mode.......................................................................................................................................... 8

3.6. Emergency lever ............................................................................................................................................ 8

4. Command station........................................................................................................................................................... 9

4.1. Dimensions...................................................................................................................................................... 9

4.1.1. Command station series 3500 .................................................................................................................... 9

4.1.2. Command station series 4500 .................................................................................................................. 10

4.2. Friction adjustment ........................................................................................................................................ 10

4.2.1. Command station series 3500 .................................................................................................................. 10

4.2.2. Command station series 4500 .................................................................................................................. 11

4.3. Programming of the command station........................................................................................................... 11

4.4. Command station label.................................................................................................................................. 12

4.5. Command station codes................................................................................................................................12

5. Actuator ....................................................................................................................................................................... 13

5.1. Drawing of actuators with mechanical interface ............................................................................................ 13

5.2. Drawing of full electronic actuator ................................................................................................................. 14

5.3. Actuator labels............................................................................................................................................... 15

5.4. Actuator Codes.............................................................................................................................................. 16

5.5. Electronic Actuator Boards ............................................................................................................................ 17

5.5.1. Actuator board ver. 3.1 ............................................................................................................................. 17

5.5.2. Relays PCB version 1.0 for electronic gearboxes..................................................................................... 18

5.5.3. Relays PCB version 2.0 for electronic gearboxes..................................................................................... 19

5.5.4. CANBus PCB for motor with CANBus interface ....................................................................................... 20

5.5.5. Galvanic insulation PCB for analogue voltage signals................................................................................. 20

6. Accessories and Options ............................................................................................................................................. 21

6.1. CANBus data transmission cable .................................................................................................................. 22

6.2. Cable actuator – electronic motor (V) ............................................................................................................ 22

6.2.1. Nanni Diesel – Throttle cable for Toyota ECU .......................................................................................... 23

6.2.2. Nanni Diesel – Cable only for the inverter (hybrid motors) ....................................................................... 23

6.2.3. Nanni Diesel – Command cable for throttel and inverter (1°part, Y cable)............................................... 23

6.2.4. Nanni Diesel – Y cable for Toshiba motor base (V) + inverter (V) ........................................................... 24

6.2.5. Nanni Diesel – Y cable for VM motor base (CANBus) + inverter ............................................................. 24

6.2.6. FPT – Throttle CANBus command cable.................................................................................................. 25

6.3. Cable actuator – gearbox solenoid driven ..................................................................................................... 25

6.3.1. Nanni Diesel – Cable for gearbox solenoid driven.................................................................................... 25

6.3.2. FPT – Cable for gearbox solenoid driven ................................................................................................. 25

6.3.3. Nanni Diesel – Cable for gearbox solenoid drive + neutral signal............................................................. 26

6.4. Cable actuator – trim/flap .............................................................................................................................. 26

6.4.1. Nanni Diesel – Cable for the trim/flap command ...................................................................................... 26

6.5. Cable actuator – Mercruiser® trim pump....................................................................................................... 27

6.6. T-Splitter........................................................................................................................................................ 27

6.7. Power supply connector ................................................................................................................................ 27

6.8. Trim/Flap option ............................................................................................................................................ 28

7. System types and installation schemes ....................................................................................................................... 29

7.1. Installation with 2 mechanical actuators – solution A .................................................................................... 30

7.2. Installation with 2 mechanical actuators – solution B .................................................................................... 31

7.3. Installation with 2 mechanical actuators – solution C .................................................................................... 32

7.4. Installation with 1 actuator – solution D ......................................................................................................... 33

7.5. Installation with 1 actuator – solution E ......................................................................................................... 34

8. Configuration of the CANBus network: end of line termination resistor and address setting of command stations and

actuators ............................................................................................................................................................................... 35

8.1. Configuration of the command station ........................................................................................................... 35

8.2. Configuration of the actuator ......................................................................................................................... 36

9. Push-pull cables installation ........................................................................................................................................ 38

9.1. Connection kit................................................................................................................................................ 38

9.2. Standard push-pull cable (E2, E3, Volvo®, C0, C3, C33…).......................................................................... 38

9.3. Push-pull cable outgoing from the Mercruiser® stern driver.......................................................................... 39

9.4. Johnson® push-pull cable .............................................................................................................................39

Flexball Italiana S.r.l. 3

10. Electrical installation .................................................................................................................................................... 40

10.1. Wiring of actuator output cables ............................................................................................................... 40

10.1.1. Cabling of the supply connector ............................................................................................................... 40

10.1.2. Electrical installation of systems with 1 motor, 1 actuator and 1 dashboard ............................................. 42

10.1.3. Electrical installation of systems with 2 motors, 1 or 2 actuators and 2 dashboards ................................ 43

10.1.4. Electrical installation of systems with 1 motor, 1 actuator and 2 dashboards ........................................... 44

10.1.5. Dimensional criteria of the power cables for the overall installation.......................................................... 45

10.2. Electrical cabling of the outgoing cables from the actuator....................................................................... 46

10.2.1. Cabling of actuators for mechanical and hybrid propulsion systems ........................................................ 46

10.2.2. Cabling of actuators for electronic propulsion systems............................................................................. 47

10.2.3. Cabling scheme from actuator to gearbox, from actuator to trim or from actuator to flap ......................... 47

11. Programming of the actuator, general guidelines ........................................................................................................ 48

11.1. Programming keypad................................................................................................................................ 48

11.2. Display and Parameters ........................................................................................................................... 48

11.3. Actuator parameters .................................................................................................................................49

11.3.1. Parameter “CC” ........................................................................................................................................ 49

12. Setting of the strokes of push-pull cables .................................................................................................................... 50

12.1. Setting of the stroke of the accelerator cable............................................................................................ 50

12.2. Setting of the stroke of the gearbox cable ................................................................................................ 51

13. Programming of the actuator in installations with mechanical motor and gearbox ...................................................... 52

13.1. Mounting of the push-pull cable................................................................................................................ 52

13.2. Programming of the push-pull cable strokes............................................................................................. 52

13.3. Specific parameters.................................................................................................................................. 53

14. Programming of actuators for installations with electronic motor and mechanical gearbox......................................... 54

14.1. Programming of the gearbox strokes........................................................................................................ 54

14.2. Specific parameters.................................................................................................................................. 54

14.2.1. Parameter A0 ........................................................................................................................................... 55

14.2.2. Parameters to configure the voltage output signal for electronic motors .................................................. 56

15. Programming of actuators for mechanical motors and electronic gearbox .................................................................. 57

15.1 Installation of motor the push-pull cable and programming of throttle mechanical strokes............................ 57

15.2 Programming of the push-pull cable strokes ................................................................................................. 57

15.3 Electrical cabling of the gearbox....................................................................................................................57

15.4 Specific parameters....................................................................................................................................... 57

16. Programming of actuators with electronic motor and electronic gearbox..................................................................... 58

16.1. Electrical wiring......................................................................................................................................... 58

16.2. Specific parameters.................................................................................................................................. 58

17. Programming of actuators with electronic CANBUS motor and mechanical gearbox.................................................. 59

17.1. Installation of the push-pull cable and programming of the cable stroke .................................................. 59

17.2. Specific parameters.................................................................................................................................. 59

17.2.1. CANBus protocol ...................................................................................................................................... 59

17.2.2. Setting of the CANBus parameter values ................................................................................................. 60

17.2.3 Technical data of the CANBus interface card........................................................................................... 61

17.3. Wiring of the outgoing actuator cables ..................................................................................................... 61

17.4. Connection to FPT motors through CANBus interface ............................................................................. 61

18. Programming of actuators with electronic CANBUS motor and electronic gearbox.................................................... 63

18.1. CANBus motor parameters....................................................................................................................... 63

18.2. Electronic gearbox parameters................................................................................................................. 63

18.3. Wiring of the actuator outgoing cables ..................................................................................................... 63

19. Programming of actuators for installations with Trim or Flap command option............................................................ 63

20. Programming of actuators with the option for hybrid motors........................................................................................ 64

21. Behaviour of the electronic system in case of failures ................................................................................................. 65

21.1. Unforeseen motor switching off ................................................................................................................ 65

21.2. Faults in the electrical network ................................................................................................................. 65

21.3. Protection in case of overload or break of the push-pull cables................................................................ 65

21.4. Troubleshooting ........................................................................................................................................ 66

21.5. LED diagnosis on command station ......................................................................................................... 67

22. How to start ................................................................................................................................................................. 68

23. Drilling mask ................................................................................................................................................................ 69

Version June 2011

Flexball Italiana S.r.l. 4

1. Introduction

This manual describes the electronic remote control system in general and its operating, performance and

safety aspects. If it is the first time that you install an electronic control system, go to section 22 where you will

be guided to the necessary steps.

2. General installation features

2.1. Description of the system and its parts

The electronic engine remote control implements mechanical and electronic solutions with digital

communication technology. Only few devices are required to compose a complete electronic engine remote

control:

•Commandstations

•Actuators

•Datacommunicationcableswhichconnectthecommand stations to the Actuators

2.2. Maximum extension of the system

The maximum configuration of the system is as shown in the following table:

Actuators The maximum number of engines that the system can control is 2

Command stations The maximum number of command stations in the installation is 3

80 meters Maximum distance between cockpit and engine room

2.3. System performance

Temperature

Operating temperature From -10 to 85°C

Storage temperature From -40 to 90°C

Mechanical features

Nominal load when actuator is providing a

pushing force 150 N (15 kg) with power consumption 1.5 A

Max load when actuator is providing

a pushing force 450 N (45 kg) with power consumption 5 A (with time <1 s)

Stroke of gearbox – forward

Stroke of gearbox – reverse Stroke can be set to between 5 and 40 mm

Throttle stroke Stroke can be set to between 5 and 80 mm

Electrical features

Power supply (*) from 9,0 to 16 Vdc or from 9,0 to 28,0 Vdc

Max. current absorbed 5 A

Current absorbed when the system isn’t loaded 0,5 A

* according to the version of the actuator

Flexball Italiana S.r.l. 5

3. Pilot instructions

Each station can be programmed for the control of one or two engines. Each lever repeats the functionality of a

traditional mechanical lever.

Moving the lever from the neutral position, after 16° forward or reverse automatically the electronic system

clutches-in respectively the forward or reverse gear. The accelerator lever has a stroke of 62° both in forward

and backward direction.

Command station series 3500

Command station series 4500

Flexball Italiana S.r.l. 6

3.1. Control keypad

On the command station it is mounted an electronic keypad with 4 push-buttons and 4 LEDs.

(*) In installations with single engine, both the green LEDs are referring to the same engine. In systems with 2

engines the push button and the green LED on the right are referring to the starboard engine while the push

button and the green LED on the left side are referring to the port engine.

Description LEDs colour

Engine (*) Green

Warm/Sync Orange

Command Red

Engine (*) Green

Command station series 3500 Command station series 4500

Flexball Italiana S.r.l. 7

It follows the table with the definition of LED and push buttons.

Push-button LED Description

(Command) (Meaning)

Engine

The left LED is for the port (left) engine, while the right LED is for the

starboard (right) engine. If the LED has a fixed light on (green), the

corresponding gearbox is in neutral position.

If the LED is blinking (green), the lever on the LED’s side is synchronised

with the lever of the station that at the moment has the Command.

Command

If it is switched off, the Station has not the command.

If is switched on, the Station has the command.

Warm/Sync

If it is blinking, the navigation system is in Warm-up mode; this means that

the engines can be warmed up without clutching-in the gear.

If the LED is fix lighted, the system is in Synchro mode

Warm/Sync

When both the levers of the Station that has the command are in neutral

position, if you press for 1,5 seconds the button Warm, it is activated the

function Warm-up.

Command

If you press Command for 1,5 seconds the station takes the command, only

if one of these two conditions are respected:

- both the lever of the station are in neutral

- both the lever are synchronized with respect to the levers of the station

that at the moment has the command

All LEDs are lighted on The control system isn’t working correctly

3.2. Acquisition of the command

It is possible to acquire the command of the boat from any Station in the following cases:

The boat isn’t moving

1. Position all the levers in neutral and press Command for 1,5 seconds.

2. LED “Command” is now lighted on while the warm/synch LED is blinking. You are in Warm-up mode:

throttle command is enabled but clutch command is disabled.

3. To take the command you must press for 1,5 seconds the Warm/Sync bush-button, afterwards the

station acquires the command.

In navigation

1. Synchronize the 2 levers of the Station which wants to acquire the command with respect to the Station

which has the command.

2. When LEDs “Engine” of two levers of the station which wants to acquire the command are blinking,

these levers are synchronised with respect to the levers of the Station which still has the command.

3. By pressing the pushbutton Command for 1,5 seconds, the new Station takes the command.

►Important: before taking the command, proof that all the passengers are safely on board.

3.3. Engine Warm-up

If both levers are in neutral, by pressing for 1,5 seconds the button Warm/Sync of the Station which has the

command, you enter in Warm-up mode. If you move the lever. it is only affected the accelerator but not the

gear. In Warm-up mode the LED Warm/Sync is blinking.

After positioning again both levers in neutral and pressing for 1,5 seconds the Warm/Sync, the system comes

back to the normal operation mode.

Flexball Italiana S.r.l. 8

3.4. Synchro mode

It is possible to command both engines at the same speed and direction with only one lever. This function can

be activated only by the command station which has the command.

With both levers in neutral position, press at the same time for 1,5 seconds the two “engine” push-buttons. The

command of both engines is now on the right lever. In Synchro operation mode, the LEDs “Warm/Sync” and

“Command” are lighted on.

From “Synchro” operation mode, if you position both levers in neutral, and press contemporaneously for 1,5

seconds the two “Engine” push buttons, the command of each engine is again assigned to the respective lever

and LED “Warm/Sync” is switched off.

The same operation of synchronisation or de-synchronisation can be performed on the station which has the

command, in case the RPM between the two motors doesn’t differ more than 10%.

3.5. Fast Start-up Mode

This function is available on the first command station as described in section 8.1 of this manual. When the

configuration FSM (Fast Start up Mode) is enabled, the command station with the FSM enabled takes

automatically the command at the power on, only if this command station is in neutral position.

If the command station is not in neutral position, the command station will take the command as soon the

neutral position will be reached.

3.6. Emergency lever

In case of emergency, the electronic system can be

switched off quickly and the engines can be operated

directly with the mechanical emergency levers.

Emergency levers are fitted on the control box. It is

sufficient to turn completely on (clockwise) knob (A).

After this operation, the gearbox can be operated

manually using levers (B) and with the throttle set to

minimum.

In order to reset the system, turn off completely

(counter-clockwise) knob (A). The emergency lever

automatically goes back to the position where it was

before activating the emergency mode, at the first

movement of the command lever.

B

A

Flexball Italiana S.r.l. 9

COMMAND

ENGINE 2

WARM/S

ENGINE 1

4. Command station

Command stations are classified as devices for the control of one or two engines, with or without trim/flap

command. Up to three command stations can be mounted in the same installation. Depending on the

application, it is very important to set the dip-switches present on the bottom part of the command station, as

described in sections 4.2 and 8.1 of this manual.

4.1. Dimensions

4.1.1. Command station series 3500

►Important: in case the screws to fix command station to the dashboard panel are not long enough, don’t

open the command station to replace them but ask for an adaptation kit.

Flexball Italiana S.r.l. 10

4.1.2. Command station series 4500

4.2. Friction adjustment

4.2.1. Command station series 3500

To adjust the inner friction of the command lever, remove the

PVC cap (A) and unscrew the fixing screw. It is possible to

adjust the friction screwing and unscrewing the inner screw

placed into the hole (B). When the regulation will be done,

mount the screw and the plastic cap.

►Important: in case of command station for one engine,

the friction is placed under the right command lever.

Flexball Italiana S.r.l. 11

4.2.2. Command station series 4500

In order to adjust the friction of the lever, it is necessary to remove the screw A

placed below the plastic base of the command station. With the help of an

hexagon screw driver size 3 mm you can loosen or tighten the screw and the

friction will become correspondingly softer or harder.

Once the friction has been adjusted, close again the hole with screw A.

Important: In case of a command station for single engine, the friction is

present only on the left lever.

4.3. Programming of the command station

At power up, the command station makes a sequence of two flashes. The first flash identifies the number of

motors and the second identifies the number of actuators present in the system. According to the length of

each flash, the command station is differently configured.

You need to configure the command station in relation to the type of installation. It is also possible to modify the

configuration of the command station by keeping pressed before powering up and continuing to keep them

pressed for 6 seconds after power up, the following push buttons:

thetwointernalpushbuttons(Warn/Sync+Command), in this case you modify the number of

actuators

(Engineleft+Engineright),inthiscaseyouchange the number of motors on the boat

Possible configurations are according to the following table:

1°flash

(identifies the number of motors)

2°flash

(identifies the number of actuators)

Installation with 1 motor

and 1 actuator Long (3 seconds) Long (3 seconds)

Installation with 2 motors

and 1 actuator Short (less than 1 second) Long (3 seconds)

Installation with 2 motors

and 2 actuators Short (less than 1 second) Short (less than 1 second)

►Important: from the factory, the command station is configured with the first flash short and the second flash

long.

1. To configure the command lever for an installation with 2 actuator boxes, press the two central push

buttons (Warm/Sync e Command) before powering up the command lever and continue to keep them

pressed for 6 seconds. The lever is now configured for installations with two motors and two actuators.

At the next normal power up, the command lever will make a sequence of 2 short flashes.

2. In case you need to configure again the command lever for installation with 2 motors and 1 actuator,

repeat the procedure of point 1.

B

Flexball Italiana S.r.l. 12

4.4. Command station label

Under the base of the command station it is present the following

label.

This labels indicates the code of the command station, the serial

number and the different dip-switches configuration according to the

type of the command station.

►Important 1: these configurations are valid according to schemes

from section 7.1 to t.5. in case of different configurations, contact the

constructor technical department

►Important 2: in the same installation can’t coexist a “1st command

station FSM” and a “1st command station”. “1st command station

FSM” replaces “1st command station” and vice versa.

4.5. Command station codes

Command stations

Descrizione Code

Command station 1 motor series 3500 3500

.

C

-

1

0

0

0

0

5

Command station 1 motor series 3500 with TRIM option 3500

.

C

-

1

1

0

0

0

5

Command station 2 motors series 3500 3500

.

C

-

2

0

0

0

0

5

Command station 2 motors series 3500 with TRIM option 3500

.

C

-

2

2

0

0

0

5

Command station 1 motor series 4500 4500

.

C

-

1

0

0

0

0

5

Command station 1 motor series 4500 with TRIM option 4500

.

C

-

1

1

0

0

0

5

Command station 2 motors series 4500 4500

.

C

-

2

0

0

0

0

5

Command station 2 motors series 4500 with TRIM option 4500

.

C

-

2

2

0

0

0

5

Command station 1 motor series 4500 with Trolling option 4500

.

T

-

1

0

0

0

0

5

Command station 1 motor series 4500 with TRIM option & Trolling 4500

.

T

-

1

1

0

0

0

5

Command station 2 motors series 4500 with Trolling option 4500

.

T

-

2

0

0

0

0

5

Command station 2 motors series 4500 with TRIM option & Trolling 4500

.

T

-

2

2

0

0

0

5

Flexball Italiana S.r.l. 13

5. Actuator

The actuator should be mounted in the engine room in a safety place but as near as possible to the propulsion

engine. With reference to the type of motor and gearboxes, with or without trim/flap, actuators are classified as

follow:

mechanical

electronic

mechanical&electronic(hybrid)

It follow mechanical drawings of the different types of actuators. The last page of this manual you find the

footprint of the actuator in scale 1:1.

5.1. Drawing of actuators with mechanical interface

►Important: the part of the drawing identified with letter (A) doesn’t exist on actuators with mechanical

interface either towards the motor or towards the gearbox.

A

Flexball Italiana S.r.l. 14

5.2. Drawing of full electronic actuator

LEFT ENGINE RIGHT ENGINE

+12 V

Fuse

CANBus

How to mount the actuator

Do not install the actuator with the

connectors upwards

Mount the actuator leaving a space of at least 25 cm on each side

Flexball Italiana S.r.l. 15

5.3. Actuator labels

Inside the actuator there are two labels indicating code and serial number. Please write them down in case you

call for assistance.

Ac

tuator

code

Serial number

Flexball Italiana S.r.l. 16

5.4. Actuator Codes

Actuator for 1 mechanical motor and 1 gearbox mechanical (no trim) 3500

.

A

-

0

0

4

0

3

9

Actuator for 1 mechanical motor and 1 gearbox mechanical (with trim) 3500

.

A

-

0

0

4

1

3

9

Actuator for 1 electronic motor (V) and 1 gearbox mechanical (no trim) 3500

.

A

-

1

1

4

0

3

9

Actuator for 1 CANBus motor and 1 gearbox mechanical (no trim) 3500

.

A

-

5

1

4

0

3

9

Actuator for 1 electronic motor (mA) and 1 gearbox mechanical (no trim) 3500

.

A

-

7

1

4

0

3

9

Actuator for 1 PWM motor and 1 gearbox mechanical (no trim) 3500

.

A

-

3

1

4

0

3

9

Actuator for 2 electronic motors (V) and 2 gearboxes mechanical (no trim) 3500

.

A

-

2

2

4

0

3

9

Actuator for 2 motors CANBus and 2 gearboxes mechanical (no trim) 3500

.

A

-

6

2

4

0

3

9

Actuator for 2 electronic motors (mA) and 2 gearboxes mechanical (no trim) 3500

.

A

-

8

2

4

0

3

9

Actuator for 2 PWM motors and 2 gearboxes mechanical (no trim) 3500

.

A

-

4

2

4

0

3

9

Actuator for 1 electronic motor (V) and 1 gearbox mechanical (with trim) 3500

.

A

-

1

1

4

1

3

9

Actuator for 1 CANBus motor and 1 gearbox mechanical (with trim) 3500

.

A

-

5

1

4

1

3

9

Actuator for 1 electronic motor (mA) and 1 gearbox mechanical (with trim) 3500

.

A

-

7

1

4

1

3

9

Actuator for 1 PWM motor and 1 gearbox mechanical (with trim) 3500

.

A

-

3

1

4

1

3

9

Actuator for 2 electronic motors (V) and 2 gearboxes mechanical (with trim) 3500

.

A

-

2

2

4

2

3

9

Actuator for 2 CANBus motors and 2 gearboxes mechanical (with trim) 3500

.

A

-

6

2

4

2

3

9

Actuator for 2 electronic motors (mA) and 2 gearboxes mechanical (with trim) 3500

.

A

-

8

2

4

2

3

9

Actuator for 2 PWM motors and 2 gearboxes mechanical (with trim) 3500

.

A

-

4

2

4

2

3

9

Actuator for 1 mechanical motor and 1 gearbox solenoid driven (no trim) 3500

.

A

-

0

3

4

0

3

9

Actuator for 2 mechanical motors and 2 gearbox solenoid driven (no trim) 3500

.

A

-

0

3

4

0

3

9

Actuator for 1 mechanical motor and 1 gearbox solenoid driven (with trim) 3500

.

A

-

0

3

4

1

3

9

Actuator for 2 mechanical motors and 2 gearbox solenoid driven (with trim) 3500

.

A

-

0

3

4

2

3

9

Actuator for 1 electronic motor (V) and 1 gearbox solenoid driven (no trim) 3500

.

A

-

1

3

0

0

3

9

Actuator for 1 CANBus motor and 1 gearbox solenoid driven (no trim) 3500

.

A

-

5

3

0

0

3

9

Actuator for 1 electronic motor (mA) and 1 gearbox solenoid driven (no trim) 3500

.

A

-

7

3

0

0

3

9

Actuator for 1 PWM motor and 1 gearbox solenoid driven (no trim) 3500

.

A

-

3

3

0

0

3

9

Actuator for 2 electronic motors (V) and 2 gearboxes solenoid driven (no trim) 3500

.

A

-

2

4

0

0

3

9

Actuator for 2 CANBus motors and 2 gearboxes solenoid driven (no trim) 3500

.

A

-

6

4

0

0

3

9

Actuator for 2 electronic motors (mA) and 2 gearboxes solenoid driven (no trim) 3500

.

A

-

8

4

0

0

3

9

Actuator for 2 PWM motors and 2 gearboxes solenoid driven (no trim) 3500

.

A

-

4

4

0

0

3

9

Actuator for 1 electronic motor (V) and 1 gearbox solenoid driven (with trim) 3500

.

A

-

1

3

0

1

3

9

Actuator for 1 CANBus motor and 1 gearbox solenoid driven (with trim) 3500

.

A

-

5

3

0

1

3

9

Actuator for 1 electronic motor (mA) and 1 gearbox solenoid driven (with trim) 3500

.

A

-

7

3

0

1

3

9

Actuator for 1 PWM motor and 1 gearbox solenoid driven (with trim) 3500

.

A

-

3

3

0

1

3

9

Actuator for 2 electronic motors (V) and 2 gearboxes solenoid driven (with trim) 3500

.

A

-

2

4

0

2

3

9

Actuator for 2 CANBus motors and 2 gearboxes solenoid driven (with trim) 3500

.

A

-

6

4

0

2

3

9

Actuator for 2 electronic motors (mA) and 2 gearboxes solenoid driven (with trim) 3500

.

A

-

8

4

0

2

3

9

Actuator for 2 PWM motors and 2 gearboxes solenoid driven (with trim) 3500

.

A

-

4

4

0

2

3

9

Flexball Italiana S.r.l. 17

5.5. Electronic Actuator Boards

5.5.1. Actuator board ver. 3.1

Position on board Pin Description Output cable

1 Vdc

JP8

Supply 2 GND Wall connector

2 V_out CH1

3 V_out CH2

1 GND CH2

JP9

Engine DX

4

MOD2

(Rev.3)

GND CH1

4 poles

2 V_out CH1

3 V_out CH2

1 GND CH2

JP10

Engine SX

4

MOD2

(Rev.3)

GND CH1

4 poles

►Important: channels 1 and 3 are dedicated to the electronic engine (ECU) while the channels 2 and 4 are

dedicated to the inverter for electric motors (hybrid motor applications).

JP12

UP

DOWN ENTER

JP1

JP2

JP7

Fusibile

JP13

JP11

JP14

JP15 JP19

21

JP8 JP3 JP18 JP17 JP16

JP10 JP9 JP6 JP5

Flexball Italiana S.r.l. 18

5.5.2. Relays PCB version 1.0 for electronic gearboxes

Relè right

gearbox

Relè right

gearbox Solenoid gearbox Trim command

1.1 5.1 Forward (brown) Trim “-“ (nero)

1.2 5.2

1.3 5.3 Vdc (yellow/green) Vdc (brown)

2.1 6.1 Reverse (blue) Trim “+” (grey)

2.2 6.2

2.3 6.3

3.1 7.1 Trim “–“ (brown) Trailer (yellow/green)

3.2 7.2

3.3 7.3 Vdc (yellow/green)

4.1 8.1 Trim “+” (blue)

4.2 8.2

4.3 8.3

Flexball Italiana S.r.l. 19

5.5.3. Relays PCB version 2.0 for electronic gearboxes

Fuse

Fusibile

123456789101112 242322212019181716151413

Pin Description

1 Vdc

2 GND

3 Vdc

4 GND

5 Left engine – Trim common contact

6 Left engine – Trim +

7 Left engine – Trim -

8 Left engine – Trailer

9 Left engine - Common neutral relays contact

10 Left engine - NC contact neutral relays

11 Left engine – Forward gear

12 GND

13 Left engine – Reverse gear

14 GND

15 Right engine - Forward gear

16 GND

17 Right engine - Reverse gear

18 GND

19 Right engine - Common neutral relays contact

20 Right engine - NC contact neutral relays

21 Right engine - Common trim contact

22 Right engine - Trim +

23 Right engine - Trim -

24 Right engine – Trailer

Flexball Italiana S.r.l. 20

5.5.4. CANBus PCB for motor with CANBus interface

Important: you need a CANBus board per each CANBus engine

The out-coming cable has a length of 3 meters. Maximum current per each

channel is 100 mA. Out signals are protected against short circuit towards

ground and towards power supply.

CANBus termination resistor of 120 ohm is already implemented on the

PCBoard but, if necessary, it can be removed.

5.5.5. Galvanic insulation PCB for analogue voltage signals

This option can be used in those cases where there are voltage differences between different ground points on

the boat. A non optimum ground network can generate circuit currents and therefore disturbances in the

transmission of command signals (see section 10.1.5.).

Each PCB performs the galvanic insulation of 2 command signal up to 250 Vdc. On each actuator it is possible

to mount 2 PCBs for the interface towards:

ElectronicECUwithvoltagesignal

ElectronicECUwithCANBusinterface

Commandofhybridmotorsfrequencyconverterdriven through a voltage signal

The PCB is mounted inside of the actuator and there aren’t any special precaution to follow durig

commissioning.

terminal

block

Terminal

n° description wire colour Kind of cable

4 Can_H White

JP4 5 Can_L Blue 2 poles

J3 J1 J4

16543212 1

23456

This manual suits for next models

2

Table of contents

Other Flexball Control Unit manuals

Popular Control Unit manuals by other brands

MASCOT

MASCOT VFlo Installation, operation & maintenance instructions

Velleman

Velleman VMM005 user manual

Kessel

Kessel Aqualift F Comfort 400V Series MANUAL FOR INSTALLATION, OPERATION AND MAINTENANCE

Trikdis

Trikdis G10 user manual

Apollo Valves

Apollo Valves DC4A Installation, operation & maintenance manual

LiteOn

LiteOn WN6508A user manual