Flexball 4000-ELT User manual

Flexball Italiana S.r.l. 1

O

Op

pe

er

ra

at

ti

in

ng

g

m

ma

an

nu

ua

al

l

&

&

m

mo

ou

un

nt

ti

in

ng

g

i

in

ns

st

tr

ru

uc

ct

ti

io

on

ns

s

Flexball Italiana S.r.l. 2

Index

1. Introduction ....................................................................................................................................... 3

2. General installation features .............................................................................................................. 3

2.1. Description of the system and its parts .................................................................................. 3

2.2. Maximum extension of the system......................................................................................... 3

2.3. Specification ......................................................................................................................... 3

3. Pilot instructions ................................................................................................................................ 4

3.1. Control keypad...................................................................................................................... 5

3.2. Acquisition of the command .................................................................................................. 6

3.5 Fast Start-up Mode ................................................................................................................... 6

4. Command station .............................................................................................................................. 6

4.1. Dimensions........................................................................................................................... 6

4.1.1. Command station series 4000........................................................................................... 6

4.1.2. Command station series 4500........................................................................................... 7

4.2. Friction adjustment................................................................................................................ 7

4.2.1. Command station series 4000........................................................................................... 7

4.2.2. Command station series 4500........................................................................................... 8

4.3. Command station set-up ....................................................................................................... 8

6. Accessories and option...................................................................................................................... 9

6.1. Power supply and speed reference cable (4 poles)................................................................ 9

6.6. T-Splitter............................................................................................................................. 10

6.9. Command cable (4 poles) ..................................................................................................... 11

8. Interface towards the motor controller and functioning principle........................................................ 12

8.1. Speed signal towards the motor’s controller .......................................................................... 13

8.2. Programming of the delay when passing from Forward to Reverse or vice versa ................... 13

8.3. CanBUS protocol .................................................................................................................. 13

8.4. Technical data of the CANBus interface card ........................................................................ 13

21. Behaviour of the electronic system in case of failures ...................................................................... 14

21.4. Troubleshooting .................................................................................................................. 14

21.5. LED diagnosis on command station .................................................................................... 14

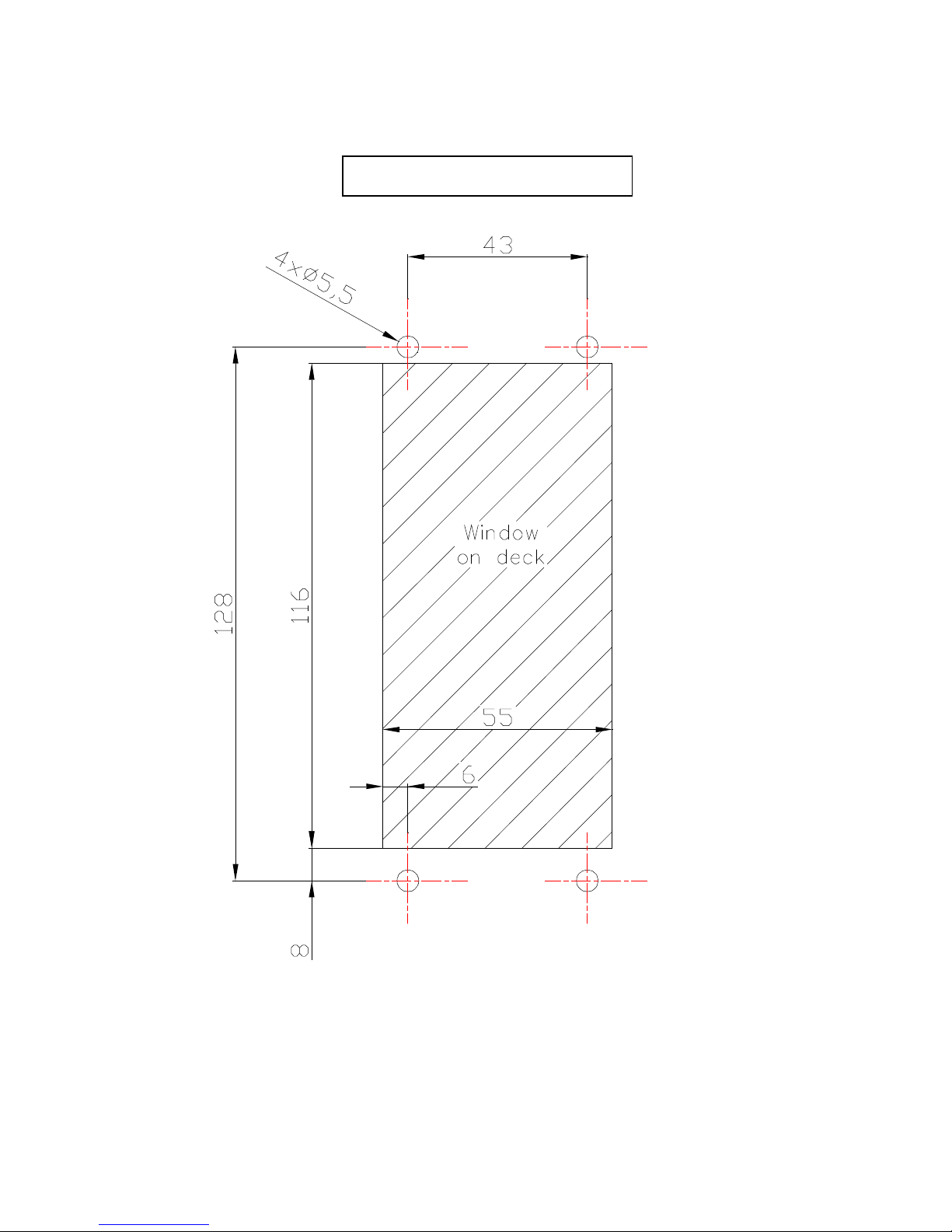

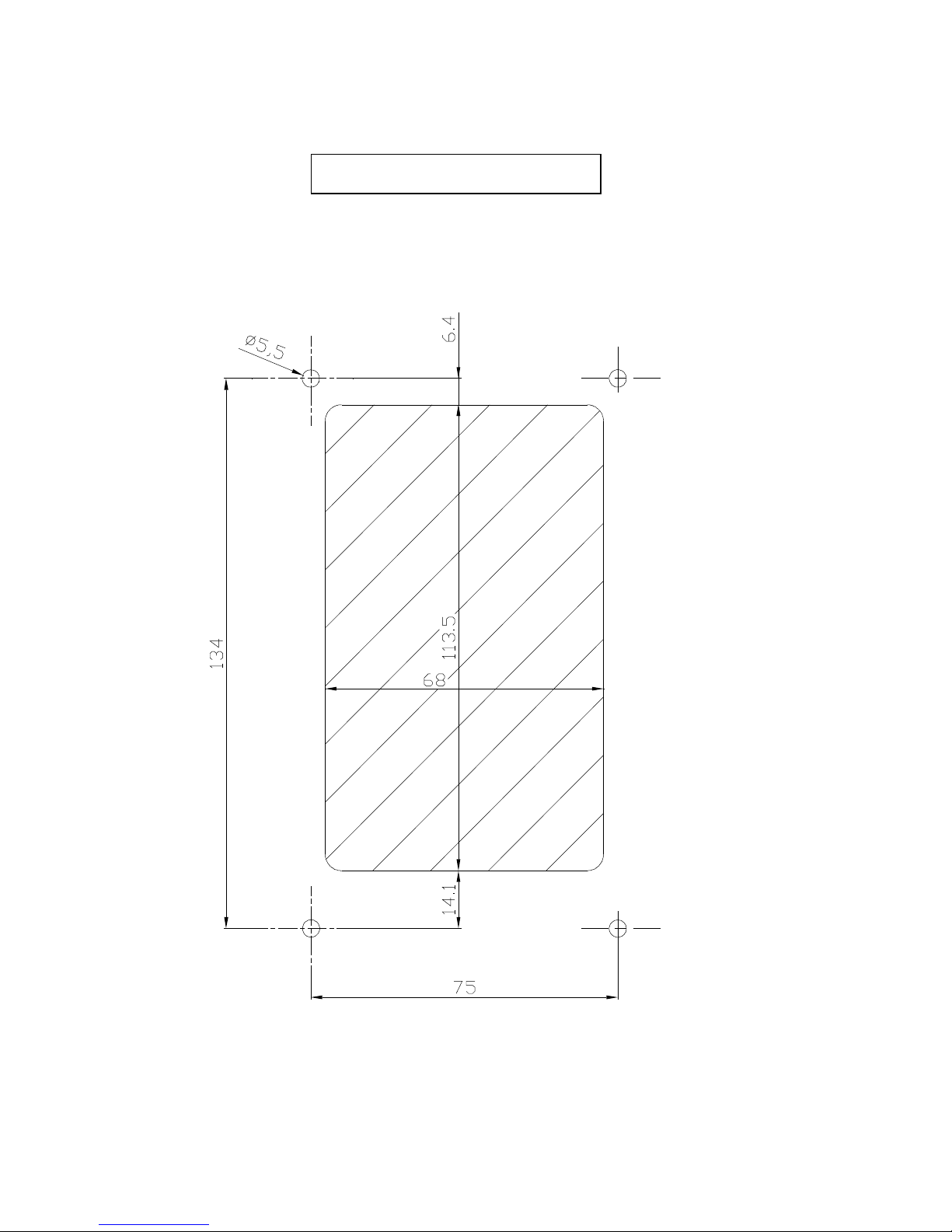

23. Drilling mask for command station ................................................................................................... 15

Version July 2013

Flexball Italiana S.r.l. 3

1. Introduction

This manual describes the electronic remote control system in general and its operating, performance and

safety aspects. If it is the first time that you install an electronic control system, go to section 22 where you

will be guided to the necessary steps.

2. General installation features

2.1. Description of the system and its parts

The electronic systems 4000 – ELT and 4500 – ELT are composed with the lever and the necessary cables

for the connection to the motor’s controller.

2.2. Maximum extension of the system

The maximum configuration of the system is as shown in the following table:

10 meters

Maximum distance between

lever

and engine room

in c

ase of voltage

interface towards the motor controller

80 meters

Maximum distance between

lever

and engine room

in case of CANBus

interface towards the motor controller

2.3. Specification

Temperature

Operating temperature

From

-

10 to 85°C

Storage temperatur

e

From

-

40 to 90°C

Electrical features

Power supply (*) From 9,0 to 28,0 Vdc

Max. current absorbed 0,5 A

Flexball Italiana S.r.l. 4

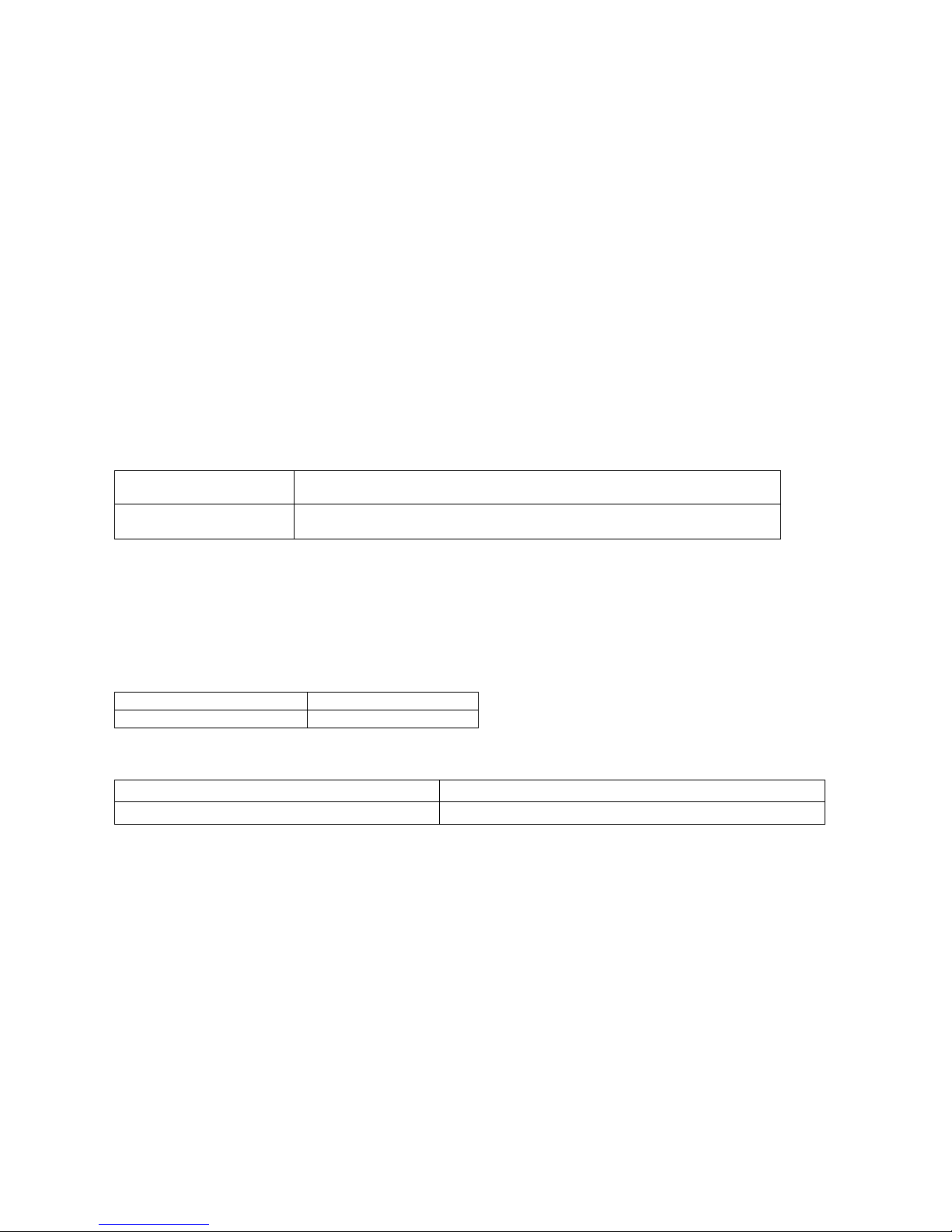

3. Pilot instructions

Each station can be programmed for the control of one engine. Each lever repeats the functionality of a

traditional mechanical lever.

Moving the lever from the neutral position, after 16°forward or reverse automatically the electronic system

clutches-in respectively the forward or reverse gear. The accelerator lever has a stroke of 35° in forward

direction and 25°in backward direction.

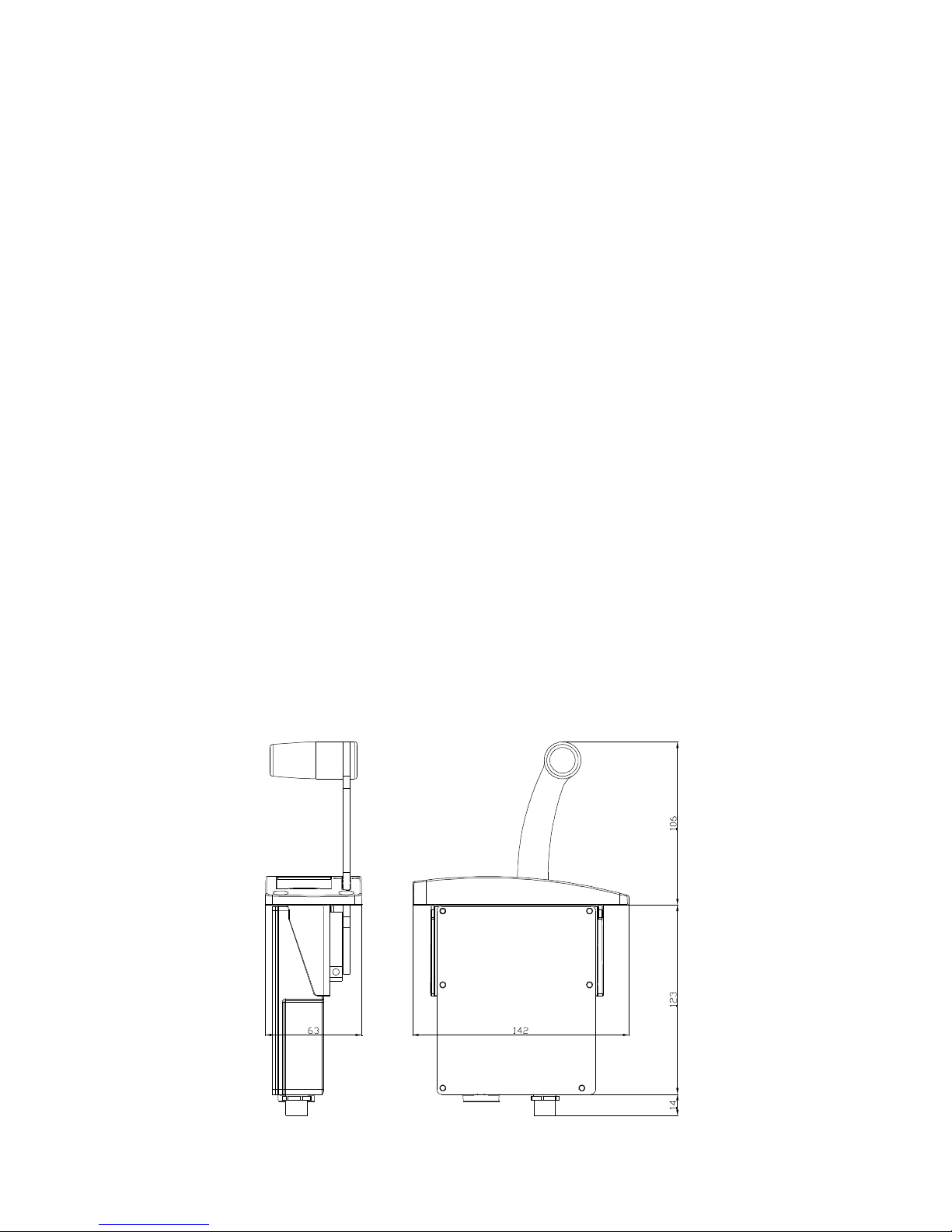

Command station series 4000

Command station series 4500

Flexball Italiana S.r.l. 5

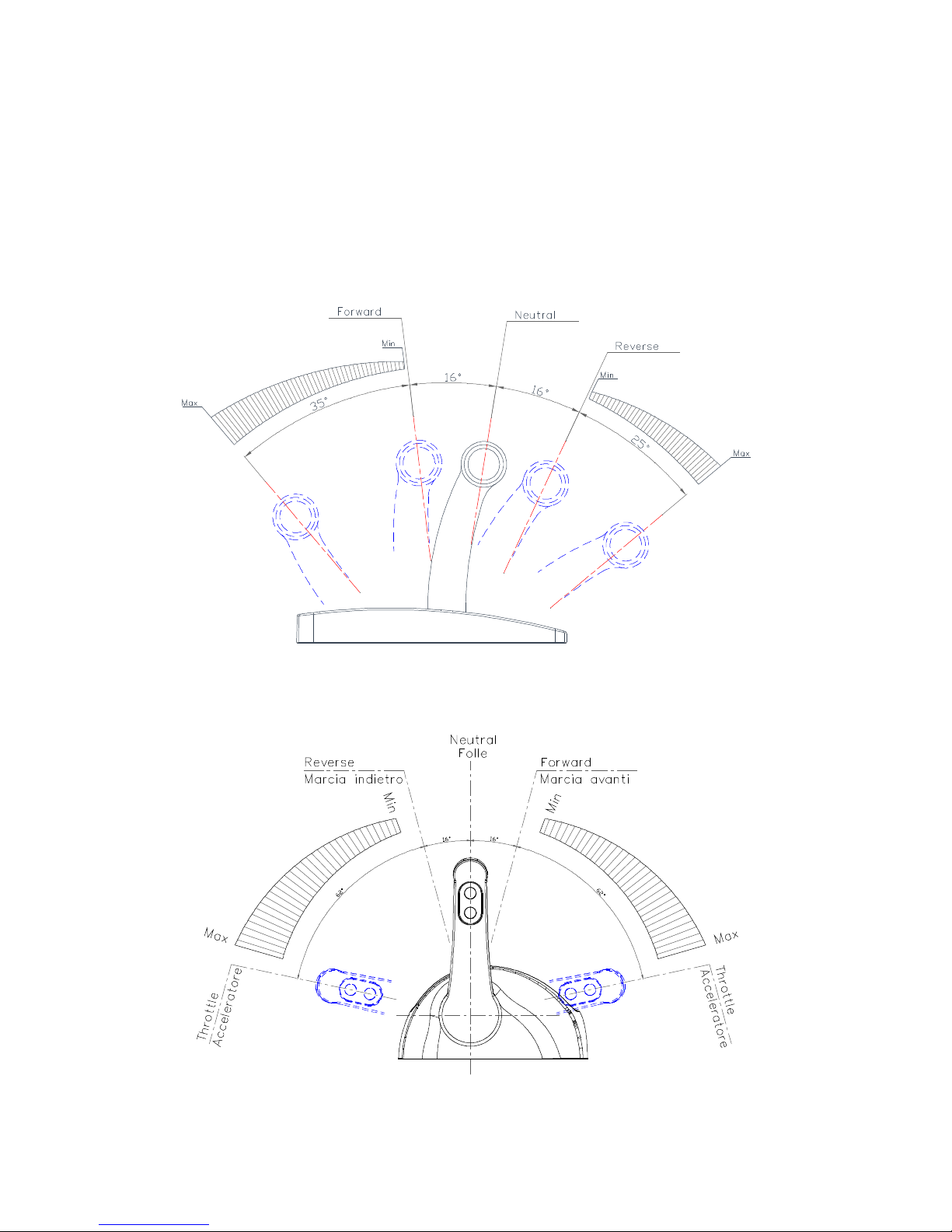

3.1. Control keypad

On the command station it is mounted an electronic keypad with 2 push-buttons and 3 LEDs.

It follows the table with the definition of LED and push buttons.

Push-button LED Description

(Command)

(Meaning)

Engine

If the LED has a fixed ligh

t on (green), the

gearbox is in neutral position.

Command

I

f it is switched off, the Station has not the command.

If is switched on, the Station has the command.

Warm up

If it is blinking, the navigation system is in Warm

-

up mode; this means that

the engines can be warmed up without clutching-in the gear.

If the LED is fix lighted, the system is in Synchro mode

Warm up

Not in use for this application

Command

If you press Command for 1,5 seconds the station takes the command, only

if one of these two conditions are respected:

- after power up lever is in neutral

- the lever is synchronized with respect to the lever of the station that at the

moment has the command

All LEDs are lighted on The control system isn’t working correctly

Description LEDs colour

Engine Green

Warm/Sync Orange

Command Red

Command station series 40

00

Command station series 4500

Flexball Italiana S.r.l. 6

3.2. Acquisition of the command

It is possible to acquire the command of the boat from any Station in the following cases:

1. Position the lever in neutral and press Command for 1,5 seconds.

►Important: before taking the command, proof that all the passengers are safely on board.

3.5 Fast Start-up Mode

This function is available on the first command station as described in section 8.1 of this manual. When the

configuration FSM (Fast Start up Mode) is enabled, the command station with the FSM enabled takes

automatically the command at the power on, only if this command station is in neutral position.

If the command station is not in neutral position, the command station will take the command as soon the

neutral position will be reached.

4. Command station

Command stations are classified as devices for the control of the engine. Up to three command stations

can be mounted in the same installation. Depending on the application, it is very important to set the dip-

switches present on the bottom part of the command station, as described in sections 4.2 and 8.1 of this

manual.

4.1. Dimensions

4.1.1. Command station series 4000

Flexball Italiana S.r.l. 7

4.1.2. Command station series 4500

4.2. Friction adjustment

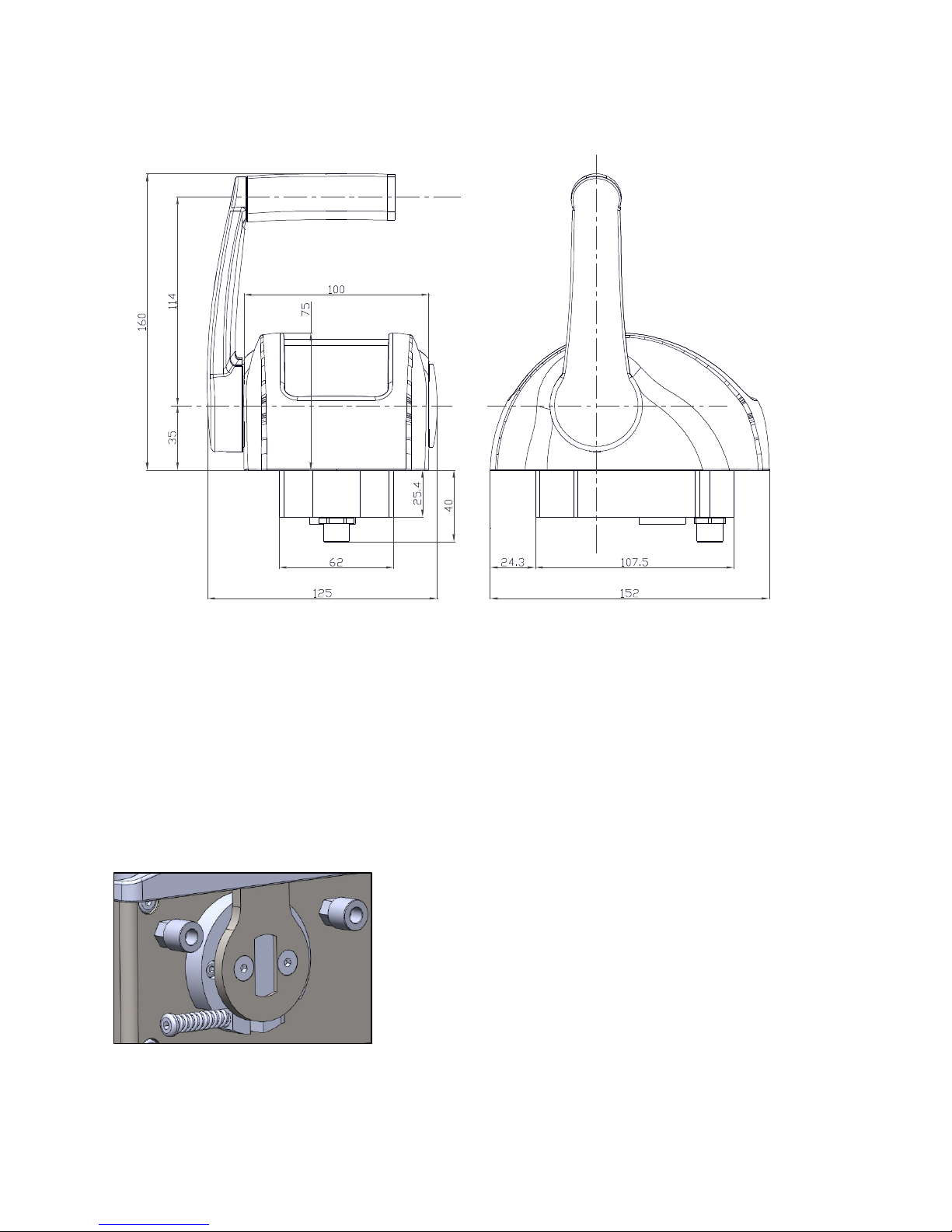

4.2.1. Command station series 4000

In order to adjust the friction of the lever, it is enough to tune the

screw that you can find just behind the control lever, as shown in

the picture on the left. With an hexagon screw driver size 2,5 mm

you can loosen or tighten the screw and the friction will become

correspondingly softer or harder.

Flexball Italiana S.r.l. 8

4.2.2. Command station series 4500

In order to adjust the friction of the lever, it is necessary to remove the screw A

placed below the plastic base of the command station. With the help of an

hexagon screw driver size 3 mm you can loosen or tighten the screw and the

friction will become correspondingly softer or harder.

Once the friction has been adjusted, close again the hole with screw A.

Important: In case of a command station for single engine, the friction is present

only on the left lever.

4.3. Command station set-up

Under the base of the command station there is a plastic cap. Unscrewing it, you can access to the dip-

switches.

Operation:

•unscrew the plastic cap;

•set the dip-switch position according to the following table;

•screw again the cap.

Under the base of the command station it is present the

following label.

This labels indicates the code of the command station, the

serial number and the different dip-switches configuration

according to the type of the command station.

Dip-switch 1

It defines how you want to setup your electronic control lever

•OFF: standard start-up mode at power up (see

section 5.xx)

•ON: Fast Start-up Mode at power up (see section

5.xx)

Dip-switch 2

Available for further developments

Dip-switches 3 and 4

Identify the delay time between forward reverse commands (inversion of direction)

Dip

-

switch 3

Dip

-

switch 4

No delay during inversion of direction OFF OFF

Delay of 1 second during inversion of direction OFF ON

Delay of 2 seconds during inversion of direction ON OFF

Delay of 4 seconds during inversion of direction ON ON

Flexball Italiana S.r.l. 9

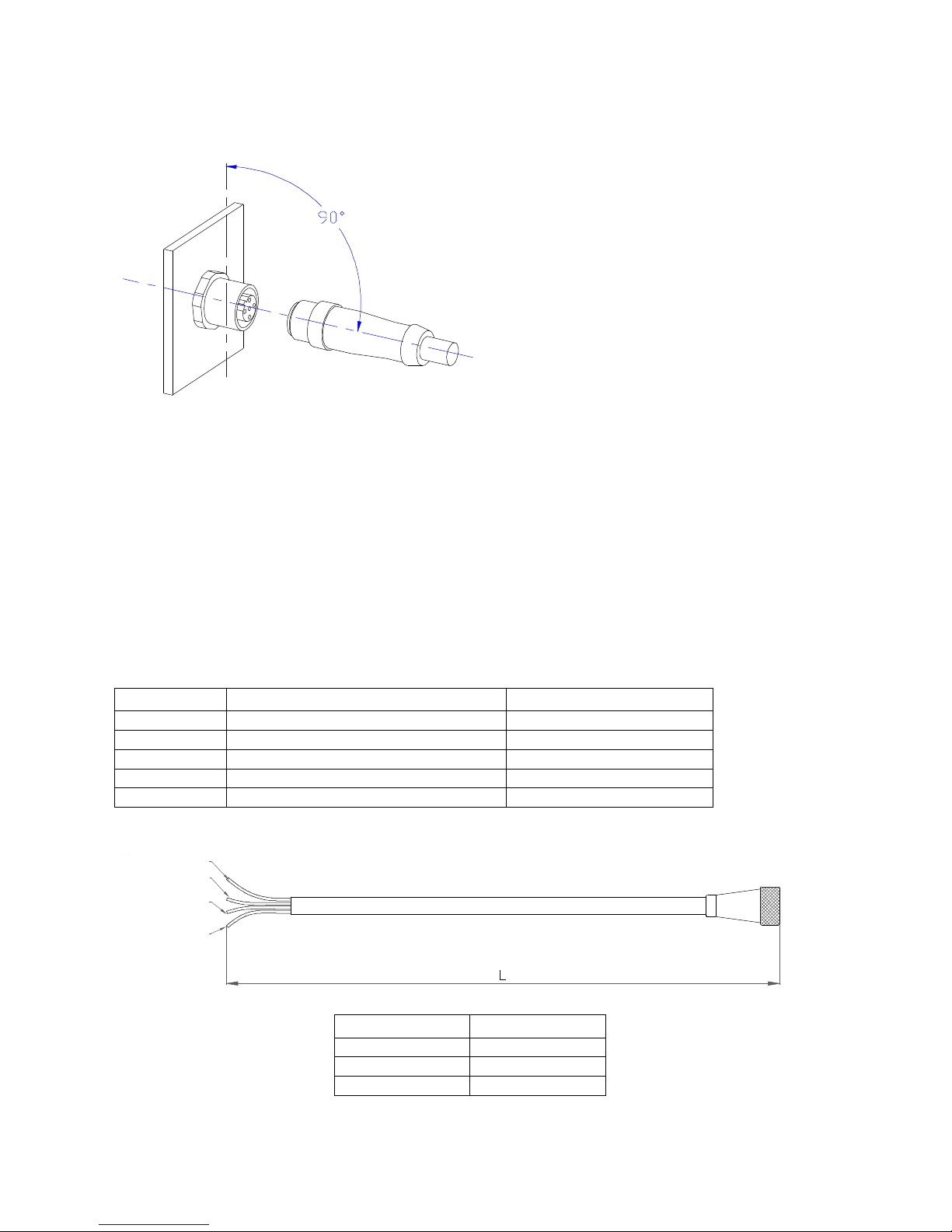

6. Accessories and option

Extreme care must be paid during electrical

installation of supply and motor cables.

►Important: for a correct mounting plug in

the connector at 90°with respect to wall side

of the actuator box. Rotate then the ring until

the cable enters into the counterpart M12.

If the cable has been inserted correctly, it must

be possible to screw completely by hand the

cable without too much efforts.

To check that the cabling is done properly, connect the supply cable on the actuator and switch-on.

If the display is lighted, the cabling is correct, otherwise it is presumable that you must invert the cable

polarities.

Cables reported here below are used in standard installations. For specific motors there are anyhow

available cables with their proper connectors; in case you need cables for specific motors, please contact

the supplier.

6.1. Power supply and speed reference cable (4 poles)

This cable is without connector on motor’s controller side.

Wire colour Function: 1 or 2 Voltage output interface Function: CANBus interface

Brown GND GND

Yellow Power supply (12/24 Vdc) Power supply (12/24 Vdc)

Green CH1 CAN_H

White CH2 CAN_L

Yellow/Green

Grey

Brown

Black

Length Code

L= 2,5 m 3500.52-02500

L= 5,0 m 3500.52-05000

L= 7,5 m 3500.53-07500

►Important: this cable is without connector on motor side

Brown

Yellow

Green

White

Flexball Italiana S.r.l. 10

6.6. T-Splitter

The T-splitter has to be used in case you want to split the signals of the Power supply and speed reference

cable (cable code 3500.34- ).

Code: N-85E010003

In case you want to:

•Duplicate the signals having the power supply and the signals together

•Separate signals from power supply

the wiring configuration is the following:

Power supply and signals together Power supply and signals split

Command

station

T-splitter

N-85E010003

Cable to the engine

3500.34-xxxxx

Command

station

T-splitter

N-85E010003

Flexball Italiana S.r.l. 11

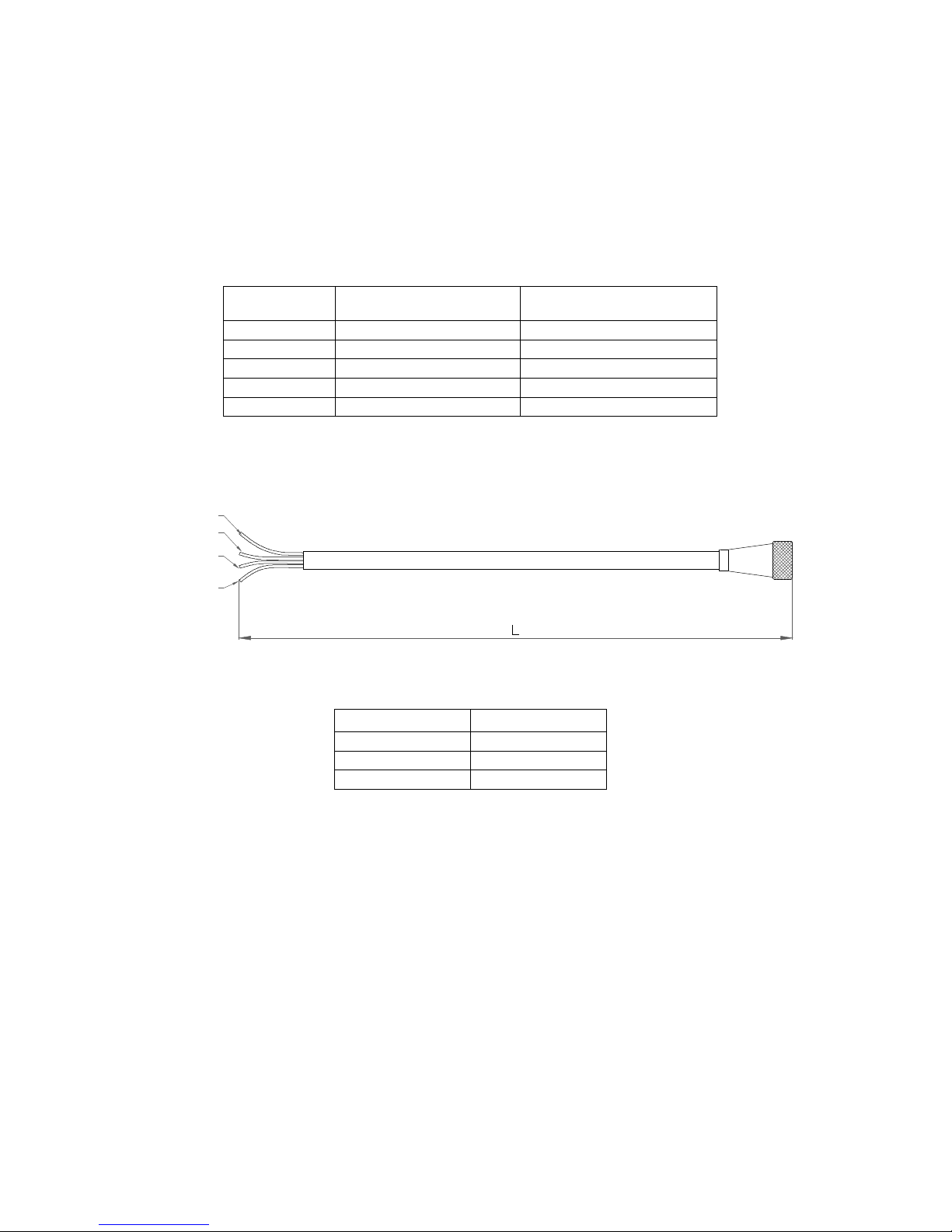

6.9. Command cable (4 poles)

This cable is without connector on motor’s controller side. Each wire is a command of a specific function

which is given to the motor’s controller with active high logic. When the command is active, signal of the

corresponding wire is high ( equal to Vcc); when the command is deactivated, signal is zero.

Each signal is determined short-circuiting the common wire via an internal relay.

Wire number Device on command

station Function

Yellow/Green Common 0 < Vcc < 60 V

Black

Relais

1

Lever is in Neutral position

Brown Relais 2 Lever is in Forward position

Grey Relais 3 Lever is in Reverse position

Maximum continuous current is 3 A for each wire.

Length Code

L= 3,0 m 3500.34-03000

L= 5,0 m 3500.34-05000

L= 7,0 m 3500.34-07000

Yellow/Green

Grey

Brown

Black

Flexball Italiana S.r.l. 12

8. Interface towards the motor controller and functioning principle

According to the position of the lever, the following commands are given through electrical

signals. Every position is clearly mechanical identified (with end of stroke or detent) and

electronic identified also:

Forward speed (switch 2)

Neutral (switch 1)

Backward (switch 3)

The following drawings are be used just as a reference to explain the lever working principle.

Electrical signals

•The analogue signal is ranging from 0,5 to 4,5 Volts and increase or decrease

proportionally with the movement of the lever. Position measurement is made with hall

effect sensor.

•Switch 1 is a normally open switch which is active when the lever is active (supply =

ON)and in neutral position.

•Switch 2 is a normally open switch which is active when the lever is in forward position.

•Switch 3 is a normally open switch which is active when the lever is in reverse position.

Forward

Reverse

0.5

V

4,5

V

Neutral

-43 degrees +43 degrees

Switch 3 = Reverse

Switch 1 = Neutral

Switch 2 = Forward

Flexball Italiana S.r.l. 13

8.1. Speed signal towards the motor’s controller

As standard, the electronic control lever provides 2 channel voltage output signals are reported in the

drawing here above. In case you need a different voltage profile, it must be specified when ordering.

As an alternative it is possible to interface to the motor’s controller via CANBus, in this case please refer to

the next chapter.

8.2. Programming of the delay when passing from Forward to Reverse or vice

versa

Sometimes to avoid shocks on the drive line, it is suggested to insert a delay time when inverting speed

direction. This delay does not occur when from neutral you move to forward or reverse.

Dip-switches 3 and 4 (see chapter 5) identify the delay time between forward reverse commands.

Dip

-

switch 3

Dip

-

switch 4

No delay during inversion of direction OFF OFF

Delay of 1 second during inversion of direction OFF ON

Delay of 2 seconds during inversion of direction ON OFF

Delay of 4 seconds during inversion of direction ON ON

8.3. CanBUS protocol

Every CANBus interface card has one output. Communication starts automatically at power-up.

This document refers to SAE J1939 CANBus protocol. The electronic system can handle also other

communication protocols.

Bit rate Repetition rate Identifier

29 bit in according to CAN 2.0B

default value default value description n°byte

250 Kbit/s 10 ms Priority 1

PGN 2

Address 1

Identifier:

Identifier Priority PGN Address

Hexadecimal values (_) 0x

_

_

0x

_

_

_

_

0x

_

_

Data field:

The 8 bytes of the Can Data Link are completely programmable according to the profile used by the motor

producer. In the data field you must write the motor speed reference. Necessary information for majority of

the motors are minimum speed and maximum speed without load.

8.4. Technical data of the CANBus interface card

Maximum speed which each channel can generate is 100 mA. Each channel output is protected against

short circuit towards ground and towards voltage supply. Termination resistor is already mounted on the

CANBus interface card but it can be removed when ordering at factory.

Flexball Italiana S.r.l. 14

21. Behaviour of the electronic system in case of failures

21.4. Troubleshooting

Irregularity What to check Section to refer

The lever doesn’t take the command

Check wiring and in case of

CANBus signalling, check that

the end of line resistance

termination on the motor

controller has been activated

Section 4.3.

21.5. LED diagnosis on command station

Command station produces signals to show either the operating conditions or possible causes of

irregularities.

LED indications

When it

happens Meaning/problem What to do

LED red is on Power up

Command station

is

powered, it has taken the

command and it is

configured correctly

-

LED green with fixed light

After power

up

Lever is in neutral, the

installation works correctly -

Green LED on command

station is blinking (50% ON,

50% OFF)

Might be a problem on the

positioning measuring

device of the command

station

Contact Flexball

Flexball Italiana S.r.l. 15

23. Drilling mask for command station

►Important: drilling mask is represented in scale 1:1

Command station series 4000

Front side

Flexball Italiana S.r.l. 16

►Important: drilling mask is represented in scale 1:1

Command station series 4500

Front side

This manual suits for next models

1

Table of contents