427-0073-12-12 Version 120 May 2015 ii

© 2015 FLIR Systems, Inc. All rights reserved worldwide. No arts of this manual, in whole or in art, may be

co ied, hotoco ied, translated, or transmitted to any electronic medium or machine readable form without the

rior written ermission of FLIR Systems, Inc.

Names and marks a earing on the roducts herein are either registered trademarks or trademarks of FLIR

Systems, Inc. and/or its subsidiaries. All other trademarks, trade names, or com any names referenced herein are

used for identification only and are the ro erty of their res ective owners.

This roduct is rotected by atents, design atents, atents ending, or design atents ending.

The contents of this document are subject to change.

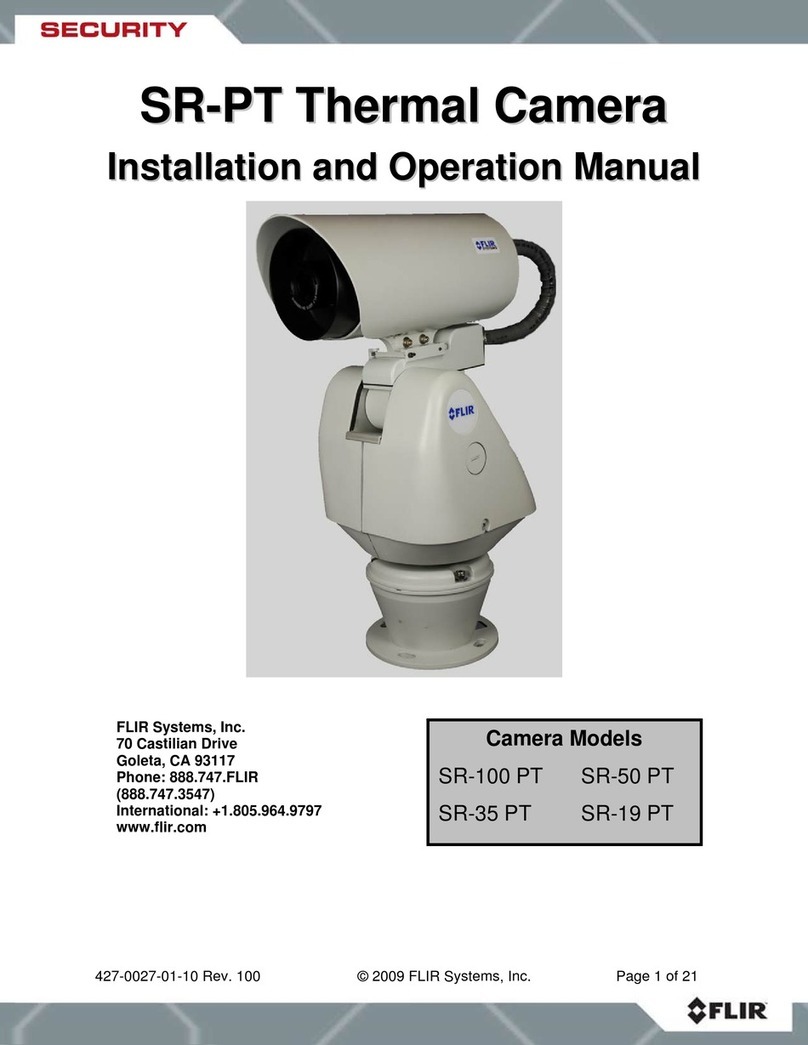

FLIR Systems, Inc

70 Castilian Drive

Goleta, CA 93117

Phone: 888.747.FLIR (888.747.3547)

International: +1.805.964.9797

htt ://www.flir.com

Important Instructions and Notices to the User:

Modification of this device without the ex ress authorization of FLIR Commercial Systems, Inc. may void the user’s

authority under FCC rules to o erate this device.

Note 1: This equi ment has been tested and found to com ly with the limits for a Class B digital device, ursuant to

Part 15 of the FCC rules. These limits are designed to rovide reasonable rotection against harmful interference

in a residential installation. This equi ment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that the interference will not occur in a articular installation. If this equi ment does

cause harmful interference to radio or television rece tion, which can be determined by turning the equi ment off

and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna;

• Increase the se aration between the equi ment and receiver;

• Connect the equi ment into an outlet on a circuit different from that of the receiver; and/or

• Consult the dealer or an ex erienced radio/television technician for hel .

Note 2: This equi ment was tested for com liance with the FCC limits for a Class B digital device using a shielded

cable for connecting the equi ment to an analog video out ut to a monitor and using a shielded USB cable for

connecting the equi ment to a ersonal com uter. When making such connections, shielded cables must be used

with this equi ment.

Industry Canada Notice:

This Class B digital a aratus com lies with Canadian ICES-003.

Avis d’Industrie Canada:

Cet a areil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Proper Disposal of Electrical and Electronic Equipment (EEE)

The Euro ean Union (EU) has enacted Waste Electrical and Electronic Equi ment Directive 2002/96/EC

(WEEE), which aims to revent EEE waste from arising; to encourage reuse, recycling, and recovery of EEE

waste; and to romote environmental res onsibility.

In accordance with these regulations, all EEE roducts labeled with the “crossed out wheeled bin” either on the

roduct itself or in the roduct literature must not be dis osed of in regular rubbish bins, mixed with regular

household or other commercial waste, or by other regular munici al waste collection means. Instead, and in

order to revent ossible harm to the environment or human health, all EEE roducts (including any cables that

came with the roduct) should be res onsibly discarded or recycled.

To identify a res onsible dis osal method nearby, lease contact the local waste collection or recycling service, the original lace

of urchase or roduct su lier, or the res onsible government authority in the area. Business users should contact their su lier

or refer to their urchase contract.

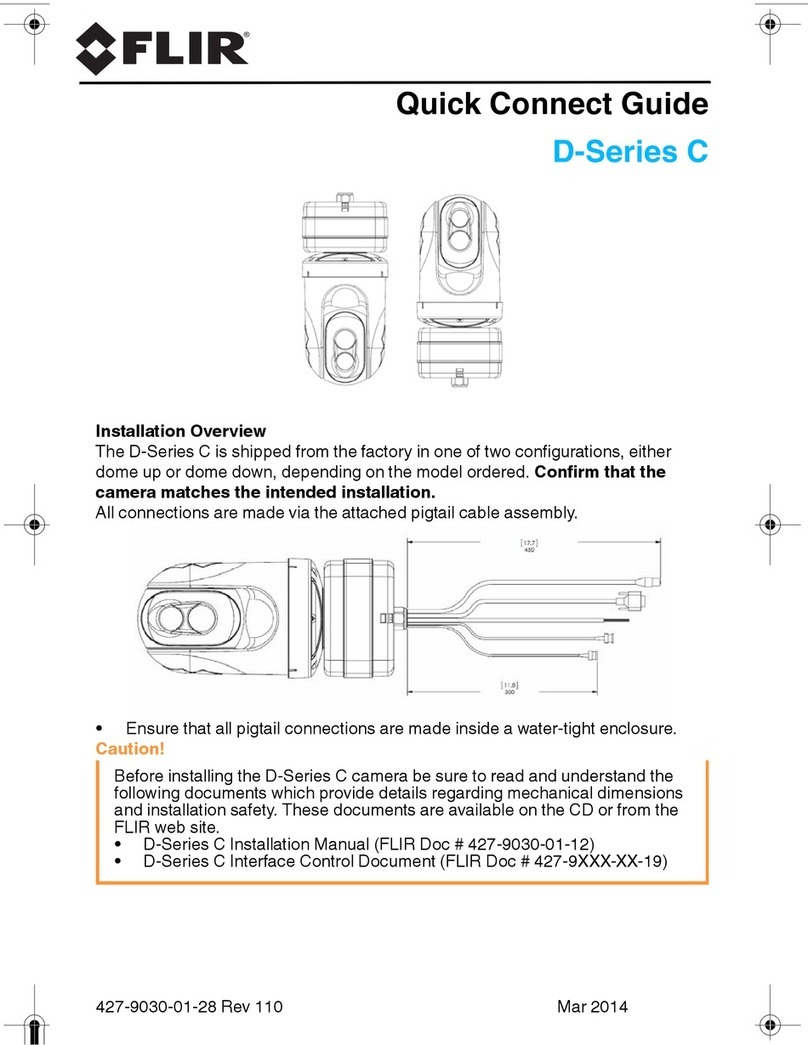

Document History

Version Date Comment

100 A ril 2014 Initial Release

110 June 2014 Minor corrections

120 May 2015 Added descri tion of Analytics setu , descri tion of IDR, other minor corrections