19-4

FCD VLAIM019-05 ©2000 Flowserve Corporation. Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Troubleshooting

If difficulty is suspected with the non-slam piston check

valve, do the following:

1. Check for the proper full-stroke operation as indi-

cated in ‘Quick-check’section.

2. Check for leaks through the gaskets. The gaskets

should be replaced whenever the valve is disas-

sembled.

3. Theseatringmaybeoutofalignmentwiththepiston.

Check step 8 in ‘Reassembly’section on page 3 for

properprocedureonaligningtheseatringandpiston.

4. Make sure the valve is properly installed in the line

with correct flow direction.

5. If the piston sticks, disassemble the valve and clean

thoroughly.

GENERAL MAINTENANCE ON PISTON

CHECK VALVES

Disassembly

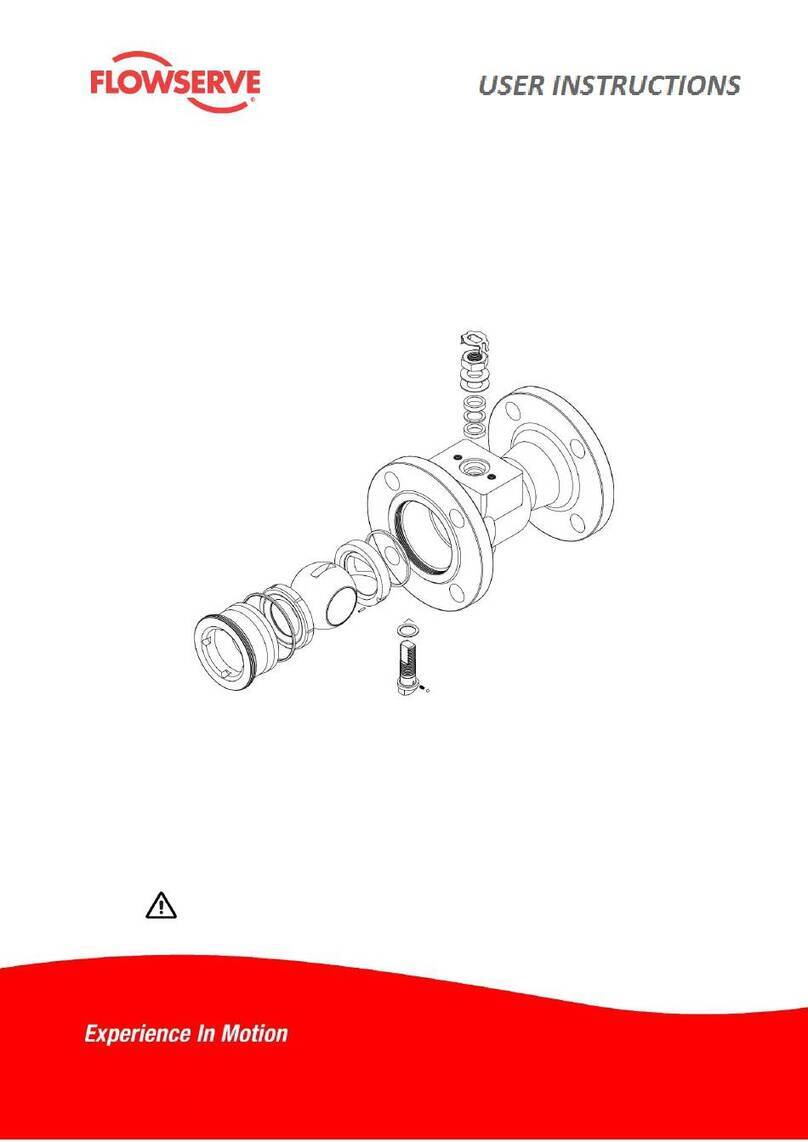

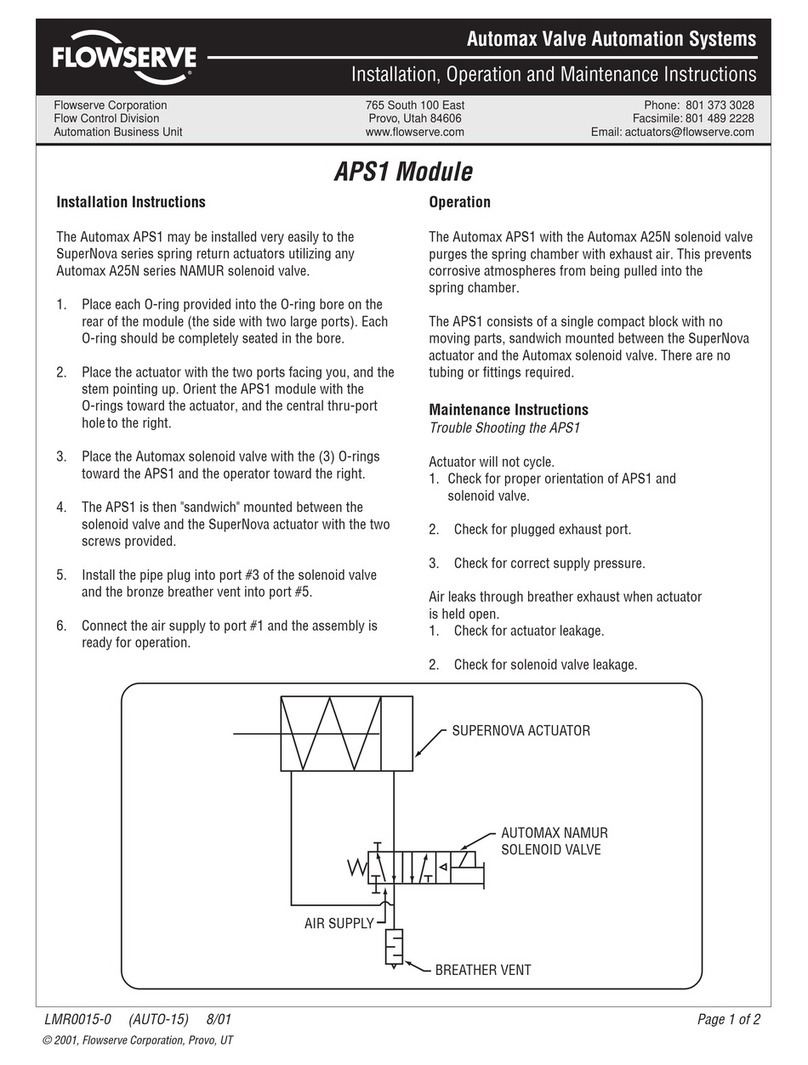

Todisassemblethepistoncheckvalve,refertoFigure2

and proceed as follows:

1. Removebodyboltingandliftbonnetcapoutofvalve.

2. Liftspring,piston,retainer,gaskets,andseatringout

of the body. Check for signs of galling and scoring

betweenpistonandretainer.Ifgallingexists,callyour

Flowserve representative, or the factory.

3. Checkthepiston’sventpassagesfordirtbuildupand

other obstacles. Clean with appropriate industrial

solvent if necessary.

4. Checkseatringandpistonseatingareasfordamage.

If remachining is attempted, care must be taken to

matchtheoriginalplugsurfacecontour.Theseatring

seating area can be remachined to a 33 degree

angle; the plug angle is 30 degrees. Remachine

surfaces of both parts if required.

Reassembly

Toreassemble the piston check valve, referto Figure 2

and proceed as follows:

1. Replace the seat ring gasket.

NOTE:Gasketsshouldbereplacedeachtimedisas-

sembly takes place.

2. Insert seat ring.

3. Install the retainer and piston.

4. Position the spring in top of the piston.

5. Replace bonnet gasket and bonnet cap.

6. Tightenonebonnet1/6ofaturn.Tightenoppositebolt

1/6of a turn. Proceed until all bolts are tightened

evenlyand completely, seatingthebonnet metal-to-

metalinthebody.Thebottomingofthebonnetcapin

the body can be easily felt through the wrench.

CAUTION: Insufficient tightening of the bolting

causes poor gasket compression and can result

in leakage.

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its

intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications

under a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible

applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation and maintenance of Flowserve products.

The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe

use of Flowserve products in connection with the specific application.

While the information and specifications presented in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or

as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect

to this product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change

without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any of its worldwide operations or offices.

For more information, contact: For more information about Flowserve, contact www.flowserve.com or call USA 972 443 6500

Regional Headquarters

1350 N. Mt. Springs Prkwy.

Springville, UT 84663

Phone 801 489 8611

Facsimile 801 489 3719

12 Tuas Avenue 20

Republic of Signapore 638824

Phone (65) 862 3332

Facsimile (65) 862 4940

Flowserve and Valtek are registered trademarks of Flowserve Corporation.

12, av. du Québec, B.P. 645

91965, Courtaboeuf Cedex,

France

Phone (33 1) 60 92 32 51

Facsimile (33 1) 60 92 32 99

Quick Response Centers

5114 Railroad Street

Deer Park, TX 77536 USA

Phone 281 479 9500

Facsimile 281 479 8511

104 Chelsea Parkway

Boothwyn, PA 19061 USA

Phone 610 497 8600

Facsimile 610 497 6680

1300 Parkway View Drive

Pittsburgh, PA 15205 USA

Phone 412 787 8803

Facsimile 412 787 1944