6-4

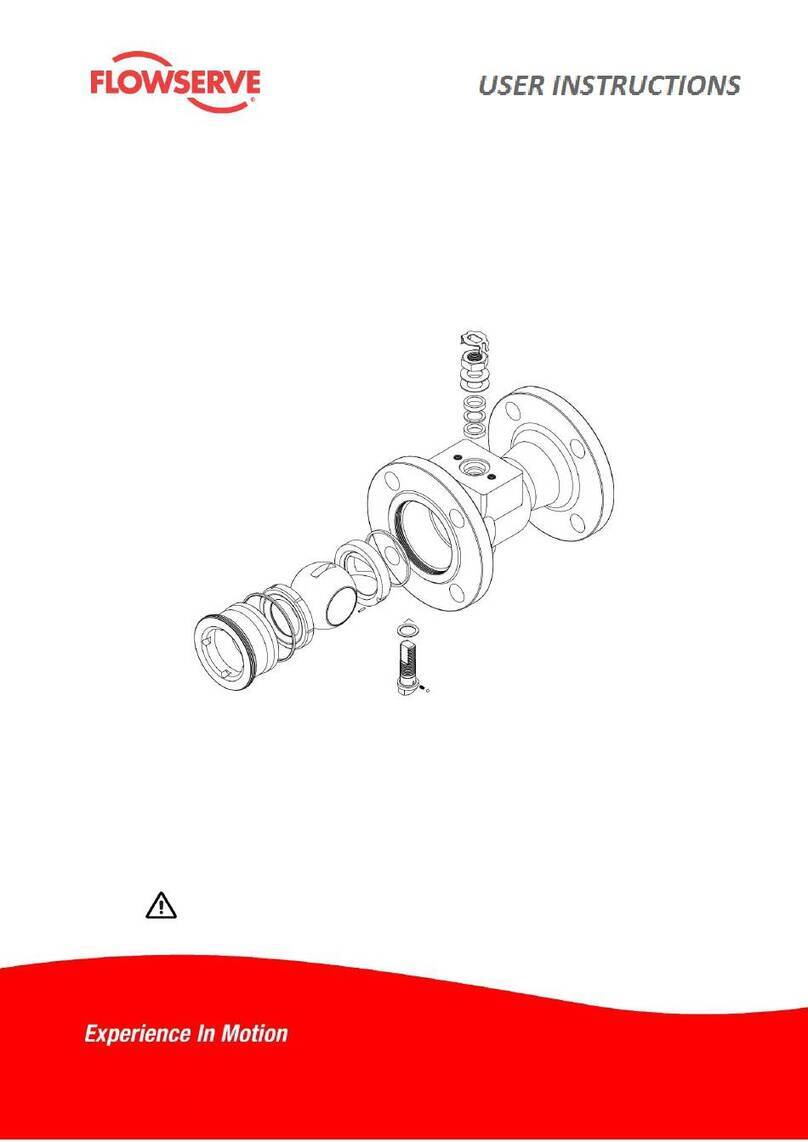

Inspecting the Screwed-in Seat Ring

1. Unscrew seat ring using a seat ring assembly tool.

NOTE: Flatsaremachinedonthe tool so a wrench

may be used to turn the seat ring. Assembly tool

supports are sometimes needed to keep the as-

sembly tool aligned properly in the seat ring.

2. Ifnecessary, remachinetheseatsurface. Theseat

angle on the seat ring is 33 degrees.

CAUTION: Insure concentricity of seating sur-

face with the outside diameter of the seat ring.

3. Install seat ring using a seat ring assembly tool.

Reassembly of Mark Six

1. Install a new bonnet gasket.

2. Carefullylower plugasfaras itwillgointothebody.

3. Slidethebonnetactuatorassemblyoverplugstem.

4. Insert guides and packing into the bonnet.

5. Place the gland flange onto the plug stem.

6. Screw the actuator stem onto the plug stem by

rotating the actuator in a clockwise direction.

CAUTION: Do not allow plug to rotate. Leave

two or three threads exposed for air-to-close

valves. For air-to-open valves, screw the plug

stem as far as it will go into the actuator stem.

7. Assemble yoke clamp or tighten the yoke bolts.

8. Cycle the valve to retract the plug.

9. Theplugheadseals,whenused,makeitnecessary

to drive the plug into the body using the actuator.

Partiallyboltdown the bonnet flangeandsupplyair

to upper actuator port to extend the plug. Repeat

operation, if necessary, to bring bonnet fully down

into the body.

10. Tighten two opposing bonnet bolts one-sixth turn.

Tighten all bonnet bolts one-sixth turn at a time,

alternating between opposing bolts. Firmly tighten

all nuts evenly and completely, using full wrench

force to compress the gasket and seat the bonnet

metal-to-metal in the body. Proper tightness re-

quires considerable force; however, the bottoming

of the parts metal-to-metal can easily be felt

through the wrench.

CAUTION: Insufficient tightening will result in

improper gasket compression.

11. Adjust stem engagement for air-to-open valves

only, using the following procedure.

NOTE: Proper stem engagement is essential on

air-to-open valves to provide stiff, stable operation

as the valve throttles near the seat.

Cycle the valve to closed position. Observe plug

positionasshownbythestrokeindicatorplate. This

position is the bottom of the actuator piston stroke.

Cyclethevalvetoopenposition. Screwtheplugout

of the actuator one-half turn. Cycle the valve to

closed position. Observe the plug position as

indicated by the stroke plate. Repeat this proce-

dure, comparing plug position each time until the

indicated plug position is about 1/8 inch above the

initial or bottom position. This procedure must be

followed to assure stiff stable operation as well as

tight shutoff. Tighten all nuts evenly and com-

pletely, using full wrench force to compress the

gasket and seat the bonnet metal-to-metal in the

body. Proper tightness requires considerable

force;however,thebottomingofthepartsmetal-to-

metal can easily be felt through the wrench.

12. Tighten the stem clamp.

13. Tighten packing nuts to slightly over finger-tight.

14. Adjust stroke indicator position to indicate closed

position when valve is closed.

Removing Actuator, Including Yoke

(Without Disassembling the Valve Body

Subassembly)

1.Fully retract the plug until the stroke indicator is

pointing to the open position.

2.Loosen the stem clamp.

3.Loosen the gland flange.

4.Remove the yoke clamp (or yoke bolts if used).

5.Turn actuator completely off the plug and bonnet.

CAUTION: Do not allow the plug stem to rotate.

Flats are machined on the stem so it may re-

quireahoist. Ifalifting ringisnotprovided,use

lifting straps around the yoke legs.

Reassembling Actuator, Including Yoke

1.Lift the plug off the seat and turn the actuator onto

the plug. On air-to-open valves screw the actuator

stem onto the plug stem as far as it will go. On air-

to-close valves, leave two or three threads exposed.

CAUTION: Do not allow the plug to turn on the

seat at any time. Do not turn the plug in the

bonnet. Flatsaremachinedontheplugstemso

it can be held with a wrench.

2.Assemble yoke clamp or tighten yoke bolts.

3.Adjust the stemengagement for air-to-open valves

only, according to the procedure outlined in the

“Reassembly of Mark Six” instructions, step 11.

4.Cycle the valve to closed position.

5.Slide the stem clamp on the actuator stem so

pointer indicated “closed” on the stroke plate.

6.Tighten the stem clamp.

7.Tightentheglandflangenutsevenlytoslightlyover

finger-tight.