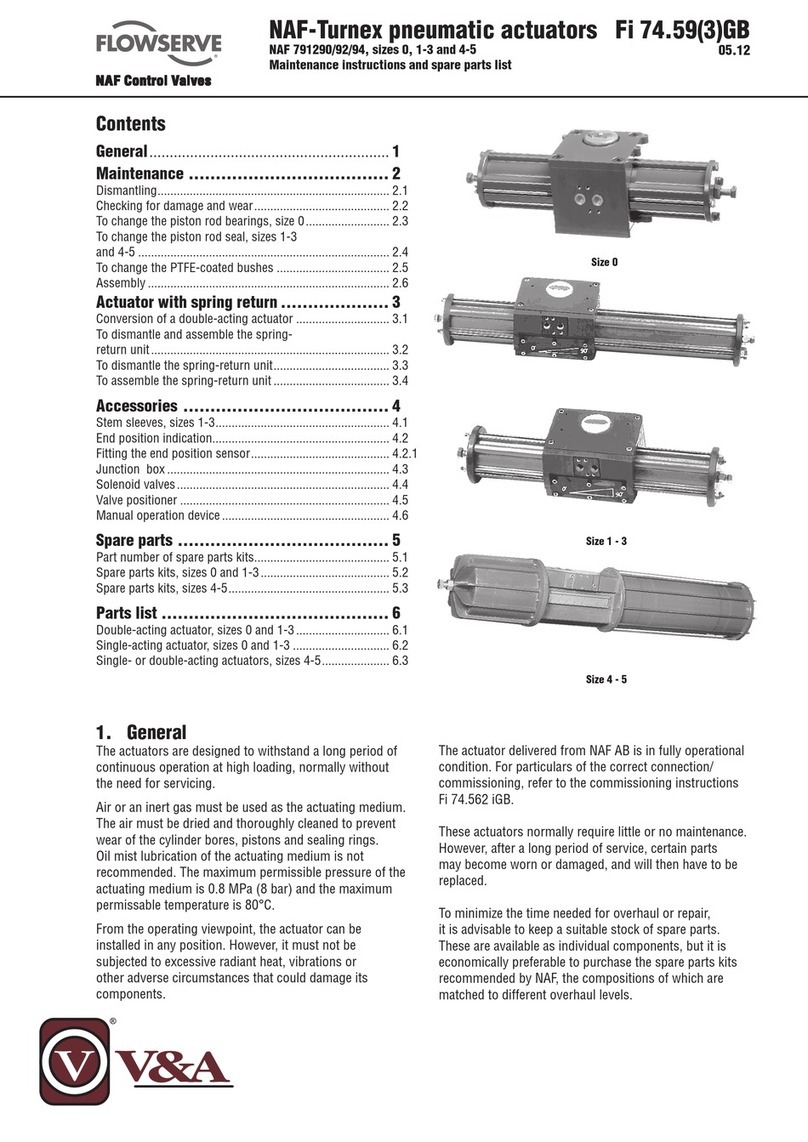

SuperNovaSeries

S050 − S200

Rack & Pinion AUTOMAX Actuators

Page

B00043e4-rev2.doc

3/4

MAINTENANCE INSTRUCTIONS

Disassembly Procedures

1. Disconnect all air and electrical supplies from actuator.

2. Remove all accessories from actuator and dismount

actuator from valve.

3. Position actuator with air supply ports facing you. Apply

air pressure to Port 2 to release spring pressure from the

Stop Bolt (9).

4. Remove the Stop Bolt Retaining Nut (14), Washer (15),

and O-ring (16) on the left Endcap (19) and turn the Stop

Bolt (9) clockwise into the Body (1) until it is flush with

the Endcap (19).

5. Exhaust air from Port 2, the Stop Bolt (9) should now

turn freely. Continue turning Stop Bolt (9) clockwise until

it is disengaged from the Endcap.

6. S Spring Return Actuator:

CAUTION: Follow step 4 to relieve force on inward travel

stop before proceeding.

To remove S Endcaps, first completely remove two

diagonal Endcap Screws (21) from one Endcap. The two

remaining Encap Screws should be removed evenly. As

the screws are removed, the springs will push the

Endcap out. Repeat for opposite side. The springs well

be totally unloaded before the screws are completely

unthreaded.

Remove the springs (23, 24, 25).

Spring return version

D Double Acting Actuator:

Remove the 8 Endcap Screws (21). Step 7 will push the

Endcaps (18, 19) from the Body (1).

7. Rotate Pinion (3) counterclockwise (D & S-FCW) or

clockwise (D & S-FCCW) to drive the Pistons (2) off the

end of the rack. Pull the Left Piston (2) from the body (1)

by pulling on the Stop Bolt (9).

8. Remove the Right Piston (2a) by pushing out through

inside of Body (1).

9. Remove the Snap Ring (5) Steel Pinion Washer (4a) and

Pinion Washer (4).

10. Tap Pinion (3) lightly with plastic mallet to remove.

11. Remove seals from pinion, endcaps, and piston. If

necessary, remove seal from top pinion bearing.

12. Top pinion bearing (26) is a light press fit into the

housing. To remove, press out towards the bottom of the

actuator body. Take care not to damage any of the

surfaces. Bottom pinion bearing (27) is split. To remove,

find split in bearing and spread apart just enough to fit

over bottom pinion.

Reassembly Procedures

1. Inspect all parts for wear and replace any worn parts as

needed. Replace all O-rings.

2. Clean all components and lightly grease cylinder bore,

pinion and seals with a multi-purpose “polymer” fortified

grease such as DuBois Chemicals MPG-2.

3. Reverse the disassembly procedures to reassemble.

4. If top pinion bearing (26) was removed, it must be

pressed back into place. The top edge of the bearing

must be even with the top of the body. Insert top pinion

bearing seal (28) into place, pressing down with a blunt

screwdriver or similar tool, taking acre not to damage the

seals.

5. The standard Pinion (3) orientation is with the top

accessory drive slot at 90° to the Body (1) in the 0°

position.

6. When fitting the Pistons (2 and 2a) ensure the teeth

engage the Pinion (3) at the same time by measuring in

from each end. Note: the orientation of the pistons will

determine the operation of the actuator. Refer to the

diagrams under “Operation” for correct piston position.

7. Test the actuator for smooth operation and air leakage at

service pressure before reinstalling.

Changing Number of Springs

1. Follow the Disassembly Procedures through step 6

2. Determine nested spring combination of inner, middle

and outer spring.Consultcatalog torque charts.Insert

appropriate spring according to the attached chart into

cylinder. Springs must be properly seated against

piston and endcap to assure that springs do not bind.

3. Re-assemble the actuator.

Spring chart models 63-200

Spring Combination 1

Spring

Group #1 Spring

(inner)

#2 Spring

(middle)

#3 Spring

(outer)

Standard

Configuration

(Air Supply)

S04 - 2 -

S05 - 1 1 3 bar

S06 - - 2

S07 1 - 2 4 bar

S08 2 - 2 5 bar

S09 1 1 2

S10 - 2 2 5,5 bar

S11 1 2 2

S12 2 2 2

Spring chart model 50

Spring Combination 1

Spring

Group #1 Spring

(inner)

#2 Spring

(middle)

#3 Spring

(outer)

Standard

Configuration

(Air Supply)

S04 1 1 -

S05 - 2 - 3 bar

S06 2 1 - 4 bar

S07 1 2 - 5 bar

S08 2 2 - 5,5 bar

S09 2 - 2

Notes: #1 Spring has one color code dot

#2 Spring has two color code dots

#3 Spring has three color code dots

S050 has maximum of 2 springs per endcap