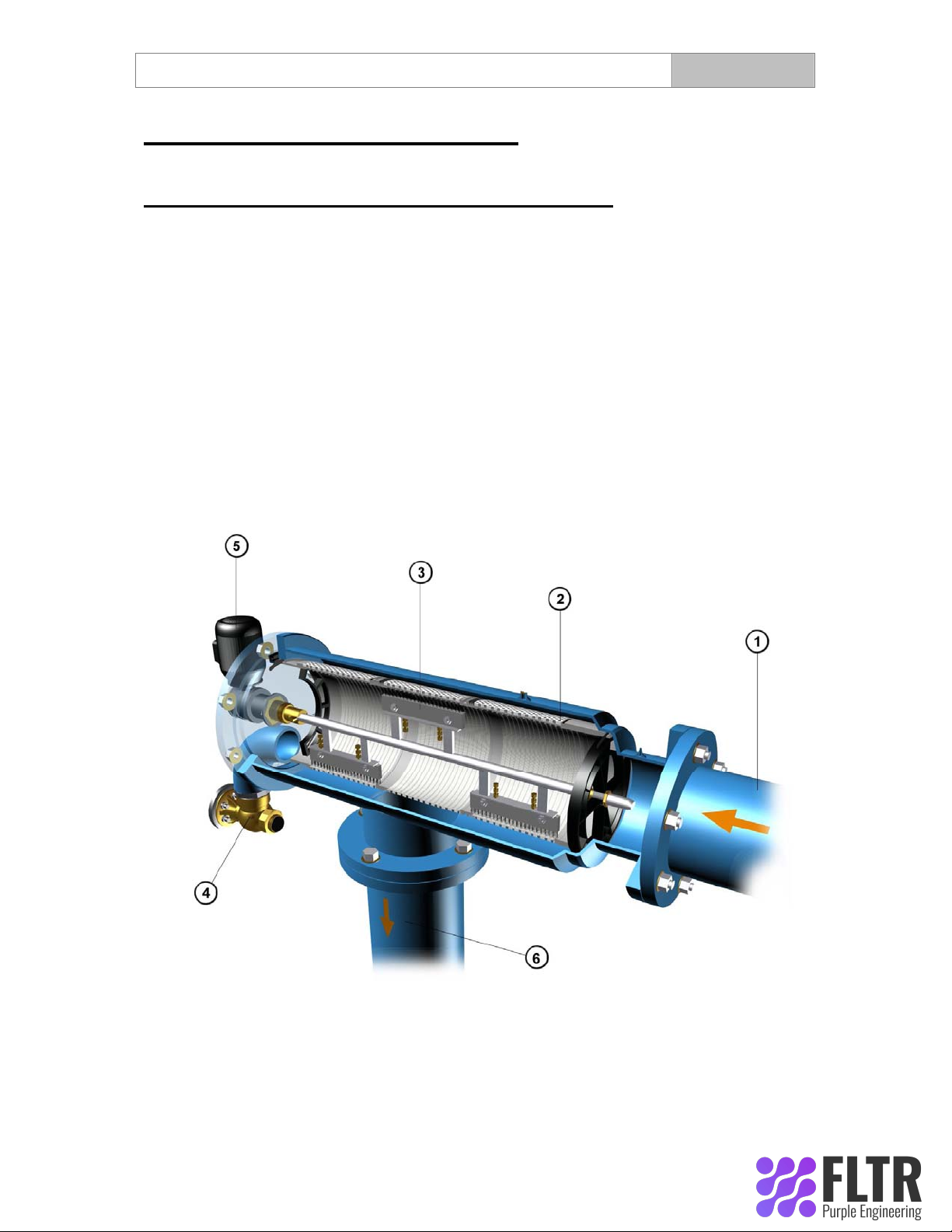

Fine Screen Assembly Removal & Installation (Figure 6 and 7)

1. Close the inlet and the outlet line valves.

2. Set the main switch at the control panel to "0" position.

3. Verify that filter is drained prior to service.

4. Remove the cover with the motor assembly.

5. Pull the screen assembly with the brushes out of the filter housing assembly

6. Than remove the brush assembly.

7. Remove the seals from the old fine screen assembly.

8. Lubricate upper and lower seals with silicon grease.

9. Slide the brush assembly into the screen and only then slide the screen assembly

with the brush assembly into the filter housing assembly.

10. Verify that the straight side of the body seal fits into the groove located in the

cover.

11. Put the cover into its place on the filter. (Take care that the motor’s axis housing is

slide on the brush axis) & install nuts and washers

12. Set the main switch at the control panel to "1" position.

13. Open the inlet and outlet line valves.

14. Perform a flushing cycle by pressing the MANUAL FLUSH switch at the control

panel.

15. Verify that the flushing valves close after 10 flushing cycle and FLUSHING lamp at

the control panel extinguishes and Check for leaks.

WARNING

Take precautions while operating the filter because the filter might enter a flushing mode

automatically, without prior warning.

For more information:

WEB

: FLTR.com.au PHONE

: (+61) 1300 62 4020 EMAIL

: [email protected] SKYPE

: Purple.Engineering