SB-25-050-A PAGE 3

Supply air must be filtered and regulated.

See Table in column 2, page 3, for re-

quired air pressure for various hose

lengths.

Note

It is required that a Devilbiss

breathable air supply hose is used

and specifically identified for

breathing air, such as, as DeVil-

biss 160001

(MPV-530)

or

160016

(MPV-550)

breathable

air hose. Each user should have

their own visor assembly.

Wearing Instructions

Risk of illness. Avoid breathing

contaminated air. Read and fol-

low the instructions below be-

fore entering a contaminated

area.

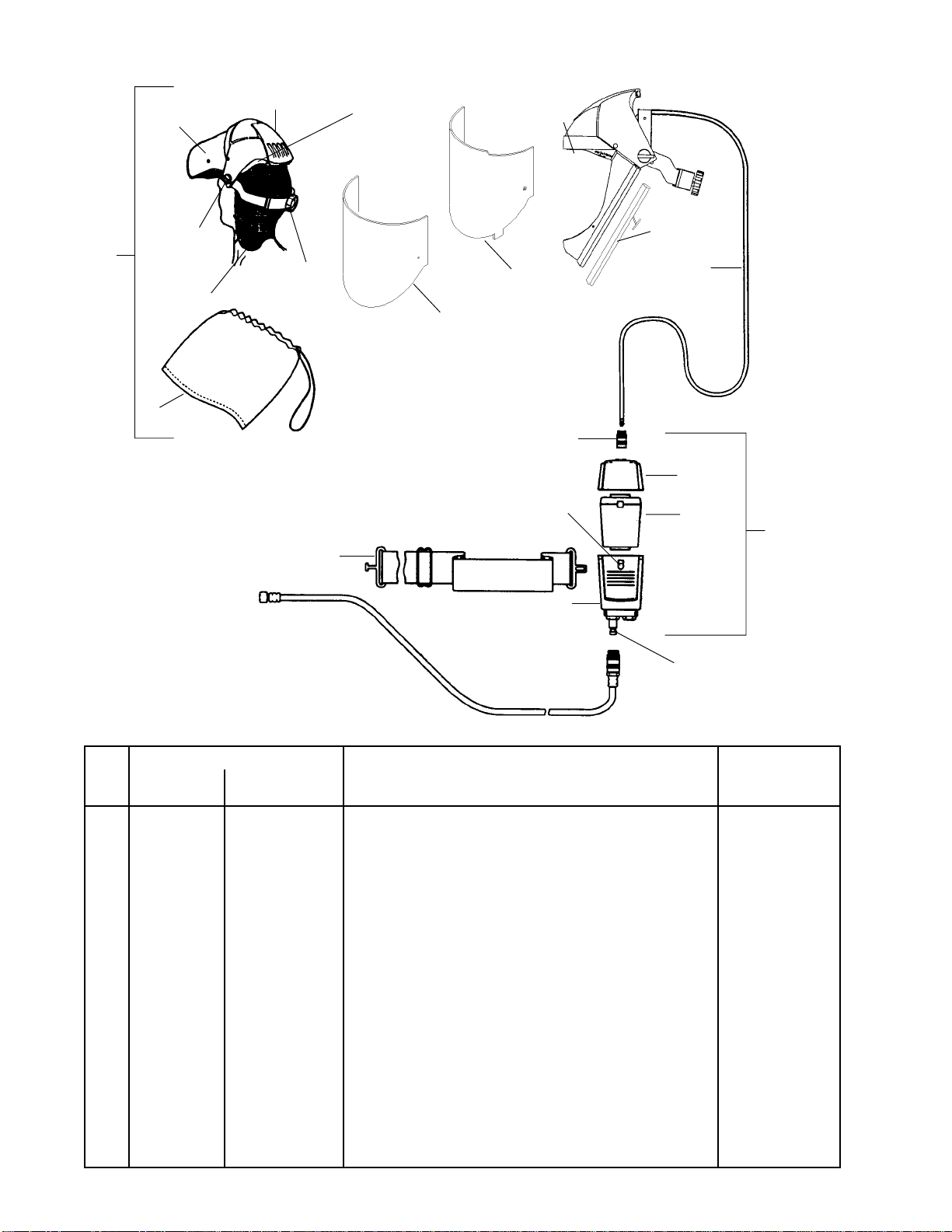

1. Connect the air supply hose to the

outlet source of Grade D air. See

illustration on page 6. Do not turn on

the air supply.

Note

Ensure that the supply hose is

long enough to allow the opera-

tor to enter and leave the con-

taminated area without discon-

necting or removing the visor.

2. Check the waistbelt and respirator

assemblies ensuring that all parts are

in good condition. Replace if dam-

aged.

3. Attach and adjust the waistbelt as-

sembly ensuring that the supply air

inlet is pointing down.

4. Connect the air supply hose to the

waistbelt inlet.

5. Connect the respirator feed tube to

the female quick disconnect on top of

the filter assembly.

6. Place the browguard visor assembly

on head; and with the visor in the

open position, adjust the crown strap

and tension knobs to obtain a secure

fit. Ensure that the feed tube is not

twisted or kinked and will not interfere

with normal movements. Make sure

the ears are not tucked inside the

faceseal cassette. Do not place ears

inside faceseal cassette.

7.

Turn on the air supply and check that

air is flowing freely to the inside of

the visor.

8.

Adjust the inlet air pressure to en-

sure that the supply pressure at the

inlet of the supply hose is within the

guidelines of the following table:

Hose Min. Press. Min. Press.

Size Hose One Hose Two Hose Max.

I.D. Length Length Lengths Press.

Inches Feet PSI PSI PSI

5/16 30 45 55 100

5/16 50 52 60 100

9. Before entering the contaminated

area, the visor must be pulled down

so the fabric skirt is touching the

face all the way around and the ten-

sion knobs are adjusted so the

visor is locked in this position.

Risk of diminished air flow.

When adjusting air pressure to

other units, ensure that the pres-

sure to the waistbelt assembly

at the point of attachment is

maintained at a minimum of

approved pressure.

MAINTENANCE

Inspection

1. Inspect equipment before each use

for damaged parts. Pay particular

attention to the hose and visor feed

tube - replace if there is any sign of

abrasion, cuts, cracks, kinks, or dis-

tortion.

2 . Replace visor covers as necessary to

ensure clear vision. Do not spray

paint or use chemicals without a

protective visor cover 165018

(MPV-

44)

in place.

3. Check for air leaks whenever pres-

sure is first applied. Check and make

sure the hose connections are

secure and that the hoses and fit-

tings are in good condition. Replace

if damaged.

4. Check before each use that the

fabric skirt is free from tears, rips,

distortion, dirt, contaminants, and

discoloration and is properly fitted.

5. Check the waistbelt periodically for

general wear.

6. Replace the activated carbon car-

tridge when the white indicator pad

becomes pink or if any odors are

experienced during wearing.

Cleaning

1. Regularly clean and/or disinfect the

visor and headband assemblies. DO

NOT USE PAINT SOLVENTS. Sol-

vents will attack the plastic lens and

render it unusable.

Recommended solutions:

a. Cleaning: 1/2 teaspoon (3 ml) of liq-

uid detergent to 1 quart (1 liter) of

warm water, mix thoroughly.

b. Disinfectant: 1/2 teaspoon (3 ml) of

bleach to 1 quart (1 liter) of warm

water, mix thoroughly.

Method for cleaning and/or disinfecting:

Use a lint free cloth dampened with the

solution and wipe the inside and outside of

the visor and headband assemblies. Re-

peat with a clean, lint free cloth dampened

with clean, lukewarm water. Allow to dry

naturally. Maximum ambient temperature

104°F. (40°C).

REPLACEMENT OF PARTS

Use only DeVilbiss replacement

components. Use of non-DeVil-

biss parts may cause equipment

malfunction and create an un-

safe conditon for the end user,

as well as void the NIOSH ap-

proval.

To replace the activated carbon filter:

1. Turn off air supply to the waistbelt

and remove air suppy hose.

2. Unscrew the two screws at the top of

the waistbelt housing and one screw

on the front.

3. Tilt the regulator forward to release

the black locating lug from the slot

in the front of the lower half of the

waistbelt housing.

4. Remove the old carbon cartridge and

fit a new replacement.

5. Relocate the black lug on the regula-

tor into the slot on the lower half of

the waistbelt housing.

6. Align regulator to bottom housing

and tighten the three screws.

7. Replace air supply hose and check

that there are no air leaks.